Search the whole station liberty-fse

QMJ2-40 Portable Brick Block Making Machine

Capacity:2 pieces per mould; 1440 pieces per 8 hours

Power Type: Diesel Engine/Electric Motor

Workers Needed: 1-2 persons

Forming Cycle:40-45 seconds

Moulding Method: Mechanical Vibration Molding

Brick Size: Different sizes and shapes including 4inch,6inch,8inch hollow blocks, solid bricks.

Introduction:

This Small Mobile Block Prouction Machine is a good choice for small block projects for new start.With Low Initial Investment, it has excellent mobility, so it can make bricks on site.In this way, it will save delivery cost and pallet cost.And this brick machine making is simple to operate, with light weight, only 1 person can use it. This manual brick making machine can make different hollow blocks, solid blocks, hollow bricks by changing customized block mould.

QMJ4-45 Mobile Simple Molding Block Machine

Capacity:4-6 pieces per mould; about 2500-4000 pieces per 8 hours

Power Type: Electric Motor

Workers Needed: 2-3 persons

Forming Cycle:40-45 Seconds

Moulding Method: Mechanical Vibration Molding

Brick Size: Different sizes and shapes including 4.5inch, 4inch, 6inch, 8inch, 10inch hollow blocks, solid bricks.

Introduction:

The QMJ4-45 is an efficient block machinery designed for ultimate flexibility. Equipped with wheels, this concrete block maker can be moved on the job site.

A key feature of block making machine for sale is its two-time vibration system. This advanced technology creates blocks with higher density and superior strength. No pallets are needed. The blockmachine molds blocks directly onto any concrete floor, saving you significant costs and simplifying your operation.

QMY6A Mobile Automatic Brick Machine

Capacity:6-9 pieces per mould; about 9000-10000 pieces per 8 hours

Power Type: Electric Motor

Workers Needed: 2-3 persons

Forming Cycle:25-30 seconds

Moulding Method: Mechanical Vibration Molding & Hydraulic Pressure

Brick Size: Different sizes and shapes including 4′, 5′, 6′ 9inch hollow blocks, solid bricks, colorful pavers, kerbstone. It is all in one brick machine.

Introduction:

The QMY6A is a concrete block making equipment engineered for large-scale, high-quality building blocks production. By simply changing the brick mold, the QMY6A machine to make cement bricks can manufacture a vast array of products to meet diverse market demands—from hollow blocks and solid bricks to colored pavers and kerbstones. It is the ideal block machine for any modern construction material enterprise focused on efficiency, quality, and growth.

DM4-40 Manual Block Maker Machine

Capacity: 4-14 pieces per mould;2200-6800 pieces per 8 hours

Power Type: Electric Motor

Workers Needed: 2-3 persons

Forming Cycle: 40-45 seconds

Brick Size: Different sizes and shapes including 400*200*200mm;400*150*200mm;400*100*200mm hollow blocks, solid bricks, I Shape,H Shape,Z Shape paver & curbstone.

Components: 350Pan Mixer+DM4-40 block machine with 1 set block mould

Introduction:

The DM4-40 fly ash brick making machine is solution for new entrepreneurs and small-scale business with limited budget, space, and production volume. This compact manual hollow block machines are available, its core strength lies in its efficient and space-saving design.The DM4-40 blocking machine is a complete production startup kit.It is the ideal choice for anyone looking to enter the block manufacturing business.

DM4-35 Automatic Paver Block Making Machine Line

Capacity: 4-14 pieces per mould; 3000-9000 pieces per 8 hours.

Power Type: Electric Motor

Forming Cycle: 35-40 Seconds

Brick Size: Different sizes and shapes including 400*200*200mm;400*150*200mm;400*100*200mm hollow blocks, solid bricks, I Shape,H Shape,Z Shape colorful paver & curbstone.

