Rotary Dryers for Frac Sand: How Do They Excel in Drying?

Rotary dryers are essential in frac sand drying. Frac sand is a critical material in the oil and gas industry. It requires precise and efficient processing. Drying it correctly makes sure it meets strict industry standards. This article explains how rotary dryers for frac sand work. It details their key advantages. We will look at how they manage the specific challenges of frac sand. These include its abrasive nature and strict moisture requirements. Understanding these points helps you choose the right frac sand drying equipment.

Table of Contents

- What are frac sand properties and drying process requirements?

- How does a rotary dryer work for frac sand drying?

- How does a rotary dryer achieve efficient and uniform frac sand drying?

- What are rotary dryer design features for abrasive frac sand and dust control?

- How do rotary dryers achieve precise moisture control for frac sand?

- How do rotary dryers optimize energy efficiency and operating costs in frac sand drying?

- How do rotary dryers integrate into frac sand production lines with automation?

- What is the daily maintenance for rotary dryers ensuring long-term reliability?

- What are the key factors for choosing a rotary dryer for frac sand drying?

- Summary and Recommendations

- About Durable

What are frac sand properties and drying process requirements?

Frac sand properties are unique. They demand specific drying methods. Frac sand is high-purity quartz. It has very round grains. It must also be very strong. These qualities make it effective as a proppant in hydraulic fracturing. The sand must meet strict size and shape standards. It must resist crushing under high pressure. These properties are vital for oil and gas recovery. The sand often comes from wet screening processes. It carries a lot of surface moisture. This moisture must be removed almost completely.

The drying process has strict requirements for you. Final moisture content must be extremely low. Typically, it needs to be below 0.1%. This prevents clumping during transport. It also ensures free flow downhole. Any moisture can cause problems. It can affect the sand’s effectiveness. This low moisture level is hard to achieve with ordinary dryers. The sand also has a high specific gravity. It is very abrasive. This means the frac sand drying equipment must be robust. It needs to handle constant wear. The equipment must not damage the sand grains. It must preserve their roundness and strength. This is why rotary dryers for frac sand are a common choice. They meet these demanding specifications.

Key Requirements for Frac Sand Drying

- Ultra-Low Moisture Content: Essential for preventing clumping and ensuring flow.

- Preservation of Grain Integrity: The drying process must not damage the sand’s shape or strength.

- High Abrasiveness Handling: Equipment must be built to resist wear from the hard quartz sand.

- High Throughput: Large volumes of sand need to be dried continuously and efficiently.

How does a rotary dryer work for frac sand drying?

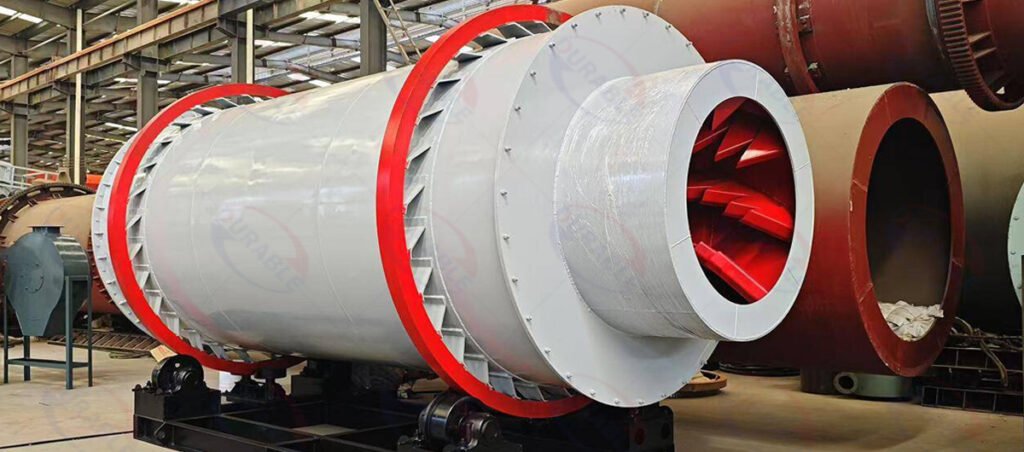

A rotary dryer works on a simple but effective principle. It uses a long, rotating cylinder. This cylinder is slightly angled. Wet frac sand enters one end. Hot gas enters either the same end or the opposite end. As the cylinder turns, internal flights lift the sand. They cascade it through the hot gas stream. This ensures excellent contact between the sand particles and the heat. This continuous tumbling and showering action promotes efficient heat transfer. It removes moisture from the sand.

