How to Process Gold Ore? The 4 Core Steps of Gold Ore Processing

As a manufacturer of Mineral Processing Equipment since 2001, we at Durable have helped design and equip countless gold mines around the world. You are looking for a clear path to turn rock into gold. The journey, known as gold ore processing or gold beneficiation, is a series of precise steps. Getting these steps right is the difference between a profitable mine and a costly failure. This guide will walk you through the four core steps that are essential to any successful gold processing plant. We will explain the technology and strategy you need to know.

Why must you analyze your gold ore’s properties first?

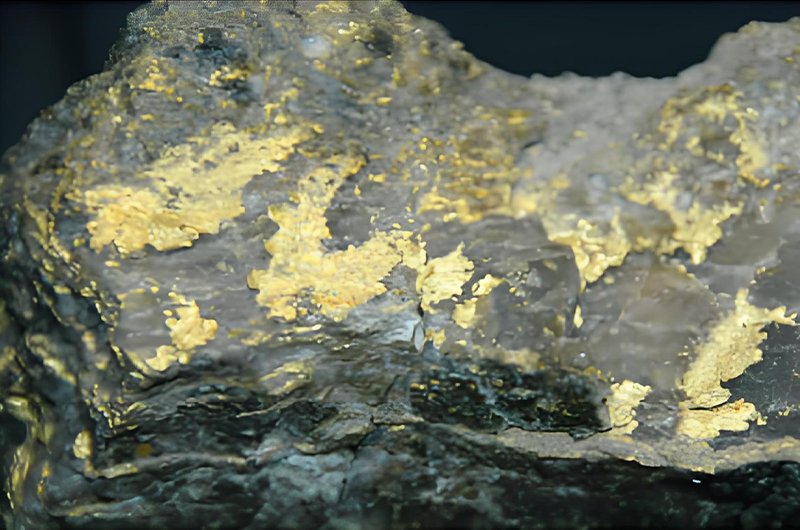

This is the most important step before you spend any money. You must diagnose your ore before you can treat it. A detailed mineralogical analysis tells you everything you need to know. It is the blueprint for your entire gold ore processingplant.

Your analysis will answer critical questions:

- What is the head grade? This tells you how much gold is in each ton of ore (e.g., grams per ton). This determines the potential value.

- What is the liberation size? This tells you how fine you need to grind the ore to free the gold particles from the waste rock.

- Is the gold “free” or “refractory”? Free gold can be recovered with simple methods. Refractory gold is locked inside other minerals (like pyrite) and requires more complex, expensive processing.

- Are there any troublemakers? Some ores contain carbon or clays that can steal gold back after it has been dissolved. We call this “preg-robbing” ore. Knowing this upfront is critical.

Without this information, you are operating blind. Investing in a proper analysis is the best money you will ever spend.

How Do You Choose the Right Gold Recovery Method?

Your ore analysis will point you to the right technology. Not all gold ore is the same. The method you choose must match your ore’s specific personality. Here are the three main paths for gold ore processing.

| Processing Method | Best For This Ore Type | Key Advantage | Key Disadvantage |

|---|---|---|---|

| Cyanidation (CIL/CIP) | Most free-milling oxide ores where gold is easily accessible. The industry standard. | High recovery rates (often >90%) and well-understood technology. | Uses cyanide, which requires careful handling and environmental management. Not effective for refractory ores. |

| Froth Flotation | Refractory sulfide ores where gold is locked inside minerals like pyrite. | Can concentrate gold from complex ores into a smaller volume for further treatment. | Does not produce pure gold directly. The concentrate requires another process (like smelting or intensive leaching). |

| Gravity Separation | Ores with coarse or “visible” gold particles. | Very low operating cost, chemical-free, and recovers gold early in the process. | Only recovers coarse gold. Cannot recover fine, disseminated gold particles. |

Most modern plants use a combination. For example, a plant might use gravity separation to catch the coarse gold first, then use the CIL process to recover the remaining fine gold. This hybrid approach often gives the best overall gold recovery.

