What Is a Concrete Block Machine?

A concrete block making machine is a piece of industrial equipment designed to manufacture concrete blocks, bricks, and pavers. You put raw materials like cement, sand, gravel, and water into it. The machine then uses intense hydraulic pressure and high-frequency vibration to compact this mixture inside a mold. This process forms a dense, strong, and uniformly shaped block in just a few seconds. This is the core of how modern construction materials are produced efficiently.

Table of Contents

- What Is a Block Making Machine, Explained Simply?

- How Does the Block Manufacturing Process Work?

- What Key Components Make Up a Block Machine?

- What Kinds of Blocks and Pavers Can It Create?

- What Raw Materials Are Used to Make Blocks?

- Why Is This Machine Essential for Construction?

- Who Uses Concrete Block Making Machines?

- What Are the Main Differences Between Machines?

- How Has Durable Perfected Block Machine Technology?

- How Does Durable Ensure Quality in Every Machine?

- What Does a Complete Durable Plant Solution Include?

- Where Can You See Our Machines in Action?

- How Do You Start Your Journey into Block Manufacturing?

What Is a Block Making Machine, Explained Simply?

A concrete block making machine is essentially a high-force compaction system. Its main job is to take a loose, semi-dry concrete mixture and transform it into a solid, man-made stone with precise dimensions. It does this by combining two powerful forces at the same time. The first is hydraulic pressure, where a powerful cylinder presses down on the material in the mold. This action squeezes out air and gives the block its basic shape.

The second force is high-frequency mechanical vibration. This is the most critical part of the process. While the material is under pressure, the machine vibrates the mold at a very high speed. This vibration causes the particles of sand and gravel to settle into the tightest possible arrangement, removing any remaining voids. The combination of this pressure and vibration results in a block that is incredibly dense, uniform, and strong. This process is repeated hundreds or thousands of times per hour.

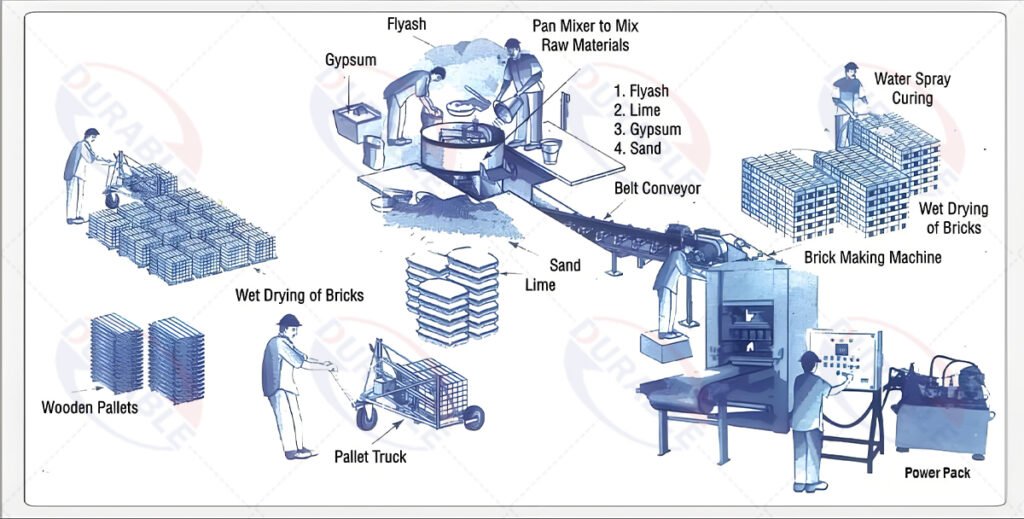

How Does the Block Manufacturing Process Work?

The block machine itself is the heart of the operation, but it is part of a larger, step-by-step manufacturing process. Understanding this full process is key to running a successful block factory. Each step must work correctly for the next one to be effective. A failure at any stage will result in poor quality blocks or a complete stop in production.

Here is the typical sequence of a block production line:

- Batching: Raw materials like cement, sand, and aggregates are measured precisely by weight in a batching machine.

