Charcoal Making Machine

A charcoal making machine, also commonly known as a carbonization furnace, biomass carbonization machine, or eco-friendly charcoal machine, is a specialized piece of equipment that heats biomass raw materials such as wood, bamboo, straw, rice husks, and coconut shells to high temperatures (pyrolysis) under oxygen-free or oxygen-limited conditions. This process decomposes the materials into charcoal, wood tar, wood vinegar, and combustible gas.

Main Types: Batch Type,Continuous Type, Gasifier Type

Processable Raw Materials:

Wood-based: Wood blocks, branches, sawdust, wood scraps,Bamboo-based: Bamboo chunks, bamboo chips , Agricultural: Straw, rice husks, corn cobs, sugarcane bagasse ,Nut Shells: Coconut shells, palm kernel shells, walnut shells, peanut shells ,Others: Municipal solid waste, sludge (requires specially designed models)

Table of Contents

- What is a Charcoal Making Machine and What Are Its Features?

- Where Are Charcoal Making Machines Used?

- How Does It Handle the Smoke and Tar?

- Can I Use Wet Sawdust or Straw to Make High-Quality Charcoal?

- How Many Workers Are Needed for the Entire Production Process?

- Continuous vs. Hoisting Furnace: Which is Better for My Business?

- Technical Parameters

- FAQs

What is a Charcoal Making Machine and What Are Its Features?

A charcoal making machine, also known as a carbonization furnace or biochar machine, is a piece of equipment that converts organic matter (biomass) into charcoal through high-temperature pyrolysis. It essentially “cooks” the raw material in the absence of oxygen.

The process is straightforward: biomass like wood chips, sawdust, coconut shells, or agricultural straw is fed into a sealed chamber. The chamber is heated, causing the biomass to decompose without burning. This process releases combustible gases and leaves behind a solid, carbon-rich product: charcoal.

Key Features of a Modern Charcoal Machine:

Eco-Friendly Operation: Modern machines are designed to be smokeless. They incorporate a gas purification system that treats the smoke produced during carbonization, making the process environmentally sound.

- Energy Self-Sufficiency: The combustible gas produced during pyrolysis can be recycled. After cleaning, this gas is piped back to the furnace’s combustion chamber to provide the heat needed for the process. Once the machine reaches a certain temperature, it can often run on its own recycled gas, significantly reducing fuel costs.

- High Efficiency: Compared to traditional earth kilns, a modern Carbonization Furnace offers much higher charcoal yield and a significantly shorter production cycle (often just a few hours instead of days).

- Versatility: These machines can handle a wide range of raw materials, from wood and bamboo to agricultural waste like rice husks and palm kernel shells.

Where Are Charcoal Making Machines Used?

The applications for charcoal making machines are broad, spanning from fuel production to agriculture and industry. The charcoal produced is a versatile product with high demand.

Pressing/Forming:

Purpose: To forcefully press the well-mixed, moist charcoal powder into a specific shape.

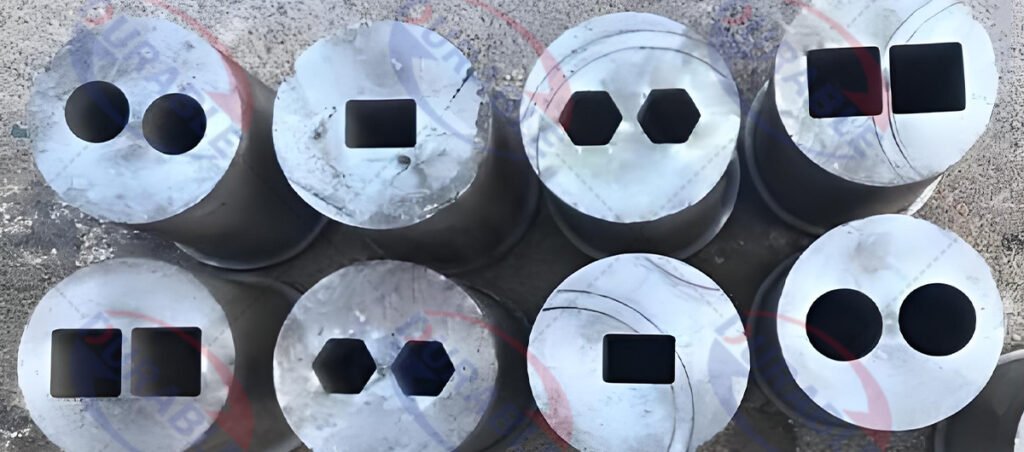

Equipment Used: Depending on the shape you want, there are different types of briquette machines:

