Search the whole station liberty-fse

QMJ2-40 Portable Manual Cement Brick Making Machine

Capacity:1400-2100 pieces per day according to your brick size

Power: 3KW

Machine Type: Mobile Concrete Bricks Machine

Block size: different size cement Hollow blocks, cement Solid bricks

Material: concrete, cement, fly ash, aggregate +water etc..

Introduction:

QMJ2-40 is The Ultimate Mobile Concrete Blocks Maker Machine.

The QMJ2-40 is a compact and versatile mobile concrete blocks maker machine, ideal for small bricks construction sites. Powered by either a 3 kW electric motor or a diesel engine, it efficiently produces 1440 blocks per 8-hour day with a 40-45 second molding cycle. Its portability and simple operation make it the perfect solution for on-site, low-investment block production, or Home construction blocks project.

QMJ4-30 Hydraulic Mobile Cement Bricks Machine

Capacity: 5800-9000 pieces per day (capacity is still depends on your cement block size)

Power: 7.7KW

Pallet size: No need pallet

Moulding Method: Vibration and Hydraulic Pressure moulding

Introduction:

QMJ4-30 is The Premier Hydraulic Cement Brick Machine for Efficient Concrete blocks Production. QMJ4-30 is a mobile hydraulic cement brick machine engineered for small to medium-scale cement bricks factory operations. This machine is also called a mobile cement egg-laying brick machine.QMJ4-30 is easily movable and lays finished blocks directly onto a concrete floor, completely eliminating the need for expensive pallets. This significantly reduces your initial investment and ongoing operational costs.Its simple operation requires minimal manpower, making it a highly efficient and profitable choice for any growing construction business.

DM4-40 Semi-automatic Cement Brick Maker Machine

Capacity: 3000-5000 pieces per day (capacity is still depends on your brick size)

Power: 9.5KW

Forming Cycle:40 Seconds

Pallet Size: 850*550*22mm

Introduction:

DM4-40 is the perfect cement block making machine designed specifically for small investors and start-up businesses.DM4-40’s greatest asset is its powerful vibration motor, a feature that guarantees the production of high-density, durable, and superior-quality blocks. It is engineered to deliver professional results from a small-scale investment.

For entrepreneurs looking for an affordable entry into the block production market without compromising on quality, the DM4-40 is the ideal and most reliable choice.

DM4-24 Small Concrete Bricks Making Machine Line

Capacity: 3000-12000 pieces per day depends on your concrete block size.

Power: 19.65KW

Raw Material:The raw materials for concrete bricks are a mixture of cement and aggregates (like sand and stone), often combined with industrial by-products such as fly ash, slag, and construction waste.

Weight: 2.3T

Pallet Size: 850*550*22mm

Introduction:

DM4-26 stands out as a premier choice and an excellent investment for small-scale cement brick production businesses. As an efficient concrete hollow blocks machine, it is specifically engineered to combine an affordable price cement brick machine. This allows entrepreneurs to enter the market without a significant initial investment, while its reliable and productive operation ensures excellent and consistent returns, making it the ideal solution for any business seeking a cost-effective and profitable manufacturing process.

