Mineral Powder to Furnace Feed: Is a Briquette Machine Your Right Investment?

At Durable, we’ve seen countless mining and smelting operations struggle with a common problem: waste dust. Fine powders from iron ore, fluorite, steel plants, and other minerals are often seen as a costly disposal issue. However, with the right technology, this “waste” can be transformed into a high-value, precisely engineered furnace feed. A mineral briquette machine is that technology. But is it the right investment for you? This guide will explain the hard truths about briquetting mineral powders, where the real challenges lie, and how to build a successful production line.

Table of Contents

Why Must My Mineral Powder Be Briquetted for a Furnace?

Loose mineral powders, like iron ore fines or dust collected from steel plant filters, cannot be fed directly into a blast furnace or kiln. Doing so would be inefficient and dangerous.

The reasons are simple:

- Airflow Blockage: The fine powder would clog the furnace, preventing the uniform flow of hot gases needed for efficient smelting or chemical reactions.

- Material Loss: A significant portion of the powder would be immediately blown out of the furnace by the high-velocity gases, becoming waste dust all over again.

- Inefficient Reactions: Without uniform size and permeability, the heat and chemical reactions within the furnace would be inconsistent, leading to poor quality final product and wasted energy.

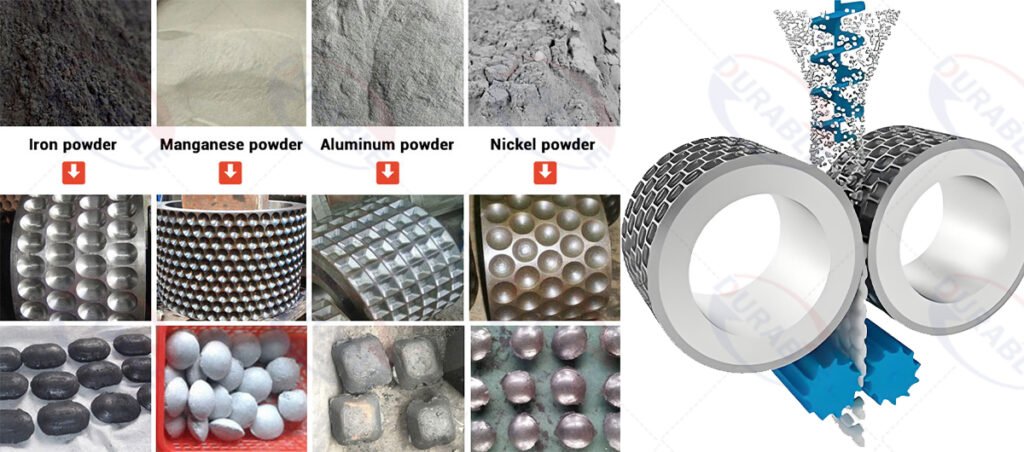

A mineral briquette machine, specifically a roller press, solves these problems by compacting the powder into dense, uniformly sized “cold-pressed pellets.” These pellets maintain the furnace’s permeability, ensuring a stable and efficient operation.

How Does a Briquetting Press Work?

The core of a mineral briquetting line is the roller press. The process is straightforward but requires precision engineering to handle the immense forces and abrasive nature of minerals.

- Step 1: Mixing: The mineral powder is mixed with a carefully measured amount of water and a specific binder for briquetting. This is done in a powerful wheel mixer to ensure every particle is evenly coated.

- Step 2: Feeding: The prepared mixture is conveyed to the briquetting press. A force-feeder, usually a screw auger, pushes the material evenly into the gap between two counter-rotating rollers.

- Step 3: Compressing: The rollers, which have pockets (molds) machined into their surface, apply extreme pressure to the material, compacting it into a solid briquette.

- Step 4: Discharging: The formed briquettes drop out from below the rollers onto a conveyor belt for the next stage: curing or drying.

The final strength of the briquette depends on three factors: the pressure of the machine, the effectiveness of the binder, and the quality of the post-processing.

Is a Binder Always Necessary, and How Does It Affect Costs?

Yes, for nearly all inorganic mineral powders, a binder is essential. Unlike biomass, these materials have no natural plasticity to hold them together after being pressed. The choice of binder is a critical technical and economic decision.

- Technical Impact: The binder must be compatible with the downstream metallurgical process. For example, binders used for iron ore fines must be low in sulfur and phosphorus, as these elements are harmful to steel quality. Bentonite clay or specialized polymers are common choices. For fluorite powder, a binder like sodium silicate (water glass) is used because it does not interfere with the fluxing process.