- Mixing: The measured materials are transported to a large concrete mixer, where water is added to create a homogenous, semi-dry mix.

- Conveying: The finished concrete mix is carried by a conveyor belt from the mixer to the hopper of the block making machine.

- Molding: The machine automatically feeds the mix from its hopper into the mold box.

- Compaction: The machine’s press head comes down, applying hydraulic pressure and high-frequency vibration to compact the mix into a solid block.

- Demolding: The fresh block is pushed out of the mold onto a pallet.

- Transporting: The pallet with the fresh blocks is transported away from the machine to a curing area.

- Curing: The blocks are left to cure for several days to gain their full strength. This often involves keeping them moist.

- Cubing & Storage: Once cured, the finished blocks are stacked into cubes by a stacker (or cuber) and moved to a storage yard, ready for sale.

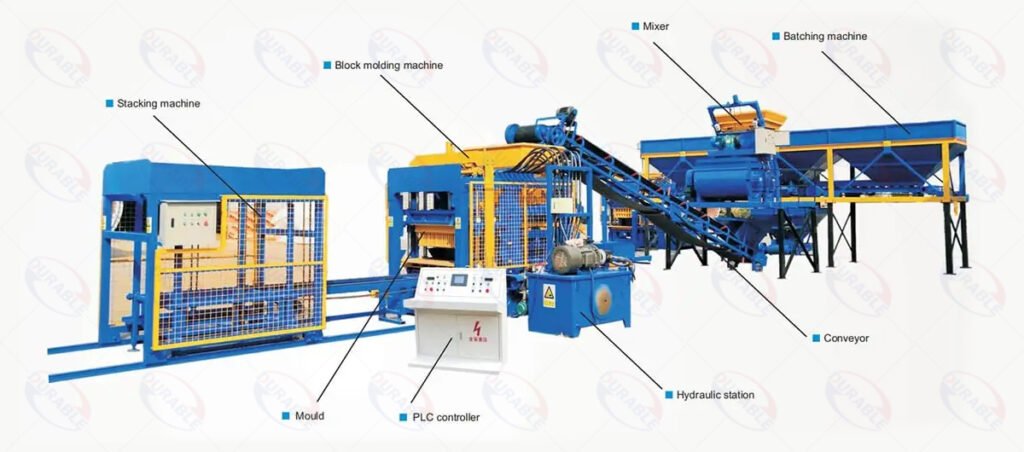

What Key Components Make Up a Block Machine?

A high-quality block machine is a complex assembly of several critical systems working together. The durability and performance of each component directly impact the quality of your blocks and the reliability of your operation. Knowing these parts helps you evaluate a machine beyond its price tag.

- Machine Frame: This is the heavy steel chassis of the machine. It must be extremely strong and rigid to withstand the constant forces of pressure and vibration without flexing or cracking.

- Mold Box: This is the high-precision tool that shapes the blocks. It is made from special wear-resistant steel and must be manufactured with very high accuracy to ensure all blocks are the same size.

- Hydraulic System: This is the muscle of the machine. It includes a powerful motor, pump, and hydraulic cylinders that generate the immense force needed to press the blocks.

- Vibration System: This is the heart of the machine. It consists of vibration motors and a vibration table that create the high-frequency shaking needed for maximum block density and strength.

- PLC Control Cabinet: This is the brain. A Programmable Logic Controller (PLC) controls every action of the machine with millisecond precision, from feeding material to demolding the block. Brands like Siemens are used for high reliability.

- Hopper and Feeder: The hopper stores the concrete mix, and the feeder drawer pushes a precise amount of material into the mold for each cycle.

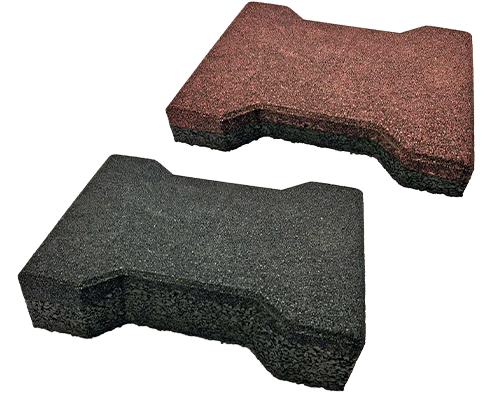

What Kinds of Blocks and Pavers Can It Create?

