A Complete Guide: What is a Rotary Dryer & How it Operates

The industrial rotary dryer represents a cornerstone in mineral processing and bulk material handling. This fundamental equipment efficiently reduces moisture content across many industries. This process proves crucial for effective material storage, transportation, and further processing. An industrial rotary dryer achieves this task efficiently. It employs a robust design and a proven rotary dryer working principle. These machines are indispensable for large-scale operations. They ensure materials meet specific moisture requirements. This impacts product quality and operational efficiency.

This guide provides a thorough explanation of the rotary dryer structure. It details the rotary dryer working principle. The article covers different rotary dryer types. It also discusses their varied applications. This information highlights how these vital pieces of equipment function. It explains their core value in industrial drying. This knowledge is key for optimizing drying processes.

Table of Contents

- What Is an Industrial Rotary Dryer and Why Does It Have Industrial Value?

- What Major Components Form an Industrial Rotary Dryer?

- How Does a Rotary Dryer Operate Effectively?

- How Do Heat Sources and Hot Air Systems Impact Drying Efficiency?

- How Do Lifter Designs Achieve Uniform Material Drying?

- What Types of Industrial Rotary Dryers Exist?

- How Do Industries Apply Rotary Dryers for Minerals and Building Materials?

- What Advantages Do Rotary Dryers Offer?

- How Do Rotary Dryers Handle Abrasive and High-Moisture Materials?

- How Do Engineers Optimize Rotary Dryer Parameters for Efficiency and Output?

- What Maintenance Strategies Extend Rotary Dryer Lifespan?

- How Does One Diagnose and Troubleshoot Common Rotary Dryer Faults?

What Is an Industrial Rotary Dryer and Why Does It Have Industrial Value?

An industrial rotary dryer processes bulk materials. It reduces their moisture content. The machine achieves this through direct or indirect contact with a heated gas stream. Its defining features include a large, inclined, rotating cylindrical shell. This continuous process machine offers high efficiency for large-scale operations.

An industrial rotary dryer’s core value lies in its high capacity to process diverse materials (granular, powdery, coarse, or lumpy). It achieves precise moisture removal, vital for preventing material degradation, reducing transportation costs, and facilitating subsequent processing—such as efficient mineral grinding or preventing spoilage.

Supporting continuous operation and delivering high throughput, these dryers are the preferred choice for demanding industries like mining, aggregates, chemicals, and agriculture. Their robust design ensures reliable, consistent performance in harsh environments, making them crucial for guaranteeing product quality and optimizing production costs as a cornerstone of modern material processing.

What Major Components Form an Industrial Rotary Dryer?

An industrial rotary dryer structure comprises several interconnected components. Each part plays a critical role in its operation. Understanding these components explains how the dryer functions. The main body is the rotating cylindrical shell. This robust design supports continuous material processing.

The rotary dryer structure prioritizes durability and efficiency, designed to withstand high temperatures, abrasive materials, and continuous rotation. Its core is the cylindrical shell (drum), typically heavy-gauge steel, supported by trunnion rollers for smooth rotation and thrust rollers preventing axial movement. A drive system (motor, gearbox, girth gear) ensures controlled drum rotation.

Inside, internal flights (lifters) are crucial for lifting and cascading material, ensuring even drying. Wet material is introduced by the feeding system, encountering hot gases from the heating system, managed by the air/gas handling system. Dried material exits via the discharge system, with a dust collection system ensuring environmental compliance. A sophisticated control system monitors all critical parameters for optimal drying conditions.

How Does a Rotary Dryer Operate Effectively?

The rotary dryer working principle involves a continuous and coordinated process. It combines mechanical movement with thermal energy. Wet material enters a rotating, inclined drum. Lifters then tumble the material through a stream of hot gas. This action efficiently transfers heat and evaporates moisture.

The rotary dryer working principle involves continuous feeding of wet material into the elevated end of the inclined, rotating drum. As the drum rotates, internal flights (lifters) scoop and cascade the material through a hot gas stream, maximizing surface area for efficient heat and mass transfer and evaporation.

The heating system introduces these gases (either direct-fired, contacting the material, or indirect-fired, transferring heat through a barrier). Moisture-laden exhaust gas stream is then drawn off by an exhaust fan through a dust collection system. Material gradually moves to the discharge end, achieving the desired moisture content, before the dried material exits.

How Do Heat Sources and Hot Air Systems Impact Drying Efficiency?

