Charcoal Coal Ball Press Machine

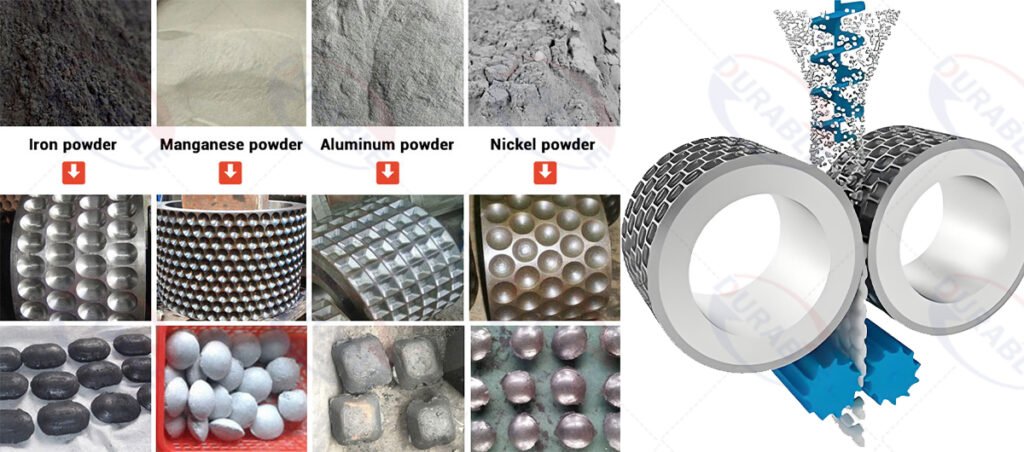

This machine, also known as a briquette press machine or roller press machine, is a specialized piece of equipment designed for a very specific purpose: to compress fine powder (like charcoal dust or coal dust) into dense, uniform, oval, or pillow-shaped briquettes (balls). It is a key machine in transforming low-value, dusty, and difficult-to-handle powder into high-value, easy-to-transport, store, and burn solid fuel.

Application Fields:The final briquettes have a diverse range of applications, spanning both industrial and consumer sectors.

Briquettes serve both consumer and industrial markets. For consumer use, charcoal briquettes provide steady heat for barbecues (BBQ) and shisha, while coal briquettes are used for home heating and cooking. Industrially, coal briquettes power facilities like cement plants and power stations, whereas charcoal briquettes offer a cleaner fuel alternative for furnaces and boilers.

How Do You Make Briquettes Strong, Smokeless, and Long-Burning?

The secret to high-quality briquettes lies in the “formula,” which is the precise mix of charcoal powder, binder, and water. The machine provides the pressure, but the formula determines the final product’s quality.

The key is the binder. It’s the “glue” that holds the charcoal powder together.

- For High-End BBQ/Shisha Charcoal: You must use starch-based binders, like corn starch or cassava starch. They are clean-burning, produce very little ash, and don’t create bad smells. This is essential for the food market. The trade-off is higher cost and a more complex process, as starch needs to be heated with water (gelatinized) to work properly.

- For Industrial Fuel Briquettes: You can use cheaper binders like sodium humate or bentonite clay. They provide good strength at a lower cost. However, they increase the ash content and are not suitable for BBQ use due to potential odors.

The “smokeless” quality comes from two things: using fully carbonized charcoal powder and using a clean binder. If your raw charcoal isn’t completely carbonized, it will smoke when the briquette is lit. Larger charcoal pieces from the carbonization furnace are first crushed into a fine powder using equipment like a Hammer Crusher before they are mixed.

We provide the machines, but you must test and perfect your own formula. It’s the most important research and development you will do. You need to find the best balance between binder cost and the briquette quality your customers demand.

Do You Need a Mixer and a Dryer? Yes, They Are Essential.

A charcoal briquette press cannot work alone. You absolutely need a mixer and a dryer to form a complete, functional production line. The real production bottleneck is almost always the dryer, not the press.

