Slow Coal Combustion in Rotary Kiln? A Guide to Optimization

As a manufacturer of Rotary Kilns and their components since 2001, we at Durable have seen firsthand how combustion efficiency is the absolute core of a profitable operation. When pulverized coal burns too slowly, it drives up fuel consumption, harms clinker quality, and creates operational nightmares like kiln rings. This guide is your practical manual for accelerating coal powder combustion. We will cover everything from the burner itself to the air dynamics that fuel the flame, helping you achieve a hotter, faster, and more efficient burn.

Table of Contents

- Why is a Multi-channel Burner the Core Equipment for This Problem?

- How Does Coal Fineness and Moisture Affect Flame Speed?

- How to Optimize Primary, Secondary, and Tertiary Air?

- How Important is Increasing Secondary Air Temperature?

- How to Ensure Full Combustion in the Precalciner?

- Conclusion: A Holistic Approach to Combustion

Why is a Multi-channel Burner the Core Equipment for This Problem?

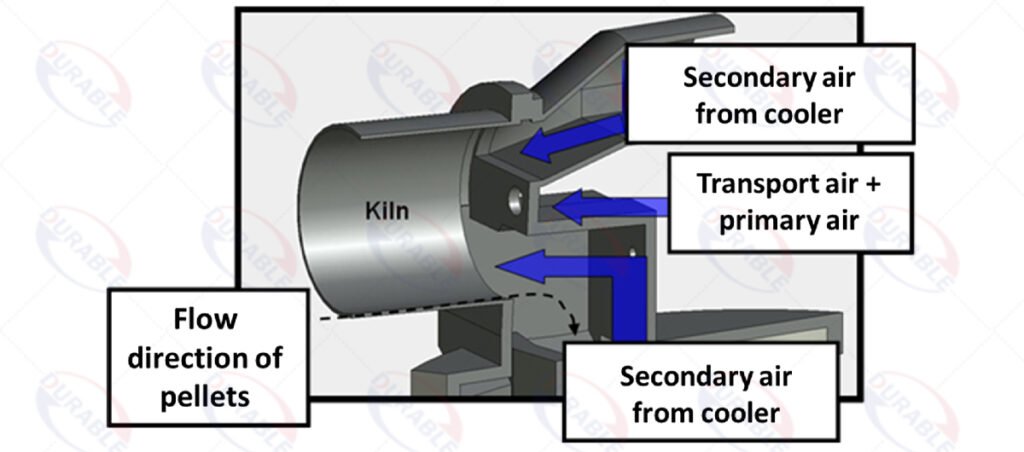

The burner is not just a pipe that sprays coal into the kiln. It is a sophisticated engineering device designed to create the perfect mixing environment for fuel and air. A modern multi-channel burner is your primary tool for controlling flame shape and intensity, which is essential for accelerating pulverized coal combustion.

Older, single-channel burners offer very little control. In contrast, a multi-channel burner allows you to independently adjust different air streams:

- Axial Air: This stream flows straight out and controls the length and forward momentum of the flame. It determines how far the heat penetrates into the kiln.

- Swirl Air: This stream is injected tangentially to create a vortex. It controls how wide the flame becomes and how aggressively it mixes with the hot secondary air.

- Central Air: Often used to cool the burner tip and can help stabilize the flame root.

By adjusting the balance between these channels, an operator can shape the flame precisely. The goal is to create a short, intense, and highly radiant flame that transfers heat efficiently to the material without directly touching the kiln shell or the material bed. Investing in a modern burner and professional tuning is the single most effective hardware upgrade for improving combustion efficiency.

How Does Coal Fineness and Moisture Affect Flame Speed?

The physical properties of your pulverized coal are just as important as the burner itself. If your fuel is not properly prepared, even the best burner will struggle. Two properties are critical: fineness and moisture.

Fineness is about distribution, not just the average. Many plants only check the residue on a single sieve (e.g., 90 microns). This can be misleading. A “good” average can hide a poor distribution of both ultra-fine and very coarse particles.

- Coarse Particles (>200 microns): These are the “lazy” particles. They ignite slowly and may not burn out completely before leaving the flame. In the kiln, they can fall into the clinker, increasing free lime (f-CaO) and reducing quality. In the precalciner, they get carried away and cause build-ups.

