Unlock Growth: What Benefits Does a Block Machine Offer?

Investing in a block machine provides significant benefits. It fosters growth in construction. Such equipment transforms raw materials into essential building units. These units include concrete blocks, clay bricks, and interlocking pavers. The advantages extend beyond mere production. They encompass economic empowerment, superior product quality, and enhanced sustainability. A block making machine serves as a strategic asset. It builds a more efficient and profitable future.

Table of Contents

- What Is a Block Machine and Why Is It Essential for Modern Construction?

- How Can a Block Machine Significantly Boost Your Profit Margins?

- What Operational Cost Savings Can You Expect with a Block Machine?

- How Does a Block Machine Ensure Superior Block Quality and Consistency?

- What Range of Construction Products Can You Create with a Modern Block Machine?

- How Does a Block Machine Improve Your Production Efficiency and Output?

- How Does Automation in Block Production Optimize Your Workforce?

- What Are the Environmental and Sustainability Benefits of Using a Block Machine?

- How Does Owning a Block Machine Give You a Competitive Edge in the Market?

- Can a Block Machine Help Scale Your Construction Business Operations?

- Is a Block Machine Easy to Operate and Maintain?

- How Does DURABLE Maximize These Block Machine Benefits for You?

- Ready to Reap These Benefits? What’s Your Next Step Towards Success?

- Common Questions About Block Machine Benefits

- Summary and Advice

- Why Choose DURABLE?

What Is a Block Machine and Why Is It Essential for Modern Construction?

A block machine is an industrial device. It manufactures blocks and bricks. These are used in construction. It compacts and molds raw materials. Materials include cement, aggregates, water. This forms uniform, durable building units. These machines are essential for modern construction, producing high-quality, standardized materials at scale. They allow consistent supply. This supports rapid urban development and infrastructure projects.

Block machines contribute to controlled manufacturing environments. This ensures product reliability. They minimize waste. They optimize material usage. Demand for efficient, cost-effective building solutions drives their necessity. These machines enable local material production. This reduces external supplier dependency. This also cuts transportation costs. DURABLE offers a wide range of machines. These include manual, semi-automatic, and fully automatic models. They also offer mobile and fixed options. Machinery development has been a focus for DURABLE. Since 1990, DURABLE has concentrated on advancing block machine technology. This ensures reliable, innovative solutions for the construction industry worldwide.

How Can a Block Machine Significantly Boost Your Profit Margins?

A block machine boosts profit margins. It offers economic advantages. The primary benefit comes from vertical integration. Companies produce their own building materials. This reduces reliance on external suppliers. It eliminates supplier markups. This lowers the cost of goods sold.

Production efficiency is a key factor. Machines operate with high output rates. They minimize labor costs per unit. This leads to higher volume and sales potential.

In-house block manufacturing allows better control over pricing. Businesses can offer competitive prices. They can maintain healthy profit margins.

Flexibility in block types diversifies revenue streams. Interchangeable molds produce hollow blocks, paving stones, etc. This adaptability meets diverse market demands. It expands the customer base.

Waste utilization enhances profitability. Incorporating industrial by-products (fly ash, slag) reduces raw material expenses. This transforms waste into valuable building components.

These factors create a pathway to increased financial returns. You gain supply chain control. You also improve raw material negotiation power. This translates into a healthier bottom line.

What Operational Cost Savings Can You Expect with a Block Machine?

Block machines offer major operational cost savings, significantly boosting a construction business’s financial health.

Material procurement costs are substantially reduced. Direct block production minimizes vendor reliance, allowing for bulk discounts on raw materials like cement and aggregates. Soil-based machines utilize free or low-cost local earth, drastically cutting input expenses.

Transportation costs decrease as manufacturing closer to sites reduces fuel consumption and logistical complexities for heavy blocks. Labor efficiency improves through automation, reducing workers needed per unit and optimizing deployment.

Energy-efficient designs lower utility bills by consuming less power for the same output. High-quality components (e.g., DURABLE’s German Schneider inverters) and proper maintenance extend machine lifespan, cutting repair and replacement costs.

These cumulative savings enhance operational efficiency and profitability. DURABLE’s experience since 1990 ensures machines are designed for maximum operational savings.

