Search the whole station liberty-fse

DM4-24 Automatic Concrete Block Manufacturing Machine price

Capacity: 4-14 pieces per mould; 3200-12,000 pieces per 8 hours

Power: electric motor

Moulding Type: vibrating moulding

Block Size: 4inch 6inch 8inch hollow blocks, solid blocks, paver bricks etc..

Introduction:

The DM4-24 Block Machine offers a proven design for efficient, consistent block production.This machine is smallest automatic machine. Not only the DM4-24 showcases advanced automation, but also the DM4-24 focuses on simplicity and ease of use, providing a strong return on investment for smaller to medium-sized operations. Ideal for producing standard blocks, pavers, and other concrete products, the DM4-24 brick making machine delivers performance you can depend on. This concrete block making machine provides a good chance for small and medium size investors. It is also an “all in one” machine, because it can make all types bricks by exchanging the block mould.

QT4-25 Automatic Brick Factory Machine Line

Capacity:4-10 pieces per mould; 5700-11520 pieces per 8 hours.

Power: 20.75KW

Application: fly ash ; cement ; concrete; sand; aggregate etc..

Introduction:

This brick machine is more automatic than DM4-24 because of the efficient material spreading system.The QT4-25 is a automatic block making machine line designed for efficient and versatile production of various concrete blocks , cement bricks, fly ash bricks. This block brick making machine is suitable for meeting the demands of small to medium-sized construction projects. The QT4-25 offers a reliable and affordable solution for manufacturing interlocking blocks, solid bricks, hollow blocks, and pavers, providing a strong return on investment for businesses entering or expanding their concrete product manufacturing capabilities.This block bricks machine line is a good choice for medium-big scale enterprise.

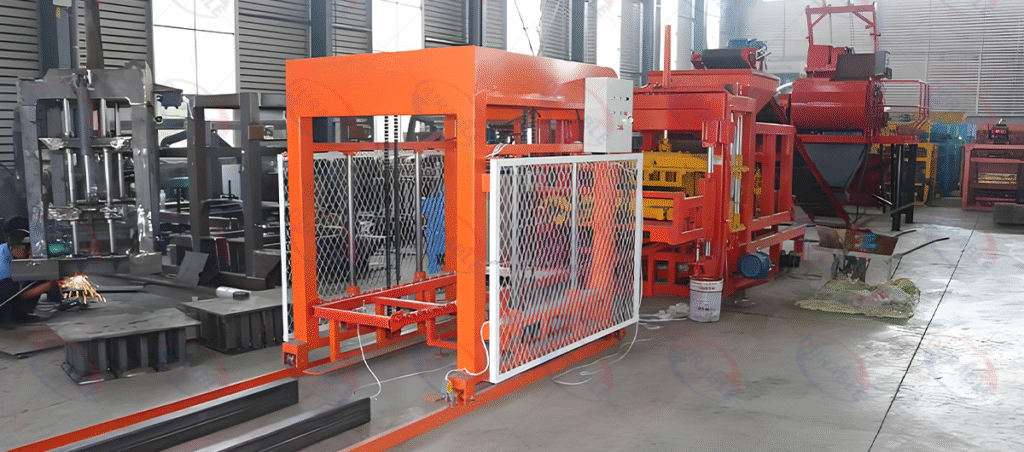

QT4-16 Automatic Paver Block Making Machine

Capacity: 4-28 pieces per mould;7600-53000 pieces per 8 hours

Forming Cycle: 16 Seconds

Application:crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, expanded perlite, and other industrial wastes

Moulding Method: Hydraulic Pressure + Vibrating Moulding

Introduction:

The QT4-16 Hydraulic Fully Automatic Brick Machine represents a significant advancement in brick and block manufacturing technology. Featuring a powerful hydraulic system and PLC control, this bricks machine automates the entire production process, from material feeding to block ejection. Its robust construction and advanced design ensure consistent and reliable operation, delivering high output and minimizing labor costs. The QT4-16 is an ideal investment for businesses seeking to maximize productivity and achieve superior block quality.