Components: JQ350 Mixer+ 6M Beltconveyor+ DM4-35 block machine

Introduction:

The DM4-35 block machine price is low, so this block making equipment is suitable for small or medium business or brick project. This brick making machines for sale represents the next evolution in compact block manufacturing.The core value of the DM4-35 brick maker for sale lies in its configuration as a complete, semi-automated production line.This integrated system minimizes manual labor and maximizes output. This Concrete block machine is a “all in one” America block machinery.

QT4-15 Stationary Concrete Block Making Machine Line

Capacity:4-14 pieces per mould; 7200-33600 pieces per 8 hours

Power Type: Electric Motor

Forming Cycle:15-20 seconds

Brick Size: Different sizes and shapes including 400*200*200mm;400*150*200mm;400*100*200mm hollow blocks, solid bricks, I Shape,H Shape,Z Shape paver & curbstone.

Introduction:

The QT4-15 machines for block making is a high-performance, fully automated concrete block machines. This block making machine line is engineered for large-scale blocks factory. This building block machine core principle is a super-strong vibration system combined with a completely automated workflow, delivering exceptional output with minimal labor. With the versatility to produce a wide range of products—from paver blocks to hollow blocks—by simply changing the mold, the QT4-15 is not just a machine; it’s a powerful, high-capacity production solution designed to dominate the market.

Are you looking to maximize your block production? A reliable block making machine is key. This equipment is essential for producing high-quality concrete blocks, pavers, and building blocks. This article covers the different types of block machines, their benefits, and factors to consider when choosing one. DURABLE MACHINE offers a wide range of durable and efficient block production equipment to meet your needs.

Last Updated: 2025.5 | Estimated Read Time: 12 minutes

A block brick making machine is a device used to manufacture various types of blocks, including concrete blocks, pavers, and building blocks. These machines automate the production process, ensuring consistent quality and high output. Block machines are used in a variety of construction projects, from residential buildings to infrastructure development.DURABLE MACHINE can provide different types block brick making machine according to your requirements. We have professional salesman recommend suitable machine according to your requirements.

A block machine is versatile and can produce various kinds of bricks, including:

The versatility of a block making machine allows you to cater to different market needs. DURABLE MACHINE can make all blocks in one machine just by exchanging block mould.

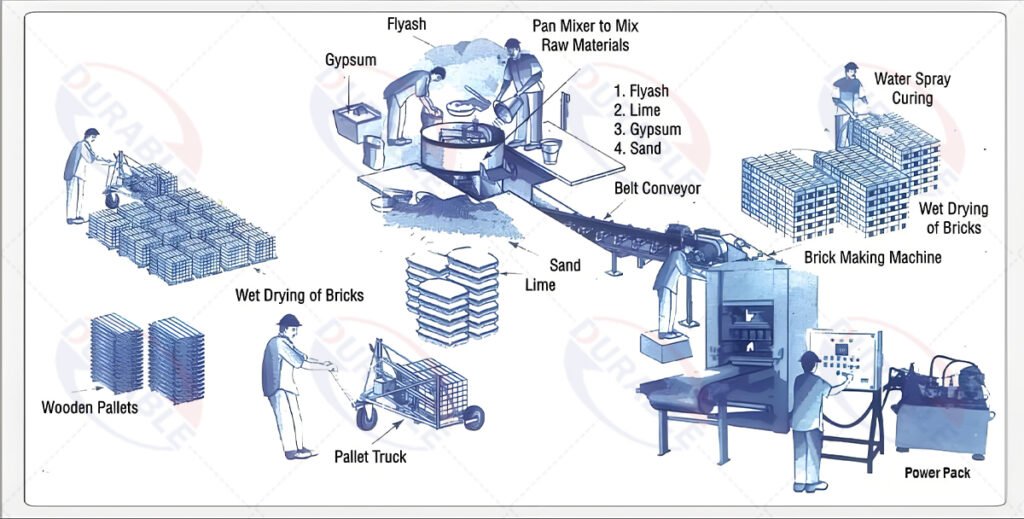

A variety of materials can be used to make blocks using a block machine, including:

Using different materials can impact the block’s properties, cost, and environmental footprint.

Concrete block machines come in various types, each suited for different production scales and automation levels.