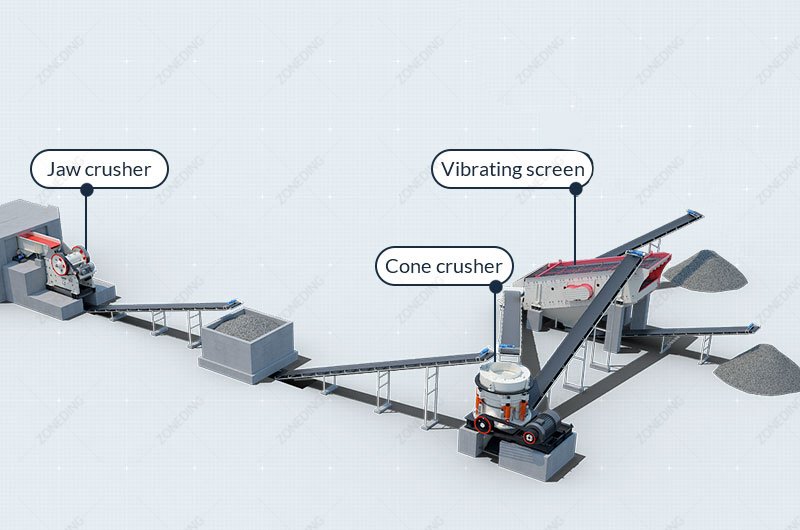

Step 1: Crushing and Grinding

The first physical step in how to process gold ore is making the ore smaller. But the real goal is not just to crush rocks. The true goal is liberation. You need to break the ore down just enough to free the microscopic gold particles from the worthless rock (gangue) they are trapped in.

- Crushing: Ore from the mine, which can be as large as a car, is fed into a primary Jaw Crusher. It is then sent to secondary and tertiary cone crushers to reduce the rock size to less than a centimeter.

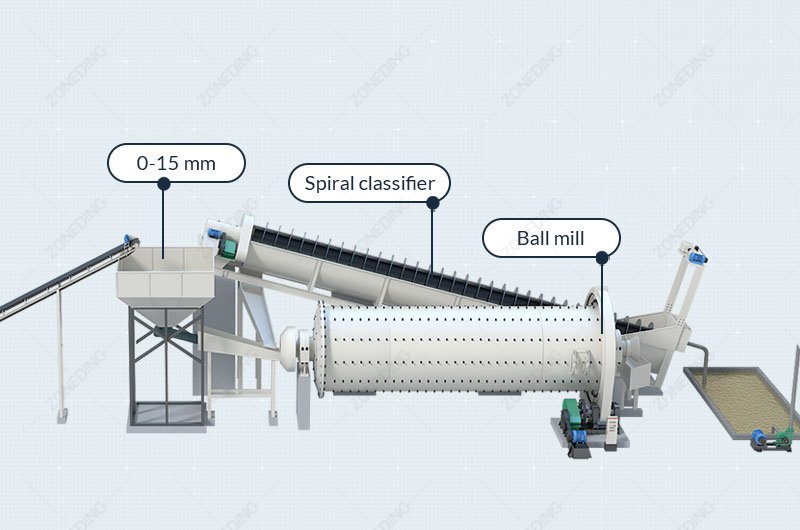

- Grinding: The crushed ore is then mixed with water and fed into a Ball Mill. The mill tumbles the ore with steel balls, grinding it into a fine, sand-like slurry.

Here is an expert tip: You should always install a gravity recovery circuit right after the grinding mill. A machine like a Knelson or Falcon concentrator can capture 20% to 60% of your total gold before it even gets to the main plant. This coarse gold dissolves very slowly in cyanide, so catching it early is a huge advantage. It is a low-cost insurance policy that boosts your daily gold production and protects you from losing valuable coarse gold to the tailings.

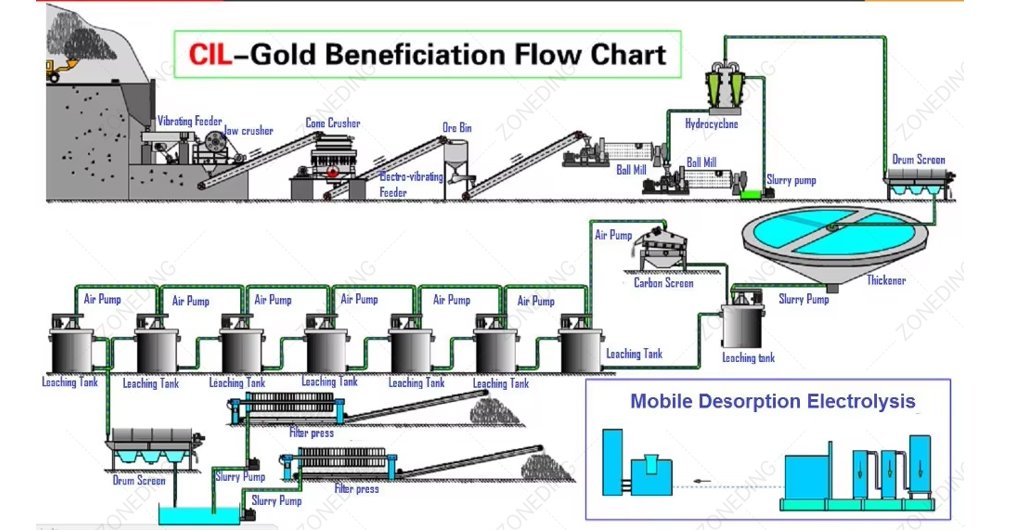

Step 2: Leaching and Adsorption (The CIL Process)

For most gold ores, the next step is to dissolve the gold. The most common method is cyanidation, and the most popular process is Carbon-in-Leach (CIL). This is where the real chemistry happens.

