Direct vs. Indirect Rotary Dryers: Efficiency First or Environment First?

Choosing the right rotary dryer is a critical decision. In my decades of experience designing processing lines, I’ve seen this choice make or break a project’s profitability and compliance. It’s a classic engineering trade-off: do you prioritize the raw thermal efficiency of a direct rotary dryer or the guaranteed product purity and environmental friendliness of an indirect rotary dryer? The answer isn’t simple, as it depends entirely on your material, your budget, and your local regulations. This guide will walk you through the analysis, helping you make the right choice for your operation.

Table of Contents

- What is a Direct Rotary Dryer?

- What is an Indirect Rotary Dryer?

- Which has better efficiency and operating costs?

- Efficiency vs. Operating Cost: Which Wins?

- Environmental Compliance & Purity: The Safer Choice?

- How Do Your Material Properties Decide the Choice?

- ROI: Balancing Initial Cost and Long-Term Costs?

- Common Questions About Rotary Dryers

- Summary: A Sledgehammer or a Scalpel?

- About Durable

- Get an Expert Recommendation for Your Project

What is a Direct Rotary Dryer?

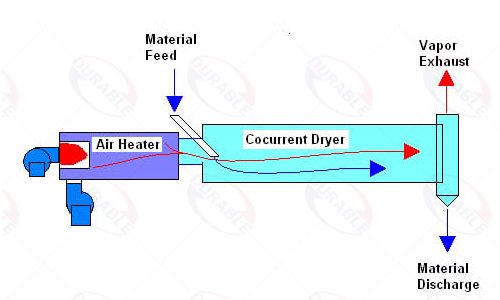

A direct rotary dryer works like a very powerful hairdryer. In this system, hot combustion gases from a furnace or burner are mixed with air and passed directly through and over the material as it tumbles inside a rotating drum. The hot gases make direct contact with your material. This direct contact allows for very rapid and efficient heat transfer. The gases then carry the evaporated moisture out of the dryer. This design is simple, robust, and very effective at removing large amounts of water quickly.

This type of dryer is a brute-force workhorse. It is excellent for drying large volumes of non-sensitive bulk materials. Think of things like sand, gravel, stone, certain types of coal, and robust mineral ores. Because the heat transfer is so direct, these dryers achieve a high thermal efficiency, which can lead to lower fuel consumption. However, this direct contact method has two major downsides. First, the material can be contaminated by the soot, ash, or other products of combustion from the gas stream. Second, the exhaust gas is a high-volume mixture of combustion products, water vapor, and a large amount of dust from your material, which makes environmental control a serious challenge.

What is an Indirect Rotary Dryer?

An indirect rotary dryer works like an oven or a roasting pan. In this design, the material tumbles inside a rotating drum that is heated from the outside. The hot combustion gases flow through an external jacket or through tubes running inside the dryer shell. The material never comes into direct contact with these heating gases. The heat transfers through the steel wall of the drum to the material through conduction and radiation. The moisture evaporated from the material is carried away by a separate, small stream of sweep gas.

This design makes the indirect rotary dryer a precise and clean instrument. Its primary advantage is that it completely prevents material contamination. This makes it the only choice for drying high-purity chemicals, pharmaceuticals, food products, and fine pigments. Because the material is isolated, the flue gas treatment is much simpler. You have two separate gas streams: the clean heating gas and a very small volume of process gas containing water vapor and some dust. This makes meeting strict dust emission standards much easier. The main trade-off is lower thermal efficiency compared to direct dryers, which can lead to higher fuel costs. The initial equipment cost is also typically higher.

Which has better efficiency and operating costs?

When comparing dryer efficiency, direct dryers have a clear advantage in thermal efficiency, but the story of total operating cost is more complex. You have to consider fuel, electricity for pollution control, and maintenance.

A direct rotary dryer typically achieves higher thermal efficiency, often in the range of 60-75%. Because heat is transferred directly, less energy is lost to the environment. This means lower fuel consumption per ton of water evaporated. However, it requires a massive and power-hungry air pollution control system to handle the large volume of dusty exhaust gas, significantly increasing electricity costs.

An indirect rotary dryer has lower thermal efficiency, usually around 45-60%. Heat must pass through the drum shell, leading to greater energy loss. This results in higher fuel consumption. But, because the exhaust stream from the material is very small and clean, the pollution control system is much smaller, simpler, and consumes far less electricity.

| Feature | Direct Rotary Dryer | Indirect Rotary Dryer | Your Practical Meaning |

|---|---|---|---|

| Thermal Efficiency | Higher (60-75%) | Lower (45-60%) | You will spend less on fuel with a direct dryer. |

| Electricity Cost | Higher (large fans & APC system) | Lower (small process gas fan) | Your power bill will be significantly lower with an indirect dryer. |

| Maintenance Cost | Higher (complex APC system) | Lower (simpler, smaller systems) | You will have fewer maintenance headaches with an indirect system. |

| Overall Operating Cost | Lower fuel cost, higher electricity & maintenance cost | Higher fuel cost, lower electricity & maintenance cost | The “cheaper” option depends on your local fuel vs. electricity prices. |

Efficiency vs. Operating Cost: Which Wins?