The mineral dryer is heated directly. This means hot combustion gases mix with the sand. This direct contact provides fast heat transfer. The drum’s rotation speed and angle control how long the sand stays inside. This is called residence time. This control is important. It ensures all sand particles dry uniformly. It also prevents overheating. The design allows for high drying efficiency. The sand slowly moves through the dryer. It becomes progressively drier as it travels. It exits from the lower end. This process makes it an ideal frac sand drying equipment for large volumes.

Rotary Dryer Core Components

- Rotating Cylinder (Drum): The main body where drying occurs. It rotates on trunnion rollers.

- Flights (Lifters): Internal metal plates that lift and cascade material through the hot gas.

- Drive System: Motors and gears that rotate the cylinder at a controlled speed.

- Heat Source: A burner (gas, oil, coal) that generates hot gas for drying.

- Feed and Discharge Systems: For continuous input of wet sand and output of dry sand.

- Exhaust System: Collects spent gases and fine dust.

How does a rotary dryer achieve efficient and uniform frac sand drying?

A rotary dryer achieves high drying efficiency and uniformity for frac sand through several design features. The continuous tumbling action of the flights ensures every sand particle is exposed to the hot air. This prevents localized overheating. It also stops some particles from staying wet. The dryer’s slightly inclined angle and adjustable rotation speed control the sand’s residence time. This time is crucial. It gives enough time for all moisture to evaporate. This process happens evenly across the entire batch of sand. This is vital for meeting the tight moisture control requirements of frac sand.

The counter-current flow design also helps a lot. In this setup, hot gases enter where the dry sand exits. Wet sand enters where the cooler exhaust gases leave. This creates the largest temperature difference throughout the dryer. This maximizes heat transfer efficiency. It ensures the driest sand meets the hottest gas. This optimizes the energy usage. It also provides consistent drying. This method prevents thermal shock to the sand. It gradually heats it. This safeguards the sand’s proppant strength. This makes rotary dryers for frac sand highly effective. They deliver a consistently dry and high-quality product.

Elements Ensuring Uniform Drying

- Adjustable Residence Time: The drum’s angle and speed control how long sand stays inside. This is fine-tuned for optimal drying.

- Optimized Flight Design: Different flight patterns ensure thorough mixing and cascading of sand. This prevents clumping.

- Counter-Current Flow: Hot gases meet the driest sand. Wet sand meets cooler gases. This maximizes thermal gradient and efficiency.

- Consistent Feed Rate: A steady flow of wet sand helps maintain stable drying conditions. This prevents fluctuations in output.

What are rotary dryer design features for abrasive frac sand and dust control?

Rotary dryers are specifically designed to handle the abrasive nature of frac sand. This is a key rotary dryer advantage. The drums are built from thick, heavy-duty steel. This resists the constant wear from quartz sand. Internal flights use wear-resistant materials. They often have replaceable liners made from abrasion-resistant alloys. This extends the life of the dryer components. The trunnion rollers and thrust rollers, which support the rotating drum, are also built robustly. They can withstand heavy loads and continuous operation. This ensures long-term reliability even with highly abrasive materials.

Dust control technology is also crucial in frac sand drying equipment. The tumbling action and hot gas flow can generate significant fine dust. This dust is valuable product. It is also a health hazard. Effective dust collection systems are integrated into the dryer setup. These systems include cyclones, multi-cyclones, and baghouse filters. Cyclones first capture larger particles. Baghouses then filter out the finest dust. This ensures compliance with environmental regulations. It also protects workers’ health. Recovered dust can sometimes be re-processed. This adds to overall efficiency. This comprehensive approach to abrasive material drying and dust management makes rotary dryers for frac sand a safe and productive choice.

Abrasive Resistance and Dust Management Features

- Heavy-Duty Shell: Thick steel construction resists abrasive wear from constant sand movement.

- Wear-Resistant Flights: Made from high-strength alloys or with replaceable wear plates.

- Robust Bearings and Rollers: Designed for continuous operation with heavy, abrasive loads.

- Integrated Dust Collection: Cyclones and baghouses capture fine dust. This protects the environment. It also recovers product.

