Why is a Clay Dryer Vital for Industrial Clay Processing?

A clay dryer is a strategic asset for successful industrial clay processing. Production issues, from poor quality to high energy costs, often stem from improper moisture in the raw clay. A clay dryer provides precise control, turning inconsistent material into a stable, predictable input for your production line. This control forms the foundation for achieving higher quality products, greater operational efficiency, and improved profitability. This analysis explains why investing in a dedicated clay dryer is critical for any major clay processing operation.

Table of Contents

- Why Control Clay Moisture Before Processing?

- How Does a Dryer Affect Final Product Quality?

- How Does Drying Boost Grinding & Mixing?

- How Does a Dryer Lower Kiln Energy Costs?

- What Are the Risks of Improper Drying?

- Do Different Clays Need Different Drying?

- How to Select the Right Clay Dryer?

- Frequently Asked Questions

- Summary and Recommendations

Why Control Clay Moisture Before Processing?

Controlling clay moisture is the first and most critical step in any industrial clay processing workflow. Raw clay from a quarry has inconsistent moisture levels, which vary with seasons, weather, and stockpile location. This variability poses a significant problem for production lines, as they cannot achieve a stable output with an unstable input. Wet, sticky clay clogs machinery, increases equipment wear, and requires more power to process. Consequently, these issues lead directly to unplanned downtime and elevated maintenance costs.

A professional clay dryer optimizes essential properties like plasticity by creating a standardized raw material with precise moisture. This streamlines all subsequent processing and ensures a high-quality final product.

How Does a Dryer Affect Final Product Quality?

The clay drying process directly determines the final quality of products like bricks, tiles, and ceramics. The most common and costly defect in these industries is cracking or deformation during firing in the kiln. This type of failure almost always results from excess moisture trapped within the clay body. When a moist clay piece undergoes rapid heating in a kiln, the trapped water converts into high-pressure steam. If this steam cannot escape in a slow, controlled manner, it generates immense internal pressure, causing the product to crack, warp, or even explode. This phenomenon drastically reduces the product qualification rate and leads to significant financial losses from wasted material, energy, and labor.

A dedicated clay dryer resolves this issue by gently and uniformly reducing the moisture content before the product enters the high-temperature kiln. This pre-drying step ensures that the amount of residual water is minimal and evenly distributed throughout the material. As a result, the product shrinks uniformly during the firing stage without developing internal stress points. This meticulous control of clay moisture leads to a massive increase in the yield of acceptable, saleable products and is a cornerstone of effective industrial clay processing. For industries like ceramics, proper drying also ensures superior glaze adhesion and a flawless finish, further enhancing final product value.

How Does Drying Boost Grinding & Mixing?

The efficiency of downstream processes, notably grinding and mixing, is heavily dependent on the condition of the raw clay. Attempting to grind or mix wet, adhesive clay presents a significant operational challenge. Wet clay has a tendency to clump and adhere to the internal surfaces of equipment, such as a ball mill or mixer. This buildup, often called “caking,” severely diminishes the machine’s efficiency and requires substantially more energy to operate as the motor struggles against the heavy, sticky mass. Moreover, this condition necessitates frequent and costly shutdowns for manual cleaning, which directly impedes overall production throughput.

Processing the material through a clay dryer first transforms it into a dry, friable, and free-flowing powder that is vastly easier to handle. This conditioned material moves smoothly through feeding systems, grinds into a consistent particle size more rapidly, and blends evenly with other additives during the mixing stage. The outcome is a dramatic improvement in production efficiency. Grinding times shorten, energy consumption decreases, and the need for manual cleaning is minimized. This optimization allows the entire production line to operate at a higher, more consistent capacity, thereby maximizing output and reducing per-ton processing costs.

How Does a Dryer Lower Kiln Energy Costs?

