How to match mixing methods & mixers for peak concrete quality?

For decades, I have seen concrete projects succeed or fail based on one key factor: the quality of the mix. This all starts with how you mix it and the machine you use. You can have the best materials. You can have a perfect design. But if the mixing is poor, your concrete will be weak. It will be inconsistent. This leads to costly problems. You need to pick the right concrete mixing methods and concrete mixers. This choice is not simple. It needs careful thought. This guide shows you how to make that choice. It helps you get high-quality concrete. This improves your project efficiency. It also boosts your profits.

Table of Contents

- Why Is Concrete Mixing Critical for Project Quality and Cost?

- Mixing Methods: Manual, Batch, and Continuous – What’s the Difference?

- Choosing the Right Concrete Mixer: Which Type Suits Your Project?

- Matching Mixer Capacity and Efficiency to Your Project Needs?

- Optimizing Concrete Mixing: Time, Order, and Additives for Strength?

- Boosting Mixing Precision: Automation and Smart Sensors?

- Mixer Maintenance and Troubleshooting: Reducing Costs and Downtime?

- Beyond Purchase Price: Uncovering Hidden Costs in Mixer Selection?

- Latest Trends in Concrete Mixing Technology for 2025

- Frequently Asked Questions

- Conclusion and Final Advice

- About Durable

Why Is Concrete Mixing Critical for Project Quality and Cost?

Proper concrete mixing is paramount for strong, durable results. Poor mixing causes uneven strength, poor workability, segregation, and weak spots, leading to cracks, early failure, safety risks, and expensive repairs. Conversely, effective mixing ensures uniform distribution, creating strong bonds for predictable strength and consistent workability. This reduces waste, prevents delays, saves costs, and keeps projects on track. Thus, choosing optimal mixing methods and equipment is foundational for project success.

The Core Principle: Uniformity in Concrete Mixing

Uniformity is concrete production’s most critical goal, ensuring every cubic meter has identical properties from evenly distributed ingredients. Non-uniformity causes inconsistent wetness/dryness, variable cement content, and significant strength differences, creating dangerous weak points prone to failure and increasing costs via excess cement. Conversely, a uniform mix guarantees reliable strength, easier placement, and reduced overall project costs.

| Mix Property | Uniform Mix | Non-Uniform Mix | Your Benefit |

|---|---|---|---|

| Strength | Consistent and predictable strength | Variable strength, weak spots | Reliable, durable structures, reduced failure risk |

| Workability | Easy to place, smooth finish | Difficult to place, poor finish, segregation | Faster construction, better aesthetics |

| Durability | Long-lasting, resistant to wear | Prone to cracks, faster degradation | Reduced maintenance, longer service life |

| Material Usage | Optimized cement and aggregate usage | Excessive material use to compensate | Lower material costs, less waste |

| For more insights on ensuring quality, consider how different mixing equipment impacts the final product. Understanding what is a twin shaft concrete mixer can help you choose the best equipment for uniform mixes. |

Mixing Methods: Manual, Batch, and Continuous – What’s the Difference?

Concrete mixing evolved from manual labor to complex machines; selecting the right method (manual, batch, continuous) is crucial.

Manual mixing, the oldest, suits only tiny jobs like DIY repairs. It’s slow, labor-intensive, and yields inconsistent quality, making it unsuitable for most construction where strength control is vital.

Machine mixing is standard, comprising two main types:

- Batch mixing is most common. Ingredients are loaded, mixed thoroughly, then discharged per batch. This offers excellent quality control and flexible mix design.

- Continuous mixing involves non-stop material feed and concrete output. Ideal for very large projects needing a steady, consistent flow (e.g., dams, long roads), it’s fast but less adaptable to on-the-fly mix changes.

- Ultimately, your choice depends on project size and required quality.