- Sealed Entry and Exit Points: Minimize dust leakage from the dryer itself.

How do rotary dryers achieve precise moisture control for frac sand?

Rotary dryers achieve precise moisture control for frac sand through advanced technical applications. This is a critical rotary dryer advantage. The system uses multiple temperature sensors. These sensors monitor the inlet and outlet gas temperatures. They also track the sand temperature within the dryer. These readings provide real-time data. This data helps control the drying process. Automatic control systems use this information. They adjust the heat input and the drum’s rotation speed. They also adjust the gas flow. This ensures the sand reaches the desired moisture level. It avoids over-drying or under-drying.

The counter-current flow design contributes greatly to this precision. It maintains a consistent thermal gradient across the dryer length. This allows for gradual and complete moisture removal. The consistent and uniform cascading of sand particles prevents moisture pockets. It ensures that every particle is dried evenly. Modern frac sand drying equipment often includes inline moisture sensors at the discharge. These sensors provide immediate feedback. This allows for final adjustments if needed. This level of control is essential. It ensures the dried frac sand consistently meets the stringent quality specifications required by the industry.

Technologies for Precise Moisture Control

- Multiple Temperature Sensors: Monitor gas and material temperatures at various points.

- Automated Control Logic: Uses PLC systems to adjust heat, speed, and airflow based on sensor data.

- Inline Moisture Sensors: Provide continuous feedback on the final product’s moisture content.

- Variable Speed Drives: Allow fine-tuning of drum rotation speed. This optimizes residence time.

How do rotary dryers optimize energy efficiency and operating costs in frac sand drying?

Rotary dryers significantly optimize energy consumption optimization in frac sand drying. This leads to lower operating costs. Their design promotes efficient heat transfer. Direct contact between hot gases and sand maximizes energy use. Modern dryers feature advanced insulation. This minimizes heat loss from the drum shell. Some systems use waste heat recovery. This captures heat from the exhaust gases. It preheats the incoming combustion air or wet sand. This further reduces fuel consumption. These features make rotary dryers for frac sand a cost-effective choice.

The robust construction and wear-resistant materials also reduce maintenance frequency. This lowers long-term drying equipment maintenance costs. Less downtime means more production. This improves profitability. A well-designed system, such as a triple-pass rotary drum dryer, can further enhance thermal efficiency. It uses the heat more completely. By using various fuel types, such as natural gas or propane, operators can choose the most economical option. This flexibility adapts to regional energy prices. All these factors contribute to a better overall cost performance for your operations.

Cost-Saving Features of Rotary Dryers

- Direct Heat Transfer: Maximizes contact between heat source and material, reducing energy waste.

- Advanced Insulation: Prevents heat loss from the dryer shell, keeping energy within the system.

- Waste Heat Recovery: Reuses heat from exhaust gases to preheat incoming air or material.

- Fuel Flexibility: Can operate on various fuels. This allows choice based on cost and availability.

- Low Maintenance Design: Fewer moving parts and durable materials reduce repair needs.

How do rotary dryers integrate into frac sand production lines with automation?

Rotary dryers integrate seamlessly into frac sand production lines. They use advanced automation solutions. This enhances overall mineral processing equipment efficiency. Sensors monitor key parameters. These include feed rate, temperature, moisture, and exhaust gas composition. Programmable Logic Controllers (PLCs) process this data. They automatically adjust dryer operations. This includes fuel input, fan speeds, and drum rotation. This ensures stable and optimal drying conditions. It reduces the need for constant manual adjustments.

Automation improves process consistency. It minimizes human error. This leads to a more uniform product. Data logging and remote monitoring capabilities are common. They allow operators to supervise the system from a control room. This improves safety and operational flexibility. Integration means the dryer communicates with other equipment. This includes wet screens, storage silos, and conveyors. This creates a fully synchronized production flow. Such sophisticated industrial dryer setups maximize throughput. They minimize bottlenecks. This ensures high-quality frac sand production.

Benefits of Automation in Frac Sand Drying Lines

- Increased Consistency: Automated controls maintain stable drying parameters. This results in uniform product quality.

- Reduced Labor Costs: Fewer operators are needed for continuous monitoring and adjustment.

- Enhanced Safety: Remote monitoring removes personnel from hazardous areas.

