How Does a Sand Dryer Work? An Expert’s Guide to Efficient Sand Drying

As an engineer who has designed and installed hundreds of drying lines, I can tell you this: drying sand is a science of control. It’s not just about applying heat. It’s about controlling temperature, airflow, and material flow to produce a consistent, high-value product at the lowest possible sand drying cost. A properly configured sand dryer is a money-making machine; a poorly configured one burns fuel and produces waste.

This guide will walk you through how a modern sand dryer, specifically the highly efficient three-cylinder dryer, works. We will look at it not as a simple machine, but as the heart of a complete sand drying production line.

Table of Contents

- Why is Drying Sand Necessary?

- Triple Pass Rotary Drum Dryer: How to Set It for Maximum Efficiency?

- Natural Gas, Diesel, Coal, or Biomass: Which Heat Source Is Cheapest?

- How to Ensure Uniform Sand Moisture Content?

- How to Configure Feed and Discharge Systems to Avoid Problems?

- When Should You Consider a Single-Cylinder Rotary Dryer?

- What Equipment is in a Complete Sand Drying Production Line?

- Common Questions About Sand Dryers

- Summary and Recommendations

- About Durable

- Contact Us

Why is Drying Sand Necessary?

Wet sand is heavy, difficult to handle, and unusable for most high-value applications. We perform drying sand operations to meet the strict requirements of several key industries.

The main reason is to produce dry mortar. Dry mixed mortar, used for plastering, tiling, and flooring, requires sand with a moisture content of less than 0.5%. Any more moisture than this, and the cement in the mix will begin to hydrate prematurely, ruining the product.

Other key applications for dried sand include:

- Glass Manufacturing: Requires extremely pure, dry silica sand.

- Foundry Casting: Uses specialty dry sand for molds.

- Construction: Producing bagged sand for various uses.

- Sports: Drying sand for golf course bunkers and volleyball courts.

By drying sand, you transform a low-value bulk commodity into a specialized, high-value industrial raw material.

Triple Pass Rotary Drum Dryer: How to Set It for Maximum Efficiency?

The three-cylinder dryer (or three-pass dryer) is the intelligent evolution of the traditional single-drum rotary dryer. It is more compact and has a much higher thermal efficiency. It works by passing the sand through three concentric cylinders inside a single drum, effectively tripling the travel distance and time the sand spends in the hot air stream.

The secret to efficiency is balancing three key parameters: temperature, rotation speed, and inclination angle.

| Parameter | Optimal Setting | What Happens If You Get It Wrong? |

|---|---|---|

| Temperature | Inlet: 600-800°C / Outlet: 60-80°C | Too High: You waste fuel and can damage the sand’s physical properties. Too Low: The sand comes out wet. |

| Rotation Speed | 4-8 RPM (Revolutions Per Minute) | Too Fast: Sand passes through too quickly and doesn’t dry. Too Slow: Output is too low, and sand may overheat. |

| Inclination Angle | 2-5 degrees | Too Steep: Sand moves too fast. Too Shallow: Material flow is slow, risking blockages. |

At Durable, we fine-tune these settings during commissioning based on your specific sand type and initial moisture content to guarantee you achieve the lowest fuel consumption per ton of dried sand.

Natural Gas, Diesel, Coal, or Biomass: Which Heat Source Is Cheapest?

The dryer heat source is the single largest factor in your operational sand drying cost. The cheapest option depends entirely on your local fuel prices and availability. There is no single “best” answer, only the best answer for you.

| Heat Source | Advantages | Disadvantages | Your Best Choice If… |

|---|---|---|---|

| Natural Gas | Clean, easy to control, low maintenance. | High initial setup cost (pipelines), price can be volatile. | You have access to a cheap, reliable gas supply. |

| Diesel/Oil | Relatively simple setup, powerful heat source. | Prices are often high and unstable, requires storage tanks. | Gas is unavailable, and you need a simple, powerful setup. |

| Coal | Often the cheapest fuel per unit of heat. | High pollution, requires robust dust collection, high labor. | Environmental regulations are lenient and coal is very cheap locally. |

| Biomass | Eco-friendly, can be very cheap if sourced locally. | Lower heat value, requires a specialized furnace. | You have access to a consistent supply of waste wood chips or shells. |

Expert Tip: Before you decide, do a simple calculation: find the cost of each fuel in your area and its heat value (BTU or kJ/kg). This will give you a true cost-per-unit-of-heat, allowing you to make a purely economic decision.

