Boost Coal Value: A Guide to Drying the 4 Types

Coal containing moisture increases transport costs and reduces energy output. This lowers profit. Coal drying is an operational step and a strategy for coal upgrading and increasing profit. You need a coal dryer for the operation. At Durable, I assist clients with this process. You must understand that not all coal is identical. A coal dryer for anthracite may not function for lignite. The use of an incorrect dryer for lignite creates a risk of fire. This guide explains coal types and how to choose a drying solution for your needs.

Table of Contents

- Why Coal Moisture Reduces Your Profits?

- What Are the Differences Between Coal Types?

- Which Parameters to Consider for a Coal Dryer?

- Which Dryer is Used for High-Moisture Lignite?

- How to Prevent Dust Explosions When Drying Coal?

- What is the ROI of a Coal Drying Line?

- What is in a Coal Drying System?

- Frequently Asked Questions

- Summary and Final Advice

- About Durable

Why Coal Moisture Reduces Your Profits?

The moisture content in raw coal reduces its commercial value. Handling coal with moisture means you pay to transport and heat water. This affects your business in two ways. First, it increases your shipping costs. If you ship 1,000 tons of coal with 30% moisture, you are paying freight for 300 tons of water.

Second, water reduces energy efficiency. When you feed coal with moisture into a boiler or furnace, the system must use energy to boil the water. This energy does not generate steam or heat a kiln. This directly lowers the coal calorific value, which is the amount of heat it produces. You have to burn more coal to get the same result. Coal drying turns this material into a fuel with a higher energy density, a process known as coal upgrading.

What Are the Differences Between Coal Types?

To choose a coal dryer, you must understand your raw material. Coal is ranked based on its age and carbon content. There are four main coal types.

1. Lignite (Brown Coal)

This is one rank of coal. It has a moisture content between 30% and 60% and a carbon content of 60-70%. The material is not hard. Lignite can combust spontaneously. The process for lignite drying uses controlled temperatures.

2. Sub-bituminous Coal

This coal has a moisture content from 15% to 30%. It has a higher energy value than lignite. The drying process carries a risk of fire and explosion if not managed.

3. Bituminous Coal

This is a type of coal used in power plants and for steel production. The material has a moisture content between 5% and 15%. Fine dust created during coal drying can ignite. This makes dust explosion a safety concern.

4. Anthracite

This is the rank of coal with the highest carbon content. Its moisture content is under 5%. Drying of anthracite is not always required.

| Coal Type | Moisture Content | Carbon Content | What This Means for You (Drying Needs) |

|---|---|---|---|

| Lignite | 30% – 60% | 60% – 70% | Drying is necessary for use and safety. |

| Sub-bituminous | 15% – 30% | 70% – 76% | Drying adds value but requires safety protocols. |

| Bituminous | 5% – 15% | 76% – 86% | Drying focuses on dust control and upgrading. |

| Anthracite | < 5% | 86% – 97% | Drying is not usually economical. |

Which Parameters to Consider for a Coal Dryer?

When you look for a coal dryer, you need answers to some questions. As a manufacturer, these are the first things I ask a client. Your answers determine the size, design, and cost of your system.

- What is your capacity? How many tons per hour (TPH) of coal do you need to process? This determines the size of the rotary dryer.

- What is your moisture content? I need to know the initial moisture of the coal and your target final moisture. Removing water from 30% down to 10% requires a system with a higher evaporation capacity than going from 15% to 8%.

- What is your fuel source? The furnace that provides hot gas for the dryer can run on natural gas, diesel, biomass, or coal. The fuel source for you will influence the burner design.

- What is your particle size? Are you drying lumps of coal or fine material like coal slime? A coal slime dryer might require different internal flight designs to prevent material from sticking.

Thinking through these parameters is the first step toward getting a quote and a system that meets your needs.

Which Dryer is Used for High-Moisture Lignite?