One of the biggest advantages of a modern block making machine is its versatility. You are not limited to making just one type of product. By simply changing the mold, the same machine can produce a huge variety of concrete products to serve different markets. This allows you to adapt your business to customer demands.

A single Durable machine can manufacture:

- Hollow Blocks: Standard blocks with one or more hollow cores, used for building walls.

- Solid Blocks: Dense, heavy blocks used for foundations and load-bearing structures.

- Paving Stones (Pavers): Interlocking or standard pavers for driveways, roads, and sidewalks.

- Curbstones: Edging stones for roads, parking lots, and landscaping.

- Retaining Wall Blocks: Specially shaped blocks for building retaining walls.

- Porous Bricks: Environmentally friendly bricks that allow water to pass through.

What Raw Materials Are Used to Make Blocks?

The raw materials for making concrete blocks are usually low-cost and widely available. The ability to use local materials is a key factor in the profitability of a block business. While the exact recipe can be adjusted, the basic components remain the same. Using industrial waste can also significantly lower your production costs.

The most common raw materials include:

- Cement: The binding agent that holds everything together.

- Aggregate: This includes sand, crushed stone, or gravel. This makes up the bulk of the block’s volume.

- Water: Necessary to activate the cement and create a workable mix.

- Additives (Optional): Pigments can be added for colored pavers.

- Industrial Waste (Optional): Materials like fly ash (from coal power plants) or slag can be used to replace a portion of the cement, reducing costs and improving block properties.

Why Is This Machine Essential for Construction?

The concrete block making machine is a cornerstone of the modern construction industry. Its importance comes from its ability to mass-produce high-quality, uniform building units at a low cost. This efficiency has a direct impact on the speed and affordability of construction projects everywhere.

The key benefits these machines bring to construction are:

- Speed: Buildings can be constructed much faster with uniform blocks compared to traditional methods.

- Cost-Effectiveness: Mass production lowers the cost of each building unit, making construction more affordable.

- Strength and Durability: Machine-made blocks are highly compacted and have superior strength and durability compared to hand-made bricks.

- Uniformity: Every block is identical in size and shape, which makes construction easier, faster, and stronger.

- Design Flexibility: Machines can produce a wide variety of shapes and sizes, giving architects and builders more creative freedom.

Who Uses Concrete Block Making Machines?

Concrete block making machines are used by a wide range of businesses and organizations involved in the construction and building materials sector. The type and size of the machine they use depend on the scale of their operations and the market they serve.

The primary users include:

- Building Material Manufacturers: These are factories dedicated to producing and selling blocks and pavers to the public and to construction companies.

- Large Construction Companies: Many large builders invest in their own machines to produce blocks on-site for major projects, ensuring a steady supply and controlling quality.

- Real Estate Developers: Developers of large housing projects or commercial complexes often set up their own block production to reduce material costs.

- Government and Municipal Projects: Governments may use these machines for public housing projects, road construction (pavers and curbstones), and infrastructure development.

- Small and Medium Enterprises (SMEs): Entrepreneurs in developing regions start small-scale block businesses to supply their local communities.

What Are the Main Differences Between Machines?

Block machines can be categorized based on their level of automation. This is the most important factor affecting the machine’s price, output, and labor requirements. The right choice depends on your budget, labor costs, and production goals.

- Manual Machines: These are the simplest type, where most operations like filling the mold and compressing are done by hand levers. They have very low output and are suitable only for very small-scale or individual projects.

- Semi-Automatic Machines: In these machines, the key processes of pressing and vibrating are automated, but tasks like moving pallets are done manually. They offer a good balance of investment and production for small to medium factories.

- Fully Automatic Machines: The entire process, from mixing raw materials to stacking finished blocks, is automated and controlled by a PLC system. These machines have the highest output, require the least labor, and produce the most consistent quality. They are the standard for serious commercial production.

