How to Achieve Best Kaolin Clay Drying: Industrial Guide

As a mineral processing equipment manufacturer, I have learned that kaolin clay drying is not just about removing water. It is about preserving the delicate properties that make kaolin valuable. Kaolin is essential for ceramics, paper, and paints. Its unique whiteness and specific particle structure define its market worth. A poorly chosen drying method can easily damage these qualities and lead to significant financial losses.

At Durable Machine, we understand these challenges deeply. We know that choosing the right industrial dryer is critical. It ensures your kaolin processing maintains high standards. This guide will help you understand the complexities of kaolin drying. We will explore different drying technologies. We will also show you how to select the best one for your needs. This way, you can avoid quality issues and control costs.

Table of Contents

- Why is Kaolin Clay Drying Crucial But Technically Challenging?

- Is a Rotary Dryer Best for Large-Scale Kaolin Production?

- How to Control Drying Temperature to Protect Kaolin Whiteness and Activity?

- How to Design for Sticky Kaolin Filter Cake to Prevent Blockages?

- Which Heat Source Is Best: Indirect or Direct?

- What Auxiliary Equipment Does an Efficient Kaolin Drying Line Need?

- How to Recover Valuable Powder While Meeting Environmental Standards?

- What Hidden Operating Costs Should You Consider for Kaolin Drying?

- Summary: Strategic Drying for High-Value Kaolin

- About Durable

- Ready to Optimize Your Kaolin Drying Process?

Why is Kaolin Clay Drying Crucial But Technically Challenging?

Kaolin clay drying is crucial because it transforms a wet, unusable material into a high-value product, but it is challenging due to kaolin’s sensitive properties.

Wet kaolin is heavy and difficult to transport. It cannot be used in most industrial applications. Drying removes this moisture, making the kaolin lighter, easier to handle, and ready for market. However, kaolin is a unique mineral. Its value comes from its fine particle size, high kaolin whiteness, and chemical inertness.

These properties are delicate. High temperatures or harsh mechanical action can easily damage them. For example, too much heat can reduce the whiteness, making the kaolin unsuitable for high-grade paper applications. Rough handling can break down the particles, affecting its performance in coatings. This means that a good kaolin clay dryer must dry effectively without compromising these critical characteristics. It is a balancing act between efficient drying and preserving product quality.

Is a Rotary Dryer Best for Large-Scale Kaolin Production?

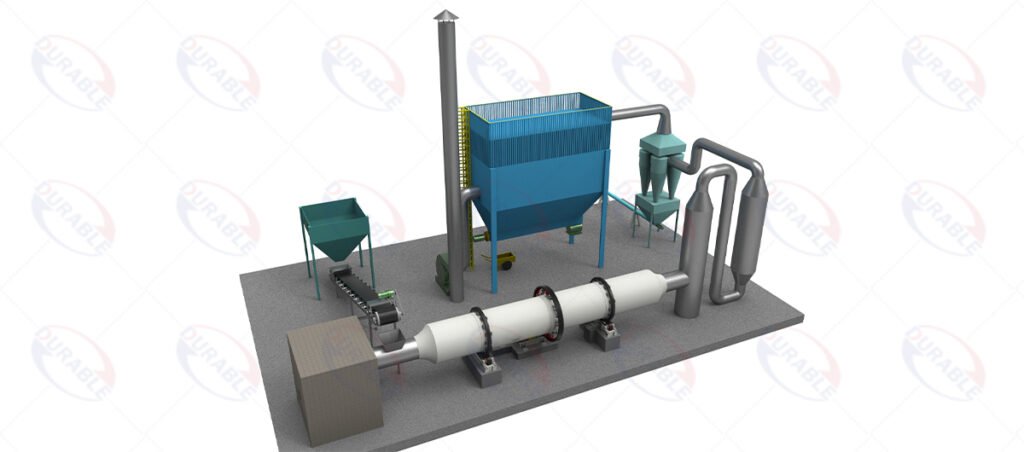

A rotary dryer, specifically an indirect heat rotary dryer, is often an excellent choice for large-scale kaolin production, especially for drying filter cake.

The traditional rotary dryer is a workhorse in many industries. For kaolin processing, its suitability depends on the form of your feed material and your final product requirements. For dewatered kaolin filter cake drying, an indirect heat rotary dryer excels. It handles large volumes continuously. It dries the material gently by contact with heated surfaces. This avoids direct contact between combustion gases and the kaolin. This preserves kaolin whiteness and purity.

