Search the whole station liberty-fse

QMY6A Mobile Electric Paver Block Machine

Capacity:9000-12000 pieces per 8 hours according to your brick size

Power: 9.6KW

Pallet Size: No need Pallet

Block size: Hollow blocks, Solid bricks, Paver blocks

Introduction:

The QMY6A Egg Laying Block Machine offers an efficient, pallet-free solution for concrete block production, excelling as a Paver blocks machine. Its unique mobile design allows direct ground production, significantly reducing costs and investment.

This versatile machine produces various concrete products, including hollow, solid, interlocking, and especially high-quality paver blocks. An efficient vibration system ensures dense, durable blocks.

DM4-40 Small Concrete Paver Block Machine

Capacity: 9-14 pieces per mould; 4500-7000 pieces per 8 hours(capacity is still depends on your brick size)

Power: 9.3KW

Pallet size: 850*450*22mm

Moulding Method: Vibration moulding

Introduction:

DM4-40 is a Manual Concrete Block Machine. It is best choice for an affordable paver brick project.With cheap price and high efficiency, DM4-40 is good for paver brick machine applications and general concrete block production. Its compact design ensures maximum output with minimal space requirements.

This brick machine easily produces paver bricks of all shapes and sizes by exchanging molds. A robust electric vibration system guarantees high-quality, dense blocks for all your construction needs.This machine is manually operated by just 2-3 workers.DM4-40 is easy to operate and maintain, ensuring quick returns on your investment.

QT4-16 Automatic Cement Paver Brick Machine Line

Capacity: 7-28 pieces per mould; 9000-30000 pieces per 8 hours (capacity is still depends on your brick size)

Power: 19KW

Forming Cycle:15-18 Seconds

Pallet Size:850*550*22mm

Introduction:

The QT4-16 is DURABLE’s automatic paver brick machine, designed for medium-scale to large-scale brick factory.

Driven by advanced German technology, this electric paver block making machine is robust and durable. Simply by changing molds, it effortlessly produces different cement blocks, including I shape,Z shape paver bricks and standard blocks, ensuring consistent, high-quality output.

If your enterprise demands a powerful, reliable, and versatile paver brick machine that combines cutting-edge performance with long-term operational resilience QT4-16 is the ultimate solution for high-volume concrete blocks.

ECOBRB Compressed Earth Paver Brick Machine

Capacity: 2 pieces per mould; 3840 pieces per 8 hours

Power: Electric motor:5.5KW; Diesel engine:6Hp

Raw Material: Clay, soil, earth, cement, sand ,water. etc.

Weight: 450KGS

Pallet Size: No need pallet

Introduction:

The ECO BRB is a powerful interlocking paver brick machine engineered for efficient clay brick production. Larger and more productive than ECO Brava, this versatile paver brick making machine easily produces various block types by changing molds. It’s also highly flexible with different clay raw materials.

Built with high-strength structural steel and special welding, the ECO BRB guarantees exceptional durability for long-term reliable performance.

M7MI Mobile Clay Paver Block Machine

Capacity: 1-2 pieces per mould; 2400-4800 pieces per 8 hours (customize according to your brick size)

Power:Disel engine:12HP

Forming Cycle: 15-20 Seconds

Brick Size: different soil Lego bricks, interlocking bricks, paver bricks etc..

Introduction:

As a mobile clay brick machine, M7MI Interlocking Paver Making Machine is renowned for its exceptional mobility and robust performance.It’s engineered with attached wheels, allowing for effortless move among the construction sites. This enhances operational flexibility.

Operating independently on diesel power, the M7MI paver brick machine is suitable for remote locations without electricity. It comes with an integrated mixer and a powerful 16MPa hydraulic pressure system. This machine consistently produces high-quality interlocking clay blocks, ensuring durability and precision for your paving and construction needs.

DM4-10 Soil Automatic Paver Block Machine Line

Capacity:4 pieces per mould; 11520 pieces per 8 hours

Forming Cycle: Less than 10 Seconds

Brick Size: different clay Lego bricks, interlocking bricks, paver bricks etc..

