How to Dry High-Moisture Materials with a Yeast Dryer: A Guide

If you’re dealing with high-moisture byproducts like yeast slurry, distiller’s grains, or sludge, you know the nightmare. Your material is wet, sticky, and difficult to handle. You’ve heard that a Yeast Dryer can turn this waste into a valuable product, but you’re worried. You’re afraid of buying a machine that constantly clogs, clumps, and requires shutdowns for cleaning. This isn’t just an equipment purchase; it’s a solution to a critical production bottleneck, and you need to be certain it will work. I understand your concern, and I’m here to explain the specific technology that makes this dryer a reliable solution, not a trouble-maker.

Table of Contents

- Why do standard dryers fail with high-moisture materials?

- What special tech inside a yeast dryer prevents sticking?

- What is the process from 85% to 10% moisture?

- How can you minimize high energy costs?

- How do you dry the material without destroying its nutrients?

- What other sticky materials can this dryer handle?

- How can I know if a yeast dryer is right for my material?

- Frequently Asked Questions

- Summary and Final Recommendation

- About Durable

Why do standard dryers fail with high-moisture materials?

A standard rotary dryer will fail because it’s not designed to handle the “sticky phase.” Trying to dry a material like wet brewer’s grain in a simple dryer is like trying to make scrambled eggs in a cold, ungreased pan. The result is a mess. When high-moisture, high-protein materials are heated, they pass through a sticky, glue-like phase.

In a standard dryer, this sticky material immediately coats the inner walls and lifting flights. This buildup does two terrible things:

- It acts as an insulator. The caked-on layer prevents heat from reaching the rest of the material, causing efficiency to plummet.

- It causes severe blockages. The buildup grows until the dryer is completely clogged, forcing a shutdown for difficult and time-consuming manual cleaning. This is the “trouble-maker machine” every plant manager fears.

What special tech inside a yeast dryer prevents sticking?

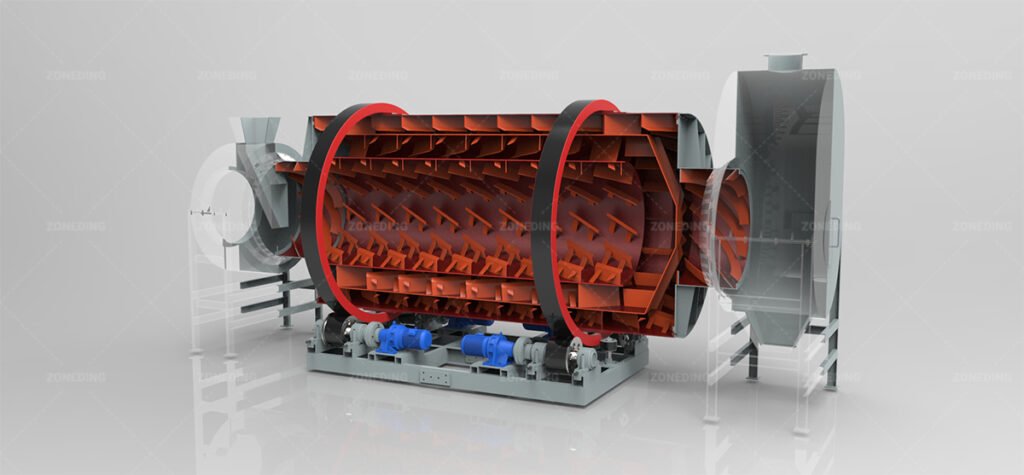

A true Yeast Dryer defeats the sticking problem with two key technologies: a powerful internal breaking device and a crucial pre-treatment process. It’s not just a rotating drum; it’s an engineered system designed specifically for the material sticking problem.

1. Internal Anti-Sticking Technology

The first third of the dryer, where the material is wettest and stickiest, is completely different from a standard dryer. Instead of simple plates that lift material, it is equipped with a high-strength dispersing mechanism, often a central shaft with heavy-duty steel paddles or chains. This device actively works to:

- Shatter and Disperse: It continuously breaks up any wet clumps that try to form.

- Scrape the Walls: It acts like a scraper, preventing any material from gaining a foothold on the inner shell of the drum.

- Agitate the Material: It aggressively churns the material, constantly exposing new, wet surfaces to the hot air, which dramatically speeds up drying through the sticky phase.

2. The “Secret Weapon”: Back-Mixing

This is perhaps the most important part of the entire drying process. Before the wet material even enters the dryer, it is put into a special mixer. Here, a portion of the final, already-dried product is blended with the incoming wet feed. Think of it like adding flour to sticky dough. The dry particles coat the wet, sticky particles, instantly changing the material’s consistency from a gluey paste into a manageable, crumbly substance that can flow freely. This pre-treatment step effectively eliminates the sticky phase before it can cause problems inside the dryer.

| Technology | How It Works | The Benefit For You |

|---|---|---|

| Breaking Device | Internal paddles/chains actively break up and scrape material. | No internal buildup, no clogging, continuous operation. |

| Back-Mixing | Blending dry product with wet feed before the dryer. | Eliminates the sticky phase, ensuring smooth material flow. |

| Co-Current Flow | Hot air and wet material enter at the same end. | Protects nutrients and provides rapid initial evaporation. |

What is the process from 85% to 10% moisture?

Transforming a high-moisture slurry into a dry, valuable powder is a multi-stage, systematic process. It’s not just about heat; it’s about smart material handling at every step.

