Concrete in Green Building: A Deep Dive into Sustainability

For decades, concrete has been the backbone of global construction. It forms our buildings, bridges, and roads. But is this common material truly sustainable? I have seen many changes in the heavy materials industry over 50 years. This question of concrete sustainability is more urgent than ever. We must understand its true environmental impact. We need to explore if it is a truly green concrete solution for sustainable construction. This guide will help you understand concrete’s environmental footprint. We will look at new ways to make low-carbon concrete. This will show how concrete can fit into a greener future.

Table of Contents

- Why is Concrete’s Carbon Footprint a Central Debate?

- How Does Concrete Compare to Other Building Materials Environmentally?

- How Do Innovations Lower Concrete’s Carbon Emissions?

- Can Recycled and Local Aggregates Make Concrete More Sustainable?

- How Do Durability, Thermal Mass, and Fire Resistance Show Concrete’s Value?

- How to Maximize Concrete’s Sustainable Advantages in Building Design?

- What Are Green Building Certifications’ Concrete Requirements?

- How Can Concrete Achieve “Zero Carbon” with Circular Economy and Carbon Capture?

- Common Questions About Concrete Sustainability

- Summary: Concrete’s Evolving Role in Sustainable Construction

- About Durable

- Build a Greener Future with Durable Concrete Solutions

Why is Concrete’s Carbon Footprint a Central Debate?

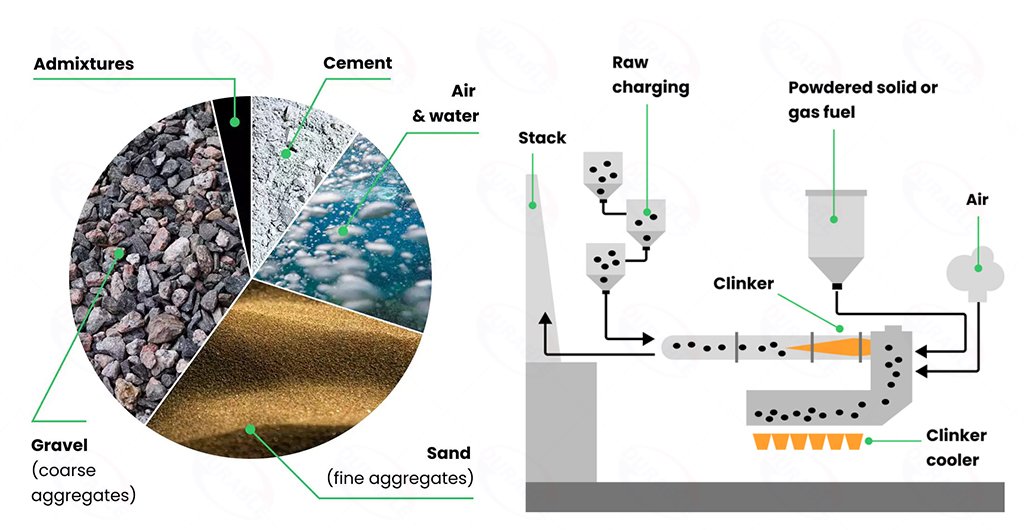

The concrete carbon footprint is the biggest challenge to its sustainability. The process of making cement, a key ingredient, releases a lot of CO2. This happens in two main ways.

First, heating limestone to high temperatures uses much energy, often from fossil fuels. Second, the chemical change of limestone itself releases carbon dioxide. This makes cement production a major source of greenhouse gas emissions.

I have seen the industry change over many years. The numbers are clear. Cement production accounts for about 8% of global CO2 emissions. This is a big part of the overall environmental impact of building materials. This high carbon footprint comes mainly from the calcination process. This process happens when limestone, a main raw material for cement, is heated. It breaks down into calcium oxide and CO2. This CO2 is released into the atmosphere. This is a chemical reaction. It cannot be avoided by just using cleaner energy. So, reducing the concrete carbon footprint means finding new ways to make cement or use less of it. This makes concrete’s environmental impact a major topic for anyone interested in sustainable construction. We constantly work on finding solutions to reduce these emissions.

How Does Concrete Compare to Other Building Materials Environmentally?

Compared to steel or wood, concrete has different environmental impacts. Steel production uses a lot of energy and natural resources. Wood can be a very sustainable option if harvested responsibly. However, concrete offers unique benefits like durability and fire resistance. A full concrete lifecycle assessment is needed to truly compare them.

When we talk about the environmental impact of building materials, we must look beyond just one factor. Steel production, for instance, requires intensive mining and smelting processes. These also have high energy consumption and carbon emissions. Wood, if sourced from certified sustainable forests, stores carbon. This makes it an attractive option. But wood also has issues like fire resistance, rot, and shorter lifespans in certain applications. This can mean more frequent replacements.