The kiln stands as one of the most energy-intensive pieces of equipment in any clay processing facility. Its primary function is to apply extremely high temperatures to induce sintering—the chemical and physical transformation of clay—not to function as an inefficient water boiler. Using a kiln to evaporate large volumes of water constitutes a massive waste of energy and capital. Water’s high specific heat and latent heat of vaporization mean it requires an enormous amount of thermal energy to convert from liquid to steam. When moist clay is fed directly into a kiln, a significant portion of the fuel is consumed just boiling off water before the actual firing process can commence, leading to high kiln energy consumption.

This is where a purpose-built clay dryer delivers a substantial return on investment. Modern dryers, particularly efficient designs like rotary dryers, are specifically engineered to remove water using hot air in the most energy-efficient manner possible. Pre-drying the clay ensures that the kiln receives material that is ready for the critical firing stage. This action dramatically reduces the thermal load on the kiln, allowing it to reach and maintain its target temperature with significantly lower fuel consumption. The resulting energy savings can be substantial, directly lowering operational costs and improving the plant’s overall energy efficiency and environmental performance.

What Are the Risks of Improper Drying?

Neglecting the necessity for a proper clay drying process or utilizing an inadequate drying method introduces severe risks that jeopardize the entire production line. The consequences extend far beyond a few cracked products, potentially leading to catastrophic failures and systemic inefficiencies. Poorly dried clay can cause frequent blockages in conveyors, crushers, and screens, leading to constant production interruptions. This situation places immense strain on mechanical components, accelerating wear and tear and ultimately shortening the lifespan of expensive machinery.

From a product standpoint, the risks are even greater, as entire batches can be ruined during firing, representing a total loss of raw materials, labor, and invested energy. For manufacturers of high-value items such as technical ceramics, a low product qualification rate is economically unsustainable. Attempting to compensate for wet clay by increasing kiln temperature or extending firing times is an ineffective strategy that drives up energy costs and can cause long-term damage to the kiln’s refractory lining. A professional clay dryer functions as a critical control point, mitigating these risks by providing a stable raw material that protects downstream investments and ensures predictable production outcomes. A quality clay brick making machine relies on this consistency.

Do Different Clays Need Different Drying?

Yes, different types of clay possess unique physical properties that necessitate tailored drying processes. A one-size-fits-all approach to drying is ineffective and can compromise material quality. Various clays exhibit distinct particle sizes, plasticities, and water-holding capacities that demand specific drying parameters. For instance, kaolin, a fine-particle clay used extensively in ceramics and paper, is highly sensitive to heat. A rapid or high-temperature drying process can damage its structure, adversely affecting its color and plasticity. Kaolin drying, therefore, requires a gentle process with precise temperature control.

Conversely, robust clays used for manufacturing bricks or lightweight aggregate may be less sensitive and can tolerate higher drying temperatures to achieve greater throughput. Bentonite, renowned for its exceptional swelling properties, requires a carefully managed drying curve to control its final characteristics. An experienced equipment manufacturer understands these material nuances. Durable Machine designs its clay dryer systems based on the specific type of clay being processed. The engineers adjust factors like the dryer’s rotational speed, internal flight design, and temperature profile to create the optimal drying environment, ensuring maximum efficiency while preserving the essential properties of the clay.

How to Select the Right Clay Dryer?

Choosing the correct clay dryer is a critical decision that directly influences an operation’s efficiency and profitability. The selection process must be grounded in a thorough analysis of specific production requirements. Three primary factors require consideration:

- Moisture Content: It is essential to determine the initial moisture content of the raw clay and the target moisture content for the final product. The difference dictates the amount of water to be removed, which is the primary factor in sizing the dryer.

- Production Capacity: The required throughput, measured in tons per hour or day, will determine the physical size—the diameter and length—of the rotary dryer drum needed to handle the volume while providing sufficient residence time.

- Material Characteristics: The type of clay is a crucial factor. Its stickiness, particle size, and heat sensitivity will influence the dryer’s design, including its rotational speed, angle of inclination, and the most appropriate heat source, such as natural gas, coal, or a biomass burner.