How Does a Block Machine Ensure Superior Block Quality and Consistency?

Block machines ensure superior quality and consistency through controlled manufacturing processes. Precision-engineered molds guarantee exact dimensions, resulting in uniform sizes and shapes. This uniformity leads to straighter walls, reduces mortar use, minimizes plastering, and lowers waste and rejection rates.

Compaction and vibration systems are critical. For concrete blocks, high-frequency vibration removes air voids, densifies material, and increases compressive strength. For compressed earth blocks, intense hydraulic pressure ensures optimal compaction, creating a denser, stronger product.

Automated batching systems manage controlled mix designs, maintaining precise ingredient ratios (cement, water, aggregates) crucial for consistent strength and durability. DURABLE machines use quality components like Siemens PLC and advanced sensors for accurate control over these parameters. This precision guarantees blocks meet or exceed strength standards, ensuring long-term structural integrity – a consistency difficult to achieve manually.

What Range of Construction Products Can You Create with a Modern Block Machine?

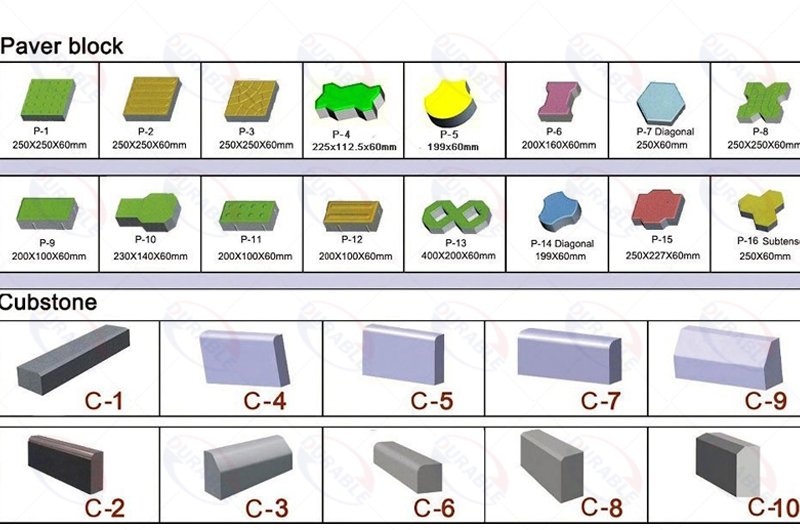

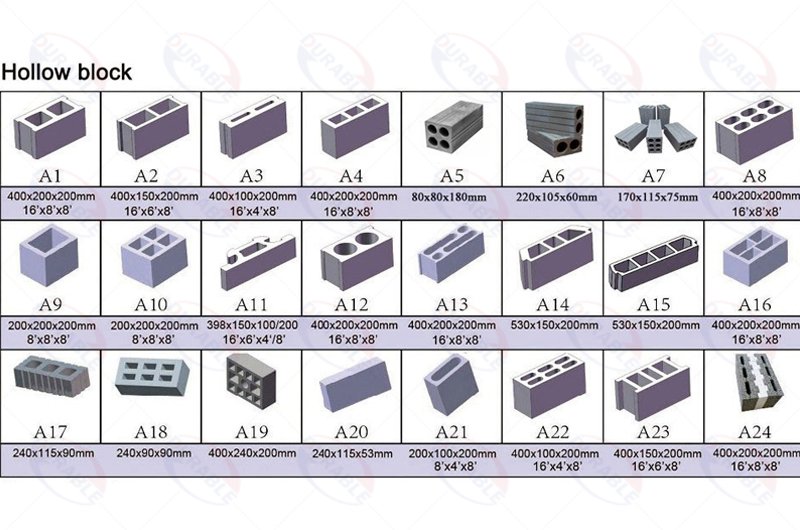

A modern block machine offers a versatile range of construction products. This adaptability is a significant advantage. With interchangeable molds, a single machine can produce numerous items. These items meet varied construction needs. Primary products include:

- Hollow Blocks: These are common for walls. Their cavities provide insulation and reduce weight. This makes them easy to handle.

- Solid Blocks: Used for structural purposes. They provide maximum strength. They are foundational elements for many buildings.

- Paving Stones: These come in various shapes and colors. They are ideal for pathways, driveways, and public spaces. Many paver block machine systems excel at this.

