Biomass Briquettes or Pellets: Which Suits Your Startup Best?

As an expert with 50 years of experience in the biomass energy sector, I know this well. For a startup, choosing between biomass briquettes and biomass pellets is never a simple “which is better” question. It is about “which is better for your starting resources, your target market, your budget, and your operating model.” Many new business owners see only the surface. Pellets are standardized and automated. Briquettes are coarser and seem less technical. My experience shows that for startups, biomass briquettes often offer more flexibility and lower entry barriers. This holds true if you find the right market and application. This guide will help you navigate this decision for your biomass fuel project selection.

Table of Contents

- Biomass Briquettes vs. Pellets: What are the Core Differences?

- Equipment Investment & Initial Costs: Which Product Suits Capital-Limited Startups Better?

- Raw Material Adaptability & Supply: Which Fuel has Broader Requirements and is Easier to Obtain?

- Production Process & Operational Difficulty: Which Product has Lower Technical Barriers and is Easier to Start?

- Product Features & Market Positioning: Which Fuel has Clearer Market Demand and Wider Sales Channels?

- Target Customer Analysis: Industrial, Commercial, or Residential, Which Market is Easier to Enter?

- Storage, Transportation Costs & Loss: Which Fuel Offers Logistical Advantages?

- Profit Margins & ROI Cycle: How Can Startups Achieve Quick Profitability?

- Environmental Standards & Policy Direction: Which Product has Greater Future Development Potential?

- Scalability & Expansion: From Small-Scale Pilot to Gradual Expansion, Which Path is Smoother?

- Startup Decision Framework: How to Make the Best Choice Based on Your Resources and Goals?

- FAQs

- Summary & Recommendations

- About Durable

Biomass Briquettes vs. Pellets: What are the Core Differences?

The core differences between biomass briquettes and biomass pellets are crucial for any startup biomass energy venture. These differences affect production, equipment, and market use. Understanding these points helps you make the right choice. It guides everything from where you get materials to how you sell your product.

Biomass pellets are small, dense cylinders. We make them by pressing finely ground biomass through a die. This process creates a standardized, high-density fuel. Pellets need strict control over the raw material size and moisture. They work best in automated systems for specific furnaces. Biomass briquettes are larger. They come in shapes like logs or squares. We make them from coarser biomass. They can also handle slightly more moisture. Briquettes can be used in more types of furnaces, even those with simpler feeding. The way we make them, the materials we need, and what the final fuel is like are very different. You must understand these core differences for your small-scale biomass production.

Equipment Investment & Initial Costs: Which Product Suits Capital-Limited Startups Better?

For a startup biomass energy business, managing money for equipment and initial costs is very important. Your choice between biomass briquettes and biomass pellets directly affects these costs. This decision can decide if your business will succeed, especially if you have little money.

Making biomass briquettes usually needs less money at the start. The machines, like a biomass briquette machine, are often simpler. They do not need as much exact pre-treatment equipment. This lowers the capital expenses (CAPEX) you need to begin. For a small-scale biomass production facility, this lower start-up cost can be a big benefit. Preparing raw materials, like crushing, might use simpler tools. This means fewer steps. Briquette production is a good choice for entrepreneurs with small budgets.

Making biomass pellets usually costs more money at the start. Pellet machines, like a pellet making machine, are more complex. They need exact control over raw material size and moisture. This means buying advanced crushers and efficient dryers. A pellet production line often has more parts and more automation. This adds to the upfront cost. So, for a startup biomass energy business focused on keeping costs low, briquette production is easier to afford. It allows you to enter the market faster and possibly get your money back sooner.

Raw Material Adaptability & Supply: Which Fuel has Broader Requirements and is Easier to Obtain?

Good raw material supply and being able to use different materials are key for any biomass fuel project selection. For a startup biomass energy company, raw material is like your “first bank.” Getting it steadily and cheaply is most important. This often matters more than choosing the right machine.

Biomass briquettes are usually more flexible with raw materials. They can use many types of farm and forest waste. This includes straw, branches, and rice husks. These materials can have different particle sizes, like 5-50mm. Briquettes also handle slightly more moisture, sometimes up to 18%. This makes finding raw materials easier and possibly cheaper for small-scale biomass production. Being able to use many local waste materials means you depend less on specific, high-quality inputs. This makes your supply wider and your project stronger.

