Wood Chipper vs. Crusher: Which Machine Do You Actually Need?

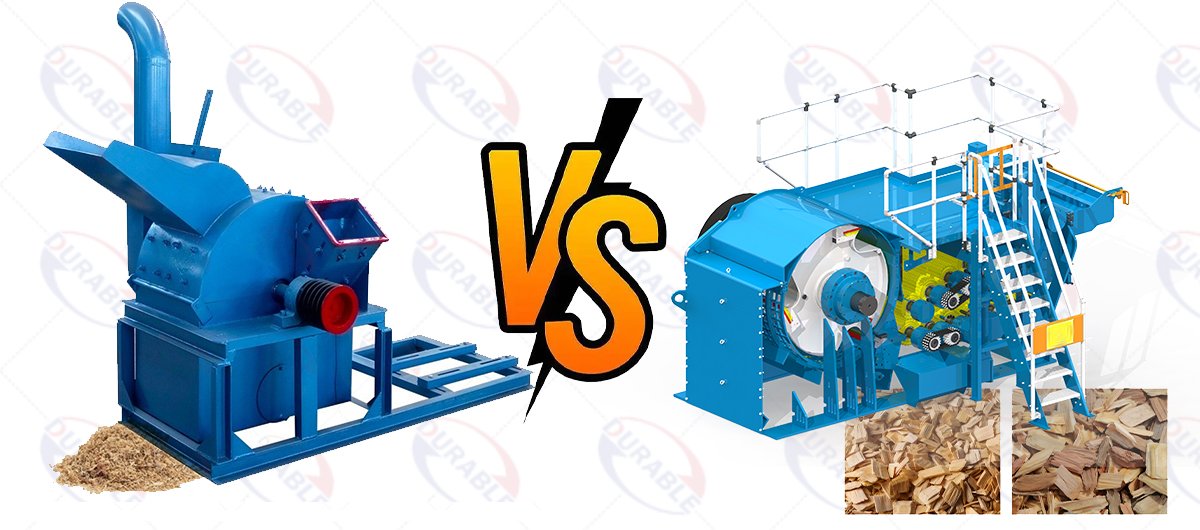

At Durable, a common question we get is, “What’s the difference between a wood chipper and a wood crusher?” People often think they are interchangeable since both make big pieces of wood smaller. This is a critical misunderstanding that can lead to buying the wrong machine, wasting money, and derailing your entire operation. One machine uses blades to “slice,” while the other uses hammers to “smash.” The difference is fundamental, and the right choice depends entirely on what you want to do with the wood after processing it.

What is a wood chipper and what does it produce?

A wood chipper is a precision machine that uses sharp knives or blades to cut wood into uniformly sized pieces called wood chips.

- How it Works: Imagine a large, rotating disc or drum with several sharp blades mounted on it. As you feed logs, branches, or clean wood into the machine, these high-speed blades slice off chips at a controlled angle. The size of the chips can often be adjusted.

- The Output: You get clean-cut, relatively flat, and consistently sized wood chips. The wood fibers are cut neatly, not torn apart.

- Best For: Applications that require long, intact wood fibers and uniform particle size.

- Pulp and Paper Manufacturing: Paper strength comes from long, interwoven wood fibers.

- Making Wood Panels (MDF, OSB, Particleboard): The manufacturing process requires specific chip geometry for structural integrity.

- Large-Scale Biomass Boilers: Uniform chips flow better in automated feeding systems and burn more predictably.

- Landscaping and Mulch: The decorative, uniform look of wood chips is ideal.

What is a wood crusher and what does it produce?

A wood crusher, often called a hammer mill, is a brute-force machine that uses blunt force to pulverize wood into a fine, fibrous material similar to sawdust.

- How it Works: Inside a steel chamber, a central rotor spins at high speed. Dozens of free-swinging “hammers” are attached to this rotor. When wood enters the chamber, it is violently struck by these hammers thousands of times, shattering and tearing it apart until the pieces are small enough to pass through a screen at the bottom.

- The Output: You get a fluffy, inconsistent, sawdust-like material. The wood fibers are smashed and ripped, not cut. The final size is determined by the size of the holes in the screen.

- Best For: Applications that require very small particles for further processing.

- Wood Pellet Production: Pellet mills need fine sawdust to press into dense pellets.

- Charcoal Briquette Making: Briquette presses require fine powder to form solid blocks.

- Animal Bedding: The soft, absorbent texture is ideal.

- Compost and Soil Amendment: The material breaks down quickly.

The Key Difference: Application, Tolerance, and Maintenance

Choosing the right machine comes down to understanding three core differences.

| Feature | Wood Chipper | Wood Crusher |

|---|---|---|

| Primary Action | Slicing with sharp blades | Smashing with blunt hammers |

| Final Product | Uniform wood chips | Fibrous sawdust or powder |

| Raw Material Tolerance | Low. Requires clean wood. A single nail can destroy a set of blades. | High. Can handle waste wood with some nails, staples, and dirt. |

| Key Use Cases | Paper pulp, MDF/OSB panels, boiler fuel | Wood pellets, briquettes, animal bedding |

Which Machine Has a Lower Operating Cost?

This depends entirely on your raw material.

- If you are processing clean logs, a wood chipper can be very efficient. However, the cost of sharpening and replacing the expensive blades is a significant ongoing expense.

- If you are processing recycled wood waste (like pallets or demolition scrap), a wood crusher is the only viable option. Its hammers are far more durable and cheaper to replace than chipper blades. For most waste wood recycling operations, the crusher has a much lower total cost of ownership.

What About Maintenance?

- Chipper: Blades need to be inspected daily and sharpened frequently to maintain chip quality and efficiency. This requires specialized equipment and skilled labor.

- Crusher: Hammers are very durable. They can often be rotated to use multiple wear edges before needing replacement. Changing hammers is a much simpler and less frequent task than sharpening blades.

Do I Need Both? The Two-Stage Solution

For very large-scale operations, especially in wood pellet production, the most efficient solution is often a two-stage process that uses both machines.

- Stage 1 (Primary Reduction): A heavy-duty wood chipper takes large logs or wood waste and efficiently reduces them to manageable, uniform wood chips.

- Stage 2 (Fine Grinding): The chips are then fed into a wood crusher (hammer mill) to be pulverized into the fine sawdust required for the pellet mill.

This combination allows each machine to operate in its most efficient range. It uses less total energy and produces a more consistent final product than trying to pulverize a large log in a single, massive crusher.

Conclusion: Your End Product Decides Your Machine

Don’t start by asking which machine is “better.” Start by defining your final product.

- Need uniform chips with intact fibers? You need a wood chipper.

- Need fine sawdust or powder? You need a wood crusher (hammer mill).

Choosing the wrong machine is one of the most expensive mistakes you can make in wood processing. It creates a bottleneck that cripples the efficiency of your entire production line.

About Durable

Durable provides a comprehensive range of industrial wood processing equipment. Whether you need a standalone wood chipper for pulp production, a robust wood crusher for recycling, or a complete, integrated production line for making pellets or briquettes, our engineers can design a system that matches your specific raw materials and production goals.

Contact us today to ensure you’re making the right choice for your operation.

Durable Machinery

Durable Machinery