Understanding Batch Mixing for Quality Control

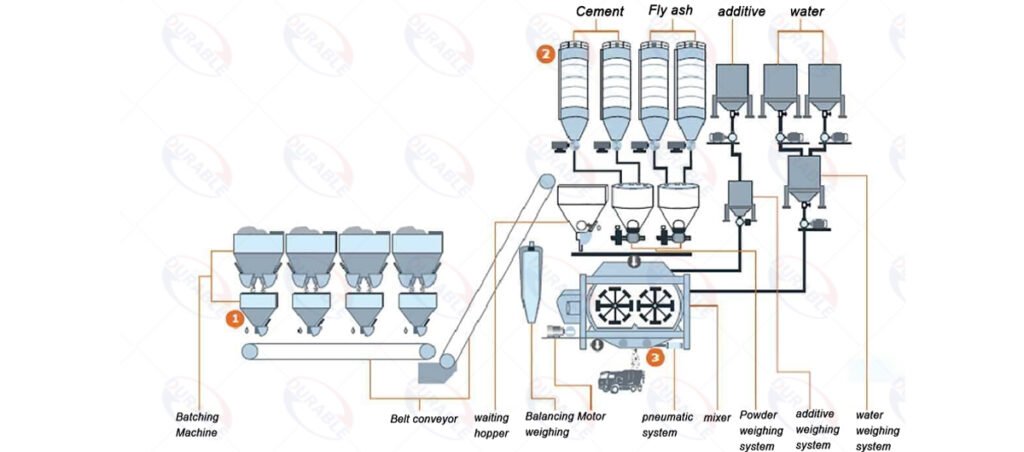

Batch mixing is the most common method in modern construction due to its superior quality control. In this process, every ingredient (aggregates, cement, water, additives) for a single load of concrete is precisely weighed and then thoroughly mixed for a set time, creating one distinct “batch.” This batch is fully discharged before the next one begins. This stop-and-go approach allows for strict quality checks and easy, flexible adjustments to the mix design between batches. For instance, a batch plant can be programmed for high-strength concrete for foundations, then switched to a lower-strength mix for non-structural elements. This flexibility is a significant advantage, ensuring each part of a project receives the exact concrete it needs, reducing human error, and guaranteeing consistent performance.

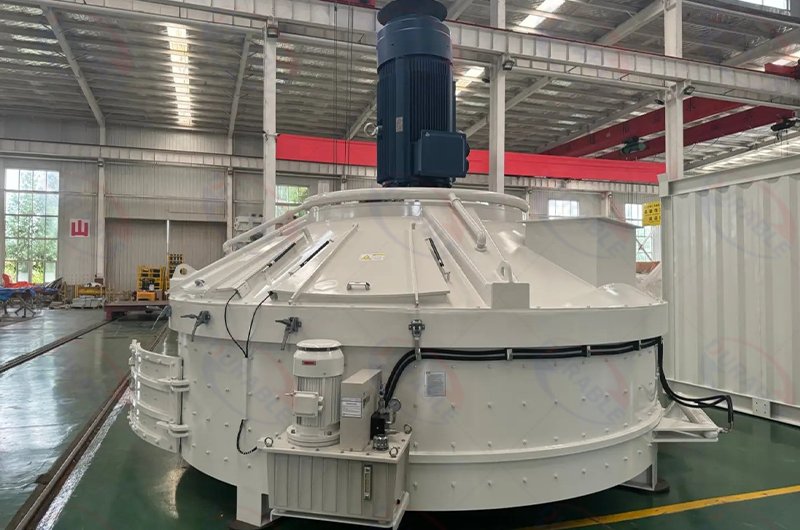

For specific mixer types, such as a planetary concrete mixer, the batch process ensures each ingredient is perfectly blended.

Continuous Mixing: High Volume, Steady Flow

Continuous mixing, though less common, is ideal for very large-scale projects demanding a constant, massive concrete supply. Raw materials continuously feed into one end, and mixed concrete continuously emerges from the other, enabling extremely high production rates for long, uninterrupted pours like highway paving or massive foundations. Its primary benefit is speed and a steady concrete stream, simplifying site logistics. However, it requires highly precise feeding systems to maintain mix proportions, as small feed rate changes impact the entire output. This method is also less flexible, making on-the-fly mix design changes difficult, thus best suited for extended periods requiring a single, uniform concrete mix.

Choosing the Right Concrete Mixer: Which Type Suits Your Project?