- Interlocking Bricks: These bricks fit together without mortar. They simplify construction. This is a hallmark of an interlocking brick machine. They offer fast building solutions.

- Curb Stones: Essential for road edges and landscaping. They define boundaries and manage water flow.

- Retaining Wall Blocks: Designed for erosion control and terracing. They create stable land contours.

- Flue Blocks: Used in chimney construction. They provide safe channels for exhaust gases.

- Decorative Elements: Some machines can produce blocks with textured or patterned faces. This adds aesthetic value to structures.

This versatility allows businesses to adapt to market demands. It expands their product offerings. It serves diverse client needs. DURABLE block machines are designed for this flexibility. They maximize production capabilities across a wide product spectrum. My company also produces specialized machines, like a clay brick making machine, to serve different material requirements.

How Does a Block Machine Improve Your Production Efficiency and Output?

Block machines significantly improve production efficiency and output through automation, delivering much faster manufacturing cycles than manual methods. They produce thousands (semi-automatic) to tens of thousands (fully automatic) of blocks per shift, accelerating project timelines and boosting ROI. Robust designs and quality components ensure continuous, reliable operation with minimal downtime.

Integrated systems (automated batching, stacking) further streamline the workflow, minimizing manual handling and bottlenecks. Our automatic brick making machine solutions offer these integrated benefits, reflecting our company’s consistent optimization since 1990 for maximized output and efficiency.

How Does Automation in Block Production Optimize Your Workforce?

Automation in block production optimizes the workforce by reassigning physically demanding tasks (mixing, molding, stacking) to machines. This allows personnel to focus on skilled roles like machine operation, quality control, and maintenance.

This shift enhances workplace safety, reducing injury risks, and boosts productivity by achieving higher output with fewer staff, thus lowering labor costs per unit. Training in automated systems also elevates workforce skills, creating more specialized, efficient, and adaptable employees ready to grow with technology.

What Are the Environmental and Sustainability Benefits of Using a Block Machine?

Block machines offer significant environmental and sustainability benefits. Unlike traditional fired bricks, cured concrete and compressed earth blocks (CEB) eliminate energy-intensive firing, drastically reducing GHG emissions and preventing deforestation.

These machines promote the use of local and recycled materials. CEB machines utilize local soil, minimizing transport emissions. Concrete block machines can incorporate industrial waste like fly ash, slag, and crushed debris, diverting waste from landfills and conserving virgin resources. Hollow blocks also provide excellent thermal insulation, reducing building energy consumption.

Our company develops fly ash brick machine technology, enabling clients to transform industrial waste into valuable building materials, contributing to greener construction.

How Does Owning a Block Machine Give You a Competitive Edge in the Market?

Owning a block machine provides a significant competitive edge, enabling cost leadership through lower in-house production costs. This leads to competitive pricing, attracts customers, and increases profit margins.

It grants direct control over the supply chain, minimizing delays and ensuring consistent material flow for smoother projects. Market responsiveness improves, allowing quick adaptation to changing demand and production of specific block types/quantities—a flexibility absent with external suppliers.

Superior consistency and strength of machine-made blocks differentiate quality, building a reputation for reliability and enhancing customer trust. Customization capacity, like unique hollow block machine designs or specialized pavers, opens niche markets and attracts premium clients. These factors collectively solidify a strong market position as a reliable source for quality construction materials.

Can a Block Machine Help Scale Your Construction Business Operations?

A block machine significantly scales construction operations by providing expansion infrastructure and increased production capacity. This enables businesses to tackle larger projects, serve more customers, and enter new markets.

Their versatility allows product diversification across residential, commercial, and infrastructure needs. Automation efficiency handles higher volumes without proportional overhead. Local production further supports geographic expansion by reducing logistics and costs.

Since 1990, our company has witnessed countless businesses grow, utilizing our block machine investments and diverse product range, including full production lines, for seamless scaling.

Is a Block Machine Easy to Operate and Maintain?

Modern block machines offer surprising ease of operation, featuring intuitive PLC control systems (e.g., Siemens technology in DURABLE machines). This simplifies production, allows quick operator training, and uses real-time sensor feedback for smooth, error-free output.