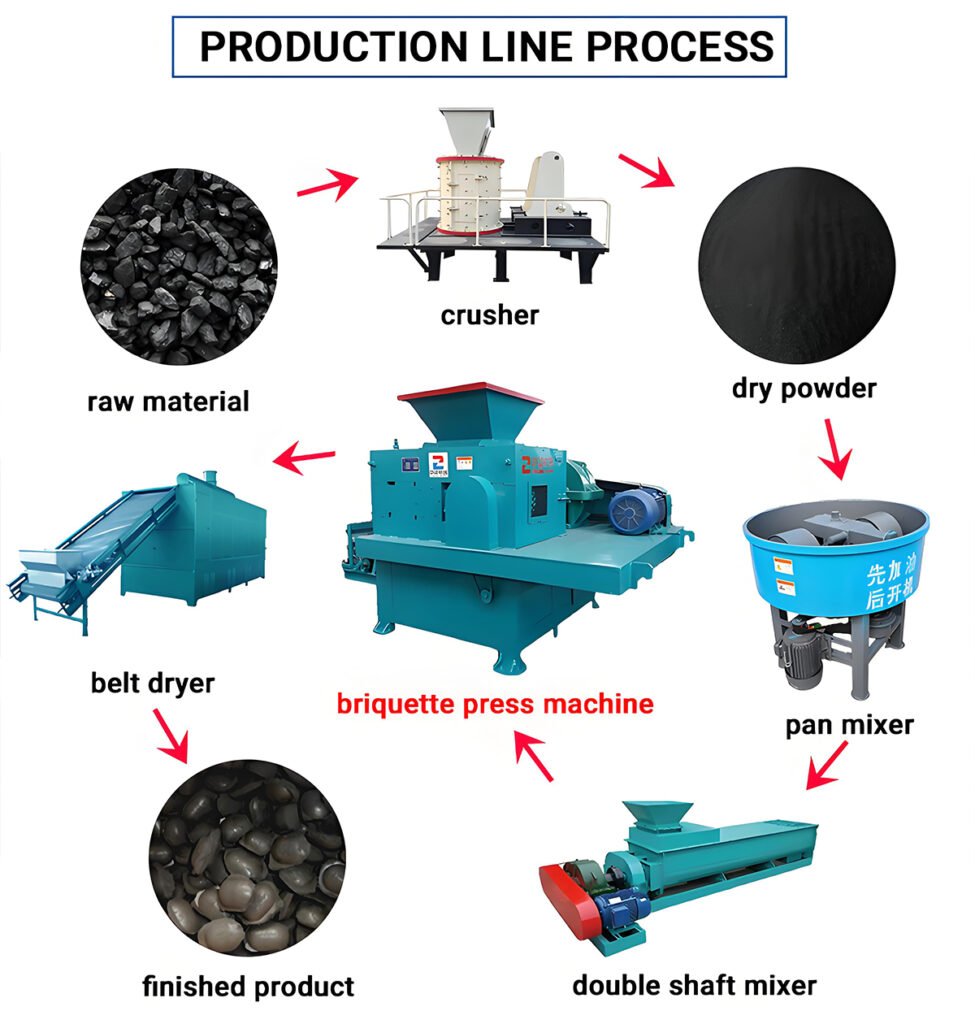

Here is how the system works together:

- Mixing (The Crucial First Step): You start by mixing your charcoal powder, binder, and water. For this, a wheel mixer is far superior to a standard horizontal mixer. A wheel mixer uses heavy rollers to simultaneously grind and blend the materials. This ensures the binder and water are distributed perfectly evenly, which is critical for strong briquettes. This step is where you control the moisture. The ideal moisture content is a very narrow window, usually between 22-25%. Too wet, and the briquettes stick to the machine. Too dry, and they crumble.

- Pressing (The Shaping Step): The evenly mixed material is then fed into the briquette press. The press uses high pressure to compact the powder into your desired shape. A press with a forced feeder will give you more consistent results.

- Drying (The Final, Critical Step): The newly pressed briquettes are wet and fragile. They have no market value at this stage. They must be dried to reduce moisture to below 5%. This makes them hard, durable, and easy to ignite. For high-volume production, a continuous mesh belt dryer or an efficient Drum Dryer is an excellent choice. For smaller batches, a simple drying room can work.

Remember, your plant’s true capacity is determined by how many wet briquettes your dryer can handle per day, not how many the press can make per hour. You must plan and budget for the entire line.

Roller vs. Stamping vs. Hydraulic: Which Press Is Best for You?