Heat source selection and hot air system configuration are crucial. They significantly impact a rotary dryer’s drying efficiency. These elements determine how effectively heat generates and transfers to the material. This directly affects both energy consumption and throughput.

Industrial rotary dryer applications employ specific heating approaches. Direct-fired heating is common, using burners to generate hot combustion gases that directly contact the material, offering high thermal efficiency with various fuels. Indirect-fired heating separates hot gases from the material, transferring heat through tubes or the shell, suitable for sensitive materials or when high product purity is required, preventing contamination.

The hot air drying system, comprising fans, blowers, and ducting, circulates these hot gases. Precise control over volume, velocity, and temperature is crucial for uniform heat distribution and rapid moisture removal. Optimizing these elements is key to drying efficiency optimization, leading to significant energy savings and enhanced production capacity.

How Do Lifter Designs Achieve Uniform Material Drying?

Internal lifters, also known as flights, represent critical components within a rotary dryer. Their design is paramount for achieving uniform material drying. Lifters repeatedly lift material and cascade it through the hot gas stream. This action maximizes surface area contact and ensures even heat distribution.

The rotary dryer working principle critically relies on internal lifters. Without them, material slides, hindering heat transfer and causing uneven drying. Lifter design (shape, size, angle, arrangement) is customized for specific material characteristics—e.g., non-blinding for sticky, curtain-effect for fine, or high-lift for coarse materials.

Their main purpose is to create a continuous “shower” of material through the hot gas stream, ensuring maximum particle exposure for rapid, uniform evaporation and an efficient material drying mechanism. This action prevents clumping, minimizes stagnant zones, and significantly boosts drying efficiency optimization, leading to consistent final product moisture and preventing localized overheating, crucial for delicate materials. Optimized lifter design is paramount for dryer performance.

What Types of Industrial Rotary Dryers Exist?

Industrial rotary dryers are classified by heat transfer method, material/gas flow, and drum configuration, offering tailored solutions for diverse materials with varying properties and moisture levels.

- Heat Transfer Method:

- Direct-Fired Dryers: Hot combustion gases directly contact material. This offers high thermal efficiency for robust materials.

- Indirect-Fired Dryers: Hot gases are separated. Heat transfers via a barrier. These are ideal for materials intolerant to direct contact or requiring high purity (e.g., specialized minerals).

- Material and Gas Flow Direction:

- Co-current (Parallel Flow) Dryers: Hot gases and wet material flow in the same direction. These are ideal for high initial moisture or temperature-sensitive materials. Hottest gases meet wettest material, preventing overheating.

- Counter-current (Opposed Flow) Dryers: Hot gases enter opposite to material flow. These are more thermally efficient. Hottest gases meet driest material. They are common for achieving low final moisture (e.g., in a sand dryer for frac sand).

- Drum Configuration:

- Single-Pass Rotary Dryers: These use one drum. Material passes once. They are suitable for many applications.

- Triple-Pass Rotary Drum Dryers: These use three concentric drums. Material passes through multiple zones. They are compact, offer higher thermal efficiency, and are space-saving. They excel for aggregates and granular materials.

How Do Industries Apply Rotary Dryers for Minerals and Building Materials?

Rotary dryers are indispensable in both the mineral and building material industries. They perform critical drying tasks. These tasks enhance product quality, reduce transportation costs, and enable further processing. Their robust design handles the demanding nature of these materials.

In the mineral industry, mineral dryer equipment processes a wide array of ores and concentrates. For instance, iron ore fines often contain significant moisture after washing or beneficiation. Drying these fines improves their handling. It also prepares them for pelletizing or smelting. Coal drying represents another crucial application. It enhances caloric value. It also reduces transportation weight. Drying makes coal suitable for various industrial uses. For aggregates, like sand and gravel, drying proves essential for specific applications. For example, dry aggregates are critical for proper bonding in asphalt production. A sand dryer specifically handles this.

The building material industry heavily relies on building material drying equipment. Clay for brick/tile production, gypsum for plasterboard (often dried in a specialized gypsum rotary dryer), and cement additives/sands all require drying for product quality, stability, and consistent performance. Rotary dryers are ideal, handling large volumes and varying moisture content efficiently. Durable Machine provides tailored solutions, including a dedicated clay dryer, meeting the industry’s demand for consistency and efficiency.

What Advantages Do Rotary Dryers Offer?