- Mechanical Dewatering (The Energy Saver): The first step is to remove as much water as possible without using heat. A screw press is used to squeeze the 85% moisture slurry down to a 65-70% moisture wet cake. This single step can cut your total energy consumption by more than half.

- Back-Mixing (The Anti-Sticking Step): The wet cake is then blended with dry product, as described above. The material entering the dryer is now a non-sticky, granular feed with around 45-50% moisture.

- Controlled Drying: The prepared material enters the yeast dryer. The internal breaking device immediately gets to work. The system is set up for “co-current flow,” meaning the hottest air meets the wettest material. This allows for rapid evaporation without scorching the product.

- Separation and Collection: The dried product (now at 10-12% moisture) exits the dryer along with the air stream. A cyclone separator collects the main product, and a baghouse filter captures any remaining fine dust to meet environmental standards.

- Cooling: The hot, dried product is passed through a cooler to bring it to a safe temperature for storage and bagging.

How can you minimize high energy costs?

The fear of high energy costs when drying high humidity materials is valid, but it can be managed with smart engineering. The goal is to use thermal energy only when absolutely necessary.

- Prioritize Mechanical Dewatering: As mentioned, a screw press uses far less energy to remove water than evaporation. This is your single biggest energy-saving opportunity.

- Optimize Your Heat Source: Our systems can be configured to use a variety of fuels, including natural gas, biomass, or even waste heat from other plant processes. Using a low-cost fuel source like a biomass burner can dramatically reduce operating expenses.

- Insulate Everything: Proper insulation on the dryer drum and ductwork prevents heat from escaping, ensuring that the energy you pay for goes into drying your product, not heating your factory.

- Automate Your Controls: A modern control system continuously monitors the outlet temperature and moisture content, automatically adjusting the feed rate and burner to run at peak thermal efficiency without wasting fuel.

How do you dry the material without destroying its nutrients?

This is a critical concern, especially when drying yeast or distiller’s grains for animal feed. The value of the final product depends on its protein activity and nutritional content. High temperatures can destroy these valuable components.

The solution is a principle called “low temperature, fast drying.” This is achieved with the co-current flow design. The hottest gases (around 500°C) come into contact with the wettest material (at 45% moisture). At this point, the evaporation is so intense that it creates a powerful cooling effect, and the material’s surface temperature will not rise much above 100°C. By the time the material is dry and more sensitive to heat, it has traveled down the drum to a zone with much cooler gas temperatures (around 100-120°C). This process gently removes water without cooking or damaging the essential proteins.

What other sticky materials can this dryer handle?

While it’s often called a Yeast Dryer, the technology is designed for a wide range of high-moisture, high-viscosity materials. We have successfully designed systems for:

- Brewer’s and Distiller’s Grains: A primary application, turning brewery waste into valuable DDGS feed.

- Municipal and Industrial Sludge: A key solution for sludge drying, reducing waste volume and creating a usable biofuel.

- Bean Dregs (Okara) and Fruit Pomace: Drying food processing byproducts for animal feed or other uses.

- Mycelium and Fermentation Residues: Used in the biotech and pharmaceutical industries.

- Manure and Animal Waste: Converting agricultural waste into fertilizer.

How can I know if a yeast dryer is right for my material?

Every sticky material behaves a little differently. The best way to eliminate your investment risk and gain full confidence is to test your specific material.

- Analyze Your Material: What is its initial and target moisture content? How sticky is it? Is it heat sensitive?

- Quantify Your Output: How many tons per hour do you need to process?

- Request a Material Test: The most critical step. We encourage potential clients to send us a sample of their material. We can run tests to determine the optimal drying parameters, energy consumption, and the effectiveness of our anti-sticking technology for your specific case. This data-driven approach removes guesswork and proves the system will work before you invest.

Frequently Asked Questions

1. What is the biggest mistake people make when drying sticky materials?

The biggest mistake is trying to save money by skipping the mechanical dewatering and back-mixing steps. This inevitably leads to a dryer that clogs, operates inefficiently, and has sky-high fuel costs.

2. Can this system handle materials over 90% moisture?

Yes, but the system must be designed for it. For extremely high moisture levels, the dewatering and back-mixing stages become even more critical to prepare the material properly before it enters the thermal drying drum.

3. Is this dryer just for yeast, or is the name misleading?

The name is based on one of its most common applications, but the technology is versatile. It is more accurately called an “anti-sticking rotary dryer” and is suitable for any high-moisture, viscous material that poses a clogging risk in standard dryers.

Summary and Final Recommendation

The fear of investing in a machine that constantly clogs is justified, but the specialized Yeast Dryer is engineered to prevent this exact problem. It is not a single machine but a complete, multi-stage system. Through critical pre-treatment steps like mechanical dewatering and back-mixing, combined with a unique internal breaking device, it defeats the material sticking problem at its source. This system reliably transforms challenging, high-moisture waste streams into valuable, dry, and easy-to-handle products.

Don’t let the fear of clogging stop you from realizing the value in your waste stream. The right technology exists, and it is proven to be effective.

About Durable

Since 2001, Durable Machine has specialized in manufacturing robust and reliable industrial equipment. We don’t just sell machines; we engineer complete solutions. Operating on a factory-direct B2B model, we have delivered customized drying and processing lines to over 120 countries. Our expertise lies in understanding challenging materials and designing systems that work consistently and profitably.

Contact our engineering team today. Send us a sample of your material, and let us show you with data how we can solve your drying challenges and turn your waste into a revenue source.

Durable Machinery

Durable Machinery