Biomass Briquette Machine

A Biomass Briquette Machine is a device designed to compress loose agro-forestry waste (biomass) into high-density, solid blocks known as briquettes. This process, often called densification, transforms low-value, difficult-to-handle waste into a clean, efficient, and easy-to-store solid fuel. These briquettes serve as a sustainable and cost-effective alternative to traditional fossil fuels like coal and firewood.

Suitable Raw Materials:The equipment can use various types of agricultural and forestry waste as raw materials, such as biomass like sawdust, shavings, rice husks, straw, bagasse, and various fruit shells.

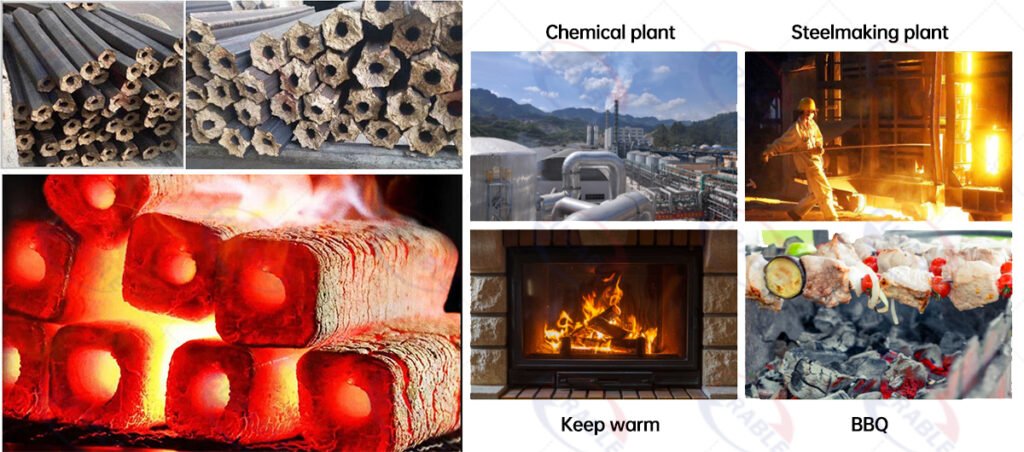

Uses of Biomass Briquettes:Industrial Fuel ,Power Generation, Residential & Commercial Heating, Raw Material for Charcoal.

Table of Contents

- Can my sawdust, straw, or rice husks become high-density fuel?

- How do biomass briquettes compare to coal in calorific value and cost?

- Do I need a crusher or dryer to go with the briquette machine?

- Punching, Screw, or Hydraulic Press: Which is best for my material?

- What is the profit potential of a biomass briquetting line, and what is the payback period?

- Are the core components (mold, screw) durable? Is maintenance difficult?

- FAQs

Can my sawdust, straw, or rice husks become high-density fuel?

Yes, loose biomass like sawdust, straw, and rice husks can be processed into dense, solid fuel briquettes. The process relies on a scientific principle known as lignin thermoplasticization, not just high pressure.

This is the process:

Biomass contains a natural polymer called lignin, which binds the plant fibers together. A Biomass Briquette Machine uses a combination of high pressure from a screw propeller and high temperature (200-300°C) from electric heating rings.

The heat softens the lignin, turning it into a natural adhesive. The screw propeller then forces this hot, softened material through a tapered mold. The high pressure compacts the fibers, and the softened lignin coats the material. When the briquette exits the machine, it cools. The lignin re-solidifies, binding the fibers into a dense, solid block. This method creates briquettes without any chemical additives. The quality of the final briquette is dependent on precise control of temperature and pressure.

How do biomass briquettes compare to coal in calorific value and cost?

Biomass briquettes are a viable alternative to fossil coal. They offer advantages in both cost and environmental impact.

The calorific value of a biomass briquette is determined by its raw material. Briquettes from wood or coconut shells typically have a calorific value between 4,000 and 4,800 kcal/kg. This is less than high-grade coal but is comparable to or greater than lower-grade coals like lignite. Our machines produce briquettes with a consistent density, which results in a stable and predictable burning rate. This consistency is important for industrial users.

