5 Key Machines in a Concrete Plant & What They Do

Making a batching plant investment is a significant step for any business. It’s easy to focus on the overall plant size or its maximum hourly output, but the real profitability and reliability of your operation depend on the quality of its individual parts. From my experience at Durable helping clients worldwide, I’ve seen that success comes down to getting the fundamentals right. A plant’s performance is only as strong as its weakest link.

Before you decide on a final configuration, you must understand the five most essential batch plant equipment systems. These are the core components of a concrete batching plant where you absolutely cannot afford to cut corners. Focusing on these areas during your concrete equipment purchasing process will build a foundation for quality, efficiency, and long-term profit.

Table of Contents

Aggregate Batcher: Your Cost Control Center?

The aggregate batching system is the starting point for every batch of concrete you produce. This system consists of large bins that hold your different sizes of sand and stone (aggregates). Underneath these bins is a weighing mechanism, typically a weigh belt or a weigh hopper, that measures the precise amount of each material for a specific mix design. The accuracy of this system is the first and most critical step in creating quality concrete.

Its precision directly impacts both your material costs and the final strength of your concrete. Aggregates make up about 70-80% of your concrete’s volume. If your weighing is inaccurate, you could be giving away free material in every batch, directly hurting your bottom line. More importantly, an incorrect ratio of sand to stone can lead to a weak, unworkable, or inconsistent product. Delivering bad concrete is the fastest way to lose customers and damage your reputation. A high-quality aggregate batching system with accurate load cells and fast-acting gates ensures every batch is consistent and meets specifications, protecting both your profits and your name.

The Mixer: The Heart of Your Plant’s Quality?

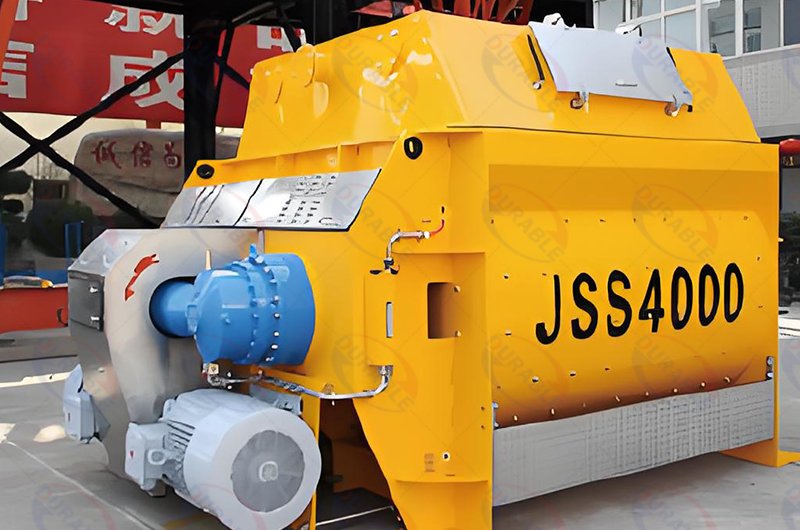

For a wet mix plant, the compulsory concrete mixer is where product quality is truly forged. While several types exist, the twin-shaft concrete mixer is the industry standard for high-volume, high-quality production. It uses two counter-rotating shafts fitted with paddles to create a highly energetic and compulsory mixing action. This process ensures that every single particle of sand and stone is evenly coated with cement paste, leading to a strong, uniform, and homogenous final product.

The choice of mixer determines not only your concrete’s quality but also your plant’s overall production capacity. A powerful and efficient twin-shaft mixer can produce a complete, perfectly mixed batch of concrete in 60 seconds or less. This speed is what allows a plant to achieve high throughput, servicing many trucks per hour for large projects. This machine endures incredible stress and abrasion. Therefore, investing in a robust mixer with high-quality wear parts, a durable gearbox, and reliable seals is a direct investment in your plant’s uptime and long-term reliability.

Cement System: Your Production Key?

A stable and reliable cement storage and conveying system is essential for uninterrupted production. This system’s primary components are the cement silo for bulk storage, a screw conveyor to transport the cement, and a dedicated cement weigh hopper to measure the precise amount needed for each batch. Since cement is the most expensive ingredient in concrete, the accuracy of this system is directly tied to your profitability.

Every kilogram of cement matters. An inaccurate cement batcher that over-weighs by even a small percentage can eliminate your profit margin on a large project. Under-weighing is even worse, as it leads directly to low-strength concrete, creating massive liability risks. The reliability of the screw conveyor is also critical. A failure here can stop your entire operation instantly. For this reason, a well-designed cement system with a high-quality cement silo, a durable screw conveyor, and a highly accurate weigh batcher is a non-negotiable part of any professional ready-mix plant configuration.

Control System: The Plant’s Brain?

