What is the difference between the concrete mixers and concrete pumps?

In the procurement of construction machinery, making an informed decision between a concrete mixer and a concrete pump is critical for project efficiency and profitability. While both are integral to concrete construction, they serve distinct and non-interchangeable functions. Misunderstanding their roles can lead to logistical bottlenecks, increased labor costs, and compromised project timelines.

This guide provides a technical and functional breakdown from a purchaser’s perspective. The fundamental distinction is this: a concrete mixer is a piece of production equipment used to manufacture concrete. A concrete pump is a piece of material handling equipment used to transport previously mixed concrete. We will analyze the specific applications, operational workflows, and key decision criteria to assist in proper equipment selection for your specific project requirements.

Table of Contents

- The Core Function of a Concrete Mixer: Production

- The Core Function of a Concrete Pump: Material Conveyance

- Synergistic Operation: The Integrated Concrete Workflow

- The Hybrid Solution: The Concrete Mixer Pump

- Common Questions from a Purchaser’s Perspective

- Q1: Does a concrete pump provide any mixing action?

- Summary and Professional Recommendation

- About Durable

The Core Function of a Concrete Mixer: Production

The primary and sole function of a concrete mixer is the manufacturing of concrete. It is designed to combine specific quantities of cement, aggregates (sand and gravel), water, and any necessary chemical admixtures into a homogeneous mixture. The quality of this mixing process directly dictates the final strength, workability, and long-term durability of the cured concrete.

The mechanical action within a mixer—whether from a rotating drum or rotating paddles—ensures that all aggregate particles are thoroughly coated with cement paste. This creates a uniform mass that is free from segregation. Investing in the right type of mixer is the first step toward quality assurance in any concrete construction project.

Key Types of Concrete Mixers and Their Applications:

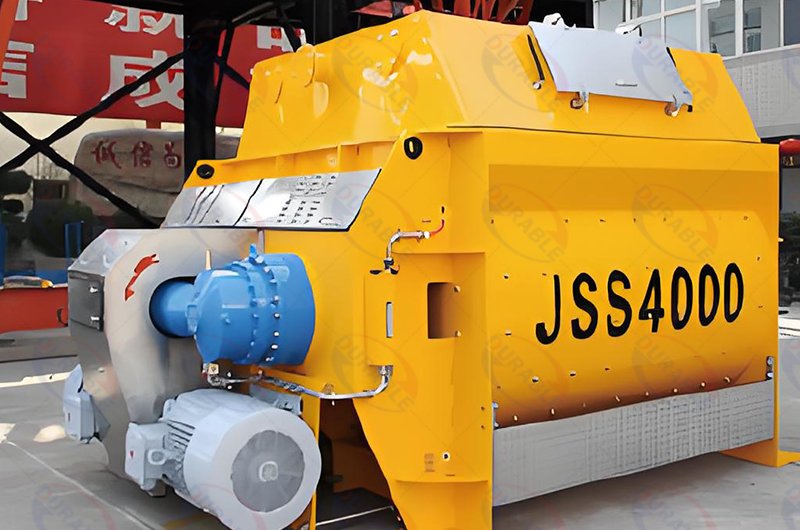

- Twin-Shaft Mixers: These are the core of stationary concrete batching plants. They offer a fast and highly energetic mixing action, making them the industry standard for producing high-strength, specification-grade ready-mix concrete.

- Self-Loading Concrete Mixers: This versatile machine combines the functions of a wheel loader, a batching system, and a mixer. It is an excellent investment for projects with limited space or in remote locations, as it provides a complete, mobile on-site production solution.

- Drum Mixers (Transit Mixers): These are found on the familiar ready-mix trucks. Their primary role is to keep the pre-mixed concrete agitated during transport from the batching plant to the job site, preventing premature setting and segregation.

The Core Function of a Concrete Pump: Material Conveyance

A concrete pump is a logistics tool. Its function begins after the concrete has been mixed. It is engineered to transfer large volumes of wet, plastic concrete from a point of delivery (typically a transit mixer truck) to the precise point of placement within the formwork. It does not alter the properties of the concrete.

The primary value of a pump is in overcoming logistical challenges. It solves the problem of how to efficiently move concrete vertically, horizontally over long distances, or into areas with restricted access. The use of a concrete pump dramatically increases placement speed, reduces the need for manual labor, and enhances site safety.

Key Types of Concrete Pumps and Their Applications:

- Boom Pumps (Truck-Mounted): This is the most common type for large-scale projects. A truck-mounted pump with a long, multi-jointed articulating boom allows for precise concrete placement at significant heights and distances. They are indispensable for high-rise buildings, bridges, and large foundations.

- Line Pumps (Trailer-Mounted): These pumps are more compact and do not have a boom. Instead, a series of steel pipes and flexible hoses are connected and laid out to transport concrete. They are ideal for ground-level slabs, residential foundations, tunnel work, and interior renovation projects.

