Common Auxiliary Charcoal Equipment & Their Role in Production

Developing an effective charcoal production line requires more than just a carbonization furnace. The furnace acts as the core. However, auxiliary equipment ensures overall efficiency, product quality, and operational sustainability. Many projects fail due to inadequate understanding or incorrect selection of these supporting systems. This article details the critical role of auxiliary charcoal making machine components. It covers their function, value, and impact on a successful efficient charcoal production line.

Table of Contents

- Selecting appropriate auxiliary equipment is critical for charcoal production line efficiency and product quality

- Crushing and drying equipment optimize raw material pretreatment efficiency for various material types

- Conveying and intelligent feeding systems ensure continuous, stable carbonization and reduce labor costs

- Charcoal forming, cooling, and packaging auxiliary equipment enhances product value and market competitiveness

- Environmental auxiliary equipment ensures production compliance in charcoal production lines

- Configuring a customized auxiliary equipment solution based on production scale, raw material characteristics, and final product requirements

- Investing in key auxiliary equipment impacts overall operational costs and economic returns

- Evaluating a supplier’s technical strength, integration capabilities, and long-term service support for auxiliary equipment

- FAQs

- Conclusion

- About Durable

Selecting appropriate auxiliary equipment is critical for charcoal production line efficiency and product quality

Selecting appropriate auxiliary charcoal making machine components significantly influences charcoal production line efficiency and product quality. The carbonization furnace itself is central. However, its performance heavily depends on the upstream and downstream processes. Industry observations indicate that the quality of raw material pretreatment, the consistency of feeding, and the effectiveness of post-processing directly determine the overall success of the operation.

Raw material pretreatment quality dictates carbonization efficiency, product quality limits, and operational cost minimums. Insufficient pre-processing leads to inefficient carbonization, substandard product output, and elevated operational expenses. Furthermore, neglecting the importance of these supporting systems often results in project failures. This highlights the integrated nature of an efficient charcoal production line. Each component, from raw material preparation to final packaging, contributes to the final product’s market competitiveness and profitability. Investing in high-quality charcoal equipment supporting systems ensures consistent performance. It also maximizes the return on investment for the entire production facility. Therefore, a comprehensive approach to equipment selection, extending beyond the core furnace, is essential for achieving optimal results.

Crushing and drying equipment optimize raw material pretreatment efficiency for various material types

Crushing and drying equipment form essential components of raw material pretreatment. These systems effectively optimize efficiency for various material types. Raw material pretreatment quality directly determines the efficiency of the biomass carbonization auxiliary equipment and the quality of the final charcoal product.

Crushing/Shredding Equipment (Crushers/Shredders) plays a vital role. The ideal raw material particle size is crucial for effective carbonization. Oversized particles hinder heat penetration, leading to uneven carbonization and extended cycle times. Conversely, excessively fine particles can cause blockages. They may also impede proper briquetting, if required, and generate substantial dust. Selecting appropriate pulverizers or disc wood chipper depends on the raw material, such as wood, straw, or rice husks. The pulverizer type, whether hammer, blade, or disc, along with screen mesh size, requires careful matching. The durability and design of cutting tools, like wear-resistant alloys and specific blade angles, are critical for equipment longevity and efficiency. Substandard cutting tools lead to frequent replacements and high maintenance costs.

High moisture in carbonization feedstock incurs substantial energy costs; ideal moisture is below 15% (briquettes below 10%). Dryer selection (e.g., sawdust dryer, wood chips dryer, airflow dryer, rotary drum dryer) considers material, initial moisture, output, and heat sources like carbonization waste heat. Efficient drying, despite initial cost, reduces carbonization energy, increases furnace output, and yields quick returns. A hammer mill crusher further prepares materials.

| Pretreatment Task | Equipment Type | Key Benefit | Impact on Carbonization |

|---|---|---|---|

| Particle Size Reduction | Hammer mill crusher, Disc wood chipper | Uniformity, increased surface area | Even carbonization, faster cycles |

| Moisture Removal | Sawdust dryer, Rotary drum dryer | Reduced energy consumption | Higher carbonization efficiency |

| Material Separation | Screening/Sorting | Purity, reduced wear | Better product quality, extended equipment life |

Conveying and intelligent feeding systems ensure continuous, stable carbonization and reduce labor costs

Efficient material conveying and intelligent feeding systems represent the circulatory and nervous systems of a charcoal production line. These systems ensure continuous, stable operation of carbonization equipment. They also significantly reduce manual labor costs. Without these systems, even the most advanced carbonization furnace struggles to achieve optimal performance.