The cost advantage of biomass briquettes is often significant. The raw material is typically a low-cost waste product. Coal has substantial mining and transportation costs. After calculating the electricity and labor costs for production, the final cost per unit of energy for biomass briquettes is usually lower than that of coal. Biomass briquettes also have much lower sulfur and ash content. This reduces boiler maintenance requirements and air pollution.

| Fuel Type | Typical Calorific Value (kcal/kg) | Ash Content | Environmental Impact |

|---|---|---|---|

| Biomass Briquettes | 4,000 – 4,800 | 2% – 10% | Carbon neutral, low sulfur |

| Lignite Coal | 3,500 – 4,500 | 20% – 40% | High CO2 and sulfur emissions |

| Bituminous Coal | 6,000 – 7,000 | 10% – 25% | Very high CO2 and sulfur emissions |

Application Areas:

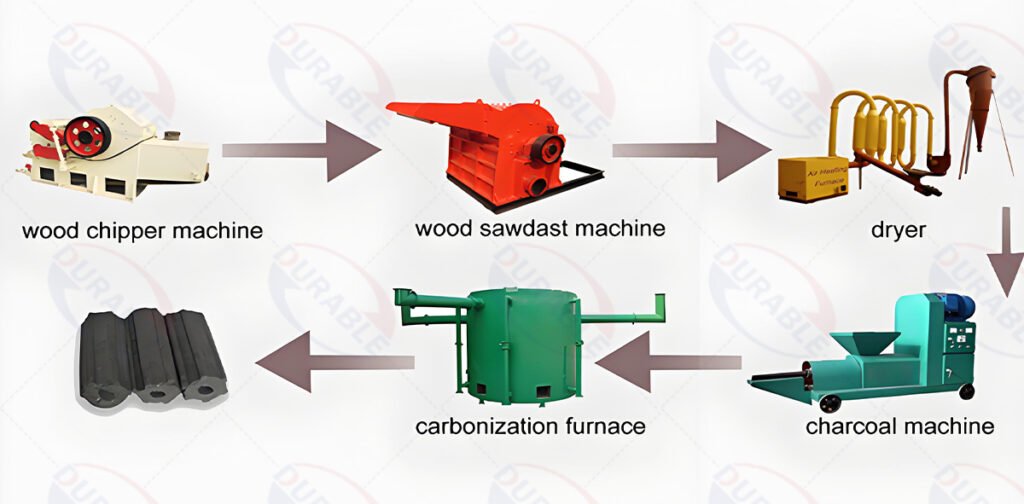

Do I need a crusher or dryer to go with the briquette machine?

Yes, in most cases, a crusher and a dryer are necessary components of a production line. The briquette machine requires raw material that meets specific conditions. The performance of the machine is directly linked to the quality of the material preparation.

There are two strict requirements for raw material entering a screw press briquette machine:

- Moisture Content must be between 8% and 12%. If moisture is above 12%, the water will vaporize into steam inside the high-temperature mold. This causes a pressure spike, often heard as a “bang,” which cracks the briquettes and can damage the equipment. If moisture is below 8%, the material is too dry for the lignin to plasticize effectively. This results in high energy consumption, poor briquette quality, and a high probability of machine jams.

- Material Size must be smaller than 5mm. The material must be small enough to flow evenly through the screw feeding mechanism. Large particles, like wood chips or long straw fibers, will block the inlet and cause the machine to jam.

For these reasons, a Hammer Mill or Crusher is required to reduce the material to the correct size. A reliable industrial Sawdust Dryer is also required to precisely control the moisture content. The investment in this preparation equipment is essential for a functional production line.

Punching, Screw, or Hydraulic Press: Which is best for my material?

Different types of briquette machines exist. The correct choice depends on the raw material and the desired final product. We manufacture these different types to provide suitable solutions.

- Punching (Stamping) Briquette Machine: This machine uses a mechanical piston to punch material into a mold. It is effective for less dense materials like peat or some types of charcoal powder. It produces large, strong briquettes and is known for its durability. Its output capacity is generally lower than a screw press.

- Hydraulic Briquette Press: This machine uses hydraulic cylinders to apply very high pressure. It is used for materials that are difficult to press, such as metal powders or certain minerals. The pressure is high and can be controlled, but the production cycle is slow, making it inefficient for high-volume biomass fuel production.