QT4-25 Automatic Concrete Blocks Maker Machine Line

Capacity: 5000-20000 pieces per day depends on your size

Power: 20.75KW

Forming Cycle: 20-25 Seconds

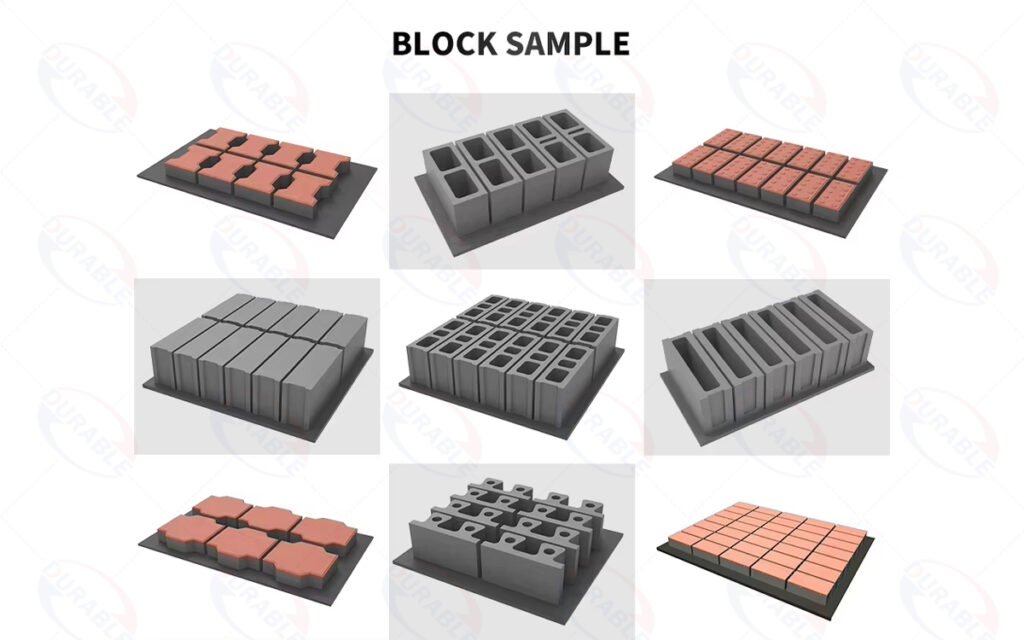

Brick Size: different cement hollow bricks, cement solid bricks, interlocking bricks, paver bricks etc..

Introduction:

For businesses seeking a smart investment in brick production, the QT4-25 is the definitive choice. This cost-effective and energy-efficient cement blocks maker machine is perfectly suited for small to medium-scale operations. Its key advantage lies in its automation, featuring an integrated material feeder, distributor, and brick discharger that boost productivity and lower labor expenses. The QT4-25 is an all-in-one solution designed to deliver reliable performance and excellent returns for your cement brick business.

QT8-15 Fully Automatic Fly Ash Bricks Making Machine Line

Capacity: 11000-30000 pieces per day depends on your block size

Forming Cycle: 15-20 Seconds

Hydraulic Pressure: 21Mpa

Pallet Size: 950*990mm

Weight: 8500KGS

Introduction:

The QT8-15 is a high-capacity, fully automatic cement blocks making machine built to meet the rigorous demands of modern construction material production. It is the ideal choice for businesses aiming to fulfill high production quotas consistently, offering a powerful, reliable, and cost-effective solution for manufacturing high-quality cement concrete blocks.The machine’s robust, top-quality steel frame ensures a long service life with minimal maintenance, making the QT8-15 a highly cost-effective choice that can fulfill your most demanding production targets for years to come.

Are you looking to start or expand your cement brick production? A reliable cement brick making machine, also known as a brick making machine, is key to efficient and profitable operations. DURABLE MACHINE is a leading manufacturer of high-quality cement brick machines, designed to meet the diverse needs of modern construction. This ultimate guide covers everything you need to know, from choosing the right machine for brick making to optimizing your cement brick production process.

Last Updated: June 2025 | Estimated Reading Time: 28 minutes

A cement brick making machine is a specialized piece of equipment used to manufacture cement bricks. This machine automates the process of molding cement, sand, and other aggregates into uniform bricks for construction. Whether you’re looking for a manual cement brick machine or an automatic brick making machine, understanding the basics is crucial.

The choice between a manual cement brick machine and an automatic brick making machine depends on your production scale and budget. Manual machines are cost-effective for small-scale production, while automatic machines offer higher output and reduced labor costs. Here’s a comparison to help you decide:

Manual Cement Brick Machine:

Automatic Brick Making Machine:

DURABLE MACHINE offers both types of bricks machines to cater to varying needs. In fact, one of DURABLE MACHINE’s first innovations was creating machines for brick making.

A high-quality cement bricks machine offers several key features and benefits: Increased production capacity, consistent brick quality, reduced labor costs, and versatility in brick design. Here’s a closer look:

While the terms are often used interchangeably, there are key differences between a concrete brick making machine and a cement brick machine. Understanding these differences can help you choose the right machine for your specific needs. Both machines produce bricks for construction, but the materials used, the brick properties, and the ideal applications can vary significantly. It is also possible to create a concrete brick machine that is portable.

The choice between a concrete brick machine and a cement brick machine also depends on your project requirements and budget. Concrete bricks generally require more cement and higher-quality aggregates, which can increase material costs. Cement bricks, with their simpler composition, may be more economical for certain applications. DURABLE MACHINE can work with you to understand your needs.