The primary function of these systems is to provide uniform feeding. Carbonization furnaces require a consistent supply of raw material to maintain stable internal temperatures and uniform reaction rates. Inconsistent feeding leads to incomplete carbonization or localized overheating. This compromises product quality and efficiency. Automated conveyors, such as belt conveyor or screw conveyor, reduce manual labor. They minimize human intervention. They also enhance safety, especially in high-temperature or dusty environments. Conveying systems are tailored to the specific characteristics of the material. This includes viscosity, particle size, and temperature. Material with high dust content requires sealed conveying systems. High-temperature materials necessitate heat-resistant conveyor belts. Variable frequency drive (VFD) controlled feeders enable precise material flow regulation.

Despite their seemingly low cost, conveyor system failures result in substantial production line downtime and financial losses. Therefore, investing in reliable and easy-to-maintain conveying equipment is crucial for long-term operational stability. These integrated systems contribute directly to the efficiency and cost-effectiveness of the entire efficient charcoal production line. They ensure a seamless transition of raw materials through different processing stages. This optimizes overall throughput and labor utilization.

Charcoal forming, cooling, and packaging auxiliary equipment enhances product value and market competitiveness

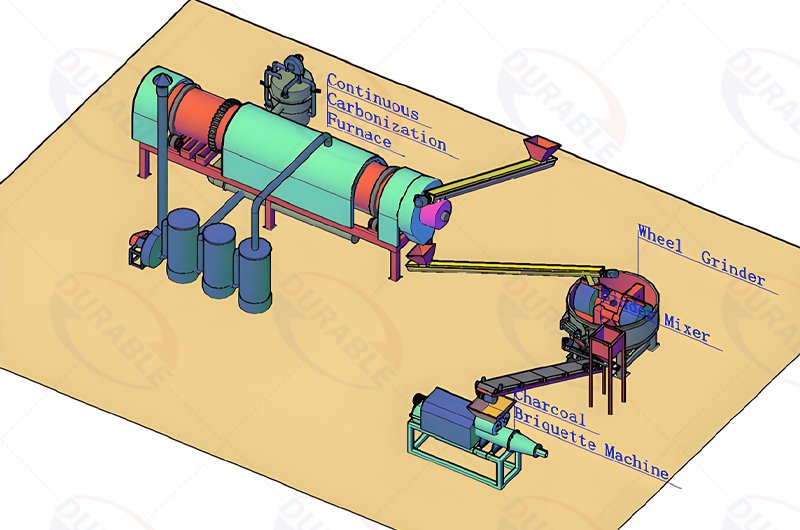

Auxiliary equipment for forming, cooling, and packaging transforms basic charcoal into high-value, market-ready products, boosting competitiveness.

The forming stage, using a biomass briquette machine, pellet making machine, or charcoal coal ball press machine, densifies loose biomass. This standardization adds value and aids efficient carbonization. Briquette/Pelletizing Equipment increases raw material density for consistent carbonization; mechanized charcoal sells for higher prices due to superior density, fixed carbon, longer burn time, and lower ash. Critical elements include mold quality (wear resistance), heating, and pressure control. Molds and screw propellers are wear parts; their quality and maintenance impact costs.

Finished Product Cooling and Sorting Packaging is crucial; precise handling enhances value, quality, and market competitiveness.