Concrete, on the other hand, is highly durable. Structures built with concrete can last for many decades, even centuries. This longevity reduces the need for constant rebuilding. This saves future materials and energy. Concrete also uses aggregates that are often locally available. This reduces transportation emissions. So, while concrete’s upfront carbon footprint is high, its long lifespan and local sourcing benefits can balance this out. We often need to weigh these different factors for each project. This helps decide what the most sustainable construction choice truly is.

How Do Innovations Lower Concrete’s Carbon Emissions?

Innovations like low-carbon concrete and cement alternatives are greatly reducing concrete’s carbon emissions. Using industrial byproducts as cement alternatives is a key strategy. These materials replace some of the energy-intensive cement in the mix. This directly lowers the overall concrete carbon footprint.

The industry is making big strides in developing sustainable cement and low-carbon concrete. One major innovation is using supplementary cementitious materials (SCMs). These are industrial byproducts. Examples include fly ash from coal power plants and ground granulated blast-furnace slag from steel production. These materials can replace up to 50% or more of Portland cement in a concrete mix. This is important because SCMs do not need the high-temperature calcination process. This means they contribute almost zero new carbon emissions.

Another area is developing completely new cement alternatives. Geopolymer cements are one such example. They use industrial waste products like fly ash or metakaolin activated with alkaline solutions. These can form a binder similar to cement but with a much lower carbon footprint. These advancements are changing how we think about green concrete. They offer pathways to significantly reduce the environmental impact of building materials. This is critical for future sustainable construction projects.

Can Recycled and Local Aggregates Make Concrete More Sustainable?

Yes, using recycled aggregates and locally sourced materials significantly enhances concrete sustainability. It reduces demand for virgin resources and cuts down transportation emissions. This helps move towards a more circular economy in construction.

The aggregates – sand, gravel, and crushed stone – make up about 60-80% of concrete by volume. Their extraction and transport have a notable environmental impact of building materials. Using recycled aggregates is a smart solution. This means taking demolished concrete and crushing it. The crushed material can then be used in new concrete mixes. This reduces the need for new quarrying. It also diverts waste from landfills. This is a prime example of sustainable construction practices.

Furthermore, sourcing aggregates locally minimizes transportation distances. This reduces the fuel consumed and the emissions produced. Many of our concrete batching plant clients, especially those with stationary concrete batching plants, focus on local aggregate suppliers. This not only lowers the concrete carbon footprint but also supports local economies. It lessens the environmental impact of long-haul trucking. These practices contribute to making green concrete a more realistic and widespread option.

How Do Durability, Thermal Mass, and Fire Resistance Show Concrete’s Value?

Beyond its carbon footprint, concrete’s intrinsic properties like concrete durability, thermal mass concrete, and excellent fire resistance contribute to its long-term concrete sustainability. These features provide lasting value and reduce operational energy needs.

When you consider the full concrete lifecycle assessment, concrete’s performance over time becomes very important. Its exceptional concrete durability means structures last a long time. This reduces the need for repairs or replacements. A bridge built with quality concrete can serve for over a century. This means the resources and energy used to build it are spread over a very long period. This is a significant aspect of sustainable construction.

Moreover, thermal mass concrete acts as a natural temperature regulator. It absorbs heat during the day and releases it slowly at night. This smooths out temperature swings inside buildings. This reduces the need for air conditioning and heating. This directly lowers a building’s operational energy consumption. This contributes to lower energy bills and fewer emissions from running the building. Concrete’s inherent fire resistance is another big safety and sustainability benefit. It limits fire spread. It protects lives and property. It also means less energy and material are needed for fireproofing systems compared to other materials. These properties combine to offer long-term value. This value often outweighs some of the initial environmental impact of building materials concerns.

How to Maximize Concrete’s Sustainable Advantages in Building Design?

Maximizing concrete sustainability happens best at the design and construction stages. This involves optimizing mix designs, reducing material waste, and thoughtfully integrating concrete’s thermal properties into the building’s plan.

Achieving truly green concrete in sustainable construction starts on the drawing board. Architects and engineers play a huge role. They can specify low-carbon concrete mixes from the start. These mixes use SCMs like fly ash or slag. This immediately reduces the concrete carbon footprint. Design for efficiency is also key. This means optimizing concrete sections to use only what is needed. This avoids over-specifying material.

During construction, careful planning minimizes waste. Using modern batching equipment, like a mobile concrete batching plant or fixed plants, ensures precise mixing. This reduces leftover material. Also, integrating concrete’s thermal mass concrete properties into passive design strategies helps. This means using exposed concrete floors or walls to store and release heat. This naturally regulates indoor temperatures. This reduces the building’s energy consumption over its lifetime. These design choices ensure that concrete’s inherent strengths are fully utilized for long-term sustainability.