Choosing the right concrete mixers is crucial. It directly impacts your project’s quality, efficiency, and budget. There are many types of mixers. Each one works best for different situations. You must understand how they work. You need to know their strengths and weaknesses. This helps you make an informed decision. The most common types are drum mixers and forced action mixers. Forced action mixers include pan, twin-shaft, and planetary mixers.

Drum mixers, the oldest type, use a rotating drum to tumble concrete ingredients, making them simple, affordable, and suitable for small to medium general-purpose jobs (e.g., tilting and non-tilting types). However, they may lack uniformity and can cause aggregate damage or segregation.

In contrast, more advanced forced action mixers (e.g., twin-shaft, planetary) utilize rotating paddles or blades within a stationary pan, generating a strong shearing action for a highly homogeneous mix. Ideal for high-performance concretes (like self-compacting concrete) and demanding applications, they offer faster, more thorough mixing with reduced aggregate damage. Though more costly, their superior concrete quality often leads to long-term savings.

Drum Mixers: Simple and Versatile Choices

Drum mixers are a common and long-standing type of concrete mixer, utilizing a large, rotating drum with internal blades to mix materials by lifting and dropping them. They come in two main types:

- Tilting Drum Mixers: These are simple, tilting the entire drum for both mixing and easy discharge. They are ideal for small jobs or intermittent use due to their ease of operation and cleaning.

- Non-Tilting (Reversing) Drum Mixers: These maintain a stationary drum but use two sets of internal blades. One set mixes when the drum rotates one way, and the other discharges the concrete when it reverses, allowing for faster cycles and better discharge control.

Both types are suitable for general-purpose concrete and are often found on smaller construction sites or for DIY projects. However, they may not achieve the perfect uniformity required for high-strength or special concretes and can be harsher on aggregates, potentially causing particle breakdown.

| Drum Mixer Type | How it Discharges | Advantages | Disadvantages |

|---|---|---|---|

| Tilting Drum Mixer | Drum tilts to pour | Simple, low cost, easy to clean | Slower discharge, less uniform mix for stiff concrete |

| Non-Tilting Drum Mixer | Internal blades reverse | Faster mixing/discharge, better control | More complex, harder to clean thoroughly |

Forced Action Mixers: Precision for High-Performance Concrete

Forced action mixers are the workhorses of modern concrete production. They are designed for superior mixing quality. They are often used for high-performance concrete (HPC). This includes high-strength, self-compacting, and fiber-reinforced concrete. These mixers have stationary pans. Inside, mixing elements rotate powerfully. This creates an intense shearing and intermixing action. This ensures every particle gets coated with cement paste. This leads to a very homogeneous mix. There are two main categories: vertical shaft mixers and horizontal shaft mixers.

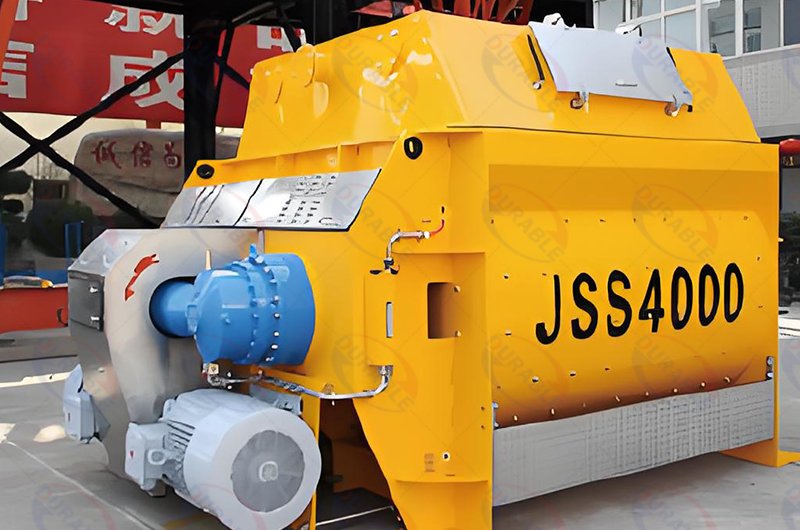

Vertical shaft mixers, like planetary or pan mixers, have one or more mixing stars or paddles. These rotate around a central vertical axis. Planetary mixers have paddles that also rotate on their own axes. This creates a complex mixing pattern. This ensures every part of the mix gets processed. This results in incredibly uniform concrete. Planetary mixers are excellent for precast concrete. They are also great for colored concrete. They work for mixes with special additives. Horizontal shaft mixers, especially twin-shaft concrete mixers, are very popular. They have two parallel shafts. These shafts rotate in opposite directions. Paddles on the shafts intermesh. This creates a very fast and aggressive mixing action. Designed for versatility, our equipment handles all types of concrete, serving both large ready-mix plants and major infrastructure projects.While more expensive, these mixers deliver speed and quality that drum mixers cannot match. This makes them ideal for critical applications.

