Search the whole station liberty-fse

QMJ2-40 Egg Laying Concrete Block Machine

Capacity:1500-3000 per 8 hours according to your brick size

Weight: 215KGS

Workers Needed: 1-2 persons

Block size: 4inch 6inch 8inch Hollow blocks, Solid bricks

Raw Material: Concrete/ Cement/Fly ash+ water

Introduction:

The QMJ2-40 block-making machine is a compact and mobile option ideal for small businesses and startups. This manual block machine offers a cost-effective entry point into hollow block production. Powered by either electric power or a diesel engine, this concrete block machine is versatile for various job sites. Its easy operation and mobility make it perfect for construction sites or small-scale brick manufacturing plants. If you’re starting a brick business on a budget, consider the QMJ2-40 hollow block machine for a reliable and productive solution. It’s a great small block making machine to start with.

QMJ4-30 Mobile Concrete Block Making Machine

Capacity: 4-6 pieces per mould; 5800-8700 pieces per 8 hours

Power Type:6KW

Weight: 1000KGS

Introduction:

The QMJ4-30 Hydraulic Mobile Block Machine is revolutionizing brick production for small to medium-sized businesses. This mobile block making machine combines affordability with superior hydraulic power, ensuring consistent and high-quality block production.Its hydraulic system guarantees uniform block density and precise dimensions, crucial for durable construction. The machine’s mobility allows for on-site production, reducing costly transportation. Versatility is key: the QMJ4-30 creates various block types, from hollow blocks to paving stones, simply by switching molds. Easy operation minimizes training, making it accessible to all skill levels. Invest in the QMJ4-30 hydraulic brick machine and experience efficient, profitable, and mobile block production.

DM4-40 Simple Concrete Block Mould Machine

Capacity: 2000-7000 pieces per 8 hours (capacity is still depends on your brick size)

Forming Cycle:40-50 Seconds

Pallet Size:850*450*22mm

Weight: 2T

Introduction:

The DM4-40 Manual Stationary Brick Machine is your ideal solution. This brick molding machine offers a cost-effective way to start your own brick production business. Its simple, manual operation makes it easy to learn and maintain.The DM4-40’s robust construction ensures years of reliable performance, producing quality bricks for various construction projects. Investing in the DM4-40 means investing in a profitable future. With low power consumption and a stationary design perfect for small spaces, this manual brick machine empowers you to control your brick supply and build a thriving business.

DM4-35 Manual Blocks Making Machine Line

Capacity: 3000-9000 pieces per 8 hours depends on your brick size

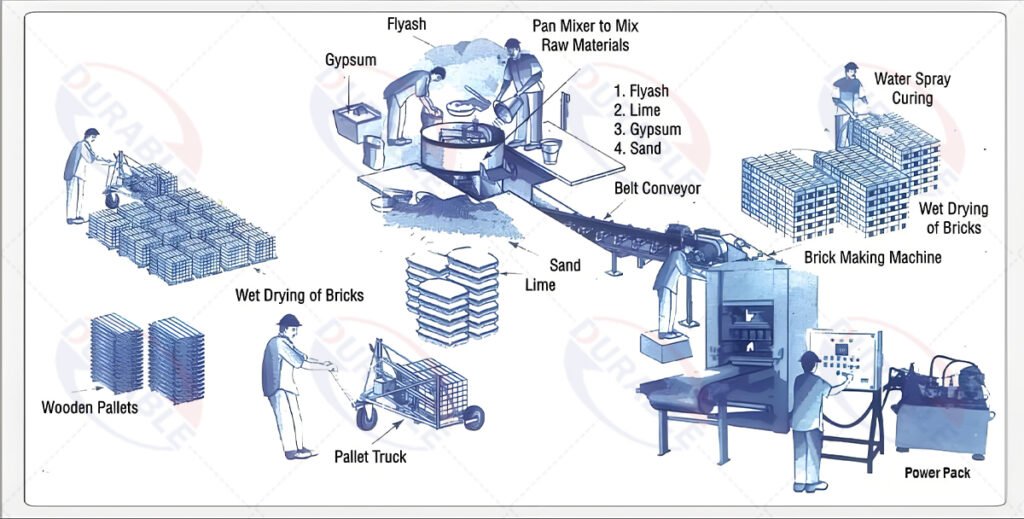

Components: JQ350 Mixer+ 6M Beltconveyor+ DM4-35 block machine

Pallet Size: 850*450*22mm

Introduction:

The DM4-35 utilizes advanced vibration technology to produce a wide variety of high-quality concrete blocks, including solid, porous, paver, and hollow blocks. Its high block production capacity enables you to meet local demand and grow your business. Easy to operate and maintain, the DM4-35 minimizes training and maximizes efficiency. This small concrete block machine offers excellent value, delivering reliable performance and a quick return on investment. Furthermore, its low power consumption helps keep operating costs down, boosting your profitability. Invest in the DM4-35 Concrete Block Making Machine today and start building a solid foundation for your success in the concrete block production market.