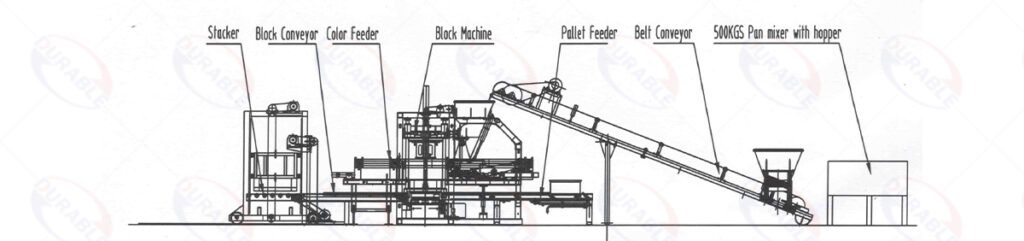

Components:500 Pan Mixer+Beltconveyor+LT4-10 host machine

Introduction:

The DM4-10 is an automatic clay paver brick machine. It is High-efficient in producing high-quality interlocking earth blocks.Its robust design integrates essential components such as a mixer, screen, conveyor belt, and a powerful Siemens motor.

DM4-10 paver brick machine with hydraulic high-pressure produces durable, high-density blocks, ideal for various paving and construction applications. Also recognized as a compressed earth block machine, the DM4-10 is manufactured by DURABLE, a trusted leader in the industry.

Are you looking to improve your paver block production process? You need efficient, cost-effective, and high-quality pavers to meet growing demand. With years of experience in the paver block machine industry, DURABLE MACHINE is your reliable partner. Let’s explore the key aspects of paver block machines. You will get useful information to make informed decisions that can significantly boost your business.

Last Updated: June 2025 | Estimated Reading Time: 15 minutes

Paver blocks, also known as paving stones, are solid, pre-cast concrete or clay units. These are commonly used for creating durable and aesthetically pleasing surfaces for walkways, driveways, patios, and roadways. They come in various shapes, sizes, colors, and textures. Paver blocks offer an attractive alternative to traditional asphalt or poured concrete surfaces, providing flexibility in design and ease of maintenance.

Paver bricks come in several types, each suited for specific applications. Interlocking pavers, concrete pavers, clay pavers, and permeable pavers are some popular choices.

Various paver block machines cater to different production scales and budgets. Manual, semi-automatic, and fully automatic machines are available to meet diverse needs.

For Concrete Pavers:

For Clay Pavers/ Soil Pavers:

Durable Machine offers a comprehensive range of brick machine types, from manual to fully automatic. We provide customizable solutions tailored to your specific production needs, including brick type, size, control system, and voltage. Discover the perfect clay paver machine or brick making machine to match your project requirements.

The required production capacity depends on the scale of your project and the demand you need to meet. Consider the area you need to cover with pavers and the timeline for completion.

Small projects may only require a manual machine with lower capacity, while larger projects benefit from an automatic machine capable of producing thousands of pavers per day.

Accurate forecasting will help you choose a machine that can handle your current needs and future growth.

A paver block machine can use various materials.

The mix design depends on the desired strength, durability, and appearance of the pavers. Experimenting with different mix ratios and materials can yield unique and attractive pavers.

The secret to vibrant, long-lasting paver colors isn’t just in the pigments used, but also in the order you add them to the mix. Introduce the pigment after the initial mixing of cement and aggregates but before the final water addition. This ensures even distribution and prevents the pigment from clumping, leading to richer, more consistent colors that resist fading over time. This is especially true for iron oxide pigments.

DURABLE MACHINE provides comprehensive support, including expert raw material mix designs. Based on your specific local raw materials, we develop precise formulations to help you produce high-quality, durable pavers. Achieve optimal strength, consistency, and finish for your paving bricks.

Key features of a high-quality brick making machine include a robust frame, efficient hydraulic system, precise mold design, and user-friendly controls. Look for machines with durable components and reliable performance to ensure long-term operation.