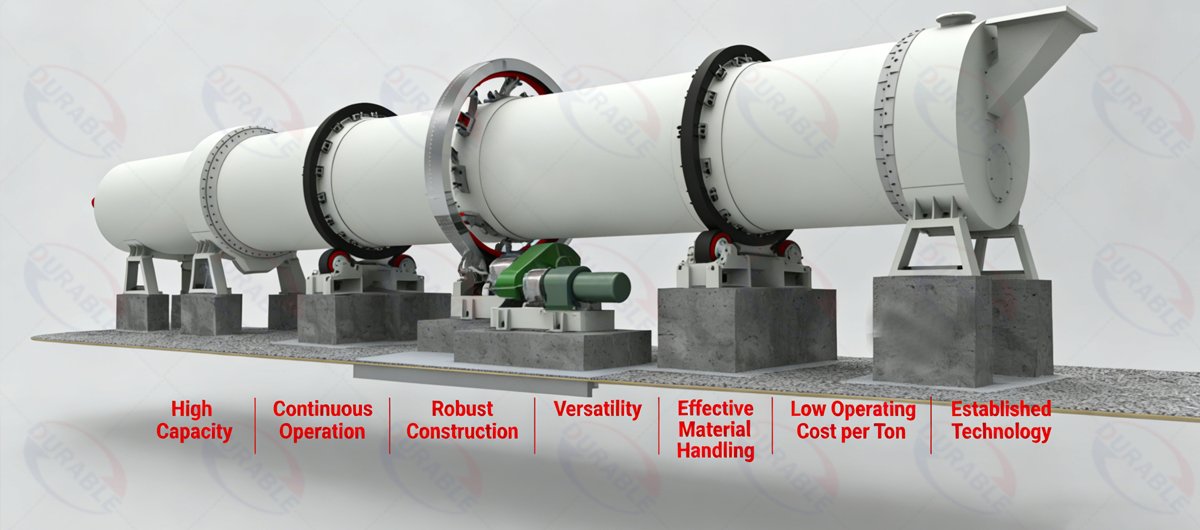

Rotary dryers offer distinct advantages over many other industrial drying devices. These benefits include high throughput capacity, continuous operation, and robust construction. They also handle a wide variety of materials. These core strengths make them a preferred choice for numerous industrial applications.

When comparing industrial dryer advantages, rotary dryers often stand out.

- High Capacity: These dryers process very large volumes of material continuously. This makes them ideal for large-scale operations in mining and construction. This contrasts with batch dryers handling smaller quantities intermittently.

- Continuous Operation: Material flows in and out without interruption. This integrates seamlessly into continuous production lines. It enhances overall plant efficiency.

- Robust Construction: Their simple yet sturdy mechanical design makes them highly durable. They withstand harsh environments. They tolerate abrasive and high-temperature conditions. This leads to a long operational lifespan with minimal structural issues.

- Versatility: Rotary dryers handle a broad spectrum of materials. These materials vary in particle size, shape, and initial moisture content. They dry anything from fine powders to large lumps. This adaptability reduces the need for multiple specialized dryers.

- Effective Material Handling: Internal flights ensure thorough mixing. They also ensure exposure of all material particles to the hot gas. This results in uniform drying and high heat transfer efficiency.

- Low Operating Cost per Ton: Once installed and optimized, the operating cost per ton of dried material can be very competitive. This results from their efficiency and high throughput. This provides significant industrial dryer advantages.

- Established Technology: Rotary dryers represent a mature technology. This means predictable performance, readily available spare parts, and established operational practices. This reduces operational risks.

These combined features make rotary dryers a highly efficient and cost-effective solution for many drying challenges. They serve as the workhorses of the drying world.

How Do Rotary Dryers Handle Abrasive and High-Moisture Materials?

Rotary dryers efficiently handle challenging materials. This includes highly abrasive or very high-moisture content materials. They employ specific design features and operational strategies to overcome these difficulties. This ensures efficient drying and prolongs equipment life.

Processing highly abrasive materials presents a significant challenge for any drying equipment. Constant friction from hard, sharp particles quickly wears down internal components. To combat this, industrial rotary dryer designs incorporate specialized wear-resistant linings. These linings often use high-chrome steel or ceramic materials. They protect the drum shell and lifters from abrasion. Lifter designs also account for wear. They may be thicker. Or they may be designed for easy replacement. Furthermore, the material flow path within the dryer is optimized. This minimizes direct impact zones. It further reduces wear.