Lignite drying presents challenges. The process must manage temperature and focus on safety. Lignite contains volatile matter. Heating it can cause it to release gases that ignite. A standard dryer is not used.

A rotary dryer that operates at a temperature below 400°C is used. This process evaporates water without altering the coal’s chemical structure. For safety, some lignite drying systems use an inert gas. Instead of air, the system uses flue gas with reduced oxygen content. This low-oxygen environment reduces the risk of fire and dust explosion. Any system for lignite drying includes fire suppression systems and temperature monitoring.

How to Prevent Dust Explosions When Drying Coal?

For bituminous coal and lignite, the risk of a dust explosion is a safety hazard. A dust explosion can occur with fuel (coal dust), oxygen (air), and an ignition source. The design of a coal dryer aims to eliminate one element of this combination.

Here is how we design our systems to prevent this:

- Temperature Control: The system has sensors to ensure the temperature inside the dryer does not exceed a set limit for that coal type.

- Dust Collection: This is required. A cyclone collector captures particles. A baghouse filter captures smaller particles. This contains dust.

- Explosion Vents: The dryer and dust collectors have rupture discs or explosion vents. These are panels designed to open to direct the force of an explosion.

- Inert Gas Option: Using flue gas with reduced oxygen is another safety measure for some types of bituminous coal.

What is the ROI of a Coal Drying Line?

Investing in a coal drying line can provide a ROI. The savings come from two areas: reduced transport costs and increased energy efficiency. Here is an example.

A cement plant uses bituminous coal with 15% moisture and a calorific value of 5,000 kcal/kg. By installing a coal dryer to reduce the moisture to 5%, the coal calorific value can increase to approximately 5,900 kcal/kg. This is an increase of approximately 20% in energy content.

This means that to produce the same amount of heat, the plant needs to burn approximately 20% less coal. Over a year, this reduction in coal consumption can lead to savings in fuel costs. The initial investment in the drying system may be paid back in one to two years.

What is in a Coal Drying System?