- Ball/Pillow Shape: Use a Roller Ball Press Machine. It has two counter-rotating rollers with ball-socket molds on their surfaces. When the mixture passes between the two rollers, it is squeezed under high pressure into ball or pillow-shaped charcoal briquettes. This is precisely the machine used for the “briquette shape” you asked about.

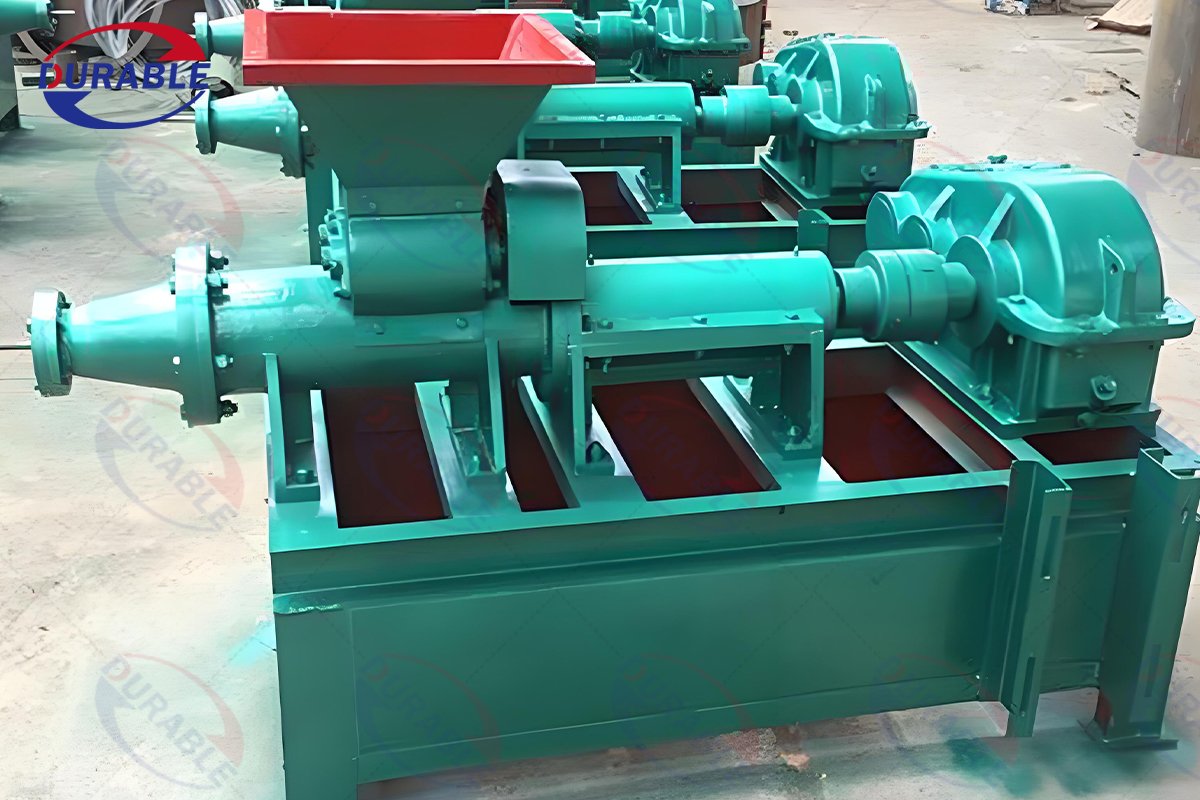

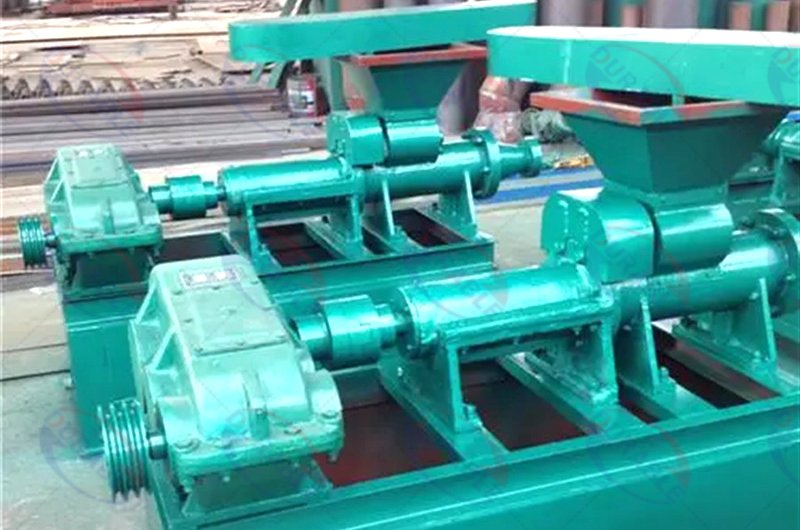

- Stick/Rod Shape: Use a Screw Extruder Machine. It uses a rotating screw auger to forcefully push the charcoal powder into a mold, extruding it into long strips or hexagonal prism-shaped charcoal sticks (commonly used for barbecue).

- Honeycomb Shape: Use a Honeycomb Briquette Machine. It uses a stamping die to press the charcoal powder into a cylindrical, perforated honeycomb shape.

- Tablet/Other Shapes: Use a Hydraulic Press or a Stamping Press. By changing different molds, it can press out various custom shapes like round tablets, square blocks, etc.

The main application areas include:

- BBQ and Hookah Charcoal Production: This is the most common use. The machine produces high-quality charcoal that can be crushed, mixed with a binder, and pressed into briquettes for barbecue or shisha/hookah use. This is a major part of our Biomass Energy Equipment lineup.

- Industrial Fuel: In many industries, machine-made charcoal is used as an alternative fuel for boilers and furnaces because of its high calorific value and low emissions compared to coal.

- Agriculture (Biochar): When used in agriculture, the product is called “biochar.” Biochar improves soil structure, water retention, and nutrient availability, acting as a powerful soil amendment. This is a rapidly growing market.