However, the tumbling action in a rotary dryer can cause some attrition, or breaking down of the delicate kaolin particles. If your final product demands extremely fine particles with no damage, a rotary dryer might not be the absolute best choice. But for most large-scale applications where a bulk dry product is needed, it offers a reliable and efficient solution. We have seen these systems operate for decades with consistent results. You can learn more about rotary drying on our main mineral dryer page.

How to Control Drying Temperature to Protect Kaolin Whiteness and Activity?

Controlling the drying temperature precisely is vital for preserving kaolin’s whiteness and chemical activity, requiring careful selection of the dryer and its heating system.

The key to maintaining kaolin whiteness and activity lies in avoiding overheating. High temperatures can cause color changes, especially for iron-containing kaolins. They can also alter the crystal structure, reducing the clay’s reactivity. Therefore, the drying process must maintain a specific, relatively low temperature profile.

For kaolin, I recommend an indirect heating dryer. This system uses a separate heat exchanger. It ensures that only clean, hot air or heated surfaces come into contact with the kaolin. This prevents contamination from combustion gases. Modern dryers use advanced sensors and automated control systems. These systems monitor and adjust the temperature within the dryer. This keeps it within the safe range for kaolin. The goal is to dry efficiently without “cooking” the material. This precision protects your product’s market value.

| Parameter | Impact on Kaolin Quality | Optimal Control Method |

|---|---|---|

| Drying Temperature | Affects whiteness, crystal structure | Indirect heating, precise temperature sensors, PID control |

| Residence Time | Prevents over-drying, particle damage | Adjustable drum speed, internal flight design |

| Airflow Volume | Efficient moisture removal, prevents hot spots | Variable speed fans, damper control |

How to Design for Sticky Kaolin Filter Cake to Prevent Blockages?

For sticky filter cake kaolin, the dryer’s internal structure must be specifically designed with anti-sticking mechanisms to prevent blockages and ensure smooth material flow.

Kaolin often comes in a sticky filter cake form after dewatering. This material can easily clump and stick to the inside of a dryer. This leads to blockages, reduced efficiency, and uneven drying. To prevent this, a specialized kaolin clay dryer must incorporate several design features.

First, the internal lifting flights of the rotary dryer are designed with specific angles and shapes. They prevent material buildup and promote continuous showering. Second, we can add internal chains or other mechanical devices that agitate the material. These prevent it from forming large lumps. Third, the dryer often operates with a higher inclination. This encourages faster material progression. Finally, a pre-breaking stage, such as a shredder, might be necessary before feeding the filter cake into the dryer. This reduces the lumps into smaller, more manageable pieces. These designs ensure a continuous and efficient drying process.

Which Heat Source Is Best: Indirect or Direct?

For high-quality kaolin, an indirect heating system is almost always superior to direct heating because it prevents product contamination and preserves purity.

When choosing a dryer heat source, the purity of your kaolin is the deciding factor.

- Direct Heating: In a direct heating system, the hot combustion gases from the furnace directly contact the material being dried. This method is highly thermally efficient and often has a lower initial dryer cost. However, for kaolin, direct heating can introduce impurities like soot, ash particles, or discoloration from flue gases. This severely compromises kaolin whiteness and overall quality.

- Indirect Heating: An indirect heating dryer uses a heat exchanger. The combustion gases heat air or another medium, which then transfers heat to the kaolin without direct contact. This ensures that only clean, hot air or heated surfaces touch the product. This method is more complex and has a higher initial cost. But it is essential for maintaining the high purity and whiteness required for premium kaolin products. For most kaolin processing applications, indirect heating is the only viable option.

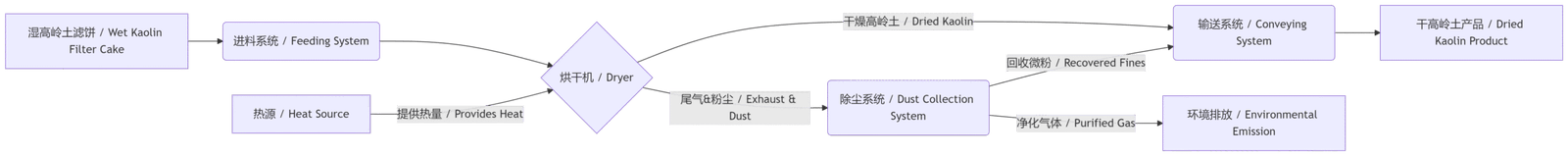

What Auxiliary Equipment Does an Efficient Kaolin Drying Line Need?

An efficient kaolin drying production line requires a suite of auxiliary equipment, including feeding, conveying, and dust collection systems, in addition to the main dryer.

