Choosing a Block Machine: A Guide for Your Construction Business

Choosing a block making machine is one of the most critical investments you’ll ever make. I’ve been in this industry for decades, and I’ve seen smart entrepreneurs build successful businesses on the back of a reliable machine. I’ve also seen others fail because they were sold on a flashy brochure instead of solid engineering. The price tag is the last thing you should look at. First, you need to understand that you aren’t just buying a machine; you are investing in a complete manufacturing system. This guide will walk you through the real factors that determine profit or loss in the block making business.

Table of Contents

- What Are the Main Types of Block Making Machines?

- How Do You Determine the Right Production Capacity?

- Automatic vs. Semi-Automatic: Which Is More Profitable?

- Can One Machine Produce Different Block and Paver Types?

- What Raw Materials Can Be Used to Reduce Costs?

- How Much Should You Budget for a Block Machine Investment?

- What Factory Space, Power, and Water Are Required?

- What Is the Real Cost of Ownership Beyond the Price Tag?

- Why Choose a Durable Machine for Long-Term Reliability?

What Are the Main Types of Block Making Machines?

Before you can choose, you need to know your options. Forget the marketing jargon. Functionally, there are three main tiers of block making machines, and each serves a very different business model.

Semi-Automatic Block Machines are the workhorses of the industry. They combine automated hydraulic pressing and vibration with manual tasks like material feeding and pallet handling. These machines are a perfect balance of investment and output, ideal for small to medium-sized factories. They require a larger labor force (typically 5-7 workers) but are robust and easier to maintain in areas where highly skilled technicians are scarce.

Fully Automatic Block Production Lines are complete, integrated systems. From the computerized batching of raw materials to the mixing, molding, and stacking (cubing) of finished blocks, every step is controlled by a PLC system. These lines require a higher initial investment but offer unparalleled consistency, minimal labor (2-3 skilled operators), and the highest production output. They are the right choice for commercial suppliers aiming to serve large markets. At DURABLE, we specialize in engineering these comprehensive systems.

How Do You Determine the Right Production Capacity?

This is the biggest trap for new buyers. They are seduced by the “blocks per hour” number and think bigger is always better. This is wrong. A machine is only profitable when it’s running. Buying a massive machine that your market can’t support means it will sit idle most of the day. This is inefficient and wears out components faster due to constant starting and stopping.

The right way is to work backward from your market. How many blocks can you realistically sell per day? Once you have that number, choose a machine that can meet that demand while running at 70-80% of its rated capacity for a single 8-hour shift. This strategy gives you room to grow and is far more efficient than running a large machine intermittently. We help our clients analyze their business plans to recommend a perfectly sized machine, ensuring their investment works for them, not the other way around.

Automatic vs. Semi-Automatic: Which Is More Profitable?

Profitability isn’t just about the machine’s price. It’s about your total operational cost per block. The choice between automatic and semi-automatic depends entirely on your local business environment.

- Choose a Semi-Automatic Machine if: Your local labor costs are low, and finding skilled technicians for PLC systems and advanced hydraulics is difficult. The lower initial investment gives you a faster path to ROI, provided you can effectively manage a larger workforce.

- Choose a Fully Automatic Block Machine if: Labor costs are high, or you need to guarantee absolute consistency for every block to meet strict building certifications. An automatic line replaces 5-7 manual laborers with 2-3 skilled operators. The investment buys you precision, lower rejection rates, and predictable output, which are the keys to long-term profitability in a competitive market.

Can One Machine Produce Different Block and Paver Types?

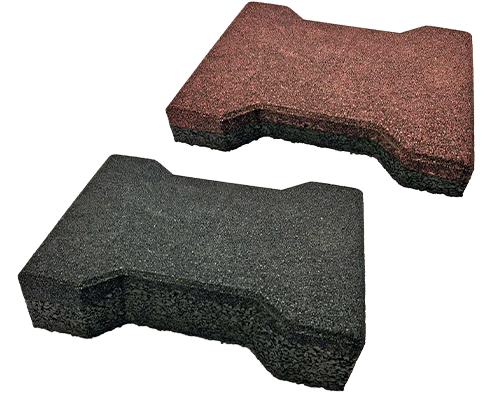

Yes, absolutely. The versatility of a block machine comes from its molds. The machine itself is the power and control unit—the “engine.” The molds are the tools that shape the final product. A high-quality machine should allow you to change molds easily to produce a wide variety of products.

