What determines the cost of a coal dryer?

When planning a procurement budget, one of the first questions is, “How much does a coal dryer cost?” The answer is that a coal dryer price is not a fixed number. It is a custom-engineered system, and its final cost is determined by your specific project requirements. Two clients can request a “coal dryer” and receive quotes that differ by hundreds of thousands of dollars.

Understanding the key factors affecting the price is essential for making an informed investment. A low initial price for a machine that fails to meet your performance or environmental standards is the most expensive purchase you can make. This guide will walk you through the primary cost drivers from a manufacturer’s perspective, helping you define your needs and prepare for a meaningful conversation about your project.

Table of Contents

- How Much Coal Do You Need to Process Daily?

- How Much Water Must Be Removed from Your Coal?

- What is Your Cheapest Local Fuel Source?

- What Type of Coal Are You Drying?

- Why Do Manufacturer Choices and Quality Matter?

- What Auxiliary Equipment Is Essential for the System?

- What Is the Price Range for Coal Dryers in 2025?

- Common Questions About Coal Dryer Costs

- Summary: Focus on Total Cost of Ownership

- About Durable

- Request a Custom Coal Dryer Quote

How Much Coal Do You Need to Process Daily?

This is the single most significant factor determining the coal dryer price. Capacity, measured in Tons Per Day (TPD) or Tons Per Hour (TPH), directly dictates the physical size of the equipment. A higher capacity requires a larger, heavier, and more powerful system.

A system designed to handle 1500 TPD is fundamentally different from one that processes 200 TPD. The increase in cost is not linear. A larger capacity means a longer and wider drum, thicker steel plates, larger support rollers and gears, and more powerful motors and gearboxes. The sheer tonnage of steel and the complexity of manufacturing these large components are the primary drivers of the initial capital cost.

| Capacity Tier | Typical Throughput (TPD) | Primary Impact on Cost |

|---|---|---|

| Small Scale | 50 – 200 | Lower steel volume, smaller motors, simpler foundation. |

| Medium Scale | 200 – 800 | Substantially larger drum, requires heavy-duty components. |

| Large Scale | 800+ | Massive engineering, oversized components, complex logistics. |

How Much Water Must Be Removed from Your Coal?

The second critical factor is the “evaporation load.” The price is driven not by the final moisture target, but by the total amount of water you need to evaporate per hour. Removing more water requires more energy and more time for the coal inside the drum.

This means a larger, more powerful heat source and often a longer dryer drum to provide the necessary residence time.

- Scenario A: Drying coal from 30% initial moisture to 10% final moisture. You must remove 20% water.

- Scenario B: Drying coal from 20% initial moisture to 10% final moisture. You only need to remove 10% water.

Even if both scenarios have the same final output tonnage, the dryer for Scenario A will be significantly more expensive because its evaporation load is double. It needs a more powerful furnace and a larger drum to handle the task.

What is Your Cheapest Local Fuel Source?

The heat source configuration is a major component of the system and has a significant impact on both the initial industrial dryer cost and long-term operating cost. The ideal choice depends on the fuel that is most economical and available at your site.

- Coal-Fired Furnace: A common choice as you can use a portion of your own product as fuel. The furnace itself is a complex piece of equipment, adding to the initial price, but it offers low long-term fuel costs.

- Gas or Oil Burner: These offer precise temperature control and clean combustion. The burner systems can have a high upfront cost, and you are subject to market prices for natural gas or oil.

- Biomass Burner: An excellent choice for sustainability. If you have access to cheap biomass like wood chips or agricultural waste, this can be very cost-effective. The biomass burner and its fuel handling system are a specific investment.

- Waste Heat / Flue Gas: If your site has another process that produces hot waste gas, using it to heat your dryer is the cheapest option operationally. However, it requires custom engineering and ducting, which affects the initial project cost.

What Type of Coal Are You Drying?

Not all coal is the same. The specific characteristics of your material directly influence the dryer’s design, materials of construction, and therefore, its price. We require a sample of your material to perform an analysis before providing an accurate coal dryer quote.

- Lignite (Brown Coal): Lignite has high moisture content and can be prone to combustion risks. It requires a dryer designed with specific temperature controls and safety features.

- Coal Slime / Slurry: This material is very fine and sticky. A lignite dryer or standard coal dryer will not work. It requires a special internal flight design with chains or breaker bars to prevent the material from clumping and sticking to the drum wall. This adds to the manufacturing complexity and cost.

