Charcoal Crusher

A Charcoal Crusher, also known as a charcoal grinder or pulverizer, is a machine designed specifically to break down large, irregular pieces of raw charcoal (from wood, coconut shells, bamboo, etc.) into smaller, more uniform granules or fine powder.

It is a crucial piece of equipment in the charcoal processing industry, especially for creating value-added products.

Crushing charcoal is rarely the final step. It is usually the first step in preparing charcoal for other uses:BBQ Briquette Production,Shisha / Hookah Charcoal Production,Soil Amendment (Biochar),Industrial Fuel.

At Durable, we’ve specialized in manufacturing Biomass Energy Equipment since 2001. We know that when you’re making charcoal products, the biggest challenge isn’t the crushing itself—it’s the dust. A cloud of fine charcoal powder is not just messy and wasteful; it’s a serious safety risk. You’re here because you need a solution, not just a machine. You need a charcoal crusher, also called a charcoal pulverizer, that is clean, safe, and efficient. This guide will walk you through the essential features of a proper charcoal grinding system, helping you understand how to solve the dust problem and produce the exact powder you need for high-quality briquettes.

Table of Contents

- How can you achieve dust-free charcoal crushing?

- How Fine Can the Charcoal Powder Get, and Can You Adjust the Fineness?

- Why Isn’t a Regular Hammer Mill a Perfect Fit for Crushing Charcoal?

- Crushing Coconut Shell vs. Wood Charcoal: What’s the Difference for Hammers and Screens?

- How Does a Charcoal Crusher Fit into a Complete Production Line?

- FAQs

How can you achieve dust-free charcoal crushing?

This is the most critical question. A proper charcoal crusher is not a standalone machine; it is a system designed around dust control. The secret to a dust-free operation is creating a negative pressure environment. Think of it like a powerful, sealed vacuum cleaner that is integrated directly with the crusher.

Here’s how a well-designed system works:

- Sealed Housing: The crusher body, inlet, and outlet are tightly sealed with gaskets to prevent dust from escaping.

- Integrated Dust Collector: A pulse jet baghouse dust collector is connected to the crusher via ducting. This unit contains multiple filter bags that capture the fine dust particles from the air.

- Powerful Fan: A fan draws air out of the crusher and into the dust collector. This creates the negative pressure, meaning air is constantly flowing into the crusher through any tiny gaps, rather than dust flowing out.

- Automatic Cleaning: The pulse jet system periodically blasts the filter bags with jets of compressed air, knocking the collected charcoal powder down into a hopper where it can be collected.

With this setup, there is virtually no visible dust leakage during operation. It protects your workers’ health, prevents a dangerous work environment (charcoal dust is flammable), and recovers all your valuable powder so nothing goes to waste. A machine sold without an integrated dust collection system is simply not a complete or safe solution.

How Fine Can the Charcoal Powder Get, and Can You Adjust the Fineness?

Yes, you have precise control over the final powder size, which is essential for making different types of charcoal products. For example, shisha charcoal requires a very fine powder, while BBQ briquettes work best with a slightly coarser mix. You can adjust the fineness, typically measured in “mesh,” using two main controls:

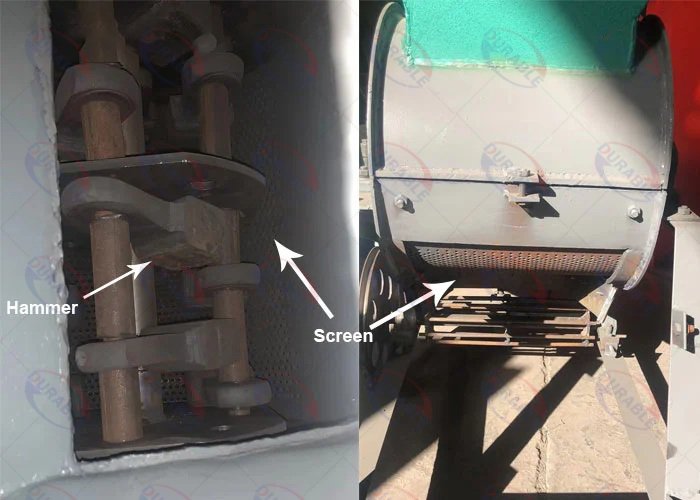

- The Sieve Screen: This is the primary control. A charcoal pulverizer has a perforated metal screen located in the bottom half of the crushing chamber. The size of the holes in this screen determines the maximum size of the particle that can exit the machine. To get a finer powder (e.g., 80-100 mesh), you use a screen with smaller holes. For a coarser product (e.g., 30-50 mesh), you use a screen with larger holes. Screens are easily interchangeable, allowing you to change your product specification in minutes.

- Rotor Speed (RPM): This is a secondary control. The speed at which the hammers spin affects the intensity of the impact. A higher rotor speed creates a more violent impact and more airflow, which tends to produce a finer powder and helps push it through the screen faster. Some advanced systems use a variable frequency drive (VFD) on the motor to allow you to fine-tune the rotor speed to achieve the perfect powder consistency.

