Boost Fertilizer Quality with the Right Rotary Drum Dryer

If you are running a fertilizer production line, you know that the final drying stage is critical. The right fertilizer dryer determines the quality, stability, and value of your final product. As a long-time manufacturer of industrial equipment, we have seen many technologies, but one stands out for its reliability and efficiency: the rotary drum dryer. It is the workhorse of the industry.

This guide is our expert advice on dryer selection. We will explain why the rotary drum dryer is the ideal choice for both compound fertilizer drying and organic fertilizer drying. You will learn about its advantages, how it is designed for different materials, and how to calculate costs. By the end, you will have a clear understanding of why this machine is the heart of so many successful fertilizer plants worldwide.

Table of Contents

- Why Is Drying the Key Process for Fertilizer Quality and Value?

- What Makes a Rotary Drum Dryer a Better Choice for Fertilizer?

- How Is the Dryer Designed for Sticky or Corrosive Fertilizers?

- How Do You Calculate the Operating Cost Per Ton of Fertilizer?

- How Can You Keep Granules Intact and Ensure Even Drying?

- How Do You Choose the Right Dryer Model for Your Output?

- What Other Equipment Do You Need for a Complete System?

- Common Questions About Fertilizer Drying

- Summary: The Robust Heart of Your Production Line

- About Durable

- Get a Custom Dryer System Proposal

Why Is Drying the Key Process for Fertilizer Quality and Value?

Drying is the critical final step because it removes excess moisture, which stops chemical reactions, prevents the product from caking, and makes it stable for bagging, storage, and transport.

In any fertilizer production line, especially after a granulation process, the fertilizer granules contain too much water. If you bag this wet fertilizer, it will cause huge problems. The moisture allows chemical reactions to continue. It causes the granules to stick together into hard clumps, a process called caking. A wet product is also heavier, increasing shipping costs. Proper moisture control through drying is essential. An effective fertilizer dryer brings the moisture level down to a stable target, usually between 2-5%. This locks in the nutrient value, ensures the granules are hard and free-flowing, and guarantees a long shelf life. It is the step that turns a semi-finished product into a valuable commercial good.

What Makes a Rotary Drum Dryer a Better Choice for Fertilizer?

A rotary drum dryer is the superior choice because it offers high throughput, robust construction, versatility for different materials, and excellent cost-effectiveness at an industrial scale.

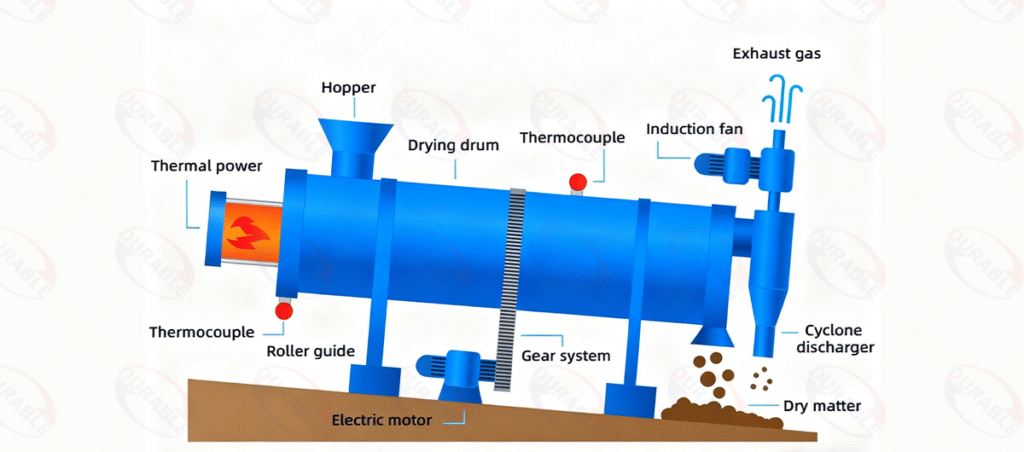

We have built many types of dryers over the years, but for large-scale fertilizer production, the rotary drum dryer is almost always our top recommendation. There are four main reasons for this.

- High Throughput: These machines are designed for continuous, 24/7 operation. They can process a massive volume of material per hour, which is essential for a commercial fertilizer production line.

- Robust and Durable: A rotary drum dryer is basically a giant, heavy-duty steel tube. It is built like a tank to withstand the demanding environment of a fertilizer plant. Its simple and proven design means it is reliable and easy to maintain.

- Versatile: It can handle a wide variety of materials. Whether you are doing compound fertilizer drying with NPK granules or organic fertilizer drying with compost or manure, the tumbling action can process it effectively.

