Rotary Drum Biomass Carbonization Furnace

A Rotary Drum Biomass Carbonization Furnace is a sophisticated piece of industrial equipment used for converting organic matter (biomass) into charcoal, bio-oil, and syngas through a process called pyrolysis.

Which making high quality charcoal can used as barbecue charcoal/hookah charcoal/shisha charcoal/or cooking fuel.

Application Materials:

wood sawdust, wood chips, coconut shell chips, bamboo chips, peanut shell, bagasse, coffee husk, wood barks, rice husk, biomass material etc.

Table of Contents

- How Does a Rotary Drum Biomass Carbonization Furnace Work?

- What Are the Advantages of a Rotary Drum Biomass Carbonization Furnace?

- Which Biomass Wastes Are Best Suited for a Rotary Drum Furnace?

- How Can I Maximize Charcoal Yield and Ensure Final Product Quality?

- Can the Flue Gas and Tar Treatment System Meet Environmental Requirements?

- What Is the Investment Budget for a Complete Production Line?

- What Are the Daily Operating Costs of a Rotary Drum Biomass Carbonization Furnace?

- How Do I Choose a Reliable Rotary Drum Biomass Carbonization Furnace Supplier?

- FAQs

How Does a Rotary Drum Biomass Carbonization Furnace Work?

It works by continuously tumbling material through controlled heat zones inside a rotating cylinder, but the pre-treatment of the material is the most critical part of the process. A Rotary Drum Biomass Carbonization Furnace is essentially a long, slightly inclined steel cylinder that rotates slowly. Raw biomass is fed into the higher end. As the drum rotates, the material tumbles and moves down towards the lower end due to gravity. The process happens in distinct zones.

- Drying Zone: The first section of the drum is the drying zone. An external heating chamber provides heat, which is transferred through the steel shell to the biomass inside. Here, the moisture in the material turns to steam and is removed.

- Carbonization Zone: As the now-dry material moves further down, it enters the hotter carbonization zone. Here, in an oxygen-poor environment, the biomass undergoes pyrolysis. It breaks down into solid charcoal, combustible gas (syngas), and tar.

- Cooling and Discharge: The hot charcoal exits the drum and enters a sealed cooling conveyor (usually a water-cooled screw auger) to bring it to a safe temperature before it is exposed to air.

The veteran’s most important point was this: “Feedstock is everything.” He said 90% of failed projects fail because of poor raw material preparation. The furnace is not a magic box. The material you feed it must be consistent in size and moisture. This pre-treatment step is not optional; it is the foundation of the entire process.

What Are the Advantages of a Rotary Drum Biomass Carbonization Furnace?

Its main advantages are continuous production and the ability to handle a wide variety of uniformly prepared materials. Compared to batch-style kilns, the rotary drum offers significant operational benefits, but only if you respect its requirements.

- Continuous Operation: This is the biggest advantage. A continuous carbonization production line can run 24/7. This maximizes throughput and makes the process much more energy-efficient than starting and stopping a batch kiln, which requires a long heat-up time for every cycle.

- Uniform Heating: The constant tumbling action ensures that every particle of the material is exposed to the heat source evenly. This leads to a more consistent and complete carbonization process compared to static kilns, where material in the center might not get enough heat.

- Process Automation: The continuous nature of the rotary drum allows for a high degree of automation. Feed rates, drum speed, and temperature can be controlled by a PLC system, reducing the need for constant manual intervention and leading to more stable product quality.

- Energy Self-Sufficiency: A well-designed system captures the syngas produced during carbonization. After cleaning, this gas is used as fuel for the heating chamber, significantly reducing or even eliminating the need for external fuel sources like diesel or natural gas during operation.

However, the veteran stressed that these advantages only exist when the system is designed and operated correctly. A poorly designed system will be plagued with problems that negate all these benefits.

Which Biomass Wastes Are Best Suited for a Rotary Drum Furnace?

The best materials are those that are low in ash and can be easily crushed into a uniform size, like wood chips, sawdust, or coconut shells. While the furnace can technically process many types of biomass, some are much more problematic than others. The key is to understand your raw material’s ash content and its melting behavior.

The veteran called this problem “slagging and ringing” – the cancer of rotary drums. When the ash in the biomass melts, it can stick to the inside wall of the drum, forming a hard ring that grows thicker over time. This ring acts as an insulator, blocking heat and reducing output. In the worst cases, it can completely block the drum, forcing a shutdown that can last for days while workers use jackhammers to remove it.

| Material Type | Suitability for Rotary Drum | Key Consideration |

|---|---|---|

| Wood Chips / Sawdust | Excellent | Low ash content, easy to dry and size. Very stable operation. |

| Coconut / Palm Shell | Excellent | High carbon content, low ash. A premium material for this process. |

| Rice Husk / Straw | Challenging | High silica in the ash. High risk of slagging and ringing. Requires lower operating temperatures. |

| Sludge / MSW | Very Challenging | Inconsistent composition, high moisture, complex ash. Requires a very specialized and robust furnace design. |

Before you commit to a project, you must get your main raw material tested for its Ash Fusion Temperature (AFT). A reliable manufacturer like Durable will insist on this. Your furnace’s operating temperature must be kept well below this point to avoid catastrophic slagging. This is one of the most important secrets to long-term operational success.

