Carbonization Machine: Powering Sustainable Waste & Green Energy

Carbonization technology has evolved significantly. It started from simple kilns and now includes intelligent, integrated systems. Many perceive carbonization equipment as merely converting “waste” into “charcoal.” However, its true value, challenges, and opportunities extend much further. This technology effectively transforms solid waste into valuable resources and generates renewable energy production. This article details the process. It covers principles, benefits, and proper equipment selection.

Table of Contents

- Carbonization equipment transforms agricultural and forestry waste into high-value products and energy

- Core working principles of carbonization technology and product application values

- Contributions of carbonization equipment to environmental regulations and waste reduction

- Assessing overall cost, running expenses, and economic returns of carbonization equipment investment

- Selecting suitable carbonization equipment models and processes

- Automation level, operational stability, and safety measures in carbonization equipment

- Prioritizing a carbonization equipment supplier’s technical strength and long-term service capability

- FAQs

- Conclusion

- About Durable

Carbonization equipment transforms agricultural and forestry waste into high-value products and energy

Carbonization equipment transforms agricultural and forestry waste into diverse, high-value products and energy, with an expanding market.

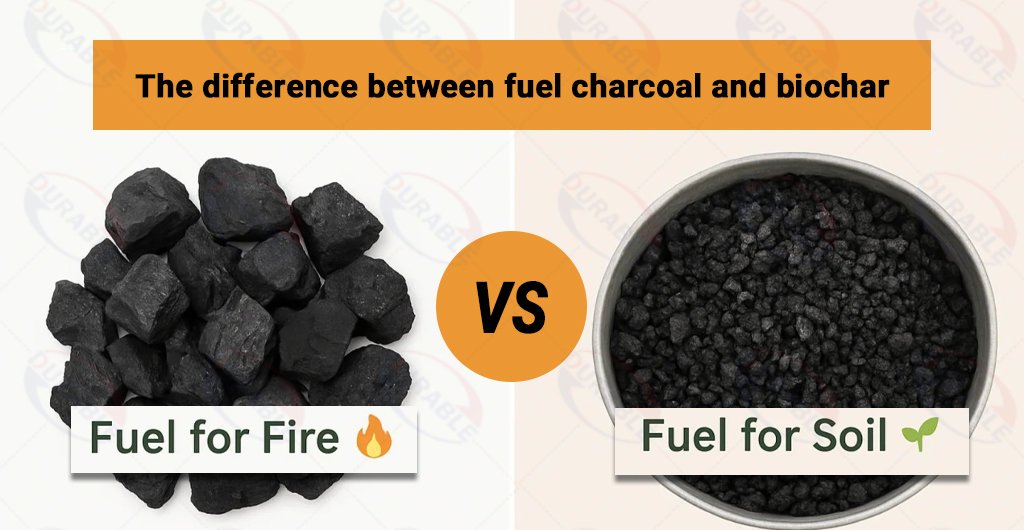

The process yields two main types of charcoal. First, fuel charcoal (traditional wood charcoal) serves as barbecue or industrial fuel; its value depends on heat content and burn time, in a competitive market. Second, biochar, with high porosity and a stable carbon structure, primarily improves soil quality, sequesters carbon, and treats water. Biochar offers significantly higher value but demands precise control during carbonization, specific raw materials, and product testing.

Biochar production often utilizes lower carbonization temperatures (350-700°C, oxygen-free) to preserve active surface and maximize fixed, stable carbon. Fuel charcoal, conversely, may use higher temperatures for heat value and density. The choice depends on the target market. Initial biochar production costs are higher due to control systems and testing, yet its market potential (especially in carbon trading and sustainable agriculture) is substantial. This transformation facilitates solid waste resource utilization and renewable energy production.

Core working principles of carbonization technology and product application values

The core working principle of carbonization technology is pyrolysis. This process involves heating biomass with minimal oxygen. The heat breaks down organic materials without combustion. This converts biomass into three primary products: biochar, combustible gas (syngas), and bio-oil/wood vinegar. Each product offers significant application value.

First, biochar is a solid, carbon-rich product with a porous structure. This structure makes it highly beneficial. Biochar improves soil quality. It helps soil retain water and nutrients, which can increase crop yields. Biochar also sequesters carbon in the soil, effectively removing carbon dioxide from the atmosphere. This contributes to climate change mitigation. Biochar also finds use in water treatment, where it filters pollutants and absorbs odors. Its large surface area enhances these properties. Therefore, biochar production holds significant importance across various industries.