- Cost-Effective: On a cost-per-ton basis, the rotary drum dryer offers one of the lowest capital and operational costs for bulk drying, making it a smart financial investment.

How Is the Dryer Designed for Sticky or Corrosive Fertilizers?

The dryer is adapted through specific internal lifter designs to handle sticky organic fertilizer and by using special corrosion-resistant steel for compound fertilizers.

A standard dryer will not work well for all fertilizers. This is where expert engineering comes in. We customize the design to handle the specific challenges of your material.

For Sticky Organic Fertilizer

Organic fertilizer drying presents a challenge because the material can be sticky. If not handled correctly, it will build up on the inside walls of the dryer, reducing efficiency and causing blockages. To prevent this, we design special internal plates called “lifters.” These lifters pick up the material as the drum rotates and shower it down through the stream of hot air. The shape and arrangement of these lifters are designed to create a “curtain” of material for maximum drying efficiency while also providing a scraping action that keeps the dryer walls clean.

For Corrosive Compound Fertilizer

Compound fertilizer drying, especially with products containing chlorides (like potash) or sulfates, is highly corrosive. A standard carbon steel dryer would be eaten away in just a few years. To solve this, we select the right material for construction. For most corrosive fertilizers, we use high-grade stainless steel, such as 304 or 316L. While the initial investment is higher, a stainless steel dryer will last for decades, making it a much more economical choice in the long run. Using the wrong material is one of the most expensive mistakes you can make in dryer selection.

How Do You Calculate the Operating Cost Per Ton of Fertilizer?

The drying cost per ton is primarily the sum of your thermal energy cost (fuel) and your electrical energy cost (power), plus minor costs for labor and maintenance.

Understanding your energy consumption is key to managing your operational budget. Here is how we help you calculate the drying cost.

- Thermal Energy (Heat): This is the largest expense. It is the energy needed to evaporate the water from your fertilizer. The cost depends on two things: how much water needs to be removed and the price of your fuel. Common heat sources include natural gas, coal, or a Biomass Burner. An efficient dryer will use less fuel to remove the same amount of water.

- Electrical Energy (Power): This is the cost to run the motors for the dryer drum, the fans, and the conveyors. While this is a smaller cost than the fuel, it is still an important part of the total energy consumption.

A good estimate is that it takes about 1.2 kWh of energy to evaporate 1 kg of water. So, to dry 1 ton of fertilizer from 30% moisture down to 5%, you need to remove 250 kg of water, which requires approximately 300 kWh of thermal energy.

| Cost Component | Description | Impact on Total Cost |

|---|---|---|

| Fuel Cost | Heat source (gas, coal, biomass) to evaporate water. | High (60-75% of total cost) |

| Electricity Cost | Power for motors, fans, and controls. | Medium (15-25% of total cost) |

| Labor & Maintenance | Operator supervision and routine upkeep. | Low (5-10% of total cost) |

How Can You Keep Granules Intact and Ensure Even Drying?

You achieve this through a combination of gentle tumbling action, customized internal lifter design, and precise control over temperature and airflow.

Producing high-quality, uniform fertilizer granules is the ultimate goal. Breaking the granules or drying them unevenly reduces the value of your product. Here is how a well-designed rotary drum dryer prevents these problems.

- Gentle Tumbling: The slow rotation of the drum provides a gentle tumbling motion. This is much less aggressive than other drying methods and minimizes the impact that can cause granules to break.

- Custom Lifter Design: As mentioned before, the internal lifters are designed to create a uniform curtain of fertilizer falling through the hot air. This ensures every granule is exposed to the same amount of heat for the same amount of time, resulting in very even moisture control.

- Precise Process Control: A modern fertilizer equipment system uses a PLC (Programmable Logic Controller). This system constantly monitors the temperature and airflow and automatically adjusts them to keep the drying conditions perfect. This prevents overheating that can damage granules and ensures a consistent final moisture content.

How Do You Choose the Right Dryer Model for Your Output?

You should choose a dryer model based on your required output in tons per hour (TPH), but you must also consider the initial moisture content of your fertilizer.

Dryer selection involves matching the machine’s capacity to your fertilizer production line‘s needs. The capacity of a rotary drum dryer is determined by its diameter and length. A larger and longer drum can hold more material and allows for a longer drying time (residence time), resulting in a higher capacity. However, a simple TPH rating is not enough. The amount of water that needs to be removed is just as important. Drying 10 TPH of fertilizer from 20% moisture is very different from drying 10 TPH from 40% moisture. The second scenario requires removing much more water and will need a larger dryer.