Matching Mixer Capacity and Efficiency to Your Project Needs?

Choosing the right concrete mixers means more than just picking a type. You must match its capacity and efficiency to your project needs. A mixer that is too small will slow you down. One that is too big wastes energy and money. You need to consider project size, your concrete recipe, and site conditions. These factors will guide your choice.

First, think about the project scale. How much concrete do you need per hour or per day? A small residential job might only need a diesel drum mixer with a 0.5 cubic meter capacity. A large commercial building or bridge might require a full concrete batching plant. This plant could have a twin-shaft mixer. It could produce 100 cubic meters per hour. The capacity of your mixer directly affects your project timeline. An undersized mixer creates bottlenecks. An oversized one has higher initial costs. It also has higher running costs.

Next, consider the concrete recipe. High-strength concrete, self-compacting concrete (SCC), or concrete with special fibers often need more intensive mixing. They need specific mixer types. For example, a planetary mixer is great for SCC because it handles sticky mixes well. A twin-shaft mixer is excellent for high-strength or roller-compacted concrete. Site conditions also play a big role. Is your site remote? Is it crowded? A self-loading concrete mixer might be perfect for remote sites. It can load, mix, and transport concrete all by itself. For a fixed factory setup, a stationary concrete batching plant is better. It offers maximum control and output. Understanding these factors helps you make a precise choice. This ensures efficiency and quality.

Assessing Project Scale and Output Requirements

Assessing your project’s scale is the first step in mixer selection. You need to calculate the total volume of concrete required. You also need to know the delivery rate. How many cubic meters of concrete do you need in one hour? How much do you need in one day? This will tell you the required output of your concrete mixing equipment. For small jobs, like a backyard patio, a small portable drum mixer might be enough. It produces 0.1 to 0.2 cubic meters per batch. For larger commercial buildings, you might need a medium-sized batching plant. This plant could produce 30 to 60 cubic meters per hour. Very large infrastructure projects, like highways or dams, demand large mobile concrete batching plants or stationary plants. These can exceed 100 cubic meters per hour.

You should also consider the batch cycle time. This is how long it takes to load, mix, and discharge one batch. A faster mixer can produce more concrete per hour, even if its batch size is similar. For example, a twin-shaft mixer has a faster mixing time than a drum mixer. So, it will have a higher effective output. Matching the mixer’s output to your placement rate is also important. If your mixer produces concrete faster than your crew can place it, you get delays and potential waste. If it is too slow, your crew waits. This adds labor costs. Therefore, a careful calculation of required capacity is essential for project efficiency.

Considering Concrete Mix Designs and Site Challenges

Concrete mix designs heavily influence your choice of concrete mixers. Not all mixes are equal. General-purpose concrete uses standard aggregates and cement. It mixes easily in most drum mixers. However, specialized concrete needs more. High-strength concrete uses specific aggregates and admixtures. Self-compacting concrete (SCC) is very flowable. It is also quite sticky. Roller-compacted concrete (RCC) is very dry. It has almost no slump. These mixes demand powerful, forced action mixers. For example, a planetary or twin-shaft mixer can handle sticky SCC. It also prevents segregation. They can also thoroughly mix the dry RCC. A drum mixer would struggle with these. It might not achieve proper uniformity. It might damage the aggregates.

Site conditions add another layer of complexity. What are the conditions of your construction site regarding access, remoteness, and available space? For remote sites, a self-loading concrete mixer is a great option. It reduces transport needs. For urban areas with tight spaces, a compact batching plant might be necessary. Some sites have strict noise or dust regulations. This might influence your choice of machine. It might also influence auxiliary equipment. A thorough site assessment is crucial. It ensures the chosen mixer can perform optimally within these real-world constraints.