- Screw Press Briquette Machine: This is the most common and efficient type for producing high-density fuel briquettes from biomass materials like sawdust, rice husks, and finely chopped straw. It uses a screw propeller and heating system to activate the lignin. It operates as a continuous process and produces briquettes with a central hole, which aids in combustion. For producing bio-coal for industrial use or for subsequent carbonization into charcoal, the screw press is the standard choice.

What is the profit potential of a biomass briquetting line, and what is the payback period?

The profitability of a biomass briquetting plant is dependent on effective cost management. The payback period is calculated by dividing the total initial investment by the monthly profit.

Initial Investment: This includes the cost of the complete Biomass Briquette Production Line, which consists of the crusher, dryer, briquette machine, and conveyors. Shipping and installation costs must also be included.

Operating Costs: These are the recurring monthly expenses.

- Raw Material Cost: This can be very low if using waste from an existing operation.

- Labor Cost: The wages for the workers needed to operate the plant.

- Maintenance Cost: The cost of replacing wear parts, primarily the screw propeller and molds.

- Electricity Cost: This is a major operating expense. It includes the power consumed by the entire line: the crusher, the dryer’s fan and heat source, the briquette machine’s main motor, and its heating rings.

Revenue: This is determined by the selling price of the briquettes and the total production volume.

Based on data from our clients, a properly managed small or medium-sized briquetting plant typically has a payback period of 12 to 18 months. Profitability is highest when raw material costs are low and the plant operates efficiently.

Are the core components (mold, screw) durable? Is maintenance difficult?

The screw propeller and the forming mold are the primary wear parts in a screw press briquette machine. They are subjected to high temperature, high pressure, and constant abrasion from the raw material. The lifespan of these components directly impacts operating costs and plant uptime.

The main cause of wear is silica (sand and grit) contained within the biomass. Materials like rice husk are high in abrasive silica, which wears down the steel components quickly.

The durability of these parts is a function of the steel they are made from:

- Standard Carbon Steel (e.g., 45# Steel): This is the lowest-cost option. Its lifespan is very short, especially with abrasive materials. It is not recommended for commercial production.

- Alloy Steel (e.g., 40Cr): A heat-treated alloy steel that offers much better wear resistance. It can last for 400-800 hours of operation, depending on the raw material.

- Alloy Steel with Welded Wear-Resistant Layer: This is the industrial standard for continuous operation. A core of tough alloy steel is covered with a welded layer of an extremely hard material, like tungsten carbide, on the high-wear surfaces. A component made with this method will last significantly longer than a standard alloy steel part, reducing replacement costs and downtime.

Daily maintenance is simple and involves lubrication and inspection. Operator training is important to prevent machine jams, which occur when material hardens inside the mold. Jams are typically caused by improper startup or shutdown procedures.

FAQs

Q1: What is the biggest operating cost when running a briquette plant?

A: The two biggest operating costs are electricity and the replacement of wear parts. The entire production line, especially the dryer and the briquette machine’s heating rings, consumes a significant amount of power. The screw propeller and molds are consumable parts that need regular replacement.

Q2: Can I make briquettes directly from wet wood chips?

A: No. The raw material must be prepared first. Wet wood chips must be processed through a crusher or hammer mill to reduce their size to below 5mm, and then processed through a dryer to reduce the moisture content to between 8% and 12%.

Q3: What happens if my raw material’s moisture is too high?

A: If the moisture content is above 12%, the water will turn to steam and expand rapidly inside the hot mold. This causes a loud “banging” sound and will produce cracked, poor-quality briquettes. It can also cause premature wear on the machine.

Q4: Why do the finished briquettes have a hole in the center?

A: The hole is a natural result of the screw press design. The screw propeller shaft creates the void. This hole is beneficial as it allows for better airflow during combustion, leading to a more complete and efficient burn.

Q5: How can I make high-quality charcoal from these briquettes?

A: This briquette machine is the first step. To make charcoal, you must take the finished biomass briquettes and heat them in a low-oxygen environment inside a separate piece of equipment called a Carbonization Furnace. This second process, called pyrolysis, removes everything but the carbon, creating dense charcoal.

Durable Machinery

Durable Machinery