Partnering with an experienced manufacturer is vital for proper dryer selection. Durable Machine’s engineers analyze these factors to engineer a complete drying solution tailored to operational goals. Making the right choice ensures the system performs efficiently, reliably, and cost-effectively. For a detailed consultation, explore the available range of industrial clay dryers.

Frequently Asked Questions

Question 1: What is the ideal moisture content for clay before firing?

The ideal moisture content depends on the specific product but typically ranges between 1% and 7% for most brick and ceramic applications. The most critical factor is achieving a uniform moisture level throughout the material.

Question 2: Can clay be air-dried instead of using a machine?

While theoretically possible for small-scale applications, air drying is too slow, unreliable, and weather-dependent for industrial production. It cannot deliver the consistent moisture content essential for high-quality, large-scale manufacturing.

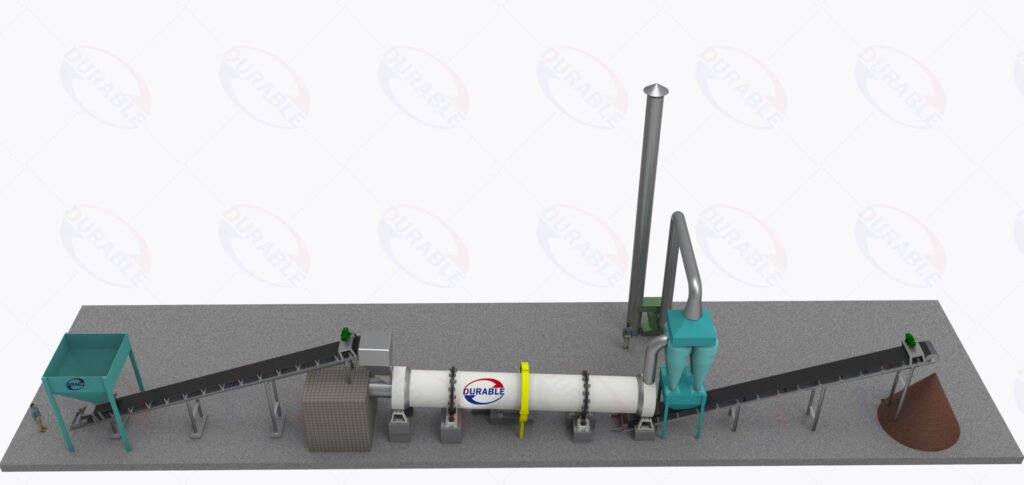

Question 3: How does a rotary clay dryer work?

A rotary dryer consists of a large, rotating cylindrical drum set at a slight inclination. Wet clay is fed into the higher end. As the drum rotates, internal plates called flights lift and cascade the clay through a stream of hot air, which flows through the drum to efficiently remove moisture.

Question 4: What is the main cause of bricks cracking in the kiln?

The single most common cause is excess or non-uniform moisture within the clay body as it enters the kiln. This trapped water violently turns to steam, creating internal pressure that fractures the brick. An effective pre-drying process is the definitive solution.

Summary and Recommendations

A professional clay dryer is an indispensable component of any modern, efficient industrial clay processing operation. Its role transcends simple water removal; it is a fundamental tool for quality control, process optimization, and cost reduction. By standardizing the raw material, a dryer facilitates higher final product quality with fewer defects, boosts the efficiency of downstream equipment like grinders and mixers, and significantly lowers the kiln energy consumption. Investing in a properly designed clay drying process mitigates production risks and delivers a clear, rapid return on investment.

For operations facing challenges with product quality, production bottlenecks, or high energy costs, an evaluation of the drying process is warranted. Since 2001, Durable Machine has been engineering and manufacturing robust mineral processing equipment. The company provides complete, customized drying solutions designed to meet specific client needs. To learn how a tailored drying system can transform a production line, contact the Durable Machine engineering team today for a professional consultation.

Durable Machinery

Durable Machinery