At Durable, we engineer our machines for flexibility. By simply swapping out the mold, the same machine can produce:

- Hollow blocks for walls

- Solid bricks for foundations

- Interlocking pavers for roads

- Curbstones for landscaping

- Specialty blocks like insulated blocks

The key is the quality of the mold itself. We use high-manganese alloy steel with advanced heat treatment and wire-cutting technology to ensure our molds last for over 150,000 cycles and produce blocks with precise dimensions every time.

What Raw Materials Can Be Used to Reduce Costs?

Cement is typically the most expensive ingredient. Reducing your reliance on it is a direct path to higher profit margins. Modern block machines are designed to work with a wide range of industrial and recycled materials.

We always advise our clients to test their local raw materials. We can then provide the optimal mix design to produce high-strength blocks while minimizing costs. Common materials include:

- Aggregates: Crushed stone, gravel, sand.

- Industrial Waste: Fly ash (from power plants), slag (from steel mills), and coal gangue. These materials not only reduce costs but also improve the final properties of the block and are environmentally friendly.

- Construction Debris: Crushed and recycled concrete can be used as a partial aggregate.

How Much Should You Budget for a Block Machine Investment?

The machine itself is only part of the total investment. A common mistake is to spend the entire budget on the main press, leaving nothing for the essential support systems. A realistic budget should be allocated as follows:

- Main Machine & Molds: 40-60% of the total cost.

- Auxiliary Equipment: 20-30% (This includes the concrete mixer, cement silo, batching plant, and conveyor belts).

- Site Infrastructure: 10-20% (This includes the factory shed, foundations, and a large concrete area for curing).

- Other Costs: 5-10% (This includes a forklift, pallets, spare parts, and shipping/installation).

A small semi-automatic line might start around $20,000 for the core equipment, while a complete automatic production line can range from $80,000 to over $300,000. We provide transparent, itemized quotes so you know exactly where your investment is going.

What Factory Space, Power, and Water Are Required?

Logistics are critical. Before you buy, you must ensure your site is prepared.

- Space: A small semi-automatic operation needs a minimum of 500-800 square meters. A medium fully automatic line requires at least 2,000-3,000 square meters to accommodate the production line, raw material storage, and curing area for the finished blocks.

- Power: Power requirements vary significantly. A simple semi-automatic machine might need 30-50 kW, while a full production line can require over 150 kW. A stable power supply is non-negotiable.

- Water: Water is essential for the concrete mix. A reliable source providing several thousand liters per day is necessary.

Our technical team provides a detailed factory layout plan for every client, optimizing the workflow and ensuring all infrastructure requirements are clearly defined before the machine ever leaves our factory.

What Is the Real Cost of Ownership Beyond the Price Tag?

The initial purchase price is just the beginning. The Total Cost of Ownership (TCO) is what truly matters for your business’s profitability over the next 10-20 years.

TCO includes:

- Energy Consumption: Our machines are designed for high efficiency, using German-brand frequency converters to reduce power consumption during startup and operation.

- Maintenance & Spare Parts: We use high-quality, wear-resistant steel and components from international brands like Siemens (PLC) and Schneider (electronics) to minimize downtime. We also provide a recommended two-year spare parts package with every machine.

- Labor Costs: Consider the long-term payroll savings of a more automated system.

- Downtime: This is the biggest hidden cost. A cheap machine that breaks down for a week can wipe out a month’s profit. Our commitment to reliability and responsive after-sales service is your insurance against costly downtime.

Why Choose a Durable Machine for Long-Term Reliability?

For over 30 years, Durable has been more than a manufacturer; we are partners in our clients’ success. We build machines designed to perform, endure, and deliver a return on investment for decades.

- Expertise in a Complete System: We don’t just sell a machine. We design and deliver the entire factory system, from raw material batching to final block cubing, ensuring every component works together seamlessly.

- Uncompromising Quality: We use globally recognized components like Siemens PLC controls, Schneider electronics, and high-quality hydraulic systems. Our frames are built from heavy-duty steel to withstand decades of high-frequency vibration.

- Customization for Your Materials: We analyze your local raw materials and customize the machine’s vibration system and mix designs to ensure you produce the strongest possible blocks at the lowest possible cost.

- Global After-Sales Support: Our relationship doesn’t end after the sale. We provide on-site installation, operator training, and lifetime technical support. With machines in over 120 countries, we have the experience to support your operation, wherever you are.

Contact us today to speak with an engineer. We will not just give you a price; we will help you develop a complete business plan, provide a custom factory layout, and deliver a block making solution built for long-term profitability.

Durable Machinery

Durable Machinery