Turn Mountains of Agri-Waste into Gold with a Rotary Dryer?

In my decades at Durable Machine, I have visited countless farms and processing plants. I always see the same two piles. One pile is the main product, the source of revenue. The other pile is the waste—wet, heavy, and often seen as a problem that costs money to solve. I am here to tell you that this second pile holds incredible value. A Rotary Dryer is the key that unlocks it. It is the most powerful tool for Agricultural Waste Treatment, turning a costly liability into a new source of profit for your business.

Why is Wet Agricultural Waste a Money-Losing Problem?

Wet agricultural waste is more than just an inconvenience; it is a constant drain on your resources. The main enemy is water. Raw biomass like straw, distillers’ grains, or manure often has a moisture content of 40% to over 80%. This high water content creates several serious financial and logistical problems for you. First, transportation costs are extremely high. You are paying to haul heavy water, not valuable material. Second, wet waste rots. It creates foul odors, attracts pests, and can lead to environmental fines. It also takes up a huge amount of space and loses its potential value every day it sits decomposing.

You cannot use this wet material for much. You cannot pelletize it, burn it efficiently for energy, or sell it as a stable fertilizer. It is a dead end. The Rotary Dryer solves this problem by directly targeting the water. It transforms your waste from a logistical nightmare into a stable, valuable commodity. By removing the water, you drastically reduce its weight and volume, stop the decomposition process, and prepare it for profitable Waste Resource Utilization. This single step changes the entire economic equation of your operation.

How a Rotary Dryer Turns Waste into “Dry Goods”

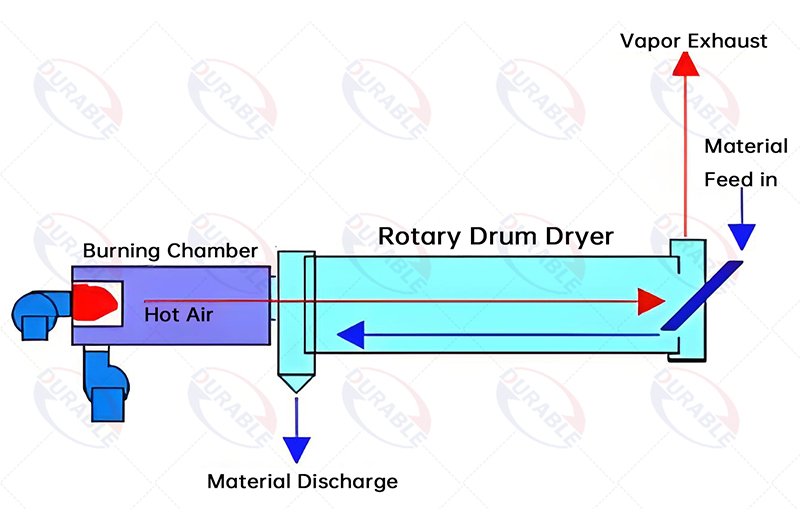

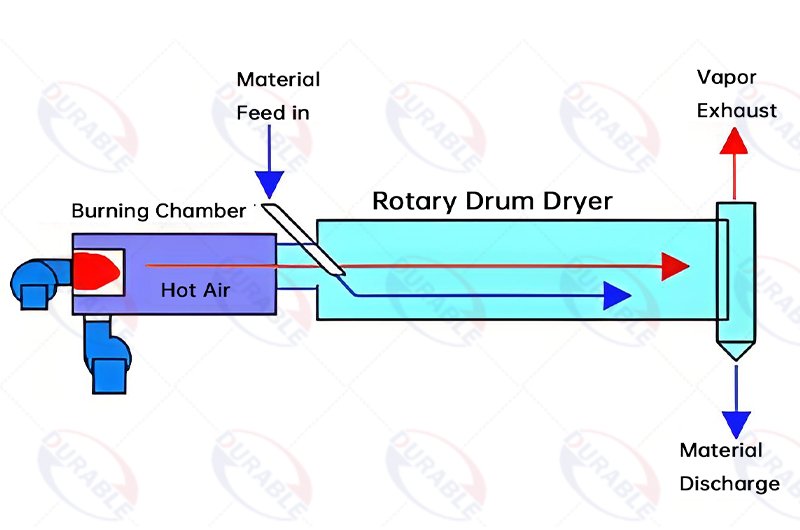

A Rotary Dryer works on a simple, powerful principle: using heat and motion to evaporate water efficiently. But for Agricultural Waste Drying, the design is highly specialized. It is not like drying sand or minerals. Biomass is lighter, more fibrous, and can be sticky. Our machines are engineered specifically for these challenges. The process begins with preparing the material. Large stalks of straw might be chopped, and very wet materials like manure might be dewatered first to reduce the energy needed for drying.

Then, the prepared waste is fed into the slowly rotating drum of the dryer. Inside the drum are special plates we call “flights.” These flights are designed to lift the biomass and shower it down through a stream of hot air. This creates a massive curtain of material, ensuring every single particle makes contact with the heat. The hot air, generated by a furnace, flows through the drum and carries the evaporated moisture away. The dryer is also set at a slight angle, so the material gently tumbles from the inlet to the outlet as it dries. We carefully control the temperature and rotation speed to ensure the waste is dried perfectly without scorching it. This turns your inconsistent, wet waste into a uniform, dry, and free-flowing product.

What High-Value Products Can Your Dried Waste Become?

Once your agricultural waste is dry, a whole new world of opportunity opens up. It is no longer waste; it is a feedstock for several profitable industries. The specific product depends on your source material, but the possibilities are extensive and can create significant new revenue for you. We have helped customers build entire businesses around these transformations.