Second, carbonization yields combustible syngas (carbon monoxide, hydrogen, methane) with high heat value, a valuable renewable energy source. Modern systems capture and combust this syngas to heat the furnace, achieving energy self-sufficiency. Excess syngas can power other processes, dry raw materials, or generate electricity, significantly cutting operating costs and reducing fossil fuel dependence by converting waste gas into usable energy.

Third, bio-oil/wood vinegar, a liquid byproduct, condenses from the process gases. Wood vinegar functions as a natural agricultural pesticide or fertilizer, while bio-oil serves as fuel or a chemical feedstock. These byproducts further enhance the overall value of the carbonization process.

Contributions of carbonization equipment to environmental regulations and waste reduction

Carbonization equipment significantly aids in meeting environmental regulations and reducing waste, offering major benefits for businesses facing stringent standards.

First, waste reduction is key. Carbonization transforms vast agricultural and forestry residues—historically burned (air pollution) or left to decompose (methane emissions)—into useful products. This greatly reduces waste volume, turning a pollution problem into a valuable resource, embodying solid waste resource utilization.

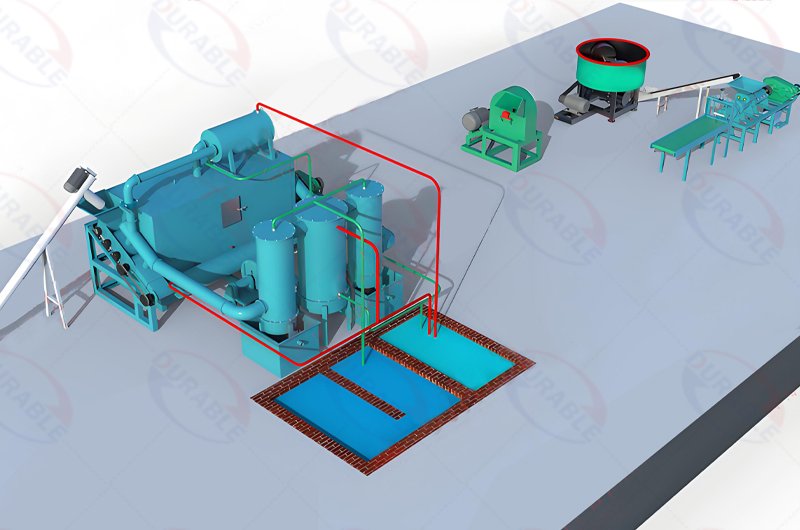

Second, carbonization ensures regulatory compliance with significant environmental benefits. Unlike polluting traditional burning, modern smokeless carbonization collects and combusts generated gases, preventing release and providing heat. Exhaust then passes through purification systems (dust collectors, scrubbers) for clean emissions, meeting or exceeding environmental standards. This avoids penalties, improves environmental image, and actively reduces greenhouse gas emissions by converting waste to biochar and renewable energy. Thus, carbonization is vital for sustainable waste management and a cleaner environment.

Assessing overall cost, running expenses, and economic returns of carbonization equipment investment

Assessing carbonization equipment cost and returns requires evaluating its “whole life value” and Total Cost of Ownership (TCO), beyond just the initial purchase.

Overall costs cover initial equipment (carbonization furnace, essential pre-treatment like a hammer mill crusher for sizing, a wood chips dryer for moisture reduction, and conveyors), plus installation, site preparation, and operator training. Raw material pretreatment for charcoal is critical; neglecting it wastes energy. Prioritizing efficient crushing, drying, and screening upfront enhances carbonization efficiency, reduces energy consumption, and extends equipment lifespan.

Running expenses include raw materials (if purchased), labor, electricity, and maintenance. Modern equipment often achieves energy self-sufficiency by recycling syngas to heat the furnace, substantially reducing fuel costs and optimizing charcoal production cost.

Economic returns come from product sales (biochar for soil amendment/carbon credits, fuel charcoal), by-product sales (wood vinegar, bio-oil), waste disposal fee savings, and carbon credits (biochar sequesters carbon for market sales). Accurate ROI and financial attractiveness require incorporating all these income streams.

Selecting suitable carbonization equipment models and processes

Selecting the correct carbonization equipment model and process proves critical for project success. Equipment must match specific project needs and raw material characteristics. A “one-size-fits-all” approach consistently fails in this industry.