The kaolin clay dryer is the heart of the system. But it cannot work alone efficiently. A complete kaolin processing line ensures smooth operation.

Key auxiliary equipment includes:

- Feeding System: This moves the wet kaolin filter cake into the dryer. A vibrating feeder or a screw feeder ensures a steady, controlled feed rate. This prevents surges or shortages.

- Conveying System: Conveyor belts or other transport mechanisms move the dried kaolin to storage or further processing.

- Heat Source: This is typically a hot air furnace. It can be fueled by coal, natural gas, oil, or a biomass burner, depending on local fuel costs and availability.

- Dust Collection System: This is critical for kaolin processing. Kaolin powder is fine and easily airborne. A multi-stage dust collection system captures these valuable fines and ensures environmental compliance.

- Control System: An automated PLC (Programmable Logic Controller) system monitors and controls all parameters. These include temperature, feed rate, and airflow. This ensures consistent product quality and efficient operation.

Integrating these components creates a seamless and highly productive kaolin clay drying solution.

How to Recover Valuable Powder While Meeting Environmental Standards?

A well-designed dust collection system is essential not only for meeting environmental regulations but also for recovering valuable finished kaolin powder, maximizing yield.

Kaolin is a fine powder. During the kaolin clay drying process, a significant portion can become airborne. This creates a dual challenge: environmental pollution and loss of valuable product. A robust dust collection system addresses both.

We typically recommend a two-stage or even three-stage system. The first stage uses a cyclone separator. This captures larger particles through centrifugal force. The second stage uses a baghouse filter. This unit is highly efficient. It captures very fine kaolin dust. The collected dust is then returned to the main product stream. This maximizes your yield. Some systems may also include a wet scrubber as a final stage for ultra-fine particles or to handle any remaining gaseous emissions. This comprehensive approach ensures that your operations are environmentally compliant. It also ensures you recover as much high-value product as possible.

What Hidden Operating Costs Should You Consider for Kaolin Drying?

When evaluating a kaolin drying project, beyond equipment purchase, you must account for hidden operating costs like energy consumption, wear parts, and environmental compliance fees.

The initial dryer cost is just one part of the equation. Many hidden operating costs can significantly impact your long-term profitability in kaolin processing.

- Energy Consumption: This is often the largest operating cost. Drying requires substantial heat. The type of dryer heat source and the thermal efficiency of the dryer directly affect your fuel or electricity bills. An inefficient system will drain your profits daily.

- Wear Parts & Maintenance: Continuous operation means wear and tear. Components like internal flights, bearings, and seals in a rotary dryer will need periodic replacement. Regular maintenance is crucial to prevent costly downtime.

- Labor Costs: While modern systems are automated, they still require skilled operators and maintenance staff.

- Environmental Compliance: Strict regulations apply to emissions. This means investing in and maintaining effective dust collection systems. It also means potential costs for permits and ongoing monitoring.

- Feed Material Preparation: If your kaolin requires pre-treatment like crushing or dewatering before drying, these steps add to the overall operating cost.

These factors underscore the importance of a comprehensive dryer selection process. It saves money in the long run.

Summary: Strategic Drying for High-Value Kaolin

Kaolin clay drying is a precise process where quality preservation is paramount. The right industrial dryer and a well-designed system are critical for maximizing your product’s value and controlling costs.

Choosing the optimal industrial dryer for kaolin processing involves a careful balance. You must consider your feed material, desired product quality, and budget. An indirect heating dryer, whether a rotary dryer for bulk or a flash dryer for fine powders, offers the best solution for preserving kaolin whiteness and purity. Investing in a complete drying line with efficient feeding, conveying, and dust collection systems is not an option. It is a necessity for efficiency and environmental compliance.

Always remember that for high-value minerals like kaolin, the lowest initial dryer cost rarely translates to the lowest total cost. A strategic investment in the right technology will protect your product quality, optimize your operations, and secure your market position for years to come.

About Durable

Durable Machine, established in 2001, is a leading manufacturer of mineral processing equipment. We specialize in designing and producing high-efficiency kaolin clay dryers. Our expertise spans various drying technologies, including indirect heat rotary dryers, ensuring we can tailor a solution to your specific kaolin processing needs. We are committed to helping you achieve superior product quality and operational efficiency.

Ready to Optimize Your Kaolin Drying Process?

Don’t let improper kaolin clay drying compromise your product’s value. Contact Durable Machine today. Our team of experts will analyze your specific kaolin characteristics and production goals. We will design a customized, cost-effective drying solution that guarantees quality, efficiency, and maximum return on your investment.

Durable Machinery

Durable Machinery