Search the whole station liberty-fse

QMJ2-40 Mobile Simple Hollow Block Machine

Capacity:2 pieces per mould; 1440 pieces per 8 hours

Power Type: Diesel Engine/Electric Motor

Workers Needed: 1-2 persons

Forming Cycle:40-45 seconds

Moulding Method: Mechanical Vibration Molding

Brick Size: Different sizes and shapes including 4inch,6inch,8inch hollow blocks, solid bricks.

Strength: Low Investment and High Efficiency; easy to operate; durable in use;easy to move; no need any pallets.

Introduction: QMJ2-40 is a mobile block machine. It can use electric power or diesel power according to your conditions. QMJ2-40 brick machine needs less investment but forming cycle is short, so it is an ideal choice for small-sized block factory or home use.

QMY6-25 Automatic Mobile Hollow Block Machine

Capacity:6-9 pieces per mould; about 9000-10000 pieces per 8 hours

Power Type: Electric Motor

Workers Needed: 2-3 persons

Forming Cycle:25-30 seconds

Moulding Method: Mechanical Vibration Molding & Hydraulic Pressure

Brick Size: Different sizes and shapes including 4.5inch, 4inch, 6inch, 8inch, 10inch hollow blocks, solid bricks, colorful pavers, kerbstone.

Strength: High-quality bricks with high-density; move easily; Low-cost without needing pallets; can use different raw materials including Sand, Cement, Fly Ash, Concrete, Boiler Slag, Mountain Flour, Industrial Waste.

Introduction: QMY6-25 is also called QMY6A egg laying block machine.As a semi-automatic brick machine, it can save much labors with higher capacity. And this hydraulic block machine cao also produce pavers like I shape, H shape, Z shape, and cerbstone. QMY6A is suitable for small-medium block factory or on-site block projects.

DM4-40 Manual Cement Hollow Block Machine

Capacity:4-14 pieces per mould;2200-6800 pieces per 8 hours

Power Type: Electric Motor

Workers Needed: 2-3 persons

Forming Cycle:35-40 seconds

Moulding Method: Mechanical Vibration Molding

Brick Size: Different sizes and shapes including 4′, 5′, 6′ 9inch hollow blocks, solid bricks, colorful pavers, kerbstone.

Strength: Small Manual machine with cheap price; strong vibration when making blocks; Precise dimensions and excellent quality.

Introduction: DM4-40 is also known as QT4-40. It is used for concrete bricks making. This machine is easy to operate and maintain. With High ROI, short turnaround time, DM4-40 is suitable for new investors for this industry, small block business.

DM4-24 Small Concrete Hollow Block Machine Line

Capacity: 4-14 pieces per drop, 3200-12000 pieces per 8 hours

Power Type: Electric Motor

Workers Needed: 2-3 persons

Forming Cycle: 20-25 seconds

Brick Size: Different sizes and shapes including 400*200*200mm;400*150*200mm;400*100*200mm hollow blocks, solid bricks, I Shape,H Shape,Z Shape paver & curbstone.

Components: 350Pan Mixer+ Beltconveyor+DM4-24 block machine(including control system, block transfer system etc..)

Strength:High-quality block machine with super-strength steel; finished blocks is with good-quality; semi-automatic block machine with less labor.

Introduction: As a cement block machine, DM4-24 takes wire-cut technology, heat-treatment technology, so the block mould is durale.And size accuracy is good. It is suitable for small-scale block factory.

QT4-16 Hydraulic Hollow Block Machine for Sale

Capacity: 4-28 pieces per drop, 7680-53760 pieces per 8 hours

Power Type: Electric Motor

Forming Cycle: 15-20 seconds

Brick Size: Different sizes and shapes including 400*200*200mm;400*150*200mm;400*100*200mm hollow blocks, solid bricks, I Shape,H Shape,Z Shape colorful paver & curbstone.

Components: 500Pan Mixer+ Beltconveyor+DM4-16 block machine(including PLC Control system, pallet feeding, hydraulic station, block transfer system etc..)