Optimizing Concrete Mixing: Time, Order, and Additives for Strength?

Getting high-quality concrete is not just about the mixer. It is also about how you use it. Three things are very important: mixing time, the order you add materials, and how you mix in additives. If you get these right, your concrete will be stronger. It will be more uniform. This saves you money. It also makes your structures last longer.

Optimal mixing time is critical: under-mixing results in non-uniform, weaker concrete, while over-mixing causes aggregate breakdown, water evaporation, and segregation. Finding the ‘sweet spot’ for each mixer and mix design is essential.

The order of adding materials also significantly impacts the mix. A common sequence is coarse aggregates first, then sand, followed by cement, with water and admixtures typically added last. This method ensures thorough mixing and prevents cement from clumping.

Admixtures, special chemicals that enhance concrete properties, must be evenly dispersed to be effective and avoid problems. They are often added with mixing water or later in the cycle to allow for proper integration and dispersion. Following these strategies ensures consistent strength and excellent workability in the final concrete.

Finding the Sweet Spot for Mixing Time

Achieving the correct mixing time is crucial for producing high-quality concrete, as both under-mixing and over-mixing can lead to significant problems.

Under-mixing results in unblended ingredients, creating uneven concrete with dry or wet spots, weak areas, and inconsistent strength because cement particles do not fully hydrate and coat the aggregates.

Over-mixing, conversely, can cause excessive heat buildup (leading to rapid setting or slump loss), aggregate breakdown (attrition) which alters particle size and affects workability and strength, and even segregation where larger aggregates settle.

The ideal mixing time varies based on the mixer type, mix design, and aggregate size. Most standard concrete mixes require 60 to 90 seconds of mixing after all ingredients are in, with high-performance mixes potentially needing slightly longer. It is essential to follow manufacturer recommendations and conduct field tests to determine the optimal time for specific conditions.

Strategic Charging Sequence and Admixture Integration

The order in which you add materials into the concrete mixers is very important. It affects how well they blend. It affects the final concrete quality. A common and effective sequence helps achieve a homogeneous mix. You should usually add about 50-70% of the coarse aggregate first. Then add all the fine aggregate (sand) and the cement. This forms a “sandwich” effect. It helps prevent the cement from clumping or sticking to the mixer walls. Next, you add about 70-80% of the mixing water. You add any admixtures at this stage too. The remaining water is added slowly until the desired consistency is reached. This final water addition allows for fine-tuning of the slump.

Admixtures are powerful chemicals. These substances modify concrete properties, improving workability, accelerating or retarding setting, and enhancing strength. Proper integration of admixtures is critical. Most admixtures are added with the mixing water. This ensures they disperse evenly throughout the mix. Some specialized admixtures, like certain fibers or superplasticizers, might need later addition. Or they might need a specific mixing period. For example, some superplasticizers work best when added at the very end of the mixing cycle. This ensures maximum effect without excessive air entrainment. Always follow the admixture manufacturer’s guidelines. This ensures they work as intended. This helps you achieve the desired concrete properties.

Boosting Mixing Precision: Automation and Smart Sensors?

To ensure high precision and consistency in modern concrete production, automation and smart sensors are critical for eliminating human error and delivering consistent quality.

Central programmable logic controllers (PLCs) manage automated systems, precisely controlling material weighing, water addition, and mixing times for each batch. This results in highly consistent concrete with reliable strength and predictable workability.

Smart sensors complement this by providing real-time data on conditions like aggregate moisture, concrete temperature, and even slump. This data allows for immediate, precise adjustments (e.g., modifying water content) to maintain the correct water-cement ratio and overall concrete quality. All data is recorded, providing a detailed history crucial for quality assurance, troubleshooting, process improvement, and waste reduction.

The Role of PLC in Modern Concrete Production

Programmable Logic Controllers (PLCs) serve as the “brains” of modern concrete batching plants, automating the entire production process as industrial computers.

They ensure high precision by controlling the precise weighing of aggregates, cement, and water using load cells, managing gates and conveyors to deliver exact material amounts according to the mix design. Once ingredients are in the mixer, PLCs govern the mixing sequence and duration, operate the mixer motor, and manage admixture additions.