The type of press you choose depends on your target product, required output, and budget.

| Press Type | Best For | How It Works | Key Advantage |

|---|---|---|---|

| Roller Briquette Press | High-volume BBQ briquettes (pillow, oval) and industrial coal briquettes. | Two counter-rotating rollers with molds press the powder as it passes between them. | High efficiency and continuous production. This is the most common and cost-effective type for large-scale operations. |

| Mechanical Stamping Press | High-density, uniform shisha/hookah charcoal cubes or tablets. | A mechanical punch repeatedly presses powder into a mold. | Excellent density and shape uniformity. Perfect for premium products where quality is everything. |

| Hydraulic Press | Very large briquettes or special industrial applications. | Uses a hydraulic press to apply immense, slow pressure. | Extremely high pressure. Good for difficult materials, but much slower and more expensive. |

For most clients looking to produce BBQ or industrial fuel briquettes, the Roller Briquette Press offers the best balance of cost, capacity, and reliability. If you are targeting the premium shisha market, a mechanical stamping press is the professional choice.

What Are the Core Components That Affect Performance and Cost?

When you buy a roller briquette press, you are not just buying a frame and a motor. The performance and your long-term operating costs are determined by two key components.

- The Rollers: The Heart of the Machine

The rollers are the most important and highest-wear part of the machine. Their material directly impacts your maintenance costs and downtime.

- Standard Rollers (65Mn Steel): This is a basic cast steel. It is the cheapest option but wears out quickly, especially with abrasive charcoal powder. You might need to replace them every few months, which means lost production time and high costs.

- Upgraded Rollers (9Cr2Mo Alloy Steel): This is a forged alloy steel. The forging process makes it much stronger, and the chromium (Cr) and molybdenum (Mo) alloys make it extremely hard and wear-resistant. These rollers can last several times longer than standard ones. We strongly recommend investing in alloy steel rollers. The higher initial cost will save you much more money in the long run.

2. The Forced Feeder: The Key to Consistency

A forced feeder is a powered screw auger located in the hopper above the rollers. It is not an optional extra; it is essential for high performance. It actively pushes the fluffy charcoal powder down into the rollers. This solves two huge problems: it prevents the powder from getting stuck in the hopper (“bridging”), and it ensures that a consistent amount of material is fed to the rollers. Without it, your briquette weight and density will be inconsistent, and your output will be much lower.

FAQs

Q1: Can I customize the briquette shapes and sizes?

A: Yes, absolutely. The shape and size of the briquette are determined by the molds carved into the machine’s rollers. We can produce rollers for many standard shapes, such as pillow, oval, square, and round. We can also create custom molds based on your specific design or logo, which can help your brand stand out in the market.

Q2: What is the approximate cost of a complete production line?

A: The cost varies widely based on capacity and automation level. A small, simple line might start around $20,000-$30,000 USD, while a large-scale, fully automated line with a high-capacity mesh belt dryer can exceed $100,000 USD. The final cost depends on the capacity of the mixer, press, and, most importantly, the dryer.

Q3: Can I sell the finished briquettes directly to the market?

A: Yes. Once the briquettes are fully dried (below 5% moisture), they are ready for packaging and sale. You need to ensure they meet the quality standards for your target market. For the BBQ market, this means they must be hard, easy to light, long-burning, and produce little smoke or smell. For industrial users, the key metrics are calorific value and ash content.

Q4: What is a typical breakage rate, and how do I reduce it?

A: A breakage rate of 5-10% from the press to the final bag is common for new operations. This is a hidden cost. Every broken briquette is wasted energy and material that has to be re-processed. You can reduce this rate by perfecting your binder formula for better strength, ensuring the moisture content is optimal, and designing your conveyor system to minimize drops.

Q5: What is the difference between making BBQ briquettes and shisha cubes?

A: The process for shisha cubes is much more demanding. Shisha charcoal requires finer powder (100-200 mesh), which is typically achieved using a specialized grinding machine like a Ball Mill to ensure a perfectly smooth texture. It also requires a food-grade starch binder, extremely high pressure from a stamping or hydraulic press for density, and a very slow, controlled drying process to prevent cracks. A standard BBQ briquette line cannot produce high-quality shisha charcoal.

Durable Machinery

Durable Machinery