How Biomass Charcoal Briquette Machines Turn Waste into Treasure

At Durable, we often meet entrepreneurs excited by the idea of waste to energy. You might have access to cheap or free biomass waste—like sawdust, rice husks, or straw—and see the potential to turn it into valuable charcoal. This is a fantastic business model, but its success hinges on one critical piece of equipment: the biomass charcoal briquettes machine. Many people think this machine simply presses sawdust into a log. This is a fundamental misunderstanding. This machine is not a press; it is a high-temperature extruder that melts and reforms your raw material. Understanding this difference is the key to turning waste into wealth.

Table of Contents

- Can I Really Use My Waste (Like Rice Husks, Straw, Sawdust) to Make Charcoal?

- What is the Complete Production Line?

- How Does the Briquette Machine Actually Work? It’s Not Pressing, It’s “Melting”

- Why Must I Briquette Before Carbonizing?

- What is the Real Budget and Profit Potential?

- Conclusion: A Scientific Approach to Waste Valorization

- About Durable

Can I Really Use My Waste (Like Rice Husks, Straw, Sawdust) to Make Charcoal?

Yes, absolutely. This is the core purpose of a biomass briquette machine. Almost any agricultural or forestry waste can be a valuable raw material for sawdust briquette or rice husk charcoal production.

However, the machine has two non-negotiable rules. Your raw material must be:

- Small: The particle size should be between 3mm and 6mm. Anything larger will jam the machine.

- Dry: The moisture content must be between 8% and 12%. Anything wetter will create steam, causing the briquettes to crack or even explode.

This means that while your raw material might be free, you must properly prepare it first. This pre-treatment step is not optional; it is essential for the entire process to work.

What is the Complete Production Line?

Turning loose sawdust into final charcoal briquettes is a four-step process. The biomass briquette machine is the heart of the line, but it cannot work alone.

- Crushing: If your raw material is larger than 6mm (like wood chips or branches), you first need a hammer mill crusher to reduce it to the required size.

- Drying: This is the most critical step. You must use a professional sawdust dryer to lower the moisture content to the ideal 8-12% range.

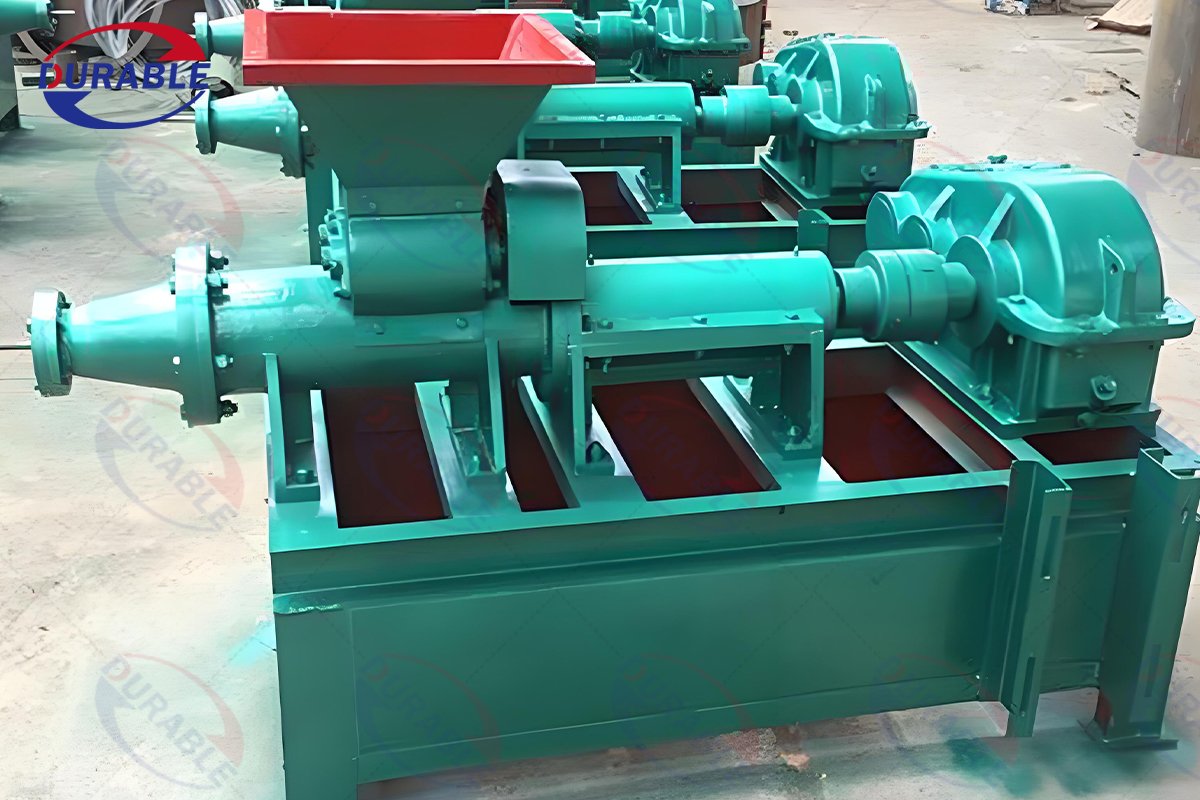

- Briquetting: The prepared, dry powder is fed into the biomass briquette machine, which forms it into dense, hollow logs called “pini-kay” briquettes.