- Ultra-Fine Particles (<20 microns): These ignite too quickly, right at the burner tip. This creates a short, weak flame that overheats the kiln hood and fails to project heat deep into the kiln.

Moisture is a heat thief. Every percentage point of moisture in the coal must be evaporated before the coal can ignite. This steals a significant amount of heat from the flame root, delaying ignition and cooling the flame. Consistent, low-moisture coal is essential for a stable and rapid combustion process.

How to Optimize Primary, Secondary, and Tertiary Air?

The secret to fast combustion is turbulent mixing, and the air you use is the engine of that mixing. Think of your air streams as a team with different roles.

| Air Type | Role | How to Optimize It for Fast Combustion |

|---|---|---|

| Primary Air | The “Skeleton” | This air carries the coal. Its job is to give the flame its initial shape and velocity. Use the minimum amount and pressure needed to transport the coal. Too much primary air will cool and weaken the flame. |

| Secondary Air | The “Muscle” | This is the hot air (800-1100°C) recovered from the clinker cooler. It is the main source of oxygen and heat. Maximize its temperature and momentum by running an efficient cooler. Strong secondary air ensures intense mixing. |

| Tertiary Air | The “Soul” (of the Precalciner) | This hot air is drawn from the cooler and sent directly to the precalciner. It provides the heat and oxygen for over 60% of the fuel combustion in modern plants. Keeping the tertiary air duct (TAD) clean and maximizing its temperature is vital for fuel efficiency. |

Optimizing these three air streams is a balancing act. The goal is to use the powerful, hot secondary and tertiary air to do the hard work of mixing, while using the cold primary air as sparingly as possible.

How Important is Increasing Secondary Air Temperature?

Increasing the secondary air temperature is one of the most effective ways to accelerate coal combustion. It is essentially free energy that preheats your combustion air, giving you a significant head start.

Think of it this way: when you inject pulverized coal into the kiln, it has to be heated up to its ignition temperature before it can burn.

- With Low-Temperature Secondary Air: A large portion of the initial energy from the flame is spent just heating the incoming coal and air. This results in a longer, lazier flame and a delayed ignition point.

- With High-Temperature Secondary Air (>1000°C): The coal is injected into an environment that is already extremely hot. Ignition is almost instantaneous. This creates a much hotter, more intense, and more compact flame, which radiates heat more effectively and improves combustion efficiency.

A high secondary air temperature is a direct indicator of an efficient clinker cooler. Every degree of heat you recover from the clinker and put back into the kiln is a degree you don’t have to generate with expensive fuel.

How to Ensure Full Combustion in the Precalciner?

In a modern plant, the precalciner is where the majority of the fuel is burned. The challenge is immense: you have only 2-3 seconds to completely burn the coal before the gases move on to the next cyclone. Incomplete combustion here is a primary cause of high fuel consumption and system blockages.

To achieve complete combustion in this short time, you must create a highly turbulent “vortex reactor.”

- Multi-Point Injection: Coal should be injected at several points and angles, not just one. This distributes the fuel throughout the hot gas volume.

- Intersection with Tertiary Air: The coal injection points must be strategically placed to intersect with the high-temperature tertiary air stream. This ensures immediate mixing and ignition.

- Optimize Residence Time: The design of the precalciner and its riser duct is engineered to create swirling and turbulence, maximizing the time the coal particles spend in the hot zone.

A key performance indicator for precalciner combustion is the CO (carbon monoxide) concentration at the outlet. An efficient precalciner will have very low CO, indicating that the fuel has been fully burned to CO₂, releasing all its energy.

Conclusion: A Holistic Approach to Combustion

Accelerating rotary kiln combustion is not about a single magic bullet. It is a holistic process of optimizing an entire system. You cannot fix a combustion problem by only looking at the burner. You must consider the quality of your fuel, the aerodynamics of your air systems, and the operational parameters of your kiln.

- Start with the Fuel: Ensure your coal is finely ground with a narrow particle size distribution and low moisture.

- Master Your Air: Use a modern multi-channel burner to shape the flame, and optimize the balance of hot secondary/tertiary air and cold primary air.

- Focus on the Precalciner: Recognize that this is your main combustion chamber and ensure rapid, turbulent mixing within its short residence time.

By systematically addressing these areas, you can transform a slow, inefficient burn into a fast, powerful, and highly efficient flame, leading to lower fuel costs, higher output, and better product quality.

Durable Machinery

Durable Machinery