How to Ensure Uniform Sand Moisture Content?

There is nothing worse than producing a batch of sand that is half bone-dry and half damp. This is a common problem, and it is almost always caused by one thing: inconsistent feeding.

To achieve a uniform final sand moisture content, you must ensure a steady, continuous, and controllable flow of wet sand into the dryer. A surge of wet sand will overwhelm the dryer, while a gap in the feed will waste heat.

Here are the keys to uniform drying:

- Use a Vibrating Feeder: Install a vibrating feeder at the outlet of your wet sand hopper. This device uses vibration to ensure a consistent, non-clogging flow of sand onto the conveyor belt.

- Variable Speed Control: Your feeding conveyor and vibrating feeder should have variable speed drives. This allows you to precisely match the feed rate to the dryer’s capacity and the sand’s initial moisture level.

- Control the Hot Air: A stable furnace and a fan with an adjustable damper are crucial for maintaining a consistent temperature and volume of hot air inside the dryer.

How to Configure Feed and Discharge Systems to Avoid Problems?

A well-designed sand drying production line is about more than just the dryer. The systems that feed material in and take it out are critical for preventing blockages and dust.

The Ideal Feeding System

- Wet Sand Hopper: A large hopper to hold a buffer of raw material.

- Vibrating Feeder: Positioned at the hopper’s outlet to prevent bridging and ensure a steady flow.

- Belt Conveyor: A conveyor with a variable speed drive to transport the sand to the dryer inlet. This system provides a smooth, controllable feed.

The Ideal Discharge and Dust Collection System

- Sealed Discharge Chute: The hot, dry sand exits the dryer into a sealed chute to minimize dust escape.

- Bucket Elevator or Heat-Resistant Belt Conveyor: This transports the hot sand to a cooling drum or directly to the product silos.

- Dust Collector: This is the most critical component for environmental compliance and safety. The hot, dusty air from the dryer is ducted to a high-efficiency baghouse Dust Collector. The collector captures over 99.9% of the fine dust, which can then be remixed with the product or disposed of safely.

Insider Tip: A cheap dust collector is the most expensive one you can buy. It will fail to meet emissions standards, clog frequently, and fill your plant with dust. Investing in a properly sized, high-quality baghouse collector is non-negotiable.

When Should You Consider a Single-Cylinder Rotary Dryer?

While the three-cylinder dryer is superior in thermal efficiency, the classic single-cylinder rotary dryer still has its place.

You should consider a single-cylinder rotary dryer if:

- Your Production Capacity is Very Large: For extremely high-tonnage applications (e.g., over 100 tons per hour), a large single-drum dryer can be a more robust and mechanically simpler solution.

- You Are Drying Larger Particles: If you are drying coarse sand, gravel, or other materials with a larger particle size, the simpler internal structure of a single-drum dryer is less prone to blockages.

- Your Budget is Tightly Constrained: A single-drum dryer generally has a lower initial purchase price than a three-cylinder dryer of similar capacity. However, remember that its higher fuel consumption may lead to a higher total cost of ownership over time.