How Has Durable Perfected Block Machine Technology?

With over 30 years of experience since our founding in 1990, Durable has focused on perfecting the core technologies that result in a superior block machine. We understand that reliability and efficiency are not just features; they are the foundation of our customers’ profitability. We have continuously invested in research and development to lead the industry.

Our technological advantages include:

- Advanced Vibration Systems: We have engineered our vibration systems to provide the optimal combination of frequency and amplitude. This ensures maximum compaction and strength for a wide range of products and raw materials.

- Intelligent PLC Controls: We use world-class Siemens PLC systems. This allows for precise, repeatable control over every cycle, ensuring every block is identical. Our intelligent systems also include fault diagnosis to minimize downtime.

- High-Precision Molds: We use advanced wire-cutting technology and heat treatment processes for our molds. This results in molds that are not only extremely durable but also produce blocks with exceptional dimensional accuracy.

How Does Durable Ensure Quality in Every Machine?

Quality is not something we add at the end; it is built into every stage of our manufacturing process. Our reputation depends on the long-term performance of our machines in demanding factory environments around the world. We achieve this through a strict focus on materials, components, and craftsmanship.

- Superior Raw Materials: The main frame of our machines is built from high-strength, thick steel to guarantee stability and a long service life. Molds and key wear parts are made from high-manganese, wear-resistant steel.

- World-Class Components: We do not compromise on critical components. We source our parts from globally recognized brands, including Taiwan Kelijia hydraulic stations, German Schneider frequency converters, and Siemens or Omron electrical components.

- Expert Engineering: Our team of 15 professional engineers oversees every aspect of design and production. They ensure that each machine is not only powerful but also energy-efficient, saving you money on electricity costs over the lifetime of the machine.

What Does a Complete Durable Plant Solution Include?

We believe that our customers’ success depends on a complete, well-integrated system, not just a single machine. That is why ZONEDING specializes in providing one-stop, turnkey solutions for block manufacturing. We take the guesswork out of setting up a factory.

When you partner with Durable, your complete plant solution includes:

- Consultation and Design: We start by understanding your specific needs, raw materials, and market. Our engineers then design a custom factory layout that optimizes workflow and space.

- Complete Equipment: We provide every piece of equipment you need, from cement silos and batching plants to concrete mixers, block machines, and automatic stackers (cubers).

- Installation and Training: Our technicians travel to your site to supervise the installation, commission the plant, and provide comprehensive training for your local operators on how to run and maintain the equipment.

- After-Sales Support: Our relationship continues long after the sale. We provide lifetime technical support and a reliable supply of spare parts to keep your operation running smoothly.

Where Can You See Our Machines in Action?

Experience is the best proof of quality. For over three decades, ZONEDING has successfully delivered block making solutions to more than 120 countries and regions across the globe. Our machines are operating in diverse climates and using a wide variety of local raw materials, from desert sand in the Middle East to volcanic ash in Southeast Asia.

This extensive global experience means we have likely already solved the challenges you will face. We understand different international standards and market demands. We have a proven track record of helping entrepreneurs and established companies alike build profitable block manufacturing businesses. We can share case studies and connect you with existing customers in your region, so you can see for yourself the reliability and performance of ZONEDING equipment.

How Do You Start Your Journey into Block Manufacturing?

Starting a block manufacturing business is a major decision, and the first step is gathering the right information. You now understand what a concrete block machine is and the process involved. The next step is to translate this knowledge into a concrete business plan for your specific situation.

Begin by asking yourself these questions:

- What is the demand for blocks and pavers in my local market?

- What raw materials are easily and cheaply available to me?

- What is my realistic production target per day?

- What is my total budget for the entire project, not just the machine?

Once you have preliminary answers, the best way forward is to speak with an expert. Contact our team at Durable. We will not just send you a price list. We will work with you to analyze your needs, recommend the right equipment, and provide a detailed, customized quotation and factory layout plan. Let our 30 years of experience guide you in building a successful and profitable business.

Durable Machinery

Durable Machinery