How Can I Maximize Charcoal Yield and Ensure Final Product Quality?

You maximize yield and quality through three things: strict feedstock control, precise temperature management, and a skilled operator. You cannot achieve excellence in one area while ignoring the others.

- Strict Feedstock Control: This is non-negotiable.

- Moisture: Your raw material must be dried to below 15% moisture. The veteran’s rule was simple: “Money spent on a good dryer is the smartest money you’ll ever spend.”

- Size: You need a high-quality crusher and screener to ensure your feedstock is within a very narrow size range (e.g., 5-20 mm). This ensures everything carbonizes at the same rate.

- Precise Temperature Management: The furnace is not just a hot tube. A good system has multiple temperature sensors along its length and a control system that can maintain a precise temperature profile. Small particles need less time and heat; larger particles need more. A stable temperature profile ensures complete carbonization without turning your valuable product into ash.

- The Skilled Operator: A good operator is worth their weight in gold. They learn to “read” the furnace. By observing the exhaust, the drive motor’s power draw, and the final product, they can make small adjustments to the feed rate or drum speed to optimize the process in real time. They are the final guarantee of quality.

Can the Flue Gas and Tar Treatment System Meet Environmental Requirements?

Yes, but only if it is a complete, multi-stage system that is properly maintained. A simple cyclone is not enough. The syngas produced during carbonization is a dirty fuel. It is full of tar, ash, and dust. Many low-cost manufacturers try to cut corners here, which leads to pollution and endless operational problems.

A reliable eco-friendly charcoal machine must have a robust gas purification train before the gas is burned.

Final Combustion: Only this clean gas should be sent to the burner to heat the furnace. The final exhaust from this combustion will then be clean enough to meet most environmental standards.

When you evaluate a supplier, carefully inspect their design for the carbonization furnace flue gas treatment system. If it looks too simple or too cheap, it is a major red flag.

Primary Dust Removal: A cyclone separator is the first step, removing the larger, heavier dust particles.

Tar Removal: This is the most critical step. The gas should then pass through a wet scrubber (spray tower) or an electrostatic precipitator (ESP) to remove the sticky tar aerosols and fine dust. The veteran warned that without this step, the tar will clog your burners, pipes, and fans within weeks.

What Is the Investment Budget for a Complete Production Line?

The furnace itself is often only 30-50% of the total project cost. You must budget for the entire system. New investors often get “sticker shock” when they realize this. A complete, functional, and reliable production line includes much more than just the carbonization furnace.

Here is a realistic breakdown of the budget for a sawdust pellet production line plan that includes carbonization:

- Feeding and Pre-treatment (40-50% of total cost):

- Crusher / Chipper

- Rotary Drum Dryer (this can be very expensive)

- Screener / Sieve

- Conveyors and Silos

- Carbonization System (30-40% of total cost):