The fully automatic batch plant control system is the brain that commands your entire operation. This system is a combination of computer hardware, specialized software, and a Programmable Logic Controller (PLC) that manages every step of the production cycle. It tells the bin gates when to open and close, runs the conveyors, monitors the weigh batchers, controls the mixer, and records every detail of every batch produced.

Investing in a modern, reliable control system is one of the smartest decisions you can make. It dramatically reduces the potential for human error, ensuring that every batch is made to the exact mix design specifications, time after time. This repeatability is the key to consistent quality. The system also optimizes the sequence of operations to achieve the fastest possible cycle time, maximizing your plant’s output and efficiency. Furthermore, the detailed reports it generates are invaluable. They provide proof of delivery for quality control and give you the data you need to track inventory, manage costs, and analyze your profitability.

Aggregate Conveyor: Belt or Bucket for Your Site?

The aggregate conveying system moves the weighed aggregates from the batcher up to the mixer or loading hopper. The two most common types of equipment for this task are the belt conveyor and the bucket elevator. The best choice for your plant depends heavily on your site layout, production volume, and long-term operational goals.

A belt conveyor is typically an inclined troughed belt system. It is known for its high capacity, reliability, and lower maintenance requirements. It is the preferred choice for high-volume stationary plants where there is sufficient space. A bucket elevator, on the other hand, lifts material vertically in a series of buckets attached to a chain or belt. Its main advantage is its very small footprint, making it ideal for compact sites or mobile plant setups where space is limited. While a bucket elevator can be a great space-saving solution, it generally requires more maintenance than a belt conveyor and has a lower conveying capacity.

How to Configure Your Concrete Plant Equipment?

After understanding these five core systems, the next step is to choose the right combination for your specific needs. There is no single “best” setup; the optimal ready-mix plant configuration depends on your budget, projected output, and the type of projects you will supply.

When considering how to choose concrete equipment, think about your business scale. For a small-scale operation, you might prioritize a lower initial cost with a simpler setup. For a large-scale commercial plant, investing in high-capacity, heavy-duty equipment will deliver a better return through higher efficiency and lower long-term operating costs. The key is to match the capabilities of each core component to your overall business plan.

| Project Scale | Recommended Mixer | Aggregate Conveyor | Key Focus |

|---|---|---|---|

| Small / Mobile | Planetary or smaller Twin-Shaft | Bucket Elevator | Compact footprint, lower initial cost. |

| Medium Commercial | Standard Twin-Shaft Mixer | Belt Conveyor | Balance of cost, output, and reliability. |

| Large Infrastructure | High-Capacity Twin-Shaft Mixer | Wide Belt Conveyor | Maximum speed, durability, and consistency. |

FAQs

1. What is the single most important piece of concrete batch plant equipment?

While all five components are critical, many experts argue the batch plant control system is the most important. It connects everything and ensures accuracy and efficiency, directly impacting quality and profitability more than any other single component.

2. How much does a concrete batching plant cost?

The cost varies dramatically based on the size, type (wet or dry), and quality of these five core components. A basic plant might start under $50,000, while a large, high-production stationary plant can cost over $500,000. Your batching plant investment should be based on a detailed analysis of your market needs.

3. Can I upgrade these components later?

Yes, it is often possible to upgrade components like the mixer or control system. However, it is far more cost-effective to invest in the right equipment from the beginning. Retrofitting can be complex and lead to more downtime than a well-planned initial installation.

4. Which component requires the most maintenance?

The compulsory concrete mixer in a wet mix plant typically requires the most attention. Its internal parts, like liners and paddles, are high-wear items that need regular inspection and replacement. Following that, the aggregate conveying system, especially a bucket elevator, needs routine checks to ensure its reliability.

5. Are these 5 core components the same for a dry mix plant?

Four of the five are very similar. A dry mix plant still needs an aggregate batcher, cement system, control system, and aggregate conveyor. The major difference is the mixer. A dry mix plant does not have a central mixer; the mixing happens in the concrete mixer truck. The “mixer” component is therefore replaced by an efficient truck loading system.

Summary and Final Advice

Your success in the concrete business is built on the quality and reliability of your production equipment. When planning your batching plant investment, focus your attention and budget on these five core components of a concrete batching plant: the aggregate batcher, the concrete mixer, the cement system, the control system, and the aggregate conveyor.

By choosing high-quality, durable equipment for these essential functions, you create an operation that is efficient, consistent, and profitable for years to come. Do not cut corners here, as a failure in any one of these systems can bring your entire business to a halt.

About Durable

Since our founding in 2001, Durable Machine has been a trusted global manufacturer of construction and mineral processing equipment. We specialize in providing a complete range of concrete batch plant equipment, tailored to our B2B clients’ needs. With factory-direct sales and exports to over 120 countries, we deliver high-quality, cost-effective solutions backed by comprehensive support, from design to after-sales service.

Contact our team today to discuss your project and get an expert recommendation on the right equipment configuration for your business.

Durable Machinery

Durable Machinery