Concrete Pump Truck vs. Line Pump: The Ultimate Decision Guide

Choosing the right equipment for a concrete pour is one of the most critical decisions you will make on a job site. The debate of concrete pump truck vs line pump is central to this choice. The wrong decision can lead to delays, increased labor costs, and project inefficiencies. As an engineer at Durable, I have helped countless contractors select the perfect pump for their specific needs. Think of it this way: a concrete pump truck, or boom pump, is like your air force. It provides reach and speed from above. A line pump, or trailer pump, is your specialized ground team. It offers precision and flexibility in places the big machinery cannot go. This guide will walk you through the key differences to help you make the best choice.

Table of Contents

- What is the core difference in how they pump?

- Why are Boom Pumps the Choice for High-Rise Projects?

- What are a Line Pump’s Advantages in Tight Spaces?

- Which Pump Offers a Better Return on Investment?

- How Do They Compare on Efficiency and Labor?

- Does the Concrete Mix Affect Pump Choice?

- Your Final Decision Checklist

- Frequently Asked Questions

- Summary and Final Advice

- About Durable

What is the core difference in how they pump?

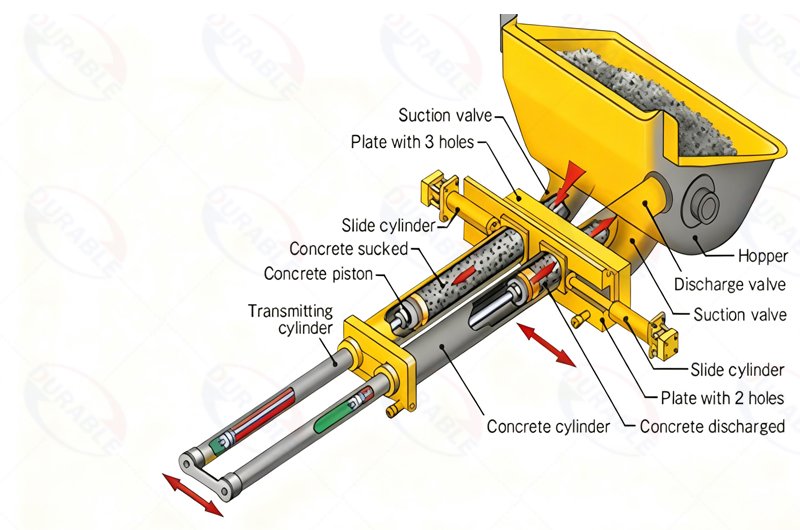

At their core, both a Pump Truck and a line pump share a similar concrete pump working principle. They both use a powerful hydraulic system with reciprocating pistons. One piston draws concrete from a hopper into a cylinder, while the other simultaneously pushes concrete from its cylinder into the outlet pipeline. A valve switches back and forth to ensure a continuous flow. This fundamental mechanism is what allows them to move heavy, viscous concrete over long distances. However, the critical difference is not in how they generate pressure, but in how they deliver the concrete to its final destination.

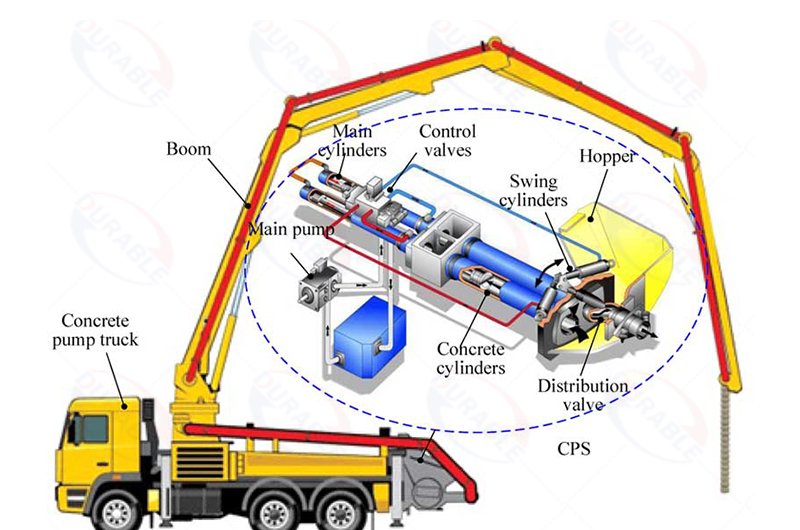

The boom pump is an all-in-one unit. The delivery system is a large, remote-controlled, articulating robotic arm (the boom) mounted directly onto the truck. This boom can be precisely positioned by a single operator to place concrete exactly where it is needed, high in the air or far across the site. In contrast, a line pump is a standalone unit, usually on a trailer. It has no integrated boom. Instead, its delivery system consists of a series of heavy-duty steel pipes and flexible rubber hoses that you must manually lay out and connect from the pump to the pour location. This makes the boom pump a solution for speed and reach, while the line pump is a solution for flexibility and access.