Introduction: QT4-16 Concrete Block Making Machine Production Line is a versatile, high-capacity solution for producing diverse concrete blocks and pavers. Hydraulic power and vibration compaction ensure superior strength and quality. Equipped with PLC control, it offers automated, cost-effective production with easy operation and low maintenance, making it an ideal choice for businesses seeking high value and efficiency.

QT6-15 Automatic Hollow Block Machine Line

Capacity: 6-33 pieces per drop, 11520-63360 pieces per 8 hours

Power Type: Electric Motor

Forming Cycle:15-20 seconds

Brick Size: Different sizes and shapes including 400*200*200mm;400*150*200mm;400*100*200mm hollow blocks, solid bricks, I Shape,H Shape,Z Shape paver & curbstone.

Components: JS500 Mixer+ Beltconveyor+QT6-15 block machine(including PLC Control Cabinet, Pallet feeder, Hydraulic station, etc..)

Introduction: The QT6-15 Concrete Block Making Machine Production Line is a high-capacity, fully automatic block machine ideal for medium to large-scale building material enterprises. Utilizing advanced hydraulic and vibration compaction technology, it produces concrete bricks—including hollow blocks, solid bricks, pavers, and curbstones. Its PLC control system ensures efficient, labor-saving operation, offering exceptional output, durability, and versatility for concrete products manufacturing.

Are you looking to improve your block production process? You need efficient, cost-effective, and high-quality hollow blocks. With over 30 years of experience in the block machine industry, DURABLE MACHINE is your reliable partner. This guide will explore the key aspects of hollow block machines. We’ll give you all the insights you need to make informed decisions. Let’s get started!

Last Updated: June 2025 | Estimated Reading Time: 12 minutes

Hollow blocks, also known as concrete blocks, are widely used in construction. They offer structural support while reducing the amount of concrete needed, making them cost-effective. Hollow bricks are generally used for building walls, fences, and other structures, offering insulation and strength.

Standard hollow block sizes vary, but commonly include 4-inch, 6-inch, and 8-inch widths, with lengths of 16 inches and heights of 8 inches. Knowing your project’s requirements will help determine the most appropriate block size for your needs.

A hollow block machine is equipment that forms hollow blocks from a mixture of cement, aggregates, and water. Different types cater to different production scales and budgets, including automatic, manual, and mobile options.

Knowing the different types helps you choose the best one for your project. Durable Machine’s brick machines can produce a variety of interlocking brick types. This ensures you have the flexibility to meet diverse construction needs.

The right production capacity depends on the scale and demands of your project. Consider the number of blocks needed daily or weekly to meet construction timelines.

Small projects may only require a manual machine with a lower capacity. Larger projects will benefit from an automatic machine capable of producing thousands of blocks per day. Estimating your needs accurately prevents bottlenecks and ensures timely project completion.

Key components of a hollow brick machine include:

Hollow blocks can be made from a variety of materials, including:

Choose a machine that can handle the materials available in your area. DURABLE MACHINE’s machines are designed to work with many materials. You can optimize your production process.

Using a hollow block machine offers several advantages:

DURABLE MACHINE helps you learn the advantages and guides you to choose a best hollow brick maker for your project.

The operation of a hollow block machine involves several steps:

Knowing this process is helpful when you start up your machine.

The price of a hollow block machine varies widely. Factors include the type of machine (manual, semi-automatic, or fully automatic), production capacity, and brand.

Manual machines typically range from $1,000 to $5,000. Automatic machines can cost between $10,000 and $100,000 or more. Consider your budget and required output.

As DURABLE MACHINE offers a wide range of machines, we are confident that we can find the correct solution.Consider your budget, production needs, and labor costs when making your decision. DURABLE MACHINE can provide detailed cost breakdowns and ROI projections to help you make the best choice for your business.

Starting a hollow block factory involves several costs:

Estimating these costs carefully will help you secure funding and plan effectively.

Regular maintenance is essential. This ensures smooth operation and prolongs the lifespan of the machine.

Knowing how to troubleshoot issues minimizes downtime. DURABLE MACHINE provides traning for workers, and we will give quick respond if your machine is broken to reduce your loss.