From Field Waste to Biomass Fuel

This is one of the most common and profitable uses. Dried straw, corn stover, wood chips, and sugarcane bagasse are excellent sources of energy. Once the moisture is reduced to around 10%, the material can be pressed into high-density biomass fuel pellets or briquettes. These pellets are a clean-burning, carbon-neutral alternative to coal and are traded as a global commodity. You can use this fuel to power your own operations or sell it on the open market. Many of our clients have completely eliminated their fossil fuel costs by using their own waste.

From Food Byproduct to Animal Feed

Many byproducts from food and beverage production are rich in nutrients but spoil quickly. A distillers’ grain dryer is a perfect example. Wet distillers’ grains from a brewery or ethanol plant will rot in days. But after drying, they become Dried Distillers Grains with Solubles (DDGS), a stable, high-protein animal feed ingredient. Similarly, fruit pomace, beet pulp, and other food processing residues can be dried and sold as valuable components for animal feed, turning a disposal cost into a product sale.

From Manure to Organic Fertilizer

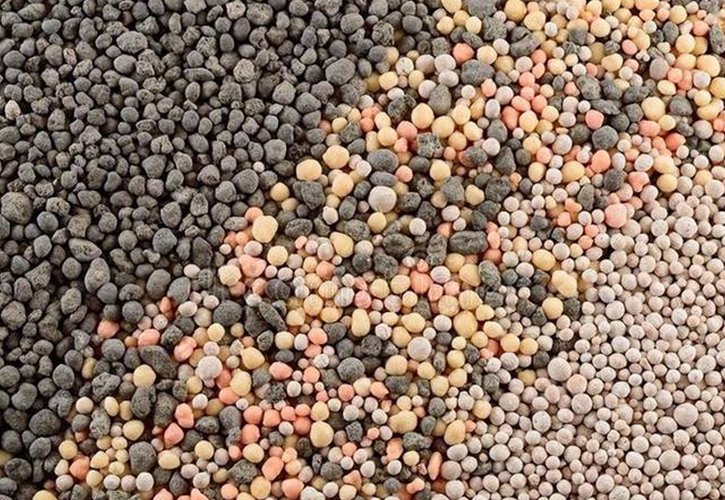

Raw manure is a major environmental liability. It is wet, smelly, and can pollute waterways. A chicken manure dryer or livestock manure dryer transforms it completely. The drying process kills harmful pathogens, eliminates the odor, and reduces the weight and volume by up to 80%. This concentrates the valuable nutrients like nitrogen and phosphorus. The final product is a dry, granular, easy-to-handle organic fertilizer that is in high demand. We help you turn a disposal headache into a premium agricultural product.

Which Heat Source and Dryer Model is Right for You?

The biggest operational cost in Agricultural Waste Drying is the fuel for the furnace. Choosing the right Dryer heat source is critical for your profitability. We work with you to analyze the most cost-effective option for your specific location and operation. Common choices include natural gas or diesel, which are clean and easy to control. Coal is another option where it is available and affordable.

However, the most sustainable and often cheapest option is to use biomass itself. We can design systems with a special biomass furnace that burns a portion of your own dried waste to generate the heat needed to dry the incoming wet material. This creates a self-sustaining loop that can reduce your fuel costs to nearly zero. The choice of dryer model also depends on your material. Sticky materials like manure or sludge require a dryer with a special internal structure to prevent buildup. Lighter materials like sawdust need specific flight designs and airflow control. We don’t sell a one-size-fits-all machine; we engineer a solution for your specific waste.

Is Investing in a Rotary Dryer a Profitable Business?

Yes, it can be an extremely profitable business. The financial model is very attractive because you are often starting with a raw material that has a low or even negative cost. People will pay you to haul their “waste” away. Your investment in a Rotary Dryer system allows you to convert this low-value material into a product with a stable market price. Your profitability depends on a few key factors: the cost of acquiring the raw waste, your Drying cost (mainly fuel and labor), and the market price for your final product, whether it’s biomass fuel, feed, or fertilizer.

We help you analyze this from day one. The key benefits that drive your return on investment include:

- Turning Disposal Costs into Revenue: Instead of paying to get rid of waste, you sell a finished product.

- Reduced Transportation Costs: You are no longer paying to ship water.

- Creating Your Own Fuel: Using a biomass furnace can dramatically lower your operational energy costs.

- Access to New Markets: You can enter the growing markets for green energy, organic farming, and sustainable animal feed.

FAQs

Q1: How much moisture can a rotary dryer remove?

A: A rotary dryer is very effective. It can take agricultural waste with a moisture content as high as 85% and dry it down to a final moisture level of 10-15%, which is ideal for producing biomass fuel, fertilizer, or feed.

Q2: What about the dust and smell from drying manure?

A: We design complete systems. This includes a robust dust collector like a cyclone separator and a baghouse filter to capture airborne particles. For materials like manure, we can also integrate an afterburner or a deodorizing tower to eliminate odors and ensure you meet all environmental regulations.

Q3: How big is a typical agricultural waste drying system?

A: The size depends entirely on your needs, from small systems processing a few tons per hour to massive industrial lines processing over 50 tons per hour. The Rotary Dryer itself is the largest component, but a full line also includes feeders, conveyors, a furnace, and dust collection equipment.

Q4: Can I use the agricultural waste itself as a fuel source?

A: Absolutely. This is one of the biggest advantages. We can equip your system with a biomass furnace that is fueled by a small portion of your dried output. This creates a closed-loop, self-sufficient system that significantly cuts your operational Drying cost.

Durable Machinery

Durable Machinery