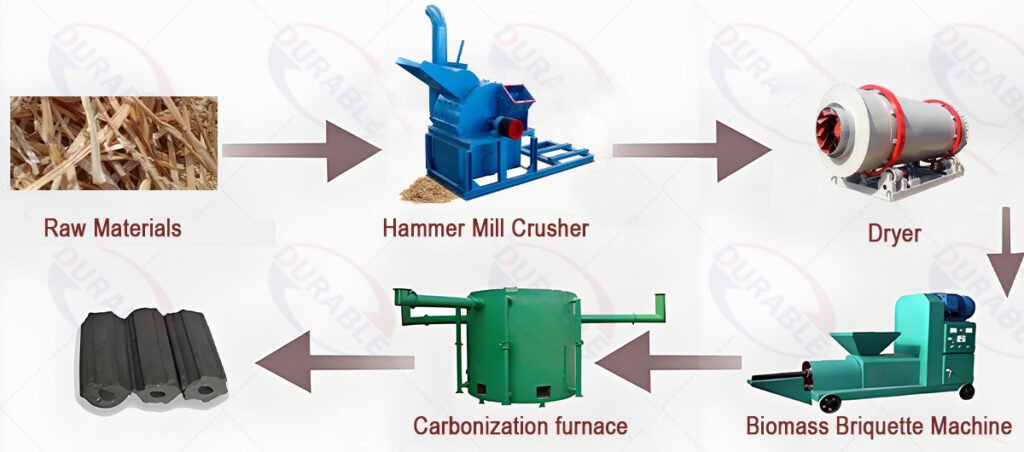

Biomass pellets, however, need very specific raw materials. They need finely ground material, usually smaller than 6mm. The moisture must be carefully controlled, ideally between 8-12%. Meeting these strict rules often means more detailed and exact pre-treatment. This means more crushing (e.g., using a hammer mill crusher) and drying. These needs can limit where you get materials. They can also raise the cost of preparing raw materials. So, for a startup biomass energy business, briquettes offer more raw material choices. This simplifies getting supplies and might lower your costs.

Production Process & Operational Difficulty: Which Product has Lower Technical Barriers and is Easier to Start?

Knowing the production process and how hard it is to run is very important for a startup biomass energy company. This helps you choose the best way for your biomass fuel project selection. The option that is “easier to start” often means fewer problems at the beginning. It also means you can get into the market faster.

Making biomass briquettes usually needs less technical skill. The process often has fewer steps. It also needs less exact control compared to pellets. Preparing raw materials for briquettes can be simpler. It might need less fine grinding. It can also handle slightly more moisture. The machines, like a biomass briquette machine, are often stronger and more forgiving. This makes the whole operation easier for a small-scale biomass production team. This is true even if the team has less technical experience. Maintenance can also be simpler. This means lower running costs and easier problem-solving.

Biomass pellets production needs more technical skill and is harder to run. The process needs exact control over raw material particle size and moisture. This means buying advanced grinding and drying equipment, such as a sawdust dryer. The pelletizing part itself, often using a pellet making machine, is sensitive to how consistent the material is. The parts that wear out, like dies and rollers, wear faster because of high pressure. This leads to higher maintenance costs and more frequent replacements. The whole biomass fuel production process for pellets is more sensitive to small errors. This makes it harder for new operators to make good quality products consistently. So, briquettes offer an easier and less demanding way to start your business.

Product Features & Market Positioning: Which Fuel has Clearer Market Demand and Wider Sales Channels?

For a startup biomass energy venture, understanding what your product offers and where it fits in the market is key. The market for biomass fuel project selection is not all the same. The best choice depends on matching your product’s features to specific market needs and sales ways. Market demand is tricky. You must think about standard products versus special ones.

Biomass pellets serve a more standard and often global market. Their even size, high density, and steady energy make them good for automated burning systems. Big markets include homes with pellet stoves, factories with pellet boilers, and large central heating projects. Also, they can be used with coal in power plants. This market needs very strict quality rules for size, density, heat, and ash. If you meet these rules, you can enter big, existing sales channels. But this needs strong quality control.

Biomass briquettes often sell more locally and to different types of customers. Their various sizes and shapes allow for custom solutions. Main customers include local small factories, farm drying places, and brick kilns. For example, carbonized briquettes are used for BBQ and catering. This market often wants special products, not strict standard ones. Briquettes may not need hard-to-get international approvals. This can give you an edge by offering custom products to local buyers. A biomass fuel market analysis shows that briquettes can use specific local needs. This gives a startup biomass energy company more ways to sell at a local level.

Target Customer Analysis: Industrial, Commercial, or Residential, Which Market is Easier to Enter?

Figuring out who your customers are is a very important step for biomass fuel project selection. For a startup biomass energy business, knowing which market is easier to enter helps you plan your first sales. Your choice between factory, business, or home users changes how fast you can get into the market and grow.

Biomass pellets mostly target markets that need standard products and automated fuel delivery. This includes big industrial boiler fuel users, central heating plants, and homes with pellet stoves. These customers often need steady quality, reliable supply, and automated feeding systems. These markets can be very big. But, getting in can be hard for a new company. This is because of strict quality rules and existing supply chains. To compete here, you need a lot of money for advanced production and good ways to deliver.