- Cost Impact: The binder is a continuous operational cost. It typically makes up 3% to 8% of the mix by weight. While it may seem small, this adds up to a significant expense over thousands of tons of production. Optimizing the binder formula to use the minimum amount necessary to achieve the required briquette strength is key to profitability.

| Common Mineral | Typical Binder | Why This Binder is Used |

|---|---|---|

| Iron Ore Fines | Bentonite, Polymers | Low in harmful elements (S, P), good strength. |

| Fluorite Powder | Sodium Silicate (Water Glass) | Does not contaminate the steel slag. |

| Manganese Ore | Molasses, Lignosulfonate | Cost-effective and provides good green strength. |

| Coal/Coke Dust | Starch, Molasses | Inexpensive and combustible. |

The Critical Role of Roller Shells: The Heart of the Machine

The roller shells are the components that do the actual pressing, and they face incredible abrasion and pressure. Their material and design are the most important factors determining the machine’s lifespan and your maintenance costs.

Do not settle for generic “alloy steel.” Ask for specifics.

- Standard Duty (e.g., Coal): For less abrasive materials, standard cast steel rollers may be sufficient.

- Heavy Duty (e.g., Iron Ore): For hard and abrasive minerals, you need high-performance forged alloy steel. The industry standard for durability is 9Cr2Mo. This is a high-chromium molybdenum alloy that is forged (not cast) and then heat-treated to achieve extreme hardness and wear resistance.

- Extreme Duty: For materials like silicon carbide, rollers with replaceable tungsten carbide inserts or specialized hard-facing weld overlays are used.

Investing in superior roller shells like 9Cr2Mo may increase the initial machine cost, but it will pay for itself many times over by reducing downtime and replacement costs. A cheap roller might last a few months; a forged 9Cr2Mo roller can last for years.

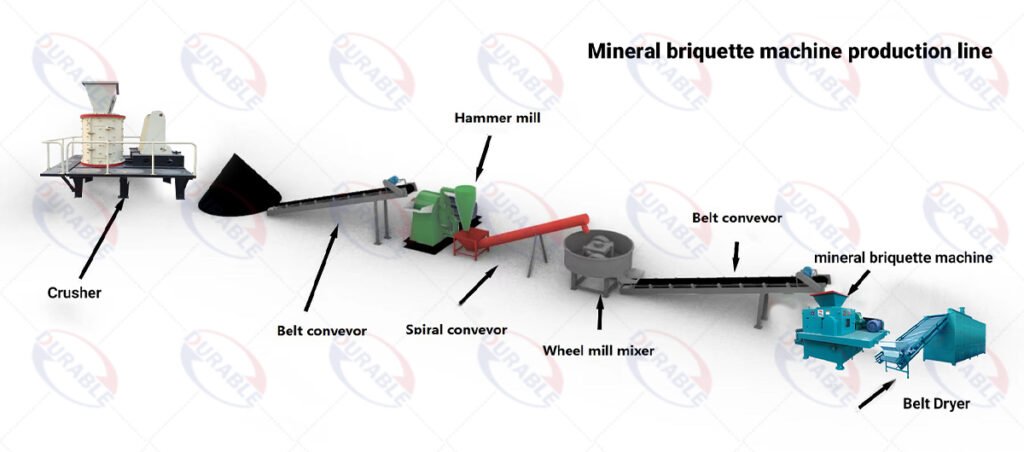

Do I Need a Complete Production Line?

A mineral briquette machine cannot operate in isolation. To produce high-quality, durable briquettes, you need a complete, integrated system.

A typical production line includes:

- Crusher: If your raw material has large lumps.

- Batching System: To accurately measure the mineral powder, binder, and water.

- Wheel Mixer: For intense, uniform mixing of the raw materials. A standard concrete mixer is not sufficient.

- Briquette Press: The core of the line, equipped with a force-feeder.

- Curing/Drying System: A critical final step. Briquettes coming off the press (“green briquettes”) are weak. They must either be cured for several days (if using a cement-like binder) or passed through a dryer (like a mesh belt dryer) to achieve their final strength.

Ignoring the need for these supporting machines is the most common reason for failure in briquetting projects.

Conclusion: A System, Not Just a Machine

Investing in a mineral briquette machine is an investment in transforming a low-value or waste material into a profitable, high-demand product. However, success depends on viewing it as a complete “material conversion system,” not just a single piece of equipment.

The key factors for success are:

- Understanding your raw material’s properties.

- Selecting the correct binder for your downstream process.

- Investing in a robust roller press with durable, forged alloy roller shells.

- Budgeting for a complete line, including proper mixing and drying equipment.

About Durable

Durable specializes in heavy-duty briquetting technology for the mining and metallurgical industries. We build robust roller presses with forged 9Cr2Mo roller shells designed for the most abrasive applications. We don’t just sell machines; we design and supply complete, turnkey briquetting lines that ensure you can produce strong, high-quality briquettes consistently and profitably.

If you’re ready to turn your mineral fines into valuable assets, contact our engineering team to discuss a solution tailored to your specific material.

Durable Machinery

Durable Machinery