PLCs can store hundreds of concrete recipes, allowing operators to select mixes with ease, which minimizes human error and guarantees consistent production steps for every batch. This consistency is crucial for high-quality concrete and reduces material waste. Furthermore, PLCs record comprehensive batch data—including weights, mixing times, and alarms—providing invaluable information for quality control, troubleshooting, and full traceability, essential for meeting modern construction standards.

Smart Sensors for Real-time Quality Assurance

Smart sensors are crucial for real-time quality assurance in concrete production, providing constant feedback for immediate adjustments to maintain consistent quality.

Moisture probes, installed in aggregate bins, measure the water content of sand and gravel. This is vital because varying aggregate moisture impacts the critical water-cement ratio, directly affecting concrete strength. The probes inform the PLC, which then automatically adjusts the amount of water added, ensuring accurate total water content and consistent strength.

Additionally, temperature sensors monitor aggregate and water temperatures, as extremes can affect setting time and workability. Some advanced systems even use sensors to estimate concrete slump inside the mixer, further enhancing consistency control. This real-time data collectively prevents bad batches, reduces waste, and provides superior control over manual methods, ultimately ensuring uniform, high-quality concrete that improves project reliability and performance.

Mixer Maintenance and Troubleshooting: Reducing Costs and Downtime?

Regular maintenance for concrete mixers is crucial for reducing operating costs, preventing expensive breakdowns, and extending their lifespan. Neglecting this leads to costly repairs, unexpected downtime, and project delays.

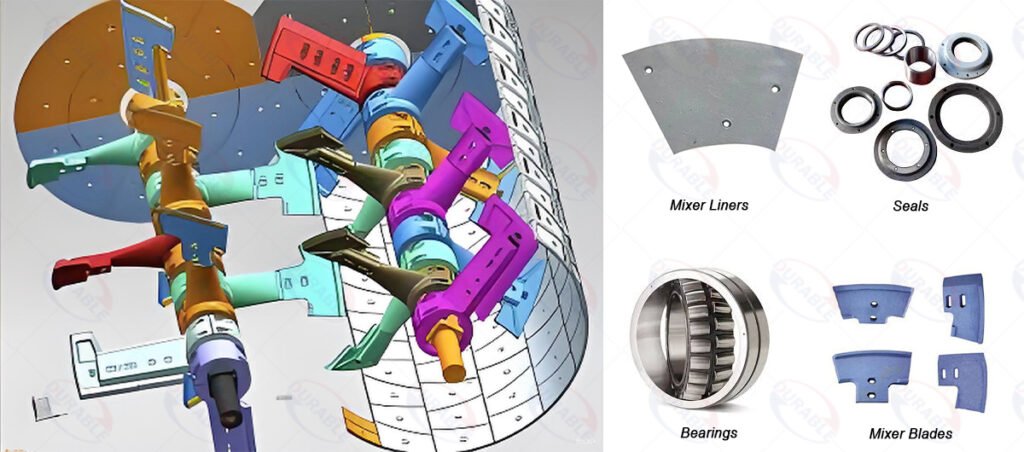

Essential daily tasks include thorough cleaning after each shift to prevent concrete residue buildup, inspecting for worn parts and loose bolts, and lubricating moving components as per manufacturer guidelines. Wear parts, such as mixer liners and paddles, are designed to be sacrificial and require timely replacement; having spares readily available helps minimize downtime. Proactive maintenance, including addressing common issues like motor overheating or poor mix quality, prevents larger, more expensive problems, ensuring the equipment runs smoothly and efficiently.