- The Rotary Drum Furnace itself

- The complete gas purification and burning system

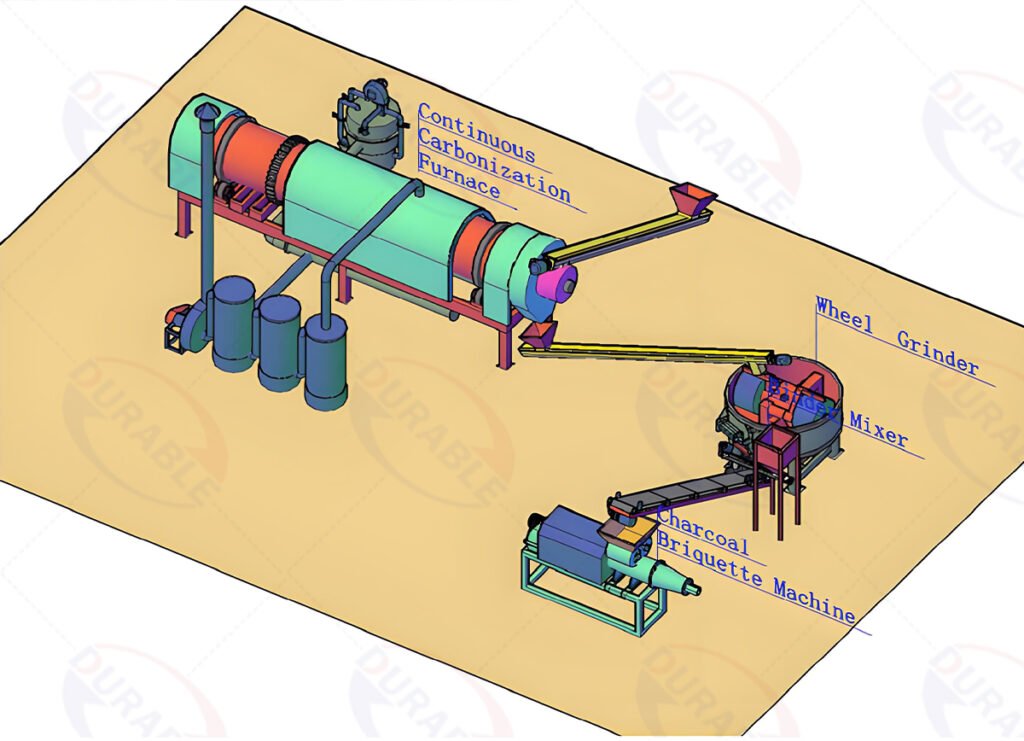

- Discharge and Post-treatment (10-20% of total cost):

- Water-cooled screw conveyor for charcoal

- Charcoal briquetting machine or grinder

- Bagging and packing system

So, if a furnace is quoted at $100,000, a realistic budget for the entire production line could be $250,000 to $350,000 or more. Trying to save money on the pre-treatment and post-treatment equipment is the most common cause of project failure.

What Are the Daily Operating Costs of a Rotary Drum Biomass Carbonization Furnace?

Your biggest daily costs are labor and maintenance, especially wear parts like seals. Energy should be low if the system is running correctly.

- Labor: You need at least one skilled operator per shift to monitor the system, plus staff for feeding material and handling the final product. Do not underestimate this cost.

- Maintenance: This is a huge hidden cost in poorly made machines. The seals at the inlet and outlet of the rotating drum are constantly wearing down. The veteran said to carefully inspect this part of any machine. Cheap graphite rope seals need constant adjustment and frequent replacement. A better design, using a combination of spring-loaded graphite rings and gas seals, costs more upfront but saves a fortune in downtime and replacement parts. You should also budget for lubricants and periodic replacement of motor bearings and drive components.

- Energy: Once the system is at temperature, the energy cost should be very low because it runs on its own syngas. However, the electricity to run all the motors (dryer, crusher, fans, conveyors) is a constant cost. Also, every time you do a cold start, you have a significant cost for the external fuel (diesel, gas) needed for pre-heating.

How Do I Choose a Reliable Rotary Drum Biomass Carbonization Furnace Supplier?

Choose a partner who is honest about the challenges, not just a salesperson who promises you the moon. The veteran’s final piece of advice was the most important.

- Ask About Their Failures: Ask the supplier to tell you about a project that had problems and how they fixed them. A reliable manufacturer like Durable will be honest about the challenges and have the experience to solve them.

- Inspect the Welds and Materials: Go to their factory. Look at the quality of the welding. Ask for material certificates for the steel they use. Is the high-temperature zone made from real heat-resistant steel (like 310S)?

- Study the Sealing and Drive System: Spend time looking at the details of the inlet/outlet seals and the drive system (gear drive is better than friction drive). These are the parts that will determine the long-term reliability of the machine.

- Talk to Their Past Customers: Ask for references of clients who have been running the machine for more than three years. Ask them about uptime, maintenance costs, and the support they receive from the manufacturer.

- Choose Experience: This is a complex piece of equipment. Choose a company that has been building them for years. At Durable, we have been in the business of heavy machinery since 2001. We build our machines to last because our reputation depends on your success.

Choosing the right supplier is the most important decision you will make. It is an investment in a long-term partnership.

FAQs

Q1: What is the difference between biochar and charcoal?

A: Technically, they are the same thing. “Biochar” is the term used when the charcoal is specifically produced for use in agriculture to improve soil. “Charcoal” is the more general term, often referring to the product used as a fuel. The production process can be adjusted to create the specific properties needed for each application.

Q2: How long can a rotary drum furnace run continuously?

A: A well-built and well-maintained furnace is designed to run 24 hours a day, 7 days a week. It should only be shut down for planned maintenance, typically for a few days every 3-6 months, depending on the abrasiveness of the material.

Q3: What is the typical service life of a rotary drum furnace?

A: The service life depends entirely on the quality of construction and the operating conditions. A cheap furnace made from standard steel might only last 2-3 years before the drum warps or corrodes. A high-quality furnace from a manufacturer like Durable, made with the correct heat-resistant alloys, can last for 10-15 years or more with proper maintenance.

Q4: Can I get a mobile version of this furnace?

A: Due to their size, weight, and the need for stable foundations and auxiliary equipment (like dryers and coolers), rotary drum carbonization furnaces are almost always stationary installations. For mobile needs, other technologies might be more suitable.

Q5: What happens if the power goes out during operation?

A: This is a critical safety consideration. A reliable system must have an uninterruptible power supply (UPS) for its control system and a backup generator to safely power the drum’s rotation and emergency cooling systems. Stopping a hot, full drum without rotation can cause it to warp permanently, destroying the furnace.

Durable Machinery

Durable Machinery