Edge chipping is a common complaint with paver blocks, stemming from insufficient compaction at the edges of the mold. Many operators focus on the overall compaction but neglect to ensure adequate vibration and pressure specifically at the mold’s periphery. Consider a machine with individually controlled vibrators around the mold box, or adjust the material distribution to compensate.

DURABLE MACHINE is engineered for excellence. We utilize Manganese 16 (Mn16) super wear-resistant steel in our construction, ensuring a structurally stable and exceptionally durable machine.Our precision molds undergo meticulous heat treatment and wire-cutting, guaranteeing accurate brick dimensions every time. This superior craftsmanship ensures 24-hour stable operation with an extremely low fault rate, providing a reliable foundation for your high-volume brick production project. Trust DURABLE MACHINE for consistent, dependable performance.

The paver block machine operation involves several steps:

Investing in a paver block machine offers several benefits:

Different mold options produce pavers in various shapes. Square, rectangular, hexagonal, and custom shapes are available to meet diverse design preferences.

The right mold choice allows you to cater to diverse customer preferences and create unique paving patterns. Investing in a paver machine with quick mold change capabilities can significantly increase your product line flexibility and profitability. Being able to switch between different paver shapes and sizes quickly allows you to respond to market demands and offer a wider range of options to your customers without incurring significant downtime.

Before buying a paver brick making machine, consider these factors:

The cost of a paver block machine depends on its type, capacity, and features.

Manual machines range from $3,000 to $7,500. Automatic machines can cost from $7,500 to $200,000 or more.

The initial investment is significant, but the long-term cost savings and revenue potential can make it a worthwhile investment.

Operating costs include

Maintenance costs cover

Regular maintenance and efficient operation can minimize these costs and extend the lifespan of your paver block machine. Without regular maintenance, small issues can quickly escalate into major problems, leading to costly repairs and extended downtime. Efficient operation, such as optimizing production schedules and minimizing waste, can also help reduce costs and improve profitability. DURABLE MACHINE’s equipment can help you achieve this goal.

Regular maintenance ensures optimal performance and extends the lifespan of your pavement brick machine. Clean the machine daily, lubricate moving parts, inspect for wear and tear, and replace worn parts promptly.

Proper maintenance not only keeps your machine running smoothly but also prevents costly breakdowns and downtime.DURABLE MACHINE offers comprehensive online/offline after-sales and staff training. We ensure fast problem resolution to minimize your losses.

Here’s what to look for when choosing a paver block machine supplier:

You can find paver block machines from various suppliers. Online marketplaces, industry trade shows, and direct manufacturers are all potential sources. Each source offers its own advantages and disadvantages.

However, for the best quality, reliability, and support, consider purchasing directly from a reputable manufacturer like DURABLE MACHINE.

DURABLE MACHINE paver block machines are known for their durability, efficiency, and reliability. DURABLE MACHINE offers a range of machines to meet diverse needs and budgets. DURABLE MACHINE provides excellent customer support and technical assistance. DURABLE MACHINE offers comprehensive product line and one-stop solution. You can buy from raw material mixing to brick making and stacking all the machines in DURABLE MACHINE.

Customization allows you to create pavers that stand out from the competition and meet the specific needs of your customers.

Yes, DURABLE MACHINE offers custom paver solutions. DURABLE MACHINE can tailor machines to your specific requirements. DURABLE MACHINE designs custom molds to produce unique paver shapes and sizes.

DURABLE MACHINE provides detailed installation instructions. DURABLE MACHINE offers on-site installation and training services. DURABLE MACHINE ensures your machine is set up correctly and your team is trained to operate it efficiently. Proper installation is essential for maximizing the performance and lifespan of your paver block machine.

The purchase process with DURABLE MACHINE involves these steps:

Investing in a paver block machine can significantly improve your production efficiency, reduce costs, and increase profitability. DURABLE MACHINE is here to help you every step of the way, from selecting the right machine to providing ongoing support and service.

Contact DURABLE MACHINE today to learn more about our paver block machine solutions and how they can benefit your business!