QT6-15 Automatic Brick Making Machine Price

Capacity:6-33 pieces per mould; 11520-63360 pieces per 8 hours

Forming Cycle: 15 seconds

Hydraulic Pressure:21Mpa

Pallet Size: 940×830×25mm

Vibration Type:Table Vibration And Hydraulic Pressure

Introduction:

The QT6-15 Fully Automatic Fly Ash Brick Making Machine is an advanced solution for the large-scale production of fly ash-based building materials. Equipped with a sophisticated PLC control system and robust hydraulic components, this machine offers precise control over the entire brick making process, ensuring consistent quality and high output. Its fully automated design minimizes the need for manual labor, streamlining your production operations and maximizing efficiency. The QT6-15 is a smart investment for businesses seeking to meet the growing demand for sustainable and affordable building materials.

QMY6-25 Automatic Egg Laying Block Making Machine

Capacity:6-9 pieces per mould; about 9000-10000 pieces per 8 hours

Power:Electric Motor

Forming Cycle:25-30 seconds

Moulding Method: Mechanical Vibration Molding & Hydraulic Pressure

Introduction:

The QMY6-25 Egg Laying Block Machine offers a practical and efficient solution for decentralized block production. This mobile machine lays blocks directly on the ground, eliminating the need for pallets and reducing handling costs. Its robust design and simple controls ensure reliable performance, while its portability allows you to easily move the machine to different job sites. The QMY6-25 mobile block making machine is an excellent investment for those seeking a cost-effective and flexible block making solution.Its mobility allows you to produce blocks wherever you need them, adapting to the specific requirements of each project.

If you are looking to improve your brick production, an automatic brick making machine is the answer. This guide will help you understand everything about these powerful machines. We will explain how they work, what they can do, and how to choose the right one for your business. At DURABLE, we want to give you the knowledge to make a smart investment that boosts your efficiency and profit.

Last Updated: 2025 May | Estimated Read Time: 17 minutes

An automatic brick making machine is a piece of equipment that produces bricks with very little human help. It handles the entire process, from mixing raw materials to forming the final bricks. We design these machines to be fast, reliable, and consistent. They use advanced systems like PLC (Programmable Logic Controller) controls to manage every step, ensuring each brick is made to the same high standard. This automation makes them a core part of any modern brick manufacturing plant.

These machines are different from manual or semi-automatic versions because they control the entire workflow. This includes feeding materials, pressing them into molds, and ejecting the finished bricks. This high level of automation reduces the need for manual labor, which lowers your costs and reduces the chance of human error. For any business looking to scale up production, from a small startup to a large construction supplier, an automatic brick machine is a necessary tool.

You can use an automatic brick making machine in many different industries and projects. Their versatility makes them valuable for a wide range of customers.

One of the best things about an automatic brick making machine is the variety of bricks it can produce. By simply changing the mold, you can create many different types of bricks to meet market demand.

Investing in an automatic brick making machine offers significant benefits that can transform your business. The main advantages are increased efficiency and consistent quality.

We offer different types of automatic brick making machines to fit various needs and production environments. You can choose a machine based on mobility, the material it uses, or its output capacity.

Based on Mobility:

Based on Raw Material:

Based on Output Capacity:

At DURABLE, we build our automatic brick making machines with advanced technology to ensure you get the best performance and reliability. We focus on features that make your production smarter and more durable.

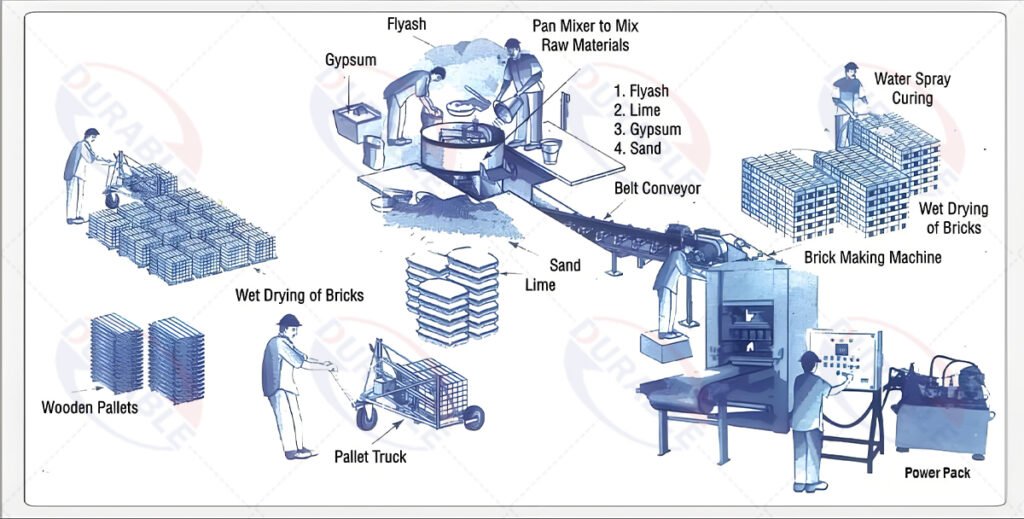

The working process of an automatic brick making machine is a streamlined sequence of steps, all managed by the PLC control system. Understanding this process helps you see how efficiency is achieved.

