Search the whole station liberty-fse

M7MI Hydraform Diesel Interlocking Brick Machine

Capacity:1-2 pieces per mould; 2500-5000 pieces per 8 hours

Power Type: Diesel Engine/Electric Motor

Workers Needed: 2-4 persons

Forming Cycle:15-20 seconds

Brick Size: Different sizes and shapes including interlocking bricks, lego bricks, etc..

Application: Rural housing projects; Construction in remote areas; Small-scale brick production businesses; Areas where clay is readily available

Introduction: M7MI Mobile clay brick machine is a portable, self-contained machine for producing clay bricks on-site. “Mobile” refers to its ability to be easily moved to different locations.

DM2-40 Manual Simple Interlocking Brick Machine

Capacity:1-2 pieces per mould; 900-1400 pieces per 8 hours

Power Type: manual

Workers Needed: 1-2 persons

Forming Cycle:40-50 seconds

Brick Size: Different sizes and shapes including interlocking bricks, lego bricks, etc..

Application: Small-scale construction projects; Home building in rural areas; Self-building projects;

Introduction:DM2-40 is a simple, manually operated machine for producing clay bricks. It is suitable for home use. This machine is cheaper than semi-automatic or automatic brick machines.Does not need electricity or fuel to operate. And it is easy to learn.

ECOBRB Small Electric Interlocking Brick Machine

Capacity:1-2 pieces per mould; 1900-3900 pieces per 8 hours.

Power Type: Diesel Engine/Electric Motor

Workers Needed: 1-2 persons

Forming Cycle: 20-25 seconds

Brick Size: Different sizes and shapes including interlocking bricks, lego bricks, etc..

Application: Residential Construction; Housing Projects;Self-Build Projects;community buildings;Infrastructure Projects

Introduction:The ECOBRB is a Semi-Automatic Clay Brick Maker. It is used for making compressed earth bricks. This brick making machine for sale can apply cement, clay as raw material. ECOBRB is a good choice for personal brick projects, small brick factory.

DM2-10 Automatic Interlocking Brick Machine Line for Sale

Capacity:2 pieces per mould;6500-7500 pieces per 8 hours

Power Type: Electric Motor

Workers Needed: 3-5 persons

Forming Cycle:10 seconds

Brick Size: Different sizes and shapes including interlocking bricks, lego bricks, etc..

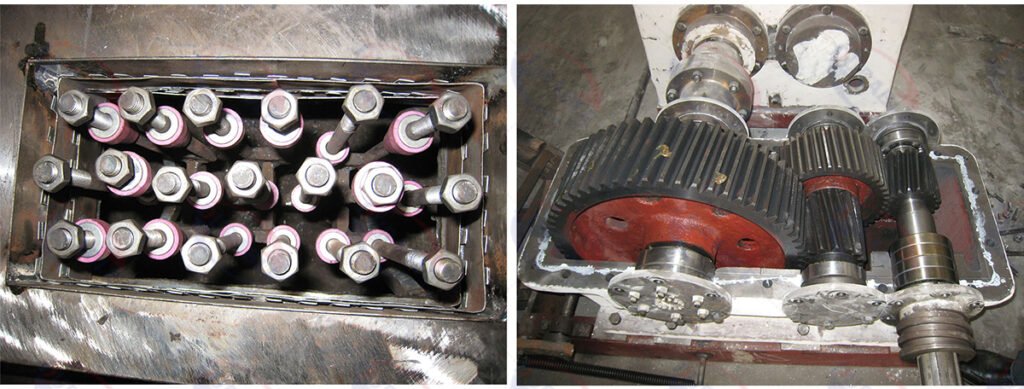

Components: Crusher+Screener+Beltconveyor+Mixer+DM2-10 Host Machine(with control system and motor etc..)

Introduction: DM2-10 is a fully automatic clay bricks machine line. It produces bricks by hydraulic pressure. so the interlocking bricks it makes are strong. And it is a automatic brick maker, only need workers to control machine. It saves much labors with high-effiency. DM2-10 is suitable for small-medium block factory.

Are you considering investing in an interlocking brick machine? This guide helps you understand what they are, their benefits, and what to consider before investing in one, and to see if it is the correct choice for your construction business.

Interlocking bricks are building materials designed to fit together without mortar. So their popularity stems from faster construction, reduced costs, and enhanced structural stability. It is like giant lego bricks.