A direct rotary dryer has higher thermal efficiency, but an indirect dryer can have a lower total operating cost in certain situations. This is a critical trade-off to understand. Thermal efficiency measures how much of the fuel’s energy is used to evaporate water. A direct rotary dryer is the champion here, often reaching 60-75% efficiency. The heat directly touches the material, so very little is wasted. This means you will spend less money on fuel for every ton of water you remove. This seems like a clear win for operating cost.

However, that is only part of the story. The direct dryer moves a massive volume of air and exhaust gas. This requires large, powerful fans that consume a lot of electricity. More importantly, this exhaust gas is full of dust. You must have a large and complex air pollution control system, like a baghouse, to clean this gas. This system has its own high operating and maintenance costs. An indirect rotary dryer has a lower thermal efficiency, maybe 45-60%, so your fuel bill will be higher. But, it handles a very small volume of process gas. The fans are smaller, and the dust collection system is much smaller and cheaper to run. When you add up the costs of fuel, electricity, and pollution control maintenance, the indirect dryer can sometimes be the cheaper option overall, especially if you face strict environmental regulations.

Environmental Compliance & Purity: The Safer Choice?

The indirect rotary dryer is unquestionably the safer and superior choice for environmental compliance and product purity. This is often the single most important factor in the rotary dryer selection process. With a direct rotary dryer, the exhaust stream is a major environmental challenge. It is a high-volume, high-temperature mix of combustion gases, water vapor, and a large amount of fine dust from your product. To meet modern air quality standards, you must install a complex and expensive flue gas treatment system. This often includes cyclones and a large baghouse filter or electrostatic precipitator. This pollution control system can be as large and costly as the dryer itself. It also creates a constant maintenance headache.

The indirect rotary dryer is designed for cleanliness. It creates two separate gas streams. The first is the clean heating gas, which never touches your product and requires minimal treatment. The second is the process gas from inside the drum. This is a very small, manageable stream of mostly water vapor. Any dust is contained in this small stream and can be captured with a small, simple dust collector. This design makes meeting dust emission limits easy and affordable. It also guarantees high product purity because there is zero risk of material contamination from soot or ash. For any business that values a clean process or operates under strict regulations, the indirect dryer is the far safer choice.

How Do Your Material Properties Decide the Choice?

Your material’s characteristics, especially its heat sensitivity and tendency to create dust, will often force the choice between a direct or indirect dryer. This is not just a preference; it is a technical necessity. A direct rotary dryer is suitable for robust, non-sensitive, and non-dusty materials. If you are doing mineral drying of products like sand, gravel, limestone, or iron ore, a direct dryer is an excellent, efficient choice. These materials are not harmed by direct contact with hot gases and do not break down into excessive fine dust.

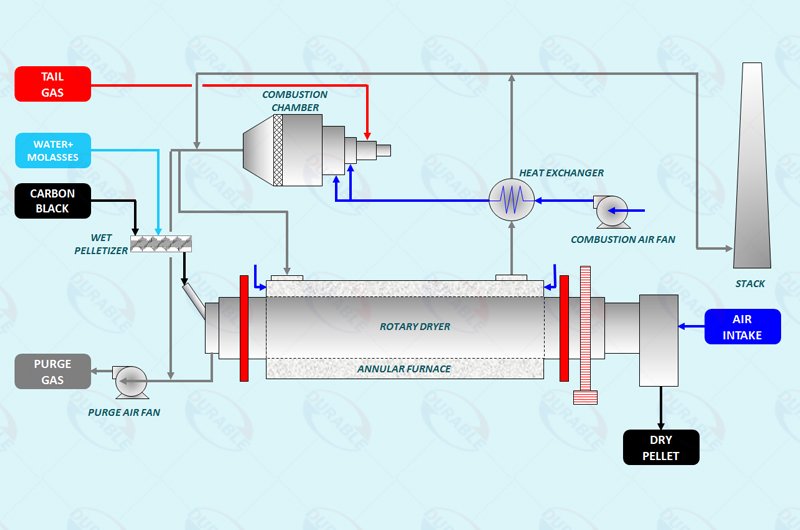

However, if your material is delicate, the choice is clear. You must use an indirect rotary dryer. This applies to many applications. For sludge drying or biomass drying, direct contact with high-temperature gases can cause the material to scorch, release harmful volatile organic compounds (VOCs), or even catch fire. For fine powders, chemicals, or food-grade products, any contact with combustion gases would cause unacceptable material contamination. For materials that are very dusty or friable, putting them in a high-velocity gas stream of a direct dryer would result in massive product losses to the dust collection system. In all these cases, the gentle, contained heating process of an indirect dryer is the only way to protect the integrity and value of your product. For more information, you can explore our range of specialized dryers, like our mineral dryer for robust materials.