- High Sulfur Coal: This can be corrosive when heated, potentially requiring the use of more expensive stainless steel or other corrosion-resistant alloys in high-temperature zones of the system.

Why Do Manufacturer Choices and Quality Matter?

The price will vary significantly based on the manufacturer’s engineering standards, component quality, and scope of service. While a higher initial price may seem daunting, it often reflects a more reliable, efficient, and longer-lasting machine.

- Engineering and Design: Experienced coal slime dryer manufacturers like Durable invest heavily in process engineering. Our designs are proven to perform under real-world conditions, ensuring you meet your production targets.

- Component Quality: The cost is affected by the brands of key components like motors, gearboxes, bearings, and electrical controls (e.g., Siemens vs. standard domestic brands). Higher quality components cost more upfront but result in lower maintenance costs and less downtime.

- Steel Grade and Welding Quality: We use high-quality steel plates and certified welding procedures. This ensures the structural integrity of the dryer, especially for large drums under constant thermal and mechanical stress.

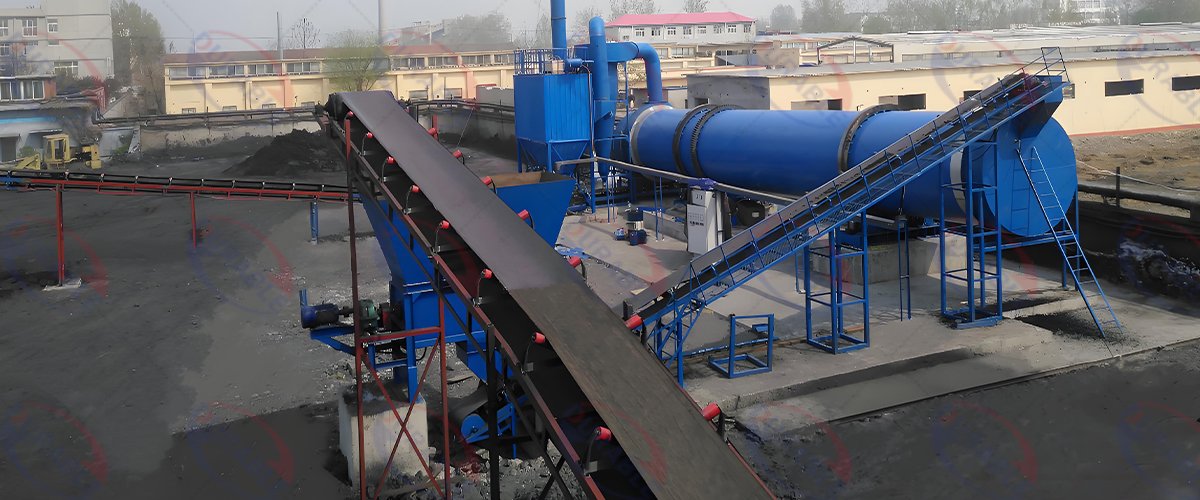

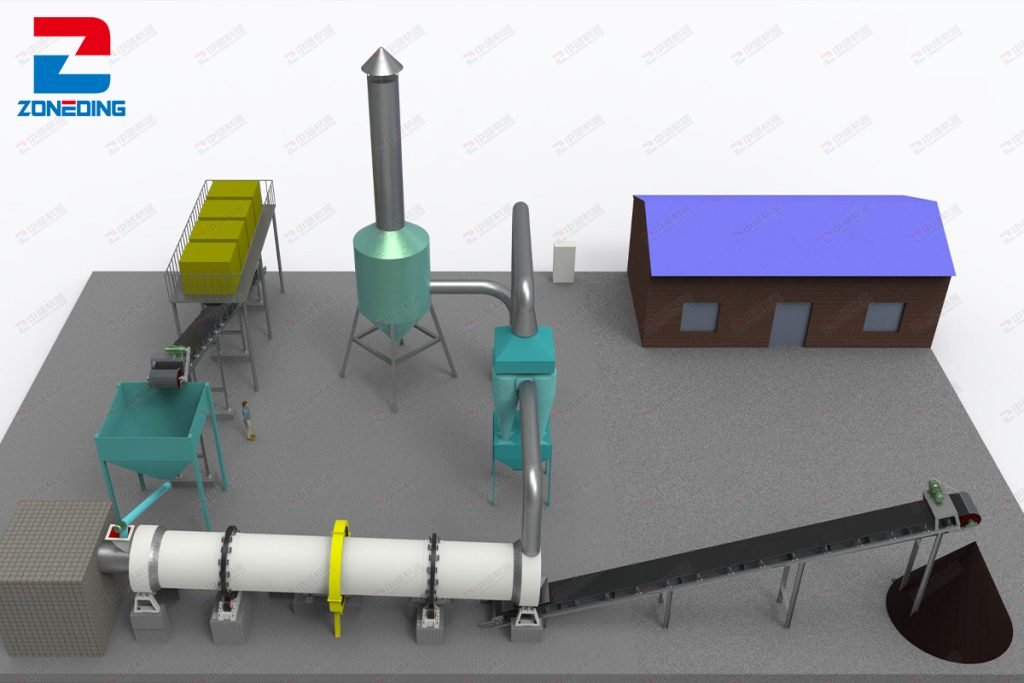

What Auxiliary Equipment Is Essential for the System?

A common budgeting mistake is only accounting for the price of the dryer drum itself. A complete, functional, and compliant drying plant is a system that includes several essential auxiliary machines. These are not optional extras.

The required auxiliary systems include:

- Feeding System: Hoppers, and conveyors to deliver a consistent flow of wet coal into the dryer.

- Discharging System: Conveyors and rotary airlock valves to handle the hot, dried product safely.

- Dust Collection System: This is non-negotiable for environmental compliance. A system combining a cyclone collector with a baghouse filter is the industry standard and is essential for clean emissions. The size and cost of this system depend on the dryer’s airflow volume.

- Control System: A PLC (Programmable Logic Controller) with a touchscreen interface costs more than a basic manual panel but provides automation, higher efficiency, improved safety, and lower labor costs.

What Is the Price Range for Coal Dryers in 2025?

While a precise quote requires a detailed analysis of all the factors above, we can provide a general price range for the complete system to help with initial procurement budget planning.

Disclaimer: These are order-of-magnitude estimates for the complete system (dryer, heat source, conveyors, dust collection, basic control panel) and are subject to change based on specific configurations and raw material costs.

| System Capacity (TPD) | Estimated Price Range (USD) | Best For |

|---|---|---|