Why are Boom Pumps the Choice for High-Rise Projects?

For pumping concrete for high-rise buildings and large-scale commercial projects, a boom pump is almost always the only practical choice. Its primary advantage is its incredible vertical and horizontal reach. Modern boom pumps have arms that can extend from 20 meters to over 70 meters, allowing them to easily reach the upper floors of a multi-story building from a single setup location on the ground. This eliminates the need for cranes, buckets, or complex scaffolding systems to lift concrete, dramatically increasing the speed and safety of the operation.

Another critical factor is the sheer volume of concrete they can move. A truck-mounted concrete pump is built for speed, capable of placing 90 to 200 cubic meters of concrete per hour. When you are pouring a large suspended slab for an office building, speed is essential to ensure the entire pour can be completed as a single, monolithic structure without cold joints. The precision of the boom, controlled by a remote, also means less labor is needed at the point of placement. A small crew can guide the end hose, compared to the large team needed to move concrete around with wheelbarrows or manage a long, heavy ground-level hose. The combination of reach, speed, and labor efficiency makes the boom pump the undisputed champion for large vertical construction.

What are a Line Pump’s Advantages in Tight Spaces?

While a boom pump excels at large, open sites, a line pump, often called a trailer pump or ground pump, dominates in situations where access is limited. This is the key point in the boom pump vs trailer pump difference. The pump unit itself is compact and can be parked on a street or in a driveway, far from the actual pour site. From there, you can run a series of hoses through narrow alleyways, inside existing buildings, up stairwells, or into backyards that would be completely inaccessible to a large pump truck.

This makes the line pump the ideal tool for concrete pumping in tight spaces. Think about residential projects like patios, swimming pools, or basement floors. It is also the only option for many interior renovation jobs, where you need to pour a new floor slab inside a warehouse or fill concrete block walls within an existing structure. While a boom is limited by its arm’s length, you can theoretically add more hoses to a line pump to cover extremely long horizontal distances, sometimes hundreds of meters. Although its pumping volume is lower (typically 15 to 70 cubic meters per hour), its unmatched flexibility makes it an essential piece of equipment for residential contractors and renovation specialists.

Which Pump Offers a Better Return on Investment?

When you are choosing a concrete pump, the long-term concrete pump ROI is a major consideration. This involves looking beyond the initial purchase price to include operational and maintenance costs. The initial concrete pump truck price is significantly higher than the line pump cost. A boom pump is a complex piece of machinery that includes a heavy-duty truck chassis, an intricate hydraulic boom, and a powerful pump, making it a major capital investment. A line pump, being a simpler, trailer-mounted unit, is far more affordable to purchase upfront.

However, the operational costs can tell a different story. A boom pump requires fewer laborers to operate and completes large jobs much faster, which can lead to significant savings on total project time and labor expenses. A line pump is more labor-intensive due to the need for a crew to set up, manage, and clean the heavy hoses. For maintenance, the boom pump’s complex hydraulic system and articulating arm require specialized and more expensive upkeep. A line pump has simpler mechanics, but the hoses and pipes are consumables that wear out and need regular replacement. The final verdict on ROI depends entirely on your business model. If you handle high-volume commercial projects, the efficiency of a boom pump will likely provide a faster return. If you specialize in smaller, varied, and access-restricted jobs, the lower initial cost and versatility of a line pump make it a sounder investment.

| Feature | Concrete Pump Truck (Boom Pump) | Concrete Line Pump (Trailer Pump) |

|---|---|---|

| Initial Purchase Cost | Very High | Moderate |

| Best Application | High-rise, large slabs, infrastructure | Residential, interior, tight access |

| Pumping Volume | High (90-200 m³/hr) | Low to Medium (15-70 m³/hr) |

| Setup Time | Fast (< 1 hour) | Slower (Requires laying all hoses) |

| Labor Required | Low (1 operator + small crew) | High (Requires a dedicated hose crew) |

| Long-Term ROI | Best for high-volume commercial work | Best for small-scale, specialized work |

How Do They Compare on Efficiency and Labor?

The difference in on-site efficiency between a concrete pump truck and a line pump is stark. A boom pump is designed for rapid deployment. A skilled operator can drive the truck onto the site, extend the outriggers for stability, and unfold the boom into position in less than an hour. The concrete mixer trucks can then pull up directly to the pump’s hopper, and the pour can begin almost immediately. This minimizes standby time for the concrete delivery and the finishing crew, keeping the project on schedule. The labor required is minimal: one certified operator to control the pump and boom, and a few concrete workers to manage the final placement.