Here is a general guideline:

| Required Output (TPH) | Initial Moisture 20-30% | Recommended Dryer Model (Diameter x Length) |

|---|---|---|

| 1-3 TPH | Wet Granules | Φ1.2m x 12m to Φ1.5m x 15m |

| 5-8 TPH | Wet Granules | Φ1.8m x 18m to Φ2.2m x 20m |

| 10-15 TPH | Wet Granules | Φ2.4m x 22m to Φ2.8m x 25m |

What Other Equipment Do You Need for a Complete System?

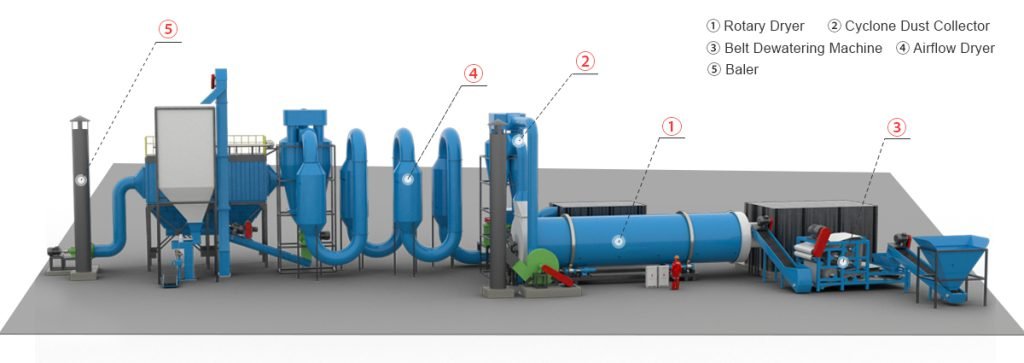

A complete drying system includes not just the dryer, but also feeding, heating, dust collection, and conveying equipment, all working together as an integrated plant.

Buying a fertilizer dryer is not like buying a single appliance. You are investing in a system. The dryer is the heart, but it needs a full body of supporting fertilizer equipment to function correctly. A typical system includes:

- Wet Fertilizer Feeder: To provide a consistent feed rate.

- Hot Air Furnace: To generate the heat for drying.

- The Rotary Drum Dryer: The main drying unit.

- Discharge Chute and Conveyor: To move the hot, dry product.

- Dust Collection System: A cyclone and a baghouse or wet scrubber are essential to capture fertilizer dust, protecting the environment and recovering valuable product.

- Cooling Drum: A second rotary drum without heat is often used to cool the fertilizer to a safe temperature before bagging.

- Final Product Conveyors and Screen: A Conveyor Belt to move the cooled product to a screen that separates out any oversized or fine particles before bagging.

- PLC Control Cabinet: The central brain that automates and controls the entire system.

Common Questions About Fertilizer Drying

Question 1: What is the difference between direct and indirect heat for fertilizer drying?

A direct heat dryer mixes the hot combustion gases directly with the fertilizer. It is more efficient but can only be used for heat-stable materials. An indirect heat dryer heats the shell of the drum, and the fertilizer never touches the flame. It is safer for heat-sensitive fertilizers like those with ammonium nitrate.

Question 2: Can I dry both organic and compound fertilizer with the same dryer?

It is possible, but not always ideal. A dryer designed with stainless steel for corrosive compound fertilizer can also handle organic fertilizer. However, you might need to adjust the temperature and rotation speed. It is best to discuss your specific needs with an engineer.

Question 3: How much space does a complete fertilizer drying system require?

The footprint can be large. A medium-capacity system (5-8 TPH) including the furnace, dryer, cooling drum, and dust collection can easily require an area of 30-40 meters in length and 10-15 meters in width.

Summary: The Robust Heart of Your Production Line

For any serious fertilizer production line, the rotary drum dryer is the proven, reliable, and cost-effective choice. It has the capacity and durability to handle industrial-scale production of both organic and compound fertilizers. The key to success is not just choosing a rotary drum dryer, but choosing one that is specifically engineered for your material’s unique properties, whether that means special lifters for organic fertilizer drying or corrosion-resistant steel for compound fertilizer drying.

About Durable

Since 2001, Durable (Durablemac) has specialized in manufacturing robust and efficient industrial processing equipment. We apply our decades of engineering experience to design and build complete production lines for clients in over 120 countries. Our fertilizer equipment is built to last, delivering reliable performance and a strong return on your investment.

Get a Custom Dryer System Proposal

Are you ready to improve your fertilizer quality and lower your operating costs? Contact our team of engineers today. We will provide a free consultation to understand your needs and design a custom drying system for your fertilizer production line. You will receive a detailed proposal with technical specifications, a full system layout, and a clear price quote. Let’s build a more profitable future together.

Durable Machinery

Durable Machinery