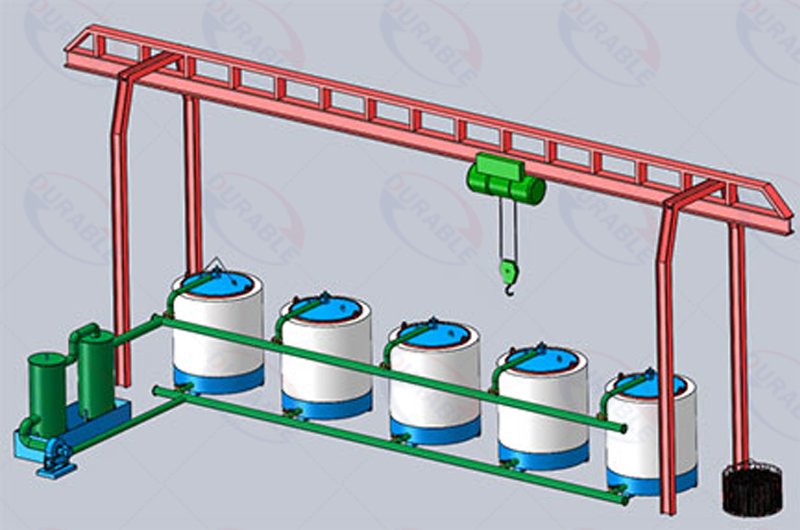

Cooling Equipment (Cooling Systems) is vital. Rapid, uniform cooling (e.g., water/air-cooled systems, dedicated tanks) prevents re-ignition, breakage, oxidation, and spontaneous combustion, ensuring safety, hardness, and extended shelf life.

Screening and Grading Equipment, like a vibrating screen, categorizes charcoal by size for diverse applications (e.g., BBQ, industrial) and pricing, maximizing value and minimizing waste.

Packaging Equipment (Packaging Machines) provides product protection, brand image, and competitiveness. Moisture-proof, attractive packaging significantly boosts prices. Automated weighing and packaging enhance efficiency and precision, crucial for an efficient production line.

| Post-Processing Stage | Auxiliary Equipment | Key Benefit | Impact on Product |

|---|---|---|---|

| Forming | Biomass briquette machine | Standardized shape, increased density | Higher market value, consistent burn |

| Cooling | Charcoal cooling machine | Prevents re-ignition, maintains hardness | Safer storage, reduced breakage |

| Grading | Vibrating screen | Categorization by size | Diversified sales, optimized value |

| Packaging | Packaging machine | Brand image, protection | Increased sale price, extended shelf life |

Environmental auxiliary equipment ensures production compliance in charcoal production lines

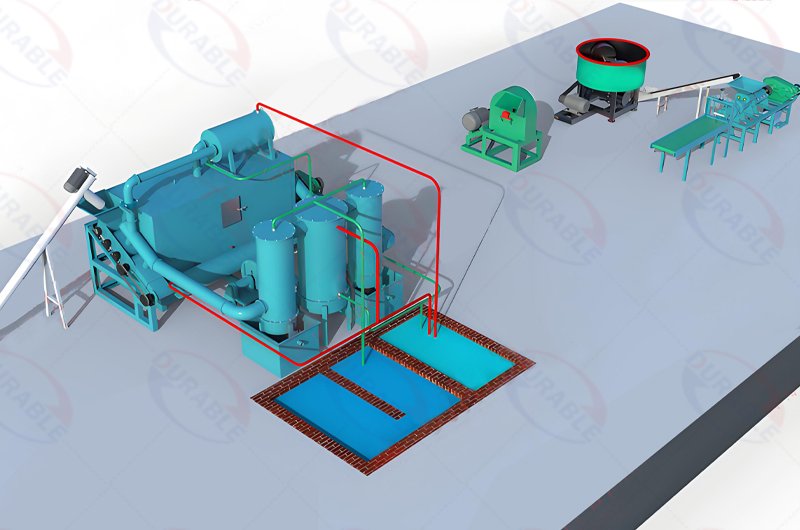

Environmental auxiliary equipment (dust removal, waste gas treatment) is critical for charcoal production compliance, though often overlooked. Carbonization flue gas is a valuable energy/chemical resource; professional purification and recovery systems are essential for sustainable projects.