Why Isn’t a Regular Hammer Mill a Perfect Fit for Crushing Charcoal?

This is a common point of confusion. While a charcoal crusher is a type of hammer mill, a machine specifically designed for charcoal has critical features that a standard, all-purpose hammer mill lacks. The crushing principle is the same—high-speed rotating hammers impacting the material—but the similarities end there.

A standard hammer mill, often used for grain or stone, typically lacks:

- Integrated Dust Control: As discussed, this is the most important feature for a clean and safe operation.

- Proper Sealing: They are not designed to contain super-fine, low-density dust like charcoal powder.

- Safety Features for Flammable Dust: A true charcoal crusher system should be fully grounded to prevent static electricity buildup, which can be an ignition source. Some larger systems may even incorporate explosion vents as an added safety measure.

Using a generic hammer mill for charcoal will result in a dusty, unsafe mess. It will technically crush the charcoal, but it will fail to manage the most significant challenge of the process. A dedicated charcoal grinding machine is engineered as a complete system to handle these specific challenges.

Crushing Coconut Shell vs. Wood Charcoal: What’s the Difference for Hammers and Screens?

While they are both charcoal, their physical properties are different, and this affects the choice of wear parts inside your crusher.

Coconut Shell Charcoal:

- Key Property: It is much harder and more abrasive than wood charcoal. This is due to a higher content of silica (which is essentially sand) in the original coconut shell.

- Hammer Requirement: Standard manganese steel hammers will wear out very quickly. For crushing coconut shell charcoal, you must use higher-grade, more wear-resistant hammers. The best choice is high-chromium cast iron hammers or hammers with tungsten carbide tips. They cost more initially but last many times longer, dramatically reducing your downtime and long-term operational costs.

- Screen Requirement: The abrasive nature can also wear down standard steel screens. Using a screen made from a harder, wear-resistant steel or even stainless steel can be a wise investment.

Wood Charcoal:

- Key Property: It is softer and less abrasive.

- Hammer Requirement: Standard, good-quality manganese steel hammers often provide a good balance of performance and cost.

- Screen Requirement: A standard heavy-duty woven steel screen is usually sufficient.

Always tell your equipment manufacturer exactly what type of charcoal you will be processing. A good supplier, like Durable, will ensure your machine is fitted with the correct type of hammers and screen for your specific material.

| Material | Hardness/Abrasiveness | Recommended Hammer Material | What This Means for You |

|---|---|---|---|

| Wood Charcoal | Low to Medium | High-Manganese Steel | Standard parts are cost-effective and work well. |

| Coconut Shell Charcoal | High | High-Chromium Iron / Carbide Tipped | You must invest in premium wear parts to avoid constant replacement. |

| Bamboo Charcoal | Medium | High-Manganese or High-Chrome | A middle ground; high-chrome is often a better long-term choice. |

How Does a Charcoal Crusher Fit into a Complete Production Line?

The charcoal crusher is a central link in the production chain. It takes large, unusable pieces of charcoal and prepares them for the machines that will form the final product. A typical BBQ Charcoal Briquette Production Line follows these steps:

- Feeding: Large chunks of raw charcoal are fed into the charcoal crusher, often using a simple belt conveyor.

- Crushing: The charcoal crusher pulverizes the charcoal into a fine powder of a specific mesh size. The integrated dust collector captures all the powder.

- Mixing: The collected charcoal powder is transported to a wheel mixer. Here, a binder (like starch) and water are added and mixed evenly with the powder to create a consistent, moldable paste.

- Briquette Pressing: The mixed material is then fed into a briquette press (like a roller press or a piston-type extruder), which forms it into the final shape (e.g., pillows, cubes, hexagons).

- Drying: The freshly pressed briquettes have high moisture content and must be dried in a continuous belt dryer or a drying room to make them hard, durable, and ready for packaging.

FAQs

Q1:Is the sieve screen the main wear part? Is it expensive to replace?

A: While the screen does wear out, the hammers are the primary wear part and take the most abuse. Sieve screens are relatively inexpensive to replace. A good quality screen is crucial for efficiency, so it’s a small cost that has a big impact on your production rate.

Q2: What are the three key details to check when buying a charcoal crusher, besides price?

A:

- The Dust Collection System: Is it fully integrated? What is the fan power and filter area? A weak dust collector is useless.

- Safety Features: Is the machine properly sealed? Does the manufacturer talk about grounding for static electricity?

- Quality of Wear Parts: Ask what material the hammers are made from. A cheap machine with cheap hammers will cost you more in the long run.

Q3: What is the difference between a crusher and a pulverizer?

A: In this context, the terms are often used interchangeably. Generally, a “crusher” might refer to a machine making a coarser product, while a “pulverizer” implies making a very fine powder. A good charcoal crusher can do both, depending on the screen and speed settings.

Q4: How much power does a charcoal crusher need?

A: Power depends on the size and capacity. A small crusher for a startup might use a 7.5 kW motor, while a large industrial unit could require 30-45 kW or more. The dust collector fan will also have its own motor.

Durable Machinery

Durable Machinery