Before starting a cement hollow blocks business, prepare the following:

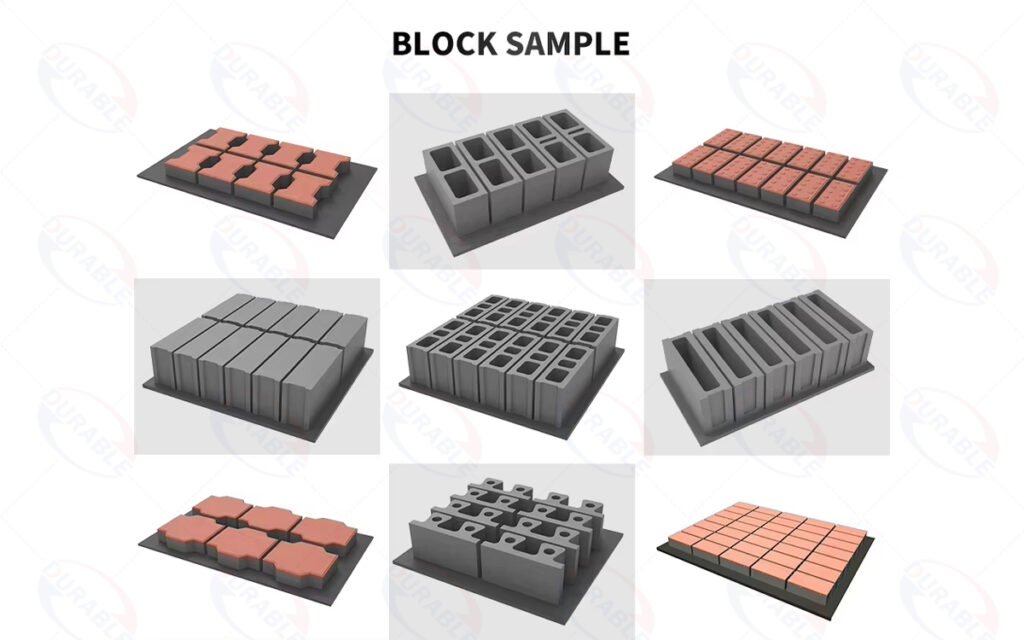

Different mold options allow “you” to produce various block sizes and shapes. Standard molds produce rectangular blocks. Specialized molds create interlocking, decorative, or custom-designed blocks.

The available sizes typically includes:4inch hollow blocks, 6inch hollow blocks, 8inch hollow blocks, 4inch solid bricks, 6inch solid bricks, 8inch solid bricks in width, kerbstone, paver bricks.Choosing the right mold allows you to meet diverse customer demands.

Choosing a hollow block machine means investing in quality, reliability, and support. Many factors need to be considered.

Our machines are designed for durability, efficiency, and ease of use, backed by our expert service.

Look for certifications and standards that indicate quality and safety. Common certifications include ISO 9001 (Quality Management), CE (European Conformity), and other regional standards.

These certifications ensure the machine meets international benchmarks for performance and safety.

DURABLE MACHINE has over 30 years of experience in the block machine industry. Durable Machine offers high-quality, reliable, and cost-effective solutions. Our machines are designed to maximize efficiency and minimize downtime. We provide excellent after-sales support, ensuring your satisfaction.

Durable Machine offers a range of machines, from manual to fully automatic, to meet diverse needs. DURABLE MACHINE is your trusted partner.

Getting a quote and consultation from DURABLE MACHINE is easy. Visit our website or contact our sales team directly.

We’ll assess your needs and provide a customized solution. A detailed quote can be expected. Expert advice can help you make an informed decision.

The purchase process with DURABLE MACHINE involves these steps:

Project Details:

The future of hollow block technology is evolving. Focus is on automation, sustainable materials, and smart features.

Some innovations include:

Investing in a hollow block machine is a strategic move. It allows you to improve efficiency, reduce costs, and produce high-quality blocks. DURABLE MACHINE is here to guide you every step of the way.

Contact us today to learn more about our products and services. You can transform your block production process.