Proactive Maintenance: Your Best Defense Against Downtime

Proactive maintenance is vital for concrete mixing equipment, ensuring efficiency, extended lifespan, and fewer breakdowns. Regular cleaning after each use, ideally with high-pressure water, prevents concrete buildup that reduces capacity, efficiency, and causes uneven wear. Lubrication of moving parts like bearings and gears is crucial to prevent friction; always follow manufacturer schedules. Daily visual inspections are also critical for loose bolts, cracks, and belt tension. Pay close attention to wear parts such as mixer liners, paddles, and scrapers; these are designed for replacement and protect the main body. Keeping a stock of common spare parts, informed by wear patterns in equipment like a Twin Shaft Concrete Mixer, minimizes downtime. A well-maintained mixer consistently produces high-quality concrete reliably, saving money on repairs and lost production.

| Wear Part | Typical Lifespan (Hours) | Maintenance Tip |

|---|---|---|

| Mixer Liners | 500-2000 | Inspect weekly, replace when worn thin |

| Mixer Paddles/Blades | 300-1500 | Inspect daily, ensure proper angle and integrity |

| Bearings | 2000-5000 | Lubricate regularly, check for abnormal noise |

| Seals | 1000-3000 | Check for leaks, replace if damaged |

Quick Troubleshooting Tips for Common Mixer Issues

Even with good maintenance, concrete mixers can face problems. Knowing quick troubleshooting saves time and frustration. If the motor overheats, check for obstructions, excessive material load, or faulty electrical connections. For poor mixing, inspect paddles/blades for wear or damage, and verify material feed and charging sequence to prevent clumping. Excessive vibration often points to loose bolts, uneven wear on rotating parts, or an unbalanced load. If concrete discharges too slowly, look for blockages at the outlet, and check the tilting mechanism or reverse discharge blades. These swift checks frequently identify simple issues, preventing larger problems and keeping your concrete production on track. Always consult your mixer’s operation manual for detailed guides.

Beyond Purchase Price: Uncovering Hidden Costs in Mixer Selection?

When you choose concrete mixing equipment, it is easy to focus only on the purchase price. But this is a big mistake. The true cost of owning a mixer goes far beyond the initial tag. You need to consider the Total Cost of Ownership (TCO). This includes hidden costs. These costs can add up quickly. They can make a “cheap” mixer very expensive in the long run. Ignoring them can hurt your project budget.

Hidden costs significantly impact concrete mixer operations. Energy consumption from powerful motors (electric or diesel) is a major factor; less efficient mixers increase utility bills. Labor costs for skilled operators and maintenance staff also add up, especially with complex or unreliable mixers demanding more attention. Maintenance costs are ongoing, covering spare parts (liners, paddles), lubricants, and repair services; lower-quality mixers often incur more frequent and costly repairs. Environmental costs involve managing dust and noise pollution, potential fines, and waste disposal. Finally, downtime is a huge hidden expense, as a stalled mixer halts the entire project, leading to lost productivity and delayed schedules that can far exceed repair bills. A comprehensive view of these costs is essential for a smart investment.

Understanding Energy Consumption and Its Impact

Energy consumption is a major hidden cost for concrete mixers. Motors in these machines are powerful. They need a lot of electricity. Or they use a lot of diesel fuel. An inefficient mixer can significantly increase your operating expenses. Consider the motor’s power rating. A larger, more powerful mixer will naturally use more energy per hour. However, a highly efficient mixer might mix faster. It might achieve better uniformity. This means you run it for less time per batch. Or you produce more concrete in the same time. This can offset the higher power rating. For instance, a twin shaft concrete mixer mixes very quickly. This reduces the overall energy per cubic meter of concrete.

Also, consider factors like start-up power. Some mixers have high start-up currents. This can affect your electricity grid. It can also incur higher demand charges. For diesel mixers, fuel efficiency is key. Different engine types have different fuel consumption rates. The cost of electricity or fuel varies greatly by region. So, you must calculate this based on your local rates. An energy-efficient mixer might have a higher initial purchase price. But it will save you a lot of money over its lifespan. This is especially true for continuous operation. This makes it a smart long-term investment.

Factoring in Labor, Maintenance, and Environmental Costs

Beyond energy, several other hidden costs impact concrete mixing equipment budgets. Labor costs are significant, requiring skilled operators for modern batching plants and maintenance technicians. Mixers that are difficult to operate or frequently break down increase labor needs and payroll. Maintenance costs are continuous, encompassing scheduled upkeep, emergency repairs, and the regular, expensive replacement of wear parts like internal liners and mixing paddles. Maintaining an inventory of critical spares also adds expense, with lower-quality components leading to more frequent and costly replacements. Environmental costs are also growing; concrete production generates dust and noise, necessitating compliance with local regulations (dust suppression, noise reduction) and proper disposal of concrete washout water. Non-compliance can result in heavy fines, affecting both budget and project reputation. Choosing a reputable manufacturer known for reliable machines and excellent support helps mitigate these ongoing expenses effectively.