High moisture material drying presents challenges like higher energy demand, clumping, and buildup. Solutions include larger/longer drums for increased residence time, specialized lifters for sticky materials, or pre-drying/mechanical dewatering. These methods improve drying efficiency optimization and reduce energy load. Adjusting the hot air system with higher temperatures or increased airflow also accelerates moisture removal. Combining robust construction with intelligent design, rotary dryers effectively manage these difficult materials, proving critical for the overall drying process flow.

How Do Engineers Optimize Rotary Dryer Parameters for Efficiency and Output?

Optimizing rotary dryer parameters is crucial for enhancing energy efficiency and production capacity. Adjusting variables like feed rate, drum speed, and hot gas conditions ensures optimal drying performance and drying efficiency optimization.

Achieving maximum drying efficiency involves balancing several interacting parameters:

- Feed Rate: The amount of wet material introduced. Optimize to avoid incomplete drying (too high) or energy waste (too low), ensuring maximum capacity.

- Drum Speed: Affects material’s cascading action. Optimal speed ensures best ‘shower’ effect, maximizing hot gas contact, preventing under-lifting (too slow) or centrifuging (too fast).

- Drum Inclination: The drum’s slope (1-5 degrees) controls material residence time. Steeper for faster passage, shallower for longer, matching drying time to moisture needs.

- Hot Gas Temperature and Flow Rate: Critical for heat transfer. Higher temperatures boost evaporation but require control for sensitive materials. Flow rate ensures sufficient air for moisture removal.

- Exhaust System Management: Exhaust fan speed controls airflow, removing moisture-laden gases. Optimization prevents re-condensation and maintains proper draft.

- Material Particle Size: Not adjustable, but understanding its distribution (e.g., finer materials dry faster but dust more) informs other parameter settings.

Careful tuning of these parameters achieves desired final moisture content with minimal energy and maximized throughput, significantly impacting profitability. Even small adjustments yield substantial efficiency improvements.

What Maintenance Strategies Extend Rotary Dryer Lifespan?

Robust maintenance is vital for rotary dryers, extending lifespan and ensuring reliability. Proactive care prevents breakdowns.

A comprehensive plan prevents issues, protects investments, and minimizes downtime.

- Lubrication: Proper, regular lubrication of all moving parts (rollers, bearings, drive) prevents wear; follow guidelines.

- Wear Components: Inspect internal flights, refractory, and drum shell for wear/damage to maintain efficiency.

- Alignment Checks: Ensure critical trunnion/thrust roller alignment to prevent wear, vibration, and stress.

- Drive System: Inspect motor, gearbox, and girth gear for wear, meshing, and abnormal noise.

- Cleaning & Dust Control: Regular cleaning and optimal dust collection prevent accumulation, protecting components and efficiency.

- Monitoring Instruments: Calibrate sensors and controls regularly for accurate readings, essential for process control.

These strategies ensure efficient, safe, long-term operation, enhancing asset value and ROI.

How Does One Diagnose and Troubleshoot Common Rotary Dryer Faults?

Efficiently diagnosing and troubleshooting common rotary dryer faults is vital. This minimizes downtime. It also prevents minor issues from escalating into major repairs. Operators must recognize abnormal symptoms. They then apply systematic diagnostic steps for quick resolution.

Even with the best dryer maintenance, issues can arise. Knowing how to quickly address them is key.

- Excessive Vibration: This represents a common fault. It indicates several problems.

- Diagnosis: Check for material buildup on flights or inside the drum. This causes imbalance. Inspect trunnion and thrust rollers for wear or misalignment. Check for loose bolts on the drive system or support structure.

- Resolution: Clean out buildup. Re-align rollers. Tighten loose fasteners. If wear is significant, component replacement may be necessary.

- Poor Drying Performance / High Final Moisture: This occurs if material fails to dry to the desired level.

- Diagnosis: Check the feed rate. Is it too high? Verify hot gas temperature. Is it too low? Check airflow. Does the exhaust fan function correctly? Inspect lifters for wear or damage. Do they create a good “shower” effect?

- Resolution: Adjust feed rate and temperatures. Check for blockages in the hot air system. Repair or replace damaged flights. Ensure proper drying process flow.

- High Fuel Consumption: Unexpected increases in fuel use.

- Diagnosis: Check burner efficiency. Is it properly tuned? Inspect drum insulation for damage. Check for excessive air leaks into the dryer. Are exhaust temperatures too high.

Durable Machinery

Durable Machinery