These bricks have unique shapes that lock together, creating a strong, stable structure. This design reduces the need for cement, saving time and money. As an expert, Durable Machine has seen a rise in their use. “You” might see them used in low-cost housing to large commercial buildings. Durable Machine has different types block making machines which can produce interlocking bricks including mobile bricks machine(M7MI etc.), manual bricks machine(DM2-40etc.),and fully automatic block machine line.

Interlocking bricks come in various shapes and sizes, each suited for different applications.And Common types include dry-stack, soil-cement, and concrete interlocking bricks, and these can be used for walls, paving, and foundations.

Knowing the different types helps you choose the best one for your project. Durable Machine’s brick machines can produce a variety of interlocking brick types. This ensures you have the flexibility to meet diverse construction needs.

Interlocking bricks offer several advantages over traditional bricks. These include faster construction, reduced material costs, improved structural integrity, and environmental benefits.

These advantages make them a smart choice for modern construction.

When selecting an interlocking brick machine, focus on durability, mold design, production capacity, and ease of use. A robust machine with quality molds and high production output ensures long-term efficiency.

DURABLE MACHINE prioritizes these features. Our machines use high-quality steel and user-friendly interfaces. DURABLE MACHINE uses high-strength steel as raw material, and parts from Siemens, Schneider, Emerson, and other famous brand. Machine quality is realiable.

Your required production capacity depends on the scale and timeline of your project. So Calculate the number of bricks needed per day to determine the appropriate machine capacity.

Choose a machine that can meet your production demands efficiently. DURABLE MACHINE offers machines with various production capacities. You can meet the needs of any size project. We have manual machine for new start and small business, semi-automatic brick machine for medium business and brick factory, automatic production line for large brick project or big brick factory.

Interlocking brick machines can use a variety of materials, making them versatile. Common materials include soil, cement, sand, and clay, allowing for the use of local resources.

Choose a machine that can handle the materials available in your area. DURABLE MACHINE’s machines are designed to work with many materials. You can optimize your production process.

An interlocking brick machine operates through a series of steps. These include mixing materials, feeding the mixture into molds, compacting, and ejecting the finished bricks.

Understanding this process helps you operate the machine effectively.

The ideal site setup ensures efficient operation. This includes a level surface, access to water and electricity, and storage space for materials and finished bricks.

A well-organized site improves productivity and safety.

The cost of an interlocking brick machine varies significantly based on several factors. These factors include the level of automation, production capacity, and the specific features of the machine. Understanding these costs can help you determine the potential Return on Investment (ROI) for your project.

As DURABLE MACHINE offers a wide range of machines, we are confident that we can find the correct solution.Consider your budget, production needs, and labor costs when making your decision. DURABLE MACHINE can provide detailed cost breakdowns and ROI projections to help you make the best choice for your business.

Regular maintenance is essential for the machine. Maintenance includes cleaning, lubrication, and replacing worn parts to ensure long-term performance.

Proper maintenance extends the life of your machine. DURABLE MACHINE offers maintenance support and spare parts.

Common problems include mold misalignment, material blockages, and hydraulic issues. Troubleshooting involves regular inspections, proper cleaning, and timely repairs.

Knowing how to troubleshoot issues minimizes downtime.

Labor requirements depend on the machine’s automation level. Manual machines require more labor, while automatic machines need fewer operators but skilled technicians.

Consider your available workforce. Then, choose the appropriate machine. DURABLE MACHINE offers machines for different labor capabilities.

The current market trends include increased demand for sustainable building materials, the use of recycled materials, and automation. These trends drive innovation and efficiency in interlocking brick production.

Stay updated with these trends to stay competitive.

Choosing an interlocking brick machine means investing in quality, reliability, and support. Many factors need to be considered.

Our machines are designed for durability, efficiency, and ease of use, backed by our expert service.

Project Details:

Future innovations include smart brick technology, the use of advanced materials, and improved machine automation. These advancements will further enhance the efficiency and sustainability of interlocking brick construction.

Investing in an interlocking brick machine can be a smart decision. Consider the benefits, key features, and market trends. DURABLE MACHINE offers high-quality machines and expert support to help you succeed.

Assess your needs. Then, choose the right machine. DURABLE MACHINE is here to help you build a more efficient and sustainable construction business. Contact us today for a free quote and consultation!