What Are Green Building Certifications’ Concrete Requirements?

Green building certification systems like LEED have specific requirements for concrete. These focus on reducing the concrete carbon footprint, using recycled aggregates, and sourcing local materials. Meeting these standards shows a commitment to sustainable construction.

For any project aiming for green building certification like LEED (Leadership in Energy and Environmental Design), concrete choice is important. These certifications look at many aspects of sustainable construction. For concrete, they typically award points for using low-carbon concrete mixes. This includes concrete made with high percentages of SCMs. Points are also given for using recycled aggregates. This includes recycled concrete aggregate (RCA). Sourcing materials from within a certain radius of the project site is another common requirement. This reduces transportation emissions. This addresses the environmental impact of building materials.

Meeting these criteria requires close collaboration. Our clients, who use our stationary concrete batching plant equipment, often work with architects and developers. They plan their concrete mixes to meet these specific certification standards. This ensures the concrete contributes positively to the project’s overall concrete sustainability score. It shows a dedication to building greener structures.

How Can Concrete Achieve “Zero Carbon” with Circular Economy and Carbon Capture?

Achieving “zero carbon” in the concrete industry will involve a combination of circular economy principles and advanced carbon capture technologies. This includes widespread adoption of sustainable cement and new ways to store CO2.

The journey to “zero carbon” for concrete is ambitious but possible. A major step is fully embracing the circular economy. This means maximizing the use of recycled aggregates from demolished concrete. It also means finding new uses for concrete waste. This reduces landfill use and raw material extraction. Developing more advanced cement alternatives is also key. These include materials like geopolymer cements. They rely on industrial byproducts instead of virgin resources.

Carbon capture, utilization, and storage (CCUS) technologies are also vital. This means capturing CO2 emissions directly from cement plants. This prevents them from entering the atmosphere. Some technologies also inject CO2 into fresh concrete. The CO2 then mineralizes within the concrete, permanently storing it. This even makes the concrete stronger. This turns the concrete itself into a carbon sink. These innovations are transforming the environmental impact of building materials. They promise a future where green concrete can truly be carbon neutral or even carbon negative. This is the ultimate goal for sustainable construction.

Common Questions About Concrete Sustainability

Question 1: Is all concrete bad for the environment because of its carbon footprint?

No, not all concrete is “bad.” While traditional cement production has a high concrete carbon footprint, the industry is rapidly developing low-carbon concrete options. These use less cement or alternative binders. Many new projects focus on green concrete to reduce environmental impact.

Question 2: What is the most effective way to make concrete more sustainable today?

The most effective way right now is to replace a portion of Portland cement with cement alternatives like fly ash or slag. This significantly reduces emissions. Using recycled aggregates is also very effective. These practices make sustainable cement and concrete readily available.

Question 3: How long does concrete last, and why does that matter for sustainability?

Well-made concrete can last 50 to 100 years or even longer. This concrete durability matters a lot for concrete lifecycle assessment. A long lifespan means fewer replacements. This saves resources and energy over the life of a structure. This is a key part of sustainable construction.

Question 4: Does concrete help save energy in buildings?

Yes, it does. Concrete has high thermal mass concrete. This means it can absorb and store heat or cool air. It releases it slowly. This helps regulate indoor temperatures naturally. This reduces the need for heating and cooling systems. This lowers a building’s overall energy consumption.

Summary: Concrete’s Evolving Role in Sustainable Construction

Concrete sustainability is a complex topic. While its carbon footprint is a major concern, continuous innovation, its inherent durability, and thermal properties make it a vital component of sustainable construction.

We have explored the challenges posed by the concrete carbon footprint. We have also seen how the industry is addressing these through low-carbon concrete and cement alternatives. The use of recycled aggregates and focusing on concrete durability highlight its long-term benefits. These efforts are making green concrete a reality. The future of sustainable construction will rely on smart design. It will also rely on advanced materials. This will make concrete a truly sustainable choice.

About Durable

Durable Machine, founded in 2001, is a trusted manufacturer of heavy machinery for construction. We produce a wide range of equipment. This includes stationary concrete batching plants, mobile concrete batching plants, and concrete mixer trucks. Our machines help clients produce high-quality concrete. This includes the new, more sustainable mixes. We support the industry’s shift towards greener building practices.

Build a Greener Future with Durable Concrete Solutions

Are you planning a sustainable construction project? Do you want to reduce your project’s environmental impact of building materials? Contact Durable Machine today. We can provide you with the equipment to produce advanced low-carbon concrete. Let us help you build for a greener future.

Durable Machinery

Durable Machinery