The core principle behind an automatic brick making machine is forming bricks through pressure and vibration. These two forces work together to create bricks with superior density and strength.

The hydraulic system is the muscle of the machine. It uses oil pressure to generate immense force, often over 100 tons. This pressure compacts the raw material particles tightly together, squeezing out excess water and air. This is what gives the bricks their high compressive strength, making them suitable for building strong walls.

The vibration system is equally important. It consists of powerful motors that create high-frequency vibrations. This shaking action causes the semi-dry concrete mix to behave like a liquid for a moment, allowing it to flow into every corner of the mold. This ensures the brick has sharp edges, a smooth surface, and no internal voids or weak spots. At DURABLE, we synchronize the pressure and vibration perfectly to produce the highest quality machine cement bricks.

Choosing the right type of brick machine depends on your production goals, budget, and labor availability. Here is a simple comparison to help you decide.

| Feature | Manual Brick Machine | Semi-Automatic Brick Machine | Fully Automatic Brick Machine |

|---|---|---|---|

| Operation | Entirely human-powered. Labor-intensive. | Some steps are automated (e.g., pressing), others manual. | Entire process is automated. Requires minimal human oversight. |

| Production Rate | Very Low (a few hundred bricks/day) | Medium (a few thousand bricks/day) | Very High (tens of thousands of bricks/day) |

| Labor Needed | High (5-8 workers) | Medium (3-5 workers) | Low (1-3 workers for supervision) |

| Brick Quality | Inconsistent. Depends on worker skill. | Consistent quality. | Highly consistent and uniform. Best quality. |

| Initial Cost | Very Low | Moderate | High |

| Best For | Small-scale projects, individuals, or remote areas. | Small to medium-sized businesses. | Medium to large-scale factories and construction companies. |

The quality and longevity of a brick making machine depend on the materials used to build it. At DURABLE, we only use top-grade materials and components to ensure our machines last for decades.

Choosing the right automatic brick making machine is a major decision. You need to consider several factors to ensure you get a machine that fits your business perfectly.

The cost of brick making machine can range from around $15,000 for a smaller, simpler automatic model to over $200,000 for a large-scale, fully integrated production line. The final price depends on several factors.

It’s important to get a detailed quote that breaks down all the costs, so you understand exactly what you are paying for.

Proper maintenance is essential to keep your automatic brick making machine running smoothly and to ensure its longevity. A well-maintained machine from DURABLE can provide reliable service for decades.

Training your operators to perform these routine checks is crucial. A proactive approach to maintenance prevents small issues from turning into major, costly breakdowns.