A line pump, on the other hand, requires a much more intensive setup process. A crew must manually carry and connect every section of steel pipe and rubber hose from the pump to the pour location. This process can take a significant amount of time, depending on the distance and complexity of the route. During the pour, a larger crew is needed to manage the heavy, pressurized hose, moving it as the pour progresses. Cleanup is also more involved, as every single section of the pipeline must be disconnected and thoroughly washed out. While the hourly concrete pump rental cost might be lower for a line pump, the increased labor and longer job duration must be factored into the total project cost.

Does the Concrete Mix Affect Pump Choice?

Yes, the type of concrete you are pumping absolutely influences your choice, but it affects both pump types in similar ways. For any pump to work effectively, the concrete mix must be “pumpable.” This means it needs to have the right consistency, or slump (typically 4 to 6 inches), and a well-graded mix of aggregates. If the mix is too dry or has too much large, sharp aggregate, it will be difficult to push through the pipeline and is very likely to cause a blockage in either a boom pump or a line pump.

That being said, there can be a slight difference. The pipes in a boom pump’s arm are typically larger in diameter (usually 5 inches) than the standard hoses used for a line pump (often 3 or 4 inches). This larger diameter can make a boom pump slightly more forgiving with harsher mixes or those containing larger aggregates. However, the fundamental rule remains: you must order a pump-friendly mix from your concrete supplier regardless of which machine you use. Always discuss the pump type with your supplier so they can provide a mix with the appropriate slump, sand content, and aggregate size to ensure a smooth, blockage-free pour.

Your Final Decision Checklist

Choosing between a concrete pump truck vs a line pump comes down to the specifics of your job. Ask yourself these four questions to make the right call quickly:

- Where does the concrete need to go? Is the pour vertical (going up) or over an obstacle? You need a boom pump. Is the pour horizontal (going across), through a building, or into a tight space? You need a line pump.

- How much concrete and how fast? Are you pouring a large volume (over 80 cubic meters) for a commercial slab where speed is critical? The boom pump is your tool. Is it a smaller, residential pour where speed is less of a concern than access? The line pump is sufficient.

- What is the job site access like? Is there enough space for a large truck to park and deploy outriggers? Are there overhead power lines or trees that would obstruct a boom? If access is open, a boom pump works. If it’s restricted, you need a line pump.

- What is your labor situation? Do you have a certified pump operator but a smaller finishing crew? The boom pump is more efficient. Do you have a larger crew available to handle the setup and management of heavy hoses? A line pump becomes a viable option.

Frequently Asked Questions

1. How far can a line pump (ground pump) actually pump concrete?

The distance depends on the pump’s power and the concrete mix. A standard trailer-mounted line pump can typically push concrete 300-500 meters horizontally or up to 100 meters vertically. Specialized high-pressure pumps used for skyscrapers can go much further.

2. Do you need a special license to operate a concrete pump truck?

Yes, absolutely. Operating a boom pump is a specialized skill that requires extensive training and certification. The operator is responsible for the safe setup and operation of heavy machinery with a long, powerful arm, and certification is required in most countries to ensure site safety.

3. For a new contractor, is it better to rent or buy a concrete pump?

For most new contractors, renting is the smarter financial choice. Concrete pump rental allows you to use the right machine for each specific job without the massive upfront investment, maintenance costs, insurance, and operator salaries associated with ownership. It gives you the flexibility to learn which type of pump you use most often before committing to a purchase.

Summary and Final Advice

The debate between a concrete pump truck vs a line pump is not about which is better, but which is the right tool for the job. A boom pump offers unmatched speed and reach for large-scale vertical and high-volume projects. A line pump provides essential flexibility and access for smaller, residential, and interior jobs.

By analyzing your project’s specific needs using our decision checklist, you can confidently select the most efficient and cost-effective solution. Understanding the boom pump vs trailer pump difference will save you time, money, and headaches on the job site.

About Durable

Since 2001, Durable Machine has been a leading manufacturer of construction machinery, specializing in a wide range of concrete equipment for the global B2B market. We offer both high-performance concrete boom pump trucks and versatile concrete mixer pumps, providing factory-direct sales to ensure competitive pricing. Our products are trusted by contractors in over 120 countries, and we provide full-service support from design and manufacturing to installation and after-sales service.

Contact us today to speak with an equipment specialist and find the perfect concrete pumping solution for your business.

Durable Machinery

Durable Machinery