| 50 – 200 TPD | $50,000 – $180,000 | Smaller operations, pilot projects, byproduct processing. |

| 200 – 800 TPD | $180,000 – $600,000 | Medium to large coal washing plants, commercial fuel producers. |

| 800 – 2000+ TPD | $600,000 – $1,500,000+ | Large-scale mining operations, power plants, dedicated fuel plants. |

For more details on the types of dryers we offer, you can explore our range of industrial rotary dryers.

Common Questions About Coal Dryer Costs

Question 1: Does the price include installation?

A: Typically, the base coal dryer quote is for the equipment itself (FOB). We offer on-site installation supervision and full turnkey installation services as separate options. The cost will depend on your location and the scope of work required.

Question 2: How much are the operating costs?

A: The main operating costs are fuel and electricity. Fuel cost is determined by your choice of heat source and the dryer’s thermal efficiency. Electricity is used to power the motors for the drum, fans, and conveyors. We can provide detailed operating cost estimates based on your specific project parameters.

Question 3: Can I get a cheaper price by excluding the dust collector?

A: We do not recommend or sell systems without an adequate dust collection unit. Operating without one is environmentally irresponsible, often illegal, and poses a significant safety risk (coal dust is combustible). The investment in a proper dust collection system is essential.

Summary: Focus on Total Cost of Ownership

The initial coal dryer price is only one part of the equation. A truly wise investment considers the Total Cost of Ownership (TCO), which includes the purchase price, energy consumption, maintenance costs, and reliability over the life of the machine.

The key is to provide your potential supplier with as much detail as possible about your:

- Required daily capacity.

- Initial and target moisture content.

- Coal type and characteristics.

- Available fuel source and cost.

With this information, an experienced manufacturer can design a system that delivers the lowest cost per ton of dried product, ensuring a fast and sustainable return on your investment.

About Durable

Since 2001, Durable has been a leading Chinese manufacturer of industrial drying and mineral processing equipment. We specialize in providing robust, reliable, and efficient solutions tailored to our clients’ specific needs. Our factory-direct model and comprehensive engineering support ensure you receive a high-value system designed for long-term profitability. We have delivered solutions to over 120 countries.

Request a Custom Coal Dryer Quote

Are you ready to turn your coal drying project into a reality? Contact our engineering team today. Provide us with your project details, and we will deliver a comprehensive, no-obligation quote for a custom-designed drying system that meets your production goals and budget.

Durable Machinery

Durable Machinery