Biomass briquettes often find it easier to get into local factory and business markets. This includes smaller factories, places that dry farm products, and brick kilns. These customers might have simpler burning machines. They want cheap, local fuel. For example, a startup biomass energy company can target local businesses needing heat for specific jobs. If carbonized, briquettes can also be sold to BBQ and catering businesses. This market often has fewer entry problems. It also lets you sell directly to customers. This means faster market entry and cash flow for small-scale biomass production businesses. Knowing these different customer needs helps a startup find the easiest and most profitable market.

Storage, Transportation Costs & Loss: Which Fuel Offers Logistical Advantages?

Good logistics, like storage, transport costs, and lost product, are key for biomass fuel project selection. For a startup biomass energy company, better logistics can greatly help profits. It helps keep running costs low from the factory to the customer.

Biomass pellets generally have big advantages in logistics. They are very dense and small. This makes them easy to store in bulk and transport efficiently. A cubic meter of pellets holds more energy than the same amount of briquettes. This means lower transport costs for each unit. Pellets are easy to handle with automated systems and pneumatic feeders. This reduces manual work and lessens loss during moving. Their standard size also makes managing stock and checking quality easier during storage. Overall, pellets lead to lower long-term logistics costs because they are compact and consistent.

Biomass briquettes, while possibly cheaper to make at first, often face bigger logistics problems. They are less dense and bigger. This means a certain volume moves less energy. This leads to higher transport costs per unit compared to pellets. Briquettes also need more storage space. Handling them can take more manual work. This can lead to more breaking and loss during loading, unloading, and stacking. A startup biomass energy firm might save money on production machines. But these higher logistics costs can reduce profits over time. So, for long-term transport, pellets are usually better for wide distribution. Briquettes are often better for local supply chains.

Profit Margins & ROI Cycle: How Can Startups Achieve Quick Profitability?

For a startup biomass energy business, knowing your profit and how long it takes to get your money back is crucial. The goal is to pick a biomass fuel project selection that lets you make money quickly. This means looking closely at both the initial costs (CAPEX) and ongoing running costs (OPEX).

Biomass briquettes often offer a faster way to make money for startup biomass energy businesses. Their machines cost less at the start. This means lower CAPEX. You can get your money back faster. If raw materials are cheap and easy to get, and many local buyers want them, a briquette business can make money sooner. The running costs, while still needing careful management (especially for drying), can be simpler than for pellets. This mix of lower initial costs and possibly faster market entry can mean you get your money back sooner for small-scale biomass production.

Biomass pellets demand higher initial CAPEX, extending the payback period. Though efficient, operating costs are high due to precise grinding, drying (often needing a sawdust dryer), and pelletizing. Wear parts, such as pellet making machine dies and rollers, further boost OPEX. For a startup, these higher initial and ongoing expenses can delay profit, requiring careful CAPEX and OPEX analysis. Briquettes may offer a safer, quicker path for those with tight budgets.

Environmental Standards & Policy Direction: Which Product has Greater Future Development Potential?

Following environmental rules and knowing policy trends is key for biomass fuel project selection. For a startup biomass energy firm, choosing a product with more future growth means keeping up with new rules and green goals. This ensures your business stays strong and grows for a long time.

Both biomass briquettes and biomass pellets are much better for the environment than fossil fuels. They lower greenhouse gases and use up waste. But pellets often fit strict environmental rules better. This is because they are standard. Their lower moisture and ash, plus steady burning, mean they burn cleaner. This makes them better for meeting air quality rules in many places. Rules often favor processed, clean-burning biomass fuels for industrial boiler fuel and home heating.

For biomass briquettes, environmental rules can be more local. While good, their varied traits might mean slightly more pollution if not managed well. However, using different raw materials, like farm waste such as straw, is strongly supported by rules in many areas for waste management. Making carbonized briquettes (e.g., using a charcoal making machine) also adds value. It creates a clean-burning charcoal product. A startup must think about local environmental rules. Knowing these details helps predict future market acceptance and support from rules. Both products help the environment. But pellets often have an edge in global standards and strict pollution control.

Scalability & Expansion: From Small-Scale Pilot to Gradual Expansion, Which Path is Smoother?

For a startup biomass energy business, thinking about how to grow and expand is very important. The goal is to find a way that lets you move smoothly from small-scale biomass production to bigger operations. This plan helps lower risks and makes growth better.

Starting with biomass briquettes offers a smoother, less risky path. Lower initial investment allows startups to test the market with easier setup and operation. This helps build raw materials and a local customer base. Growth is flexible and gradual, adding capacity as demand and funds increase, avoiding large upfront spending. Experience gained can also lead to future diversification, like pellets.