Flue Gas Purification Systems (Smoke Purification System), including cyclone dust collectors, water scrubbers, and tar separators, remove dust, tar, and acidic gases to meet emission standards. Tar separator design directly impacts wood vinegar/tar quality and recovery. Equipment selection must strictly adhere to local environmental regulations.

Waste Heat Recovery Systems recycle purified high-temperature flue gas to heat dryers (creating an energy closed loop), produce hot water/steam, or fuel other equipment. Despite higher initial investment, they significantly reduce energy/fuel costs, optimizing production towards “zero/negative energy consumption.” This ensures compliance and minimizes the ecological footprint.

Configuring a customized auxiliary equipment solution based on production scale, raw material characteristics, and final product requirements

Configuring a customized auxiliary charcoal making machine solution requires careful consideration. Production scale, raw material characteristics, and final product requirements all influence the selection process. A tailored approach ensures maximum efficiency and profitability for the efficient charcoal production line.

First, assess the production scale. Small-scale operations may benefit from batch-type drying and carbonization. Larger industrial facilities require continuous and highly automated systems. This influences the capacity and type of all auxiliary equipment, from crushing and drying to conveying and packaging. Next, analyze raw material characteristics. Different biomass types, such as wood logs, sawdust, rice husks, or agricultural stalks, have varying properties. These properties include moisture content, density, and chemical composition. For instance, high-moisture materials necessitate more robust drying solutions, like a large-capacity rotary drum dryer. Fibrous materials might require a hammer mill crusher for optimal particle size.

Finally, define the final product requirements. Is the goal to produce high-density briquettes, fine charcoal powder, or biochar for soil amendment? This choice impacts the need for briquetting machines like a biomass briquette machine or specific grinding and packaging equipment. A customized charcoal production solution considers all these factors. It integrates individual auxiliary units into a cohesive and optimized system. This comprehensive planning ensures that each component supports the overall efficiency and objective of the production line. It minimizes bottlenecks and maximizes throughput.

Investing in key auxiliary equipment impacts overall operational costs and economic returns

Investing in key auxiliary charcoal making machine components significantly impacts the overall operational costs and expected economic returns of a charcoal production project. While these investments add to the initial capital outlay, they yield substantial long-term benefits that far outweigh the upfront expense. A proper understanding of the charcoal equipment ROI is crucial.

High-quality auxiliary equipment directly contributes to charcoal production cost optimization. For instance, efficient drying equipment, like a sawdust dryer, reduces the energy consumed during carbonization by lowering the moisture content of raw materials. This directly translates to lower fuel costs. Automated conveying and feeding systems decrease labor requirements. They also minimize human error, leading to more consistent production and fewer operational disruptions. Furthermore, robust crushing equipment, such as a hammer mill crusher, ensures optimal particle size. This improves carbonization efficiency and reduces wear and tear on subsequent machinery.

Economic returns are enhanced through improved efficiency (higher throughput/yield) and enhanced product quality (e.g., well-formed briquettes from a biomass briquette machine command premium prices). Environmental auxiliary equipment (like waste gas treatment) ensures regulatory compliance, avoiding fines and improving corporate image. Waste heat recovery systems provide free energy, creating additional cost savings. Strategic investment in these crucial auxiliary components drives down operational costs, maximizes profitability, and significantly contributes to an efficient charcoal production line.

| Investment in Auxiliary Equipment | Impact on Operational Costs | Impact on Economic Returns |

|---|---|---|

| Efficient Drying | Reduced fuel consumption | Higher carbonization yield |

| Automated Conveying & Feeding | Lower labor costs | Increased throughput, less error |

| Quality Crushing | Less wear on machinery | Improved carbonization, consistent quality |

| Forming & Packaging | Reduced waste | Higher product value, broader market |

| Environmental Systems | Avoided fines, energy savings | Regulatory compliance, positive image |

Evaluating a supplier’s technical strength, integration capabilities, and long-term service support for auxiliary equipment

Selecting auxiliary charcoal making machine suppliers demands evaluating technical strength, integration capabilities, and long-term service support, not just price. A reliable supplier acts as a partner for an efficient charcoal production line.