- Carbonizing: These briquettes are then loaded into a charcoal making machine (carbonization furnace) where they are heated in an oxygen-free environment to be converted into high-quality charcoal.

Skipping any of these steps, especially crushing and drying, will lead to project failure.

How Does the Briquette Machine Actually Work? It’s Not Pressing, It’s “Melting”

This is the most misunderstood part of the briquetting process. The machine does not just use pressure to compact the material. It uses extreme heat and pressure to plasticize the wood’s natural binder.

Here is the secret: Lignin Plasticization.

Lignin is a natural polymer found in wood and biomass that acts like glue. The briquette machine is engineered to melt this lignin.

- High Temperature: A heating collar warms the machine’s forming sleeve to 250-300°C. At the same time, the intense friction from a high-speed screw propeller generates massive internal heat.

- High Pressure: The screw propeller forces the material through the tapered sleeve, creating immense pressure.

- The “Melting” Process: Under this combined heat and pressure, the lignin melts and becomes a sticky, natural adhesive. As the briquette is extruded from the machine, it cools rapidly, and the lignin re-solidifies, “welding” all the biomass fibers together into an incredibly dense and solid log.

Think of it less like a press and more like a giant hot glue gun that uses the material’s own natural glue.

Why Must I Briquette Before Carbonizing?

You might wonder, why not just carbonize the loose sawdust directly and then press it into briquettes? This is a crucial strategic choice that determines your final product’s quality and value.

The hollow-core briquettes made by the machine are specifically designed for perfect carbonization.

- The Critical Center Hole: This hole is not a flaw; it’s a key feature. During carbonization, gases and tar must escape from the briquette. The hole provides a clear channel for these gases to exit. Without it, pressure would build up inside, causing the briquette to crack or explode into useless pieces.

- Even Heating: The hole allows heat to penetrate the briquette from both the outside and the inside, ensuring a fast, even, and complete carbonization process.

If you carbonize loose sawdust first, you get a low-density charcoal powder. You would then need a different machine, a charcoal ball press machine, which requires an additional chemical binder to stick the powder together. This creates lower-quality charcoal that produces more smoke and ash. For high-grade BBQ charcoal, the “briquette first, then carbonize” method is the only way to go.

| Method | Briquette First, Then Carbonize | Carbonize First, Then Briquette |

|---|---|---|

| Process | Sawdust -> Briquette -> Charcoal | Sawdust -> Charcoal Powder -> Briquette |

| Binder Needed | No (uses natural lignin) | Yes (chemical binder required) |

| Final Product | High-density, smokeless BBQ charcoal | Lower-density, smokier coal balls |

| Market Value | High | Low to Medium |

What is the Real Budget and Profit Potential?

Investing in a complete charcoal production line is a significant decision. The “waste is free” idea can be misleading because there are real operational costs to consider.

Your main costs will be:

- Capital Investment: The cost of the crusher, dryer, briquette machine, and carbonization furnace.

- Electricity: The dryer and briquette machine are the largest consumers of energy. This is often the biggest operational expense.

- Labor: For collecting materials and operating the line.

- Maintenance: The screw propeller on the briquette machine is a high-wear part. It is a consumable, like the tires on a car, and will need to be repaired or replaced regularly.

However, the return on investment (ROI) can be very high. You are transforming a low-value (or even negative-value) waste product into a high-demand commodity. High-quality machine-made charcoal briquettes are uniform, easy to package, and burn longer and cleaner than traditional lump charcoal. This allows them to command a premium price in the BBQ, restaurant, and industrial markets. A well-run operation can often achieve a full ROI in 1-2 years.

Conclusion: A Scientific Approach to Waste Valorization

A biomass charcoal briquettes machine is the key to a profitable agricultural waste recycling business. But success requires understanding the science behind it. It is not a simple press. It is a precision extruder that relies on the thermal properties of lignin and requires carefully prepared raw material. By investing in the complete line—crushing, drying, briquetting, and carbonizing—you are not just getting rid of waste; you are building a modern energy factory that produces a consistent, high-value, and in-demand product.

About Durable

At Durable, we provide end-to-end solutions for the charcoal industry. We understand that a successful operation depends on every machine in the charcoal production line working together seamlessly. From robust crushers and efficient dryers to our reliable biomass briquette machine and advanced carbonization furnaces, we provide the technology and expertise to help you turn your biomass resources into a profitable enterprise.

Contact our team today to discuss your raw materials and business goals, and let’s engineer the right solution for you.

Durable Machinery

Durable Machinery