Moving from small-scale biomass production to making a lot of pellets can be harder. Pellet lines are usually made for producing a lot. They need a more complete and complex setup. Growing pellet production often means a big jump in money and technical needs. This includes bigger, more exact machines for preparing raw materials, drying, and making pellets. Pellets can save money when you make a lot. But making the first big jump can be riskier for a new company with little money. So, briquettes usually offer a safer and easier way to manage money. It lets you test the market and grow slowly in the biomass energy field.

Startup Decision Framework: How to Make the Best Choice Based on Your Resources and Goals?

For a startup biomass energy company, making the best choice needs a clear way to decide. This way brings together all the things we talked about. It matches what you have to what you want to achieve for biomass fuel project selection. You will succeed if you match things well, not just by picking what seems “best.”

First, check what raw materials you can get and how much they cost. If you have many cheap farm or forest waste materials locally, and they have different moisture levels, biomass briquettes might be better. If you can get a steady supply of clean, dry wood waste, then biomass pellets are more likely to work. This first check of “raw material as your first bank” is key. Second, look at your money budget and how much risk you can take. Briquettes need less money at the start and to run. This makes them good for small-scale biomass production and getting money back faster. Pellets need more money at first but can make more money in standard markets.

Third, research local demand: briquettes (factories, farms, restaurants), pellets (homes, large factories, export). Note standard vs. special needs. Fourth, assess team skills: briquettes need less technical skill; pellets demand more precise skill and quality control. Finally, plan for growth and environmental rules: both are eco-friendly, but pellets meet stricter global regulations, suiting regulated markets. This ensures optimal project selection for your startup.

FAQs

Question 1: Which fuel, biomass briquettes or pellets, has lower initial investment?

Typically, the initial equipment investment for a biomass briquette production line is lower than for a biomass pellet production line. This includes the briquette machine itself and pre-treatment equipment.

Question 2: How important is raw material moisture content for biomass fuel production?

Raw material moisture content is very important. High moisture greatly increases drying costs, lowers production efficiency, and reduces product quality. Pellet fuel has stricter moisture requirements.

Question 3: What are the main application markets for biomass pellet fuel?

Biomass pellet fuel is mainly used in residential pellet stoves, industrial pellet boilers, central heating projects, and co-firing with coal power plants. Market demand is highly standardized.

Question 4: Do biomass briquettes always require binders?

Biomass briquettes, under certain conditions (like screw extruders processing lignin-rich materials), may not need binders. However, some raw materials or pressing equipment might require a small amount of binder.

Question 5: How can I estimate drying costs in total operating expenses?

Drying costs typically account for 30-50% or even more of the entire production line’s operating expenses. This depends on the raw material’s initial moisture content and the efficiency of the chosen drying equipment.

Question 6: How can a biomass fuel project meet environmental standards?

A biomass fuel project should meet environmental standards through efficient dust collection systems, exhaust gas treatment equipment, and by choosing low-ash, low-sulfur raw materials. Carbonized biomass fuel burns cleaner.

Summary & Recommendations

Choosing between biomass briquettes and biomass pellets as a startup’s entry point requires a deep understanding of your resources and target market. Biomass briquettes generally offer lower initial investment, wider raw material adaptability, and lower technical operational barriers. This makes them a preferred choice for startups with limited capital, aiming to quickly validate the market and reduce risk. If you can further invest in a carbonization furnace to produce carbonized biomass briquettes, it can boost product value.

In contrast, biomass pellets target a more standardized, higher-value market. They require higher equipment investment, more rigorous raw material pre-treatment, and strict quality control. While the ROI cycle might be longer, their product standardization, logistical advantages, and broad market potential attract companies with more capital and technical expertise. Therefore, conduct thorough market research, detailed cost accounting, and fully understand your raw material characteristics. These are the cornerstones of your success.

About Durable

Durable Machine, established in 2001, is a leading Chinese manufacturer. We specialize in mineral processing equipment and construction machinery. We also apply our industrial process knowledge to biomass energy equipment. Durable designs and builds complete, integrated biomass fuel production lines, focusing on briquette machines. Our solutions prioritize efficiency, reliability, and environmental responsibility. We understand that every project is unique. So, our team at Durable works closely with clients. We design systems to match specific biomass types, production needs, and business goals. From initial consultations and plant design to custom equipment manufacturing, installation support, operator training, and comprehensive after-sales service, Durable ensures your investment leads to successful outcomes.

For expert advice and a custom plan for your biomass briquette machine project or pellet making machine project, contact Durable’s engineering team today.

Durable Machinery

Durable Machinery