Technical strength signifies deep understanding of carbonization science and engineering. Experienced engineers design efficient, safe equipment, demonstrating expertise in supporting systems and raw material pretreatment (crushing, drying). This knowledge allows for optimization strategies to achieve specific charcoal properties and custom solutions for different raw materials and product goals.

Integration capabilities involve seamlessly connecting all auxiliary components with the main carbonization furnace, ensuring machine compatibility and functional central control. This integrated approach minimizes operational bottlenecks and maximizes overall system efficiency, avoiding issues from incompatible standalone machines.

Long-term service support is vital post-purchase. This includes installation, commissioning, training, readily available spare parts, and prompt technical assistance for troubleshooting or upgrades. Such support ensures consistent equipment performance, minimizes downtime, and maximizes investment. Opting for a low-cost supplier with weak support often leads to breakdowns, poor product quality, and high maintenance, negating any initial savings. Prioritize comprehensive capabilities for a successful and sustainable charcoal production project.

FAQs

Question 1: Why is selecting appropriate auxiliary equipment critical for charcoal production line efficiency and product quality?

Auxiliary equipment critically impacts raw material preparation, carbonization efficiency, and product quality, making its selection crucial for production line efficiency and profitability.

Question 2: How do crushing equipment (e.g., wood chippers, hammer mills) and drying equipment (e.g., airflow dryers, rotary drum dryers) optimize raw material pretreatment efficiency for various material types?

Crushing achieves uniform particle size; drying reduces moisture. Both optimize heat penetration, carbonization uniformity, and energy efficiency for diverse raw materials.

Question 3: What role do environmental auxiliary equipment, such as dust removal and waste gas treatment systems, play in a charcoal production line, and how do they ensure production compliance?

Environmental equipment removes flue gas pollutants and recovers waste heat, ensuring emission compliance, minimizing environmental impact, and saving energy.

Question 4: What specific impact does investing in these key auxiliary equipment have on the overall operational costs and expected economic returns of a charcoal production project?

Strategic investment reduces fuel, labor, and maintenance costs while increasing product yield and quality, thereby leading to higher revenue and better ROI.

Question 5: When selecting a supplier for charcoal production line auxiliary equipment, what aspects of their technical strength, integration capabilities, and long-term service support should be critically evaluated?

Evaluate the supplier’s engineering expertise (design, customization), seamless component integration, and commitment to reliable post-sales support and spare parts.

Conclusion

Developing an effective charcoal production line requires strategic investment beyond the carbonization furnace, encompassing a full suite of auxiliary charcoal making machine components. These systems—from raw material pretreatment, conveying, and forming (e.g., a biomass briquette machine) to cooling, packaging, and environmental controls—collectively determine efficiency, product quality, and profitability. Optimal crushing/drying, integrated conveying, value-adding forming, and environmental compliance/energy recovery are key. Careful component configuration, based on specific production needs, raw materials, and final product requirements, is vital. Selecting a supplier with proven technical strength, integration capabilities, and robust service support is also paramount. This comprehensive approach ensures an efficient charcoal production line, maximizing economic returns while adhering to environmental standards.

About Durable

Durable Machine, established in 2001, is a prominent Chinese manufacturer. It specializes in mineral processing equipment and construction machinery. Durable also applies its industrial process knowledge to biomass energy equipment. Durable designs and constructs complete, integrated biomass fuel production lines. The company focuses on briquette machines and carbonization solutions. Its solutions prioritize efficiency, reliability, and environmental responsibility. Durable’s team collaborates closely with clients. It designs systems to match specific biomass types, production needs, and business goals. From initial consultations and plant design to custom equipment manufacturing, installation support, operator training, and comprehensive after-sales service, Durable ensures successful outcomes for its investments.

For expert advice and a custom plan for your efficient charcoal production line or horizontal charcoal carbonization furnace project, contact Durable’s engineering team today.

Durable Machinery

Durable Machinery