DURABLE MACHINE automatic block machines offer advanced features for efficient and reliable production.

Using a concrete block machine offers several benefits over traditional block making methods:

These benefits make concrete block machines a worthwhile investment for any block production business.

Blocks made by machine are used in a wide range of applications, including:

The versatility of blocks makes them essential for numerous construction sectors.

Mobile block machines and stationary concrete block machines offer different advantages:

Mobile Block Machines:

Stationary Concrete Block Machines:

The choice depends on your production needs and operational requirements.

The price of a hollow block machine varies widely. Factors include the type of machine (manual, semi-automatic, or fully automatic), production capacity, and brand.

The price of a block making machine varies based on several factors:

Budgeting for a block making machine involves considering the initial cost, installation expenses, operating costs, and maintenance expenses. Get premium, durable machinery at the best possible price, straight from the source supplier-DURABLE MACHINE.

Using a brick moulding machine involves the following steps:

Proper training and adherence to safety guidelines are essential for operating a brick moulding machine.

A typical block moulding machine line includes the following components:

DURABLE MACHINE offers complete block moulding machine lines with integrated components for seamless operation.

The number of blocks produced per mould and the number of blocks on a pallet depends on the machine’s design and the block size. Typical production rates range from a few blocks to over a dozen per cycle. Pallet capacity varies based on block dimensions and weight.

DURABLE MACHINE engineers will customize the block mould according to your specific brick size and brick shape, and calculate the number of blocks on a pellet, or how many blocks can be made at one time.

When choosing a durable block machine, consider the following factors:

Consumables in brick making machines include:

Maintaining an inventory of essential consumables minimizes production interruptions.

Proper maintenance is essential for ensuring the longevity and optimal performance of your concrete block machine. Key maintenance tasks include:

DURABLE MACHINE provides comprehensive maintenance services and support for our block machines.

Finding a reliable cement block machine manufacturer requires careful research. Here are some tips:

DURABLE MACHINE has been a trusted cement block machine manufacturer for over 30 years. We pride ourselves on quality, reliability, and customer service.

Choosing DURABLE MACHINE for your block production needs offers numerous benefits:

DURABLE MACHINE is your trusted partner for block production equipment.

The space requirements for setting up a block factory depend on the production capacity and level of automation. Generally, a basic block factory requires:

Planning the layout efficiently is crucial for optimizing workflow and maximizing space utilization.

Block making can have environmental impacts, but there are ways to mitigate them:

Sustainable block production practices can reduce the environmental footprint of the industry.

Operating a block making machine involves several safety considerations:

Adhering to safety guidelines protects workers and prevents accidents.

Question 1: What is the lifespan of a block making machine?

The lifespan of a block making machine depends on the quality of the machine and the maintenance it receives. A well-maintained machine can last for 10-15 years or more.

Question 2: How much space do I need for a block factory?

The space required depends on the production capacity and level of automation. A basic block factory may need 5,000 to 10,000 square feet.

Question 3: What is the power consumption of an automatic block machine?

The power consumption varies depending on the machine’s capacity and design. Typically, it ranges from 30kW to 75kW.

Question 4: Can I use different types of materials in a block making machine?

Yes, you can use various materials such as cement, sand, aggregates, fly ash, and slag, depending on the machine’s design and capabilities.

Question 5: How often should I perform maintenance on my block making machine?

Regular maintenance should be performed at least once a month, including cleaning, lubrication, and inspection of parts.

Question 6: How can I ensure the quality of blocks produced by the machine?

Use high-quality materials, follow proper mixing and molding procedures, and ensure the machine is well-maintained.

Question 7: What is the cost of a pallet of concrete blocks?

The cost of a pallet of concrete blocks varies depending on the block size, type, and location. Typically, it ranges from $200 to $400 per pallet.

Question 8: How many blocks are there on a pallet of cinder blocks?

The number of cinder blocks per pallet depends on the block size. Typically, there are 90 to 120 cinder blocks per pallet.

Contact DURABLE MACHINE today to learn more about how our block making machines can transform your production and increase your profitability.