Latest Trends in Concrete Mixing Technology for 2025

The world of concrete production is always changing. New technologies are making mixing better. They make it more efficient. They also make it more sustainable. For 2025, we see a few key trends. These trends focus on smart systems. They focus on green concrete. They also focus on making equipment more flexible.

Modern concrete mixers are evolving with several key trends to enhance efficiency and sustainability.

Firstly, they are becoming smarter, leveraging internet connectivity and sensors for remote monitoring and predictive maintenance. This technology anticipates part failures, significantly reducing unexpected downtime and saving both time and money.

Secondly, the industry is moving towards “green concrete.” Mixers are adapting to use less cement, incorporate recycled materials, and blend in more supplementary cementitious materials (SCMs), thereby reducing concrete’s carbon footprint.

Lastly, modular designs are gaining popularity, offering ease of transport and setup, which is particularly beneficial for mobile concrete batching plants and projects that move from site to site.

These advancements collectively enable the production of better concrete, more efficiently and more responsibly.

Latest Developments at a Glance

- IoT Integration: Concrete mixers now have Internet of Things (IoT) sensors. These sensors collect data on performance. They monitor things like motor temperature. They track mixing time. This data is sent to the cloud. You can access it from anywhere. This helps with remote management. It also allows for early detection of problems.

- AI for Mix Optimization: Artificial intelligence (AI) is coming to concrete production. AI systems analyze historical data. They also use real-time sensor input. This helps optimize mix designs. It can adjust water content based on aggregate moisture. It can fine-tune mixing times. This ensures consistent strength. It reduces material waste.

- Advanced Material Handling: New conveyors and feeders are smarter. They prevent segregation of aggregates. They deliver materials more precisely. This improves mix quality before it even enters the mixer. This is especially important for complex concrete recipes.

Frequently Asked Questions

1. What is the most common mixer type for a large ready-mix plant?

The twin-shaft concrete mixer is the most common. It offers fast, efficient mixing. It handles high volumes. It produces very consistent concrete. This makes it ideal for ready-mix production.

2. How long should I mix concrete for?

For most standard concrete in a batch mixer, 60 to 90 seconds is typical after all materials are in. Too short leads to unevenness. Too long can cause issues. Always check your mixer and mix design specifications.

3. Can I use a drum mixer for high-strength concrete?

While possible for small batches, it is not ideal. Drum mixers may not provide enough shearing action for full homogeneity. High-strength concrete often needs forced action mixers like twin-shaft or planetary types.

4. What is the main advantage of a self-loading concrete mixer?

The main advantage is its versatility. A self-loading concrete mixer can load its own materials. It mixes concrete on-site. It then transports and discharges it. This is great for remote or small jobs. It reduces the need for other equipment.

Conclusion and Final Advice

Choosing the right concrete mixing methods and equipment is paramount to a project’s success, directly influencing concrete quality, efficiency, and overall costs. It’s crucial to understand your project’s scale, concrete specifications, and site conditions to make an informed decision and avoid costly mistakes, ensuring high-quality, durable concrete production.

The ultimate advice is to never compromise on mixer quality. While a cheap mixer might seem appealing, it often leads to expensive problems like poor concrete quality, frequent breakdowns, and project delays. Investing in robust equipment from a reputable supplier, who offers expertise and excellent support, pays dividends in the long run through superior concrete, higher efficiency, and better project outcomes.

About Durable

Since 2001, Durable has been engineering and manufacturing concrete mixing equipment and other construction machinery, specializing in building complete, customized solutions rather than just selling machines. Their team of 15 experienced engineers works closely with clients to design mixing solutions tailored to specific project and business needs. From their Zhengzhou factory, they have delivered reliable systems to over 120 countries.

To enhance concrete quality and project efficiency, Durable invites prospective clients to contact their team for a professional consultation and a detailed proposal regarding their concrete mixing methods and mixer selection.

Durable Machinery

Durable Machinery