QT3-20 Hydraulic Molding Block Machine Line

Capacity:3-10 pieces per mould; 4200-14000 pieces per 8 hours

Power: 16KW

Forming Cycle: about 20 seconds

Introduction:

The QT3-20 Hydraulic Block Making Machine provides an excellent entry point into the concrete products market. This robust machine is designed to produce a wide variety of concrete blocks, bricks, and pavers, making it ideal for small to medium-sized businesses. With its hydraulic pressing system, the QT3-20 ensures consistent block density and durability, resulting in high-quality products that meet industry standards. Its versatile mold options allow you to create various block shapes and sizes, catering to diverse customer demands. Built with heavy-duty steel, this machine offers long-lasting performance and requires minimal maintenance. Invest in the QT3-20 Hydraulic Block Making Machine and experience a reliable and profitable solution for your concrete block production needs.

QT6-15 Fully Automatic Block Molding Machine Line

Capacity:6-33 pieces per mould;11520-63360 pieces per 8 hours

Forming Cycle: about 15 seconds

Brick Size: all in one block making machine line

Introduction:

The QT6-15 Fully Automatic Block Making Machine is a robust and efficient system designed for large-scale operations. This automatic brick making machine streamlines your entire production process, from material feeding to stacking, minimizing labor costs and maximizing output. Its PLC intelligent control system ensures precise and consistent block production, while versatile mold options allow you to create a variety of concrete products, including hollow blocks, solid bricks, and pavers. Designed for durability and reliability, the QT6-15 is a long-term investment for businesses seeking to optimize their concrete block manufacturing capabilities. Explore the benefits of fly ash bricks production and achieve unparalleled efficiency with this state-of-the-art machine.

A Block Molding Machine is the cornerstone of modern construction. For any business in concrete block production, this block manufacturing equipment is the key to high efficiency, consistent quality, and strong profits. A high-performance concrete block machine turns raw materials into valuable building blocks with precision. This guide covers everything from how a cement block machine works to advanced maintenance. We want to help you make a smart investment with a trusted block machine maker like DURABLE.

Last Updated: May 2025 | Estimated Read Time: 18 minutes

A Block Molding Machine is a piece of industrial equipment used to make concrete blocks. People often call it a concrete block machine or a hollow block machine. The machine blocks are made by compacting a mix of cement, sand, and water inside a steel mold. This block molding process uses strong hydraulic pressure and high-frequency vibration.

This action packs the material tightly and removes air, creating a strong block. Modern machines, like the cinder block machine, are highly automated. They use PLC systems to control the whole process, from feeding materials to ejecting the finished product. This ensures every block from the block molder meets exact size and strength standards.

Using a concrete block molding machine brings major advantages to your business, primarily boosting efficiency and profitability. Investing in modern block manufacturing equipment over a potentially unreliable used block machine for sale offers several key benefits:

Calculating the return on investment for a block molding machine is a critical step. The ROI depends on your local market, including the cost of materials, labor, and the price you can sell your blocks for. For a brick making machine for sale in USA, the high demand for construction materials can lead to a fast ROI. The key factors are the machine’s high output and low labor needs.

A fully automatic blocks machine can run with just a few operators, drastically cutting your payroll. The machine’s efficiency means you produce more blocks per hour, increasing your sales capacity. For example, if a machine helps you save $50,000 per year in labor and generate an extra $100,000 in sales, your annual gain is $150,000. Many of our customers, even when comparing against a used concrete block making machine for sale in USA, find that a new machine’s reliability leads to a full return on investment in 12 to 24 months.

We offer several types of cement block maker machines to fit different needs. You can choose based on the level of automation or mobility, ensuring you find the perfect fit for your production scale and budget.

Based on Operation:

Based on Mobility:

A modern concrete block machinery is very versatile. You can produce many different concrete products just by changing the block mold.

The blocks from a block production machine are essential for modern construction. Their uses are widespread.

A block molding machine follows a precise, multi-step process.

The block making machine price can vary a lot. It can be a few thousand dollars for a manual cinder block maker or over $200,000 for a full automatic line. You should consider the total cost, not just the initial concrete block machine price. Key factors affecting the cement block manufacturing machine price include:

Choosing the right block making machine for sale is a big decision. Your choice should depend on your specific needs.

A cement block production machine has several key parts.

A great benefit of a block moulding machine is its ability to use many raw materials. This helps you use local, cheap materials.

Regular maintenance ensures your block molding machine performs well for a long time. It reduces downtime and improves block quality.

Choosing DURABLE for your block molding machines means you are investing in over 30 years of experience.

Buying a brick machine for sale from DURABLE in China is an easy process.

Our service continues long after the sale of your block manufacturing equipment.

1. How profitable is Brick Manufacturing?

Brick manufacturing is very profitable with the right setup. Your success depends on local material costs and market demand. An efficient brick maker machine for sale lowers production costs per block, leading to great profit margins.

2. How is the availability of cement block making machine spare parts?

DURABLE keeps all standard spare parts in stock. For key parts, we use global brands like Siemens, which are often available locally in your country, ensuring you can get parts for your concrete brick machine quickly.

3. Certification of DRUABLE block maker machine?

All DURABLE block maker machines are made to international standards and have CE and ISO9001 certification. This ensures your brick block making machine meets strict safety and quality rules.

4. Lead time and Logistics of DURABLE Machinery?

The lead time for a single block machinery unit is about 30 days. For a full production line, it is 45 to 60 days. Our logistics team handles shipping to ensure safe and timely delivery.

5. Technology of DURABLE block machine?

DURABLE concrete block machines use advanced technology. This includes strong hydraulic systems for high compaction, synchronized vibration for dense blocks, and smart Siemens PLC controls for precise, automatic operation.