What Does a Concrete Plant Do? A Simple Guide

After 50 years in this industry, I’ve seen that the most successful contractors understand a simple truth: a concrete batching plant isn’t just a machine for mixing cement. It’s a highly sophisticated factory that produces the single most critical material for any project. Think of it as a giant, industrial-scale kitchen. It takes raw ingredients like stone, sand, and cement, follows a precise engineering recipe, and manufactures high-strength concrete with a level of precision, consistency, and speed that is simply impossible to achieve otherwise. It’s the heart that pumps life into your construction project and a powerful center for generating profit.

Table of Contents

- What a concrete plant essentially does?

- How Does It Turn Rock into Revenue? The Process

- What Are the Main Types of Concrete Plants?

- Is Owning a Plant Cheaper Than Buying Concrete?

- Beyond Production: Other Benefits a Plant Offers

- How to Know If Your Business Needs a Concrete Plant?

- Frequently Asked Questions

- Summary and Final Recommendation

- About Durable

What a concrete plant essentially does?

At its core, a concrete plant performs four essential functions to transform raw materials into a finished product. It takes the guesswork out of concrete production and turns it into a controlled, repeatable industrial process. This is the foundation of all modern, quality construction. It’s not just about mixing; it’s about absolute control over the final product. Every action is designed to deliver consistency, quality, and scale. This is the primary function of a batching plant.

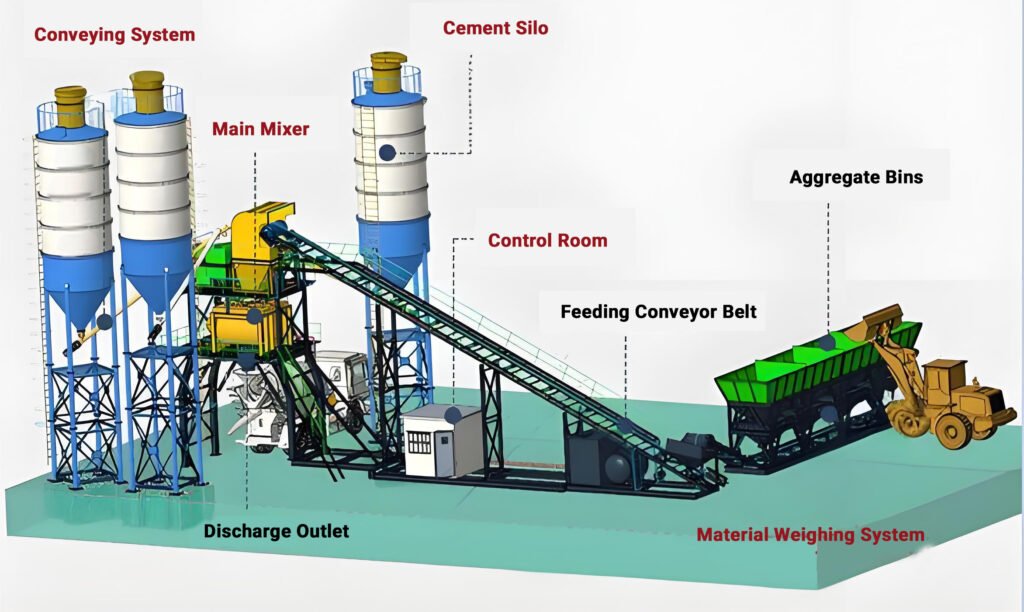

The Anatomy of a Modern Concrete Plant: Its Key Systems

To truly understand what a concrete plant does, you need to look at its individual systems. Each part has a specific job, and they all work together like the organs in a body to produce a perfect result. In my experience, a plant is only as strong as its weakest system.

Material Storage System (The Pantry)

This is where all your raw ingredients are kept safe and ready. A well-organized storage system is the first step in quality control.

- Aggregate Bins: Large, open-topped steel containers that hold different sizes of sand and stone separately.

- Cement Silos: Tall, sealed towers that store cement powder. The sealed design of a bolted silo is critical to protect the cement from air and moisture, which would ruin it.

- Water and Admixture Tanks: Separate tanks hold the water and various liquid chemical admixtures, which are like special spices to give the concrete unique properties.

Material Conveying System (The Arteries)

This system moves the heavy materials from storage to be measured and mixed. It needs to be fast and reliable to keep production moving.

- Belt Conveyors: The most common method for moving aggregates from the storage bins up to the weighing hoppers.

- Screw Conveyors: These are large, enclosed screws that draw the fine cement powder from the bottom of the silo and transport it horizontally or at an incline to the cement weigher.

Material Weighing System (The Recipe)

This is the most critical system for ensuring quality. Precision here is non-negotiable.

- Weigh Hoppers: Separate weighing buckets for aggregates, cement, water, and admixtures. They are suspended on highly sensitive electronic scales called load cells.

- Control System Integration: The scales send real-time data to the central control system, which closes the gates once the exact target weight is reached.

The Mixing System (The Heart)

This is where the chemical reaction that creates concrete begins. The quality of your mixer determines the quality of your concrete. The most common and effective type I’ve seen in modern plants is the twin-shaft concrete mixer. Its powerful, compulsory mixing action ensures every particle of sand and stone is coated with cement paste.

The Control System (The Brain)

This is the nerve center of the entire operation. Modern plants use a PLC (Programmable Logic Controller) system with a computer interface. From a control room, a single operator can manage the entire concrete production process, from weighing and mixing to discharging. It stores hundreds of different recipes, records all production data, and ensures every batch is made to the exact same specification.

The Dust Control System (The Lungs)

An often-overlooked but vital system. Mixing and moving dry cement powder creates a lot of dust. A good dust collection system captures this dust, protecting the environment, ensuring worker safety, and preventing the loss of valuable material.