ROI: Balancing Initial Cost and Long-Term Costs?

A direct dryer has a lower initial purchase price, but an indirect dryer can offer a better long-term equipment ROI in regulated environments. When you buy a dryer, you are making a long-term investment. It is important to look at the total cost of ownership, not just the upfront price tag. A direct rotary dryer system is typically less expensive to purchase initially. The dryer itself is a relatively simple piece of equipment.

However, the hidden cost lies in the mandatory air pollution control system. In many parts of the world, this system can cost as much as the dryer itself, doubling your initial investment. An indirect rotary dryer is more complex to build, so its initial purchase price is higher. But its pollution control system is much smaller, simpler, and cheaper. The real difference in equipment ROI appears over years of operation. The large, complex pollution control system for a direct dryer requires significant ongoing maintenance, costly filter bag replacements, and high electricity consumption. These long-term operating costs can be very high. The simpler system on an indirect dryer has much lower maintenance needs. Therefore, if you are in an area with strict environmental laws, the higher initial investment in an indirect dryer can pay for itself through lower long-term operating and compliance costs.

Quick Checklist for Your Final Decision

Use this simple table to help you make the right choice based on your specific project needs.

| Factor | Choose a DIRECT Rotary Dryer If… | Choose an INDIRECT Rotary Dryer If… |

|---|---|---|

| Your Material | It is robust, non-heat sensitive, and not dusty (e.g., sand, stone). | It is a fine powder, heat-sensitive, or high-purity (e.g., chemicals, sludge). |

| Purity Needs | Minor contamination from combustion gas is acceptable. | Your product must remain 100% pure and uncontaminated. |

| Environmental Rules | You operate in an area with lenient air emission regulations. | You must meet strict environmental and dust emission standards. |

| Budget Philosophy | Lowest initial equipment cost is the top priority. | You prioritize lower long-term operating and compliance costs. |

| Primary Goal | You need the highest possible fuel efficiency for bulk drying. | You need a clean, gentle process that protects your material’s value. |

Common Questions About Rotary Dryers

Question 1: What is the biggest hidden cost of a direct rotary dryer?

The biggest hidden cost is almost always the air pollution control system. The initial purchase price, ongoing maintenance, filter replacements, and the high electricity consumption of the large fans can significantly increase the total cost of ownership.

Question 2: Can an indirect dryer be fuel-efficient?

Yes. While it is inherently less efficient than a direct dryer, a well-designed indirect dryer with proper insulation and heat recovery systems can still be very efficient. The choice of an efficient heat source, such as a modern biomass burner, can also dramatically reduce fuel costs.

Question 3: Is it possible to dry sticky materials?

Yes, but it requires special design features. For sticky materials like sludge or clay, both dryer types may need internal modifications like chain curtains or knockers to prevent material from building up on the inside walls of the drum.

Summary: A Sledgehammer or a Scalpel?

The direct vs. indirect rotary dryer decision comes down to understanding your specific needs. There is no single “best” dryer, only the “right” dryer for your material and your operational context. The direct rotary dryer is a brute-force workhorse. It is a powerful, efficient tool for drying large volumes of robust materials where absolute purity is not required. The indirect rotary dryer is a precise, clean instrument. It is the necessary choice for protecting the value of sensitive, fine, or high-purity materials and for ensuring easy compliance with environmental laws. Think of it as choosing between a sledgehammer and a scalpel. By choosing the right tool for the job, you ensure a more efficient, compliant, and profitable operation.

About Durable

Since 2001, Durable has been a trusted global manufacturer of industrial processing equipment. We design and build a comprehensive range of robust and reliable rotary dryers, both direct and indirect, to meet the specific needs of our clients in over 120 countries. Our factory-direct approach means you get high-quality machinery at a competitive price, backed by our team of experienced engineers who are ready to help you succeed.

Get an Expert Recommendation for Your Project

Are you unsure which dryer is right for you? Contact our technical sales team today. We will analyze your material characteristics, your production goals, and your regulatory requirements to provide a detailed quote on the perfect drying solution for your business. Let us help you make a smart investment.

Durable Machinery

Durable Machinery