Low maintenance is another key benefit. DURABLE machines, built with high-wear-resistant steel and international components (e.g., Taiwan Kelijia hydraulics, German Schneider inverters), reduce repairs and minimize downtime. Regular, simple checks keep them optimal, making their robust construction and smart design reliable, long-term investments requiring less attention.

How Does DURABLE Maximize These Block Machine Benefits for You?

DURABLE maximizes block machine benefits, leveraging over three decades of expertise since 1990. Its robust, efficient machines use high-wear-resistant steel and renowned international components (e.g., Taiwan Kelijia hydraulics, German Schneider converters), ensuring longevity and minimal downtime.

Offering a comprehensive product line, DURABLE provides ‘one-stop’ full-process solutions from mixing to stacking, simplifying procurement and ensuring seamless integration. Customization is key, with solutions tailored to specific client needs—raw materials, output, and brick sizes. A global presence across 120+ countries ensures deep market understanding and optimization for local conditions.

Full-service support—including design, manufacturing, installation, training, and after-sales maintenance—ensures clients fully realize investment advantages. This holistic approach delivers superior performance, reduces operational costs, and supports sustainable growth. We partner with you every step of the way.

Ready to Reap These Benefits? What’s Your Next Step Towards Success?

Maximizing block machine benefits demands careful planning and a strategic approach. Begin by assessing specific needs: desired production capacity, block types, and available raw materials. An experienced manufacturer like DURABLE can guide your selection process.

DURABLE offers personalized consultations, detailed proposals, and comprehensive quotes for machines and entire production lines, along with installation and training assistance. Investing in a DURABLE machine secures a reliable, high-performance asset, boosting profitability, operational efficiency, and sustainable construction practices. Initiate a consultation for a well-informed decision and successful business growth. Do not hesitate to reach out.

Common Questions About Block Machine Benefits

Question 1: What is the primary benefit of producing blocks in-house?

Primarily, cost reduction. It eliminates supplier markups and reduces transportation expenses, significantly boosting profit margins.

Question 2: Can block machines use recycled materials?

Yes, many modern block machines offer raw material flexibility, incorporating industrial waste like fly ash, slag, and crushed construction debris to promote sustainability.

Question 3: How does a block machine contribute to construction quality?

Block machines produce blocks with precise dimensions and consistent strength. This results in straighter walls, reduced mortar usage, and enhanced structural integrity.

Question 4: Are block machines suitable for small businesses?

Yes, DURABLE offers a range of manual and semi-automatic models suitable for small-scale operations, with built-in scalability for future growth.

Question 5: What kind of support does DURABLE offer after purchase?

DURABLE provides full-service support including installation, commissioning, personnel training, and comprehensive after-sales maintenance, ensuring smooth operation and longevity.

Summary and Advice

Investing in a block machine yields multifaceted economic, operational, and environmental benefits. Companies boost profits by reducing material/transport costs, achieving superior product quality, and expanding market reach through versatile production. It significantly improves production efficiency, optimizes workforce utilization, and enhances environmental sustainability via waste utilization and reduced carbon footprints. This provides a strong competitive edge and supports business scaling.

To maximize these benefits, partnering with an experienced manufacturer is crucial. DURABLE offers high-quality, customizable block machines with comprehensive support, including design, manufacturing, and after-sales service. Careful planning, material analysis, and a commitment to quality are essential for a successful, profitable investment. Assess your needs and choose a partner committed to your success.

Why Choose DURABLE?

Choose DURABLE, a leading Chinese B2B block machine manufacturer with a proven track record. Established in 1990, we offer over three decades of industry expertise. We provide a diverse range of high-quality machines for concrete and clay brick manufacturing, covering the entire production process from raw material handling to stacking.

Our customizable solutions ensure optimal performance for specific client requirements. Quality is paramount, utilizing high-wear-resistant steel and components from top global brands like Siemens, Omron, Taiwan Kelijia, and German Schneider. Factory-direct sales ensure competitive pricing, complemented by full-service support, from design to installation and maintenance.

Exported to over 120 countries, DURABLE’s global reach and successful case studies underscore our reliability and expertise. For tailored solutions and reliable equipment, choose DURABLE. Contact us today for a consultation to build your future with confidence.

Durable Machinery

Durable Machinery