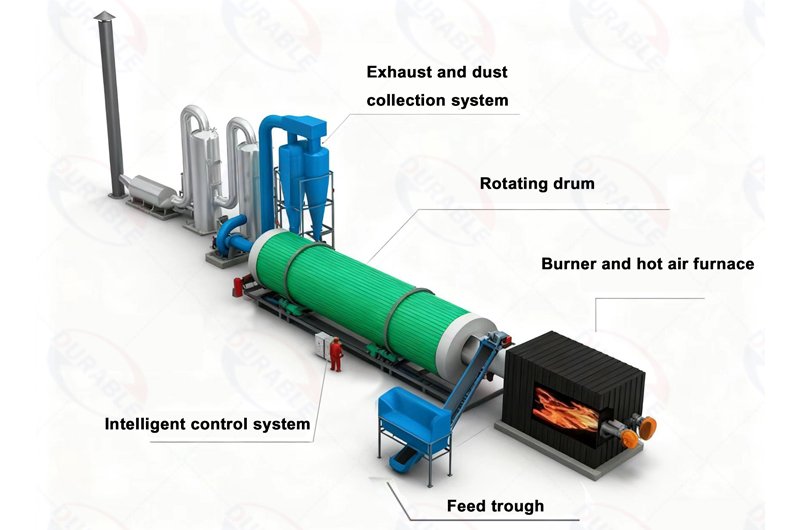

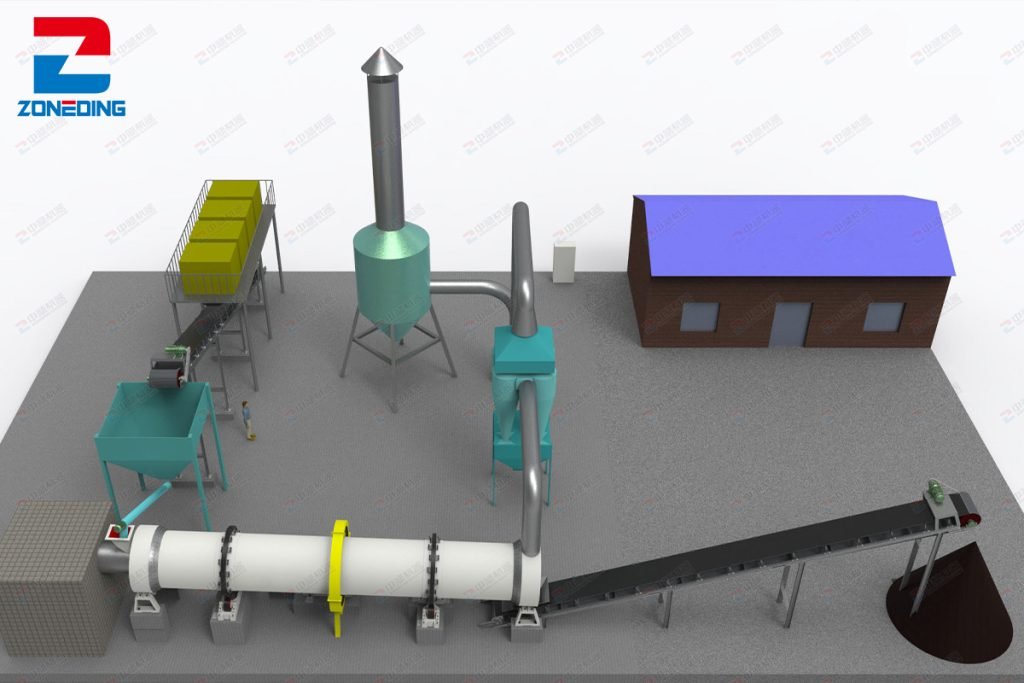

A coal drying solution is more than the dryer drum. It is a production line. A system, which we design and provide at Durable, includes several components.

- Feeding System: A hopper and a vibrating feeder to create a flow of coal into the system at a set rate.

- Infeed Conveyor: A conveyor belt to transport the material to the dryer entrance.

- Heat Source: A furnace or a biomass burner to generate the hot gas.

- Rotary Dryer Drum: The rotating cylinder where drying takes place. It includes the drive system, support rollers, and internal flights that lift and move the coal through the hot gas.

- Dust Collection System: A cyclone and/or baghouse to capture dust for safety, environmental compliance, and product recovery.

- Discharge System: A sealed chute and conveyor to transport the dry coal.

- Control Panel: A PLC system to monitor temperatures, control motor speeds, and manage safety interlocks.

Frequently Asked Questions

1. Can I use one dryer for different coal types?

This is not advisable. A dryer built for lignite drying will not operate at its designed capacity for bituminous coal. Using a bituminous dryer for lignite creates a risk of fire or explosion.

2. What are the maintenance tasks for a rotary coal dryer?

The tasks include lubricating the support roller bearings and the drive gears, inspecting the internal flights, and checking the seals at the feed and discharge ends to prevent air leakage.

3. How long until a return on investment (ROI)?

The ROI depends on your operating volume, the initial moisture content, and fuel costs. For many operations like power plants or cement factories, the payback period is often 12 to 24 months due to savings in fuel costs.

Summary and Final Advice

Do not let water reduce your profit. Coal drying is an investment for operational efficiency and safety. You must understand the material and select the correct equipment.

- Lignite requires systems that operate at low temperatures with safety features.

- Bituminous coal drying requires dust explosion prevention.

- A system is more than just the dryer; it is an integrated line.

By turning coal with moisture into a fuel with higher energy content, you can cut costs and increase the profitability of your operation.

About Durable

Since 2001, Durable Machine has been a B2B manufacturer of industrial dryer systems and other mineral processing equipment. As a factory-direct supplier, we have delivered engineered solutions to clients in over 120 countries. We provide everything from design and manufacturing to on-site installation and training.

Contact our engineering team for an analysis of your coal drying needs and a quote.

Durable Machinery

Durable Machinery