Synergistic Operation: The Integrated Concrete Workflow

On most commercial and industrial construction sites, mixers and pumps function as components of an integrated system to ensure a continuous and efficient pour. They are not mutually exclusive choices but rather partners in a production and delivery chain.

The standard operational workflow is as follows:

- Production: A stationary concrete mixer at a batching plant produces a batch of concrete according to project specifications.

- Transportation: The concrete is loaded into a transit mixer truck. The truck’s rotating drum maintains the concrete’s quality during transport.

- Transfer & Placement: At the job site, the transit mixer discharges the concrete into the hopper of a concrete pump. The pump then conveys the concrete through its system to the final placement point.

This workflow leverages the high-quality production of a stationary mixer with the high-speed placement capabilities of a pump, optimizing the entire process.

The Hybrid Solution: The Concrete Mixer Pump

For specific applications, a hybrid machine known as a concrete mixer pump offers a combined solution. This single piece of construction machinery integrates a mixing drum and a line pump onto one chassis.

This equipment is a strategic choice for:

- Remote Projects: Ideal for sites where access to ready-mix concrete suppliers is unreliable or economically unfeasible.

- Medium-Scale Applications: Well-suited for projects like residential construction, swimming pools, or infrastructure repair, where the volume requirements do not justify the cost of a large boom pump and multiple ready-mix deliveries.

- On-Demand Production: It provides the flexibility to produce fresh concrete on-site as needed and immediately pump it into place, minimizing waste.

Key Decision Criteria for Equipment Selection

Choosing the correct equipment requires a careful analysis of your project’s specific parameters. The following table provides a decision-making framework from a procurement standpoint.

| Decision Criterion | Recommended Equipment Solution | Rationale |

|---|---|---|

| Project Scale & Volume | Small (Under 10m³): Portable Mixer Medium (10-100m³): Self-Loading Mixer or Mixer Pump Large (Over 100m³): Ready-Mix Delivery + Pump | Match production/placement capacity to project demand to optimize cost and schedule. |

| Site Accessibility | Unobstructed Access: Direct pour from a Transit Mixer or Self-Loading Mixer Vertical/Horizontal Obstacles: Concrete Pump (Boom or Line) | The primary justification for a pump is to overcome physical barriers to placement. |

| Required Pour Rate | Low/Intermittent: On-site Mixer High/Continuous: Concrete Pump | Pumps can place concrete at rates exceeding 100m³/hour, essential for large, monolithic pours. |

| Concrete Quality Specs | Standard Quality: On-site Mixers are suitable. High-Performance/Engineered Mix: Use a Batching Plant (Forced Mixer) + Transit Mixer | High-specification concrete requires the precise control and powerful action of a stationary plant mixer. |

Common Questions from a Purchaser’s Perspective

Q1: Does a concrete pump provide any mixing action?

A: No. A concrete pump is a positive displacement conveyance system. Attempting to use it for mixing by introducing raw materials will not work and will cause severe mechanical damage to the pump’s pistons and valve system.

Q2: What is the operational difference between a boom pump and a line pump?

A: A concrete pump truck (boom pump) is a self-contained unit for rapid deployment and placement at height or reach. A line pump requires more manual setup of pipelines but offers greater versatility for reaching confined or distant ground-level locations. The choice depends on the specific placement challenge.

Q3: From a cost perspective, when is on-site mixing more advantageous than ready-mix?

A: On-site mixing (using a self-loading mixer or similar) is often more cost-effective for smaller to medium-sized projects, projects in remote locations, or when multiple small pours are needed over a longer period. Ready-mix becomes more economical for large, continuous pours where volume and speed are the primary cost drivers.

Summary and Professional Recommendation

The selection of a concrete mixer versus a concrete pump is a fundamental decision based on function.

- A Concrete Mixer is a manufacturing asset, essential for the production of concrete.

- A Concrete Pump is a logistics asset, essential for the efficient placement of concrete in challenging locations.

A thorough evaluation of your project’s scale, site logistics, required pour rate, and quality specifications is mandatory for making the correct equipment selection. For large-scale operations, these machines work in a synergistic workflow. For specialized applications, hybrid units like the concrete mixer pump offer a valuable, cost-effective solution.

About Durable

Established in 2001, Durable is a leading Chinese manufacturer specializing in a wide range of concrete equipment. Our B2B focus allows us to provide robust, reliable machinery, including complete concrete batching plants, twin-shaft mixers, self-loading concrete mixers, and concrete pumps. With a global presence in over 120 countries, we offer factory-direct pricing and comprehensive support, ensuring our clients receive equipment that maximizes operational efficiency and return on investment.

Durable Machinery

Durable Machinery