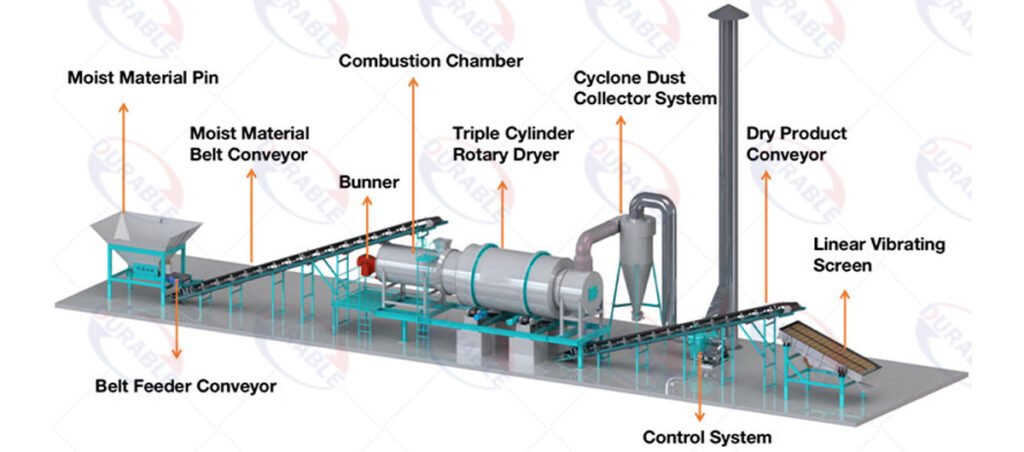

What Equipment is in a Complete Sand Drying Production Line?

A complete, turnkey sand drying production line is a system of machines working in harmony. Here is a typical layout:

- Wet Sand Hopper with Vibrating Feeder: For material storage and controlled feeding.

- Belt Conveyor: To transport wet sand to the dryer.

- Furnace / Hot Air Stove: The dryer heat source (e.g., gas, coal, or biomass).

- Sand Dryer: The core machine (typically a three-cylinder dryer).

- Discharge Belt Conveyor: To transport the hot, dry sand.

- Baghouse Dust Collector: To clean the exhaust air.

- Vibrating Screen: To classify the dried sand into different sizes if required.

- Bucket Elevator: To lift the final product into storage.

- Finished Product Silos: To store the dried sand.

- Control Panel: A central PLC system to monitor and control the entire line.

Common Questions About Sand Dryers

Q 1: What is the final moisture content after drying?

A: A good sand dryer can reliably reduce the sand moisture content from as high as 15-20% down to less than 1%. For applications like dry mortar, we typically aim for a final moisture content of 0.5% or lower.

Q 2: How much does it cost to dry one ton of sand?

A: This varies greatly depending on the initial moisture, ambient temperature, and your local fuel costs. However, using an efficient three-cylinder dryer, the sand drying cost can range from $2 to $5 per ton. The biggest factor is your choice of dryer heat source.

Q 3: What is the main advantage of a three-cylinder dryer?

A: The main advantage is its high thermal efficiency. By recycling the heat through three passes, it uses up to 30-40% less fuel than a single-cylinder rotary dryer of the same capacity. It is also more compact, saving valuable plant space.

Q 4: Can you dry manufactured sand?

A: Yes, sand dryers are perfectly suited for manufactured sand drying. Because manufactured sand often has a more angular shape and higher fines content, a well-designed feeding system and a high-efficiency dust collector are especially important.

Summary and Recommendations

Successfully drying sand is a process of precise control. It starts with choosing the right technology, like a high-efficiency three-cylinder dryer, and matching it with the most economical dryer heat source for your location.

To achieve a high-quality product at a low sand drying cost, you must focus on the entire system:

- Ensure a consistent feed rate to get uniform moisture content.

- Invest in a high-quality dust collection system for safety and compliance.

- Fine-tune the dryer’s parameters (temperature, speed, angle) to maximize efficiency.

By viewing your operation as a complete sand drying production line, you can transform wet sand into a valuable product and build a profitable business.

About Durable

We are Durable, also known as Durable Machine. We are a Chinese manufacturer specializing in mineral processing and construction equipment since 2001. We focus on B2B business and provide a full range of products for the dry mortar and drying industries, including sand dryers, batching plants, and dust collection systems. Located in Zhengzhou, we use our state-of-the-art facilities and strict quality control to deliver reliable and efficient equipment to over 120 countries. As a direct dryer manufacturer, we offer competitive pricing and complete, tailored solutions.

Contact Us

Are you planning to set up a sand drying operation or upgrade your existing equipment? Contact our team of engineers today. We can help you design a complete, efficient sand drying production line tailored to your specific needs and budget, ensuring you achieve the lowest possible operating costs.

Durable Machinery

Durable Machinery