A machine that makes bricks generally operates through a series of automated steps. These steps include mixing the materials, molding the bricks under high pressure, and then ejecting the formed bricks for curing. Here’s a simplified breakdown:

A cement brick maker is essential for various businesses and individuals. Construction companies, brick manufacturers, and even DIY enthusiasts can benefit from having a reliable cement brick maker.

Cement block maker machines are essential for modern construction. They offer efficiency, precision, and versatility. This is because they make the production of cement blocks much easier, faster and at a higher quality. These blocks are crucial building materials. They are used in everything from homes to huge infrastructure projects.

Cement block maker machines provide many advantages. They let construction companies make blocks on-site. This can greatly reduce transportation costs and delays. These machines can produce blocks of different sizes, shapes, and densities. This flexibility is important for meeting the specific needs of each construction project. The precision of these machines ensures consistent block dimensions, which simplifies construction and improves structural integrity. They offer a practical and economical solution for meeting the ever-growing need for building materials in both urban and rural areas.

For instance, DURABLE MACHINE provides cement block maker machines with automated features that ensure high-quality and uniform blocks, contributing to faster construction times and reduced labor costs.

A concrete brick maker typically uses a combination of cement, sand, aggregates, and water. The exact proportions vary depending on the desired brick strength and application.

A concrete block maker machine is versatile and can produce a variety of blocks for different construction needs. From standard bricks to interlocking pavers, these machines can be adapted to create various shapes and sizes.

Choosing the best machine to make cement blocks involves considering several factors: Production capacity, automation level, brick types, and budget. Here’s a checklist:

A versatile bricks machine can produce various types of bricks to meet different construction requirements. These can include standard bricks, paving bricks, interlocking bricks, and decorative bricks.

Here is a list of potential bricks:

Keeping your bricks maker in good shape is important. Doing so helps it run well for a long time. Proper maintenance also avoids unexpected breakdowns. It saves you money in the long run.

Following these tips will help you keep your bricks maker in good condition. This will ensure it runs well and lasts a long time.

DURABLE MACHINE provides detailed maintenance guides and support for all our bricks maker models. We are committed to helping you keep your machine running smoothly.

Finding quality bricks and cement for sale is crucial for ensuring the durability and longevity of your construction projects. Local suppliers, online marketplaces, and direct manufacturers are all viable options.

Finding good bricks and cement for sale is key for strong, lasting structures. Knowing where to get reliable, high-quality materials is important.

What to Consider:

Making bricks machine often involves different production methods: Manual, semi-automatic, and automatic. All methods have potential. Understanding these differences can help you pick the machine for brick making that meets your needs.

DURABLE MACHINE can offer different cement block making machine, you can choose according to your requirements for your block factory or bricks project.

A manual cement brick machine offers several benefits: Low initial cost, simplicity of operation, and suitability for small-scale projects.

A fly ash brick making machine offers a sustainable alternative to traditional cement brick production. By utilizing fly ash, a byproduct of coal combustion, these machines reduce environmental impact and produce durable bricks.

Bricks made machine have seen significant innovations in recent years. These include advanced automation, improved mold designs, and the use of sustainable materials.

To increase production efficiency with a machine for brick making, consider these strategies: Optimize material mixing, ensure proper machine maintenance, and streamline the brick curing process.

DURABLE MACHINE stands out as a premier choice for your cement brick machine needs due to our unwavering commitment to delivering cutting-edge, reliable, and highly efficient solutions. With a proven track record spanning several decades, we have honed our expertise in designing and manufacturing machines for brick making that consistently exceed industry standards. Our dedication to innovation, quality craftsmanship, and exceptional customer support ensures that you receive a cement brick machine that not only meets but surpasses your expectations, empowering your business to thrive in today’s competitive construction landscape.

Here are compelling reasons to choose DURABLE MACHINE:

DURABLE MACHINE offers high-quality cement brick machines designed for reliability, efficiency, and versatility. We provide comprehensive support, competitive pricing, and innovative solutions to meet your specific brick production needs. With decades of experience, DURABLE MACHINE has perfected the machine for brick making. Contact us today.

In conclusion, investing in a cement brick making machine is essential for modern construction businesses. Reach out to DURABLE MACHINE today, where we can help you grow. Also, be sure to investigate the brick manufacturing machine price so that you can determine which machine meets your business needs.

Contact DURABLE MACHINE today to learn more about our paver block machine solutions and how they can benefit your business!