How Does It Turn Rock into Revenue? The Process

The working process of a concrete plant is a beautifully engineered sequence. I’ve commissioned dozens of these, and the efficiency is always impressive.

- Loading Aggregates: A wheel loader scoops sand and stone into the correct aggregate storage bins.

- Recipe Selection: The plant operator selects the required concrete recipe from the computer control system.

- Automatic Weighing: The system automatically conveys and weighs the precise amount of aggregates, cement, water, and admixtures into their respective hoppers.

- Charging the Mixer: Once all materials are weighed, they are discharged into the central mixer in a specific sequence (often aggregates and water first, then cement) to ensure the best blend.

- Mixing: The mixer runs for a pre-set time, typically just 30 to 60 seconds, to create a perfectly homogeneous batch of concrete.

- Discharging: A gate at the bottom of the mixer opens, and the fresh concrete is discharged into a transit mixer truck waiting below. The entire cycle for one batch can be completed in about two minutes.

What Are the Main Types of Concrete Plants?

Not all construction projects are the same, so not all concrete plants are the same. I always advise clients to choose the type that best fits their business model and project needs.

Stationary vs. Mobile Plants: Which is for you?

A stationary concrete batching plant is a large, permanent structure built on a concrete foundation. It’s designed for high-volume, long-term production in one location, making it perfect for ready-mix suppliers serving a city or a large precast factory. In contrast, a mobile concrete batching plant is designed for easy transport and setup. Its main components are built on a wheeled chassis, allowing it to be moved from one job site to another. This is ideal for contractors working on specific projects like roads, bridges, or airports in remote locations.

Commercial vs. Engineering Plants: Selling or Building?

- Commercial Concrete Plants: These are the large, high-output stationary plants used by ready-mix concrete suppliers. Their goal is to produce many different types of concrete for sale to various customers. They are built for speed, reliability, and the flexibility to change recipes quickly.

- Engineering Concrete Plants: These are typically dedicated to a single large construction project. The focus here is less on variety and more on producing a massive volume of a few specific, high-quality concrete mixes. Both mobile and smaller stationary plants can be used for this purpose.

Is Owning a Plant Cheaper Than Buying Concrete?

This is a question I get from contractors all the time. The answer is not a simple yes or no. Owning a plant becomes more profitable than buying concrete when your project volume crosses a certain threshold. It’s a strategic decision based on a cost-benefit analysis.

- Project Volume: If your company consistently uses a large amount of concrete, the savings on material costs can quickly pay for the plant. Buying sand, stone, and cement in bulk is always cheaper than buying ready-mix concrete.

- Project Location: For remote job sites, the cost of transporting ready-mix can be extremely high. Setting up a dedicated plant on-site is often far more economical.

- Quality Requirements: For projects with strict specifications, producing it yourself gives you total control over concrete quality control, reducing the risk of costly rejections.

- Supplier Reliability: If you constantly face delays from suppliers, owning your own plant puts you in control of your project’s timeline and concrete supply chain.

Beyond Production: Other Benefits a Plant Offers

Owning a concrete plant does more than just make concrete. It transforms your business.

- Enhanced Bidding Power: When you control your own concrete supply, you can bid more competitively on larger and more complex projects.

- New Revenue Stream: You can sell any surplus concrete to smaller local contractors, turning your plant into a second business.

- Improved Reputation: Becoming a producer of high-quality concrete enhances your brand’s reputation for quality and reliability in the market.

How to Know If Your Business Needs a Concrete Plant?

Deciding whether to make the investment comes down to a few clear signals. You should seriously consider investing in a concrete plant if you answer “yes” to several of these questions:

- Are your projects frequently delayed because of late concrete deliveries?

- Do you operate in remote areas where ready-mix is unavailable or very expensive?

- Is your monthly concrete bill a major factor in your project costs?

- Do you want total control over your concrete quality for high-spec projects?

- Are you looking for a new revenue stream by selling materials to others?

- Do you want to scale up your operations to take on larger, more profitable contracts?

Frequently Asked Questions

1. What is the difference between a wet and a dry concrete plant?

A wet plant (central mix) has a large mixer that blends all ingredients into finished concrete before loading it into a truck. A dry plant (transit mix) weighs the dry ingredients into the truck, and water is added for the truck to do the mixing en route. Wet plants offer superior quality control.

2. What are the common models of concrete plants?

Plants are often named by their theoretical hourly output in cubic meters. For example, an HZS25 produces 25 m³/hour, while an HZS180 can produce 180 m³/hour. The right model depends entirely on your project’s demand.

3. How much does a concrete plant cost?

The concrete plant cost varies widely based on its type (mobile/stationary), size (capacity), and configuration (mixer type, silo quantity). It’s a major capital investment, but one that can offer a rapid return for high-volume users.

Summary and Final Recommendation

A concrete batching plant is far more than a simple mixer. It is the heart of any modern construction project and a powerful profit center for your business. It turns the highly variable task of making concrete into a precise, controlled, and scalable industrial process. By giving you full control over your concrete supply chain, it allows you to guarantee quality, meet tight deadlines, and significantly reduce material costs in the long run.

Whether you are a large-scale contractor or a growing ready-mix supplier, investing in the right concrete plant is a strategic decision that empowers you to build better, faster, and more profitably.

About Durable

Since our founding in 2001, Durable Machine has been a professional manufacturer of construction and mineral processing equipment. We operate on a factory-direct B2B model, providing high-quality machinery to clients in over 120 countries. Our facilities are fully equipped to ensure excellent quality control at every stage, guaranteeing your complete satisfaction with our robust and reliable equipment.

If you’re ready to take control of your concrete supply chain, contact our expert team. We can help you analyze your needs and recommend the perfect concrete plant to drive your business forward.

Durable Machinery

Durable Machinery