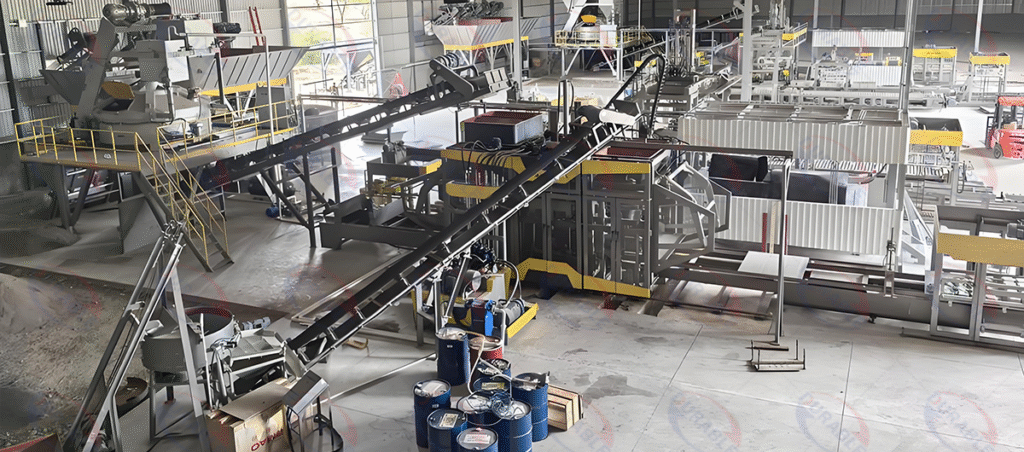

Proper installation is the first step to successful brick production. Before your new automatic brick making machine arrives, you need to prepare your site. A solid, level concrete foundation is essential. This foundation must be thick enough to support the machine’s weight and absorb the constant vibrations without cracking. You also need enough space not just for the machine, but for storing raw materials, a large area for the fresh bricks to cure, and a place to store the finished product.

Your facility must have a stable, three-phase industrial power supply with the correct voltage. A reliable water source is also necessary for mixing the concrete and for daily cleaning of the equipment. While the bricks machine making process is automatic, the initial setup requires expertise. At DURABLE, we provide detailed foundation drawings and can send our engineers to your site to guide the installation and train your team, ensuring everything is set up for optimal performance from day one.

Even the best machines can face issues. Knowing how to quickly identify and solve common problems will minimize downtime. Here are a few typical scenarios you might encounter with your automatic brick machine:

Problem: Bricks are weak or crumbly.

Problem: Bricks have rough edges or cracks.

Problem: The machine stops suddenly.

An automatic brick machine dramatically improves brick quality through precision and consistency. Unlike manual methods, which depend on worker skill and effort, automation ensures every single brick meets the same high standard. The system uses an automatic batching plant to measure the exact amounts of cement, sand, and water for every batch. This guarantees a uniform raw material mix, which is the foundation of a strong brick.

The combination of powerful hydraulic pressure and high-frequency vibration is controlled precisely by the PLC. This process forces out air pockets and compacts the material to a uniform density throughout the brick, creating superior strength and durability. Our high-precision, heat-treated molds ensure every brick has exact dimensions and sharp, clean edges. This level of control eliminates human error, resulting in a consistent supply of high-quality machine cement bricks that builders can rely on.

Making great bricks is only half the battle; you also need to sell them. Start by identifying your ideal customers. Are you targeting large construction companies, smaller independent builders, or retail hardware stores? Tailor your sales approach to each group. The superior quality and consistency of your automatic brick products are your biggest selling points. Offer samples so potential buyers can see and feel the difference.

Showcase the variety of products you can create. Make a simple catalog with photos and specifications of your solid blocks, hollow blocks, and decorative pavers from your automatic paver block making machine. Building strong relationships with local contractors is key. Offer them reliable delivery schedules and competitive pricing. Finally, consider creating a simple website or a social media page to display your products to a wider audience, making it easy for new customers to find and contact you.

For over 30 years, DURABLE has been a leader in the brick making machine industry. We are not just a supplier; we are your partner in production. We have exported our machines to over 120 countries and have a deep understanding of the global market.

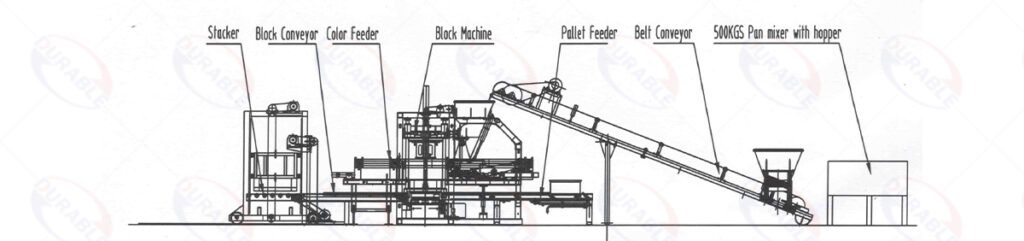

Our strength lies in our one-stop solution. We provide everything you need for a complete brick manufacturing plant, from crushing raw materials and mixing concrete to forming blocks and stacking the final product. We use high-quality, wear-resistant steel and world-class components like Siemens PLCs and Schneider electronics to build machines that are efficient, intelligent, and incredibly durable. Our experienced engineers can customize any machine or production line to fit your exact needs. When you choose DURABLE, you choose a legacy of quality, innovation, and unwavering customer support.

Contact us today to get a custom quote and find out how a DURABLE automatic brick machine can revolutionize your business.