First, consider raw material characteristics. What type of biomass will the system process? Is it agricultural waste, such as rice husks or corn cobs? Or is it forestry waste, like wood chips or branches? Each raw material possesses distinct moisture content, particle size, and chemical composition. For instance, wet materials require efficient dryers prior to carbonization. Materials like sawdust may need a pellet making machine or biomass briquette machine to increase density. This improves heat transfer and efficiency. The raw material type also influences the final product. For example, rice husks contain high silica, resulting in high ash content in the biochar. Achieving low ash charcoal production method necessitates using low ash raw materials.

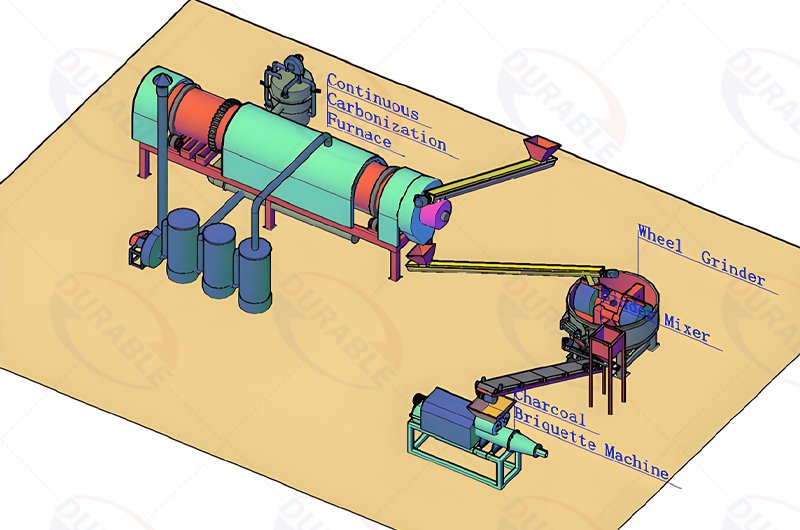

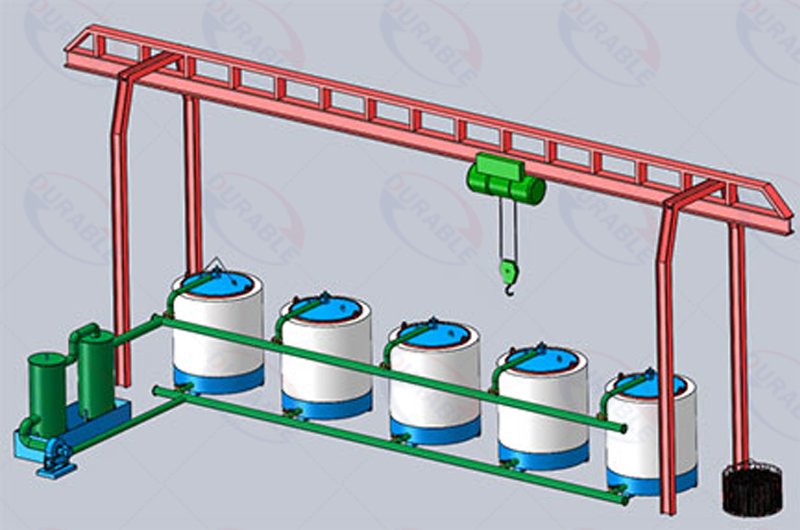

Second, evaluate project needs: desired output (batch/continuous, fuel charcoal or high-value biochar for soil amendment). For continuous, high-output requirements, a rotary drum biomass carbonization furnace or square continuous biomass carbonization furnace may be optimal. For smaller, flexible operations, a vertical hoist biomass carbonization furnace offers advantages (easy loading/unloading). Space and budget constraints also influence decisions. Careful carbonization furnace selection is paramount for better performance, superior returns, and longevity. A reputable supplier will assist in testing raw materials and selecting the best equipment and process, ensuring a successful carbonization production line.

Automation level, operational stability, and safety measures in carbonization equipment

Modern carbonization equipment features high automation, excellent operational stability, and robust safety measures, ensuring efficient, reliable, and safe operation.

Regarding automation, advanced carbonization equipment uses smart control systems (PLCs, HMIs). PLCs collect sensor data (temperature, pressure, gas flow), while HMIs allow operators to configure and monitor. The system automatically adjusts fuel, air, and process times for precise temperature control, flawless execution, reduced human error, consistent product quality, and optimized energy.