- Optimized Performance: Systems automatically adjust to changing conditions. This maintains peak efficiency.

- Data-Driven Decisions: Real-time data helps managers make informed operational and maintenance decisions.

Explore other essential mineral processing equipment like a magnetic separator for complete solutions.

What is the daily maintenance for rotary dryers ensuring long-term reliability?

Daily drying equipment maintenance is crucial for the long-term reliability of rotary dryers for frac sand. Operators should perform visual inspections every day. Check for unusual noises or vibrations. Look for leaks around bearings and seals. Ensure all safety guards are in place. Grease moving parts regularly. This includes trunnion rollers, thrust rollers, and gears. Proper lubrication prevents premature wear. It maintains smooth operation. This simple daily routine catches minor issues early. It prevents them from becoming major problems.

Cleaning is also part of daily care. Remove any material buildup on the outside of the drum or around critical components. This prevents overheating and corrosion. Check the heat source. Ensure it is free from obstructions. Verify that the feed and discharge areas are clear. Regularly inspect the internal flights for wear or damage. This is especially important when processing abrasive material drying. Addressing these points immediately ensures the industrial dryer operates safely and efficiently. It extends the dryer’s lifespan. This protects your investment.

Essential Daily Checks for Rotary Dryers

- Lubrication: Grease trunnion rollers, gears, and other moving parts.

- Visual Inspection: Check for unusual wear, loose bolts, or leaks.

- Temperature Monitoring: Ensure operating temperatures are within normal ranges.

- Cleanliness: Remove any material buildup from the drum and surrounding areas.

- Safety Checks: Verify all emergency stops and safety devices are functional.

What are the key factors for choosing a rotary dryer for frac sand drying?

Choosing the right rotary dryer for frac sand requires careful consideration. This is a critical selection guide for your investment. First, assess your required throughput. This is the volume of wet sand you need to dry per hour. The dryer’s capacity must match your production needs. Consider the initial moisture content of your wet sand. Also, consider the desired final moisture content. These factors affect the dryer’s size and heat input requirements. The type of fuel available and its cost are also important. This impacts energy consumption optimization.

The frac sand properties, especially its abrasiveness, influence the dryer’s construction materials. Look for robust designs with wear-resistant components. Effective dust control technology is non-negotiable. Ensure the system includes comprehensive dust collection. Consider the level of automation desired for integration into your mineral processing equipment line. A reputable manufacturer offers customization. They provide strong after-sales support. This includes installation, training, and parts. Choosing wisely ensures efficient, reliable, and cost-effective drying for years to come.

Key Considerations for Your Rotary Dryer Purchase

- Capacity: Match the dryer’s throughput to your specific production demands.

- Moisture Levels: Ensure the dryer can handle your feed moisture and achieve your target dryness.

- Material Abrasiveness: Select a dryer with durable, wear-resistant construction.

- Fuel Type and Cost: Choose a dryer compatible with available and economical fuel sources.

- Dust Management: Prioritize systems with effective dust collection.

- Automation and Integration: Plan for how the dryer will fit into your existing or new production line.

Summary and Recommendations

Rotary dryers are indispensable for frac sand drying. They efficiently handle the unique challenges of this abrasive material. Their robust design and precise moisture control ensure high-quality output. They also offer significant energy consumption optimization. This makes them a cost-effective choice for your operations. Key advantages include high throughput, durability against abrasion, and advanced dust control. Proper drying equipment maintenance ensures long-term reliability. Careful selection guide application leads to the best dryer for your specific needs.

Durable Machine specializes in frac sand drying equipment. We offer a range of high-performance sand dryers and mineral dryers. Our rotary dryers for frac sand are built for maximum efficiency and durability. We provide complete solutions. These include design, manufacturing, and support. To discuss your frac sand drying project or to learn more, please contact our expert team today. We help you find the perfect drying solution.

About Durable

Durable Machine, established in 2001, is a professional Chinese manufacturer. It specializes in B2B construction and mineral processing equipment. Based in Zhengzhou, the company focuses on the research, development, and production of robust machinery. This includes various industrial dryer solutions, such as rotary dryers for different applications. Our state-of-the-art facilities and stringent quality control measures ensure complete customer satisfaction. Durable proudly exports its high-performance products to over 120 countries. We offer factory-direct solutions for diverse global industrial needs.

Durable Machinery

Durable Machinery