Here is how the CIL process works in simple terms:

- Leaching: The ground ore slurry is pumped into a series of large, agitated tanks. A very dilute solution of sodium cyanide is added. This chemical dissolves the solid gold particles, turning them into a liquid gold-cyanide complex that is dissolved in the water.

- Adsorption: At the same time, we add activated carbon to the tanks. Activated carbon acts like a magnet for the dissolved gold. The gold-cyanide complex sticks to the surface of the carbon.

- Counter-Current Flow: The ore slurry moves from the first tank to the last. The carbon moves in the opposite direction, from the last tank to the first. This is very efficient. It means the freshest, most active carbon meets the slurry with the lowest gold concentration, ensuring no gold is missed. The carbon loaded with the most gold meets the fresh slurry with the highest gold concentration.

A critical, often overlooked factor here is dissolved oxygen. The chemical reaction that dissolves gold needs oxygen just as much as it needs cyanide. If your tanks are starved of oxygen, you are just wasting cyanide and losing gold. A well-run plant actively injects air or oxygen into the CIL tanks to keep the reaction going at full speed.

Step 3: Recovery and Smelting

Now that the gold is loaded onto the activated carbon, we need to get it off. This happens in the secure part of the plant, often called the “gold room.”

The process has three main parts:

Elution (or Stripping): The loaded carbon is moved to a special vessel. A hot, caustic cyanide solution is used to wash the carbon, which forces the gold to come off the carbon and back into the solution. This creates a very small volume of very high-grade gold solution.

- Electrowinning: This high-grade solution is then pumped into an “electrowinning cell.” We pass an electric current through the solution. This causes the gold to plate out of the solution onto steel wool cathodes. It looks like a dark sludge.

- Smelting: Finally, the gold sludge is scraped from the cathodes, mixed with fluxes, and melted in a furnace at over 1,100°C (2,000°F). The impurities are skimmed off as slag, leaving behind nearly pure molten gold. This is then poured into molds to create Doré bars. These bars, typically 80-90% gold, are the final product of the mine.

Step 4: Tailings Management

What happens to the ore after the gold has been removed? This leftover material is called tailings. Responsible management of tailings is a critical part of modern gold mining.

The tailings slurry from the CIL circuit still contains the process water and residual cyanide. Before it can be stored, it must be treated.

- Cyanide Destruction: The tailings are sent to a dedicated circuit where a reagent (like SO₂/Air or peroxide) is used to destroy any remaining cyanide, making the water safe.

- Dewatering: The treated tailings are often sent to a thickener to recover most of the water. This water is then recycled back to the grinding circuit to reduce the mine’s overall water consumption.

- Storage: The thickened tailings are then pumped to a specially designed and lined tailings storage facility (TSF) for secure, long-term storage.

Proper tailings management protects the environment and is essential for maintaining a social license to operate.

FAQs

Q1: What is a “gold recovery rate”?

A: The gold recovery rate is the percentage of gold from the original ore that is successfully captured and turned into a Doré bar. A typical CIL plant aims for a recovery rate of 90% to 95%. It is a key measure of the plant’s efficiency.

Q2: What is the difference between the CIL and CIP process?

A: They are very similar. In Carbon-in-Leach (CIL), leaching and adsorption happen in the same tanks. In Carbon-in-Pulp (CIP), the ore is first leached in a series of tanks, and then the slurry is sent to another series of tanks where carbon is added for adsorption. CIL is often preferred as it can handle “preg-robbing” ores better.

Q3: How much does a gold processing plant cost?

A: The cost varies dramatically depending on the size (tons per day), the complexity of the ore, and the location. A small pilot plant might cost a few hundred thousand dollars, while a large, complex plant for refractory ore can cost hundreds of millions.

Conclusion: Putting It All Together

A successful gold processing plant is a system where every step works in harmony with the next. The journey from a raw stone to a valuable Doré bar is a process of physical and chemical transformation. It starts with smart analysis, followed by efficient liberation in the grinding circuit, and precise chemical separation in the CIL or flotation plant.

- Analyze Your Ore: This is your map. Don’t start without it.

- Crush and Grind for Liberation: Free the gold efficiently. Use gravity to catch coarse gold early.

- Choose the Right Separation Method: Use CIL for most ores, but be ready for flotation if your ore is refractory.

- Recover and Refine: The gold room is where you turn your hard work into a final, sellable product.

Understanding these four core steps is fundamental to knowing how to process gold ore.

Durable Machinery

Durable Machinery