Operational stability stems from indirect heating, preventing uneven heating and combustion. Designs like “one machine, multiple tanks” (e.g., vertical hoist biomass carbonization furnace) enable continuous batch processing, minimizing downtime. High-quality materials (refractory bricks, special alloys) resist high temperatures and corrosive gases, ensuring long-term, stable operation.

Safety measures are paramount due to high heat and flammable gases. Equipment integrates multiple features: gas monitoring with CO alarms, proper ventilation, sealed inner tanks to prevent leaks and oxygen ingress (critical for fire prevention), emergency stops, and controlled cooling to prevent hot charcoal ignition. All features adhere to strict carbonization equipment safety standards, ensuring safe operation for personnel and the environment.

Prioritizing a carbonization equipment supplier’s technical strength and long-term service capability

Prioritizing a carbonization equipment supplier’s technical strength and long-term service capability is crucial. This approach surpasses merely focusing on the lowest price. A reliable supplier functions as a true partner.

Technical strength means a supplier understands carbonization science, designing and building efficient, safe equipment. Experienced engineers are vital for equipment selection, customization, and optimizing processes for specific raw materials and product goals like high fixed carbon charcoal or desired biochar properties. They offer guidance on pre-treatment (crushing, drying) and exhibit deep knowledge of the carbonization process flow and raw material behavior.

Equally crucial is long-term service capability. Post-purchase support includes installation, commissioning, training, spare parts, and technical assistance for troubleshooting or upgrades. This ensures smooth operation, minimizes downtime, and maximizes ROI. A robust service network demonstrates commitment. Conversely, cheap suppliers with weak support often lead to breakdowns, poor product quality, and high maintenance, negating initial savings. A strong, experienced partner like Durable Machine offers both technical expertise and dedicated long-term service, ensuring successful, sustainable carbonization projects.

FAQs

Question 1: What is the primary distinction between fuel charcoal and biochar?

Fuel charcoal is for combustion, emphasizing heat and burn time. Biochar, conversely, improves soil and sequesters carbon, valued for its porous structure and stable carbon.

Question 2: Why does raw material pretreatment hold such importance for carbonization?

Effective pretreatment, including drying and consistent sizing, enhances carbonization efficiency. It also reduces energy waste, prolongs equipment lifespan, and improves product quality.

Question 3: How does carbonization contribute to renewable energy production?

The process generates combustible gases (syngas). These gases can be recycled to heat the furnace, generate electricity, or dry raw materials, thus enabling system energy self-sufficiency.

Question 4: Can carbonization equipment process diverse types of solid waste?

Yes, modern carbonization equipment offers versatility. It processes agricultural waste, forestry waste, and other biomass. Key factors include proper pretreatment and selecting the appropriate equipment model.

Question 5: What criteria should guide the selection of a carbonization equipment supplier?

Prioritize suppliers demonstrating strong technical expertise, proven long-term service capabilities, and a commitment to assisting clients in choosing and operating suitable equipment.

Conclusion

Carbonization equipment powerfully transforms solid waste into valuable resources and produces renewable energy. This technology offers substantial economic and environmental benefits, creating profit and sustainability by converting agricultural/forestry waste into high-value biochar and clean energy. Pyrolysis, intelligent gas recycling, and stringent environmental controls ensure an efficient, eco-friendly process. Investing demands assessing costs/returns, selecting equipment based on raw material/project goals, and partnering with a supplier possessing robust technical and service capabilities. With high automation, stable operation, and comprehensive safety measures, this technology is critical for solid waste resource utilization and a sustainable future.

About Durable

Durable Machine, established in 2001, operates as a leading Chinese manufacturer. It specializes in mineral processing equipment and construction machinery. Durable also applies its industrial process knowledge to biomass energy equipment. Durable designs and constructs complete, integrated biomass fuel production lines. The company focuses on briquette machines and carbonization solutions. Its solutions prioritize efficiency, reliability, and environmental responsibility. Durable’s team collaborates closely with clients. It designs systems to match specific biomass types, production needs, and business goals. From initial consultations and plant design to custom equipment manufacturing, installation support, operator training, and comprehensive after-sales service, Durable ensures successful outcomes for its investments.

For expert advice and a custom plan for your carbonization production line or vertical hoist biomass carbonization furnace project, contact Durable’s engineering team today.

Durable Machinery

Durable Machinery