- Activated Carbon Production: The charcoal produced can be used as a raw material to create activated carbon, which is used in a huge range of filtration and purification processes (water, air, etc.).

How Does It Handle the Smoke and Tar?

A modern, eco-friendly charcoal making machine uses a dedicated purification system to handle the smoke and tar. This is a critical feature that separates professional equipment from crude, polluting kilns.

Here’s the process:

- Smoke Collection: The dense, yellow smoke created during pyrolysis is first channeled away from the main furnace. This smoke is a mixture of combustible gases, water vapor, tar, and dust.

- Purification: The smoke passes through a series of purification devices. This typically includes a cyclone dust collector to remove larger dust particles and a spray tower (or scrubber). In the spray tower, water mists cool the gas, causing the tar and some acids to condense and wash out.

- Gas Recycling: After this cleaning process, what remains is a clean, combustible gas (syngas). This gas is then piped to the furnace’s burner to be used as fuel. The tar and wood vinegar are collected in a separate tank.

This system not only prevents air pollution but also turns a waste product (smoke) into a valuable resource (fuel), making the entire operation more efficient.

Can I Use Wet Sawdust or Straw to Make High-Quality Charcoal?

No, you cannot feed wet raw materials directly into the furnace and expect good results. The moisture content of your raw material is one of the most critical factors for a successful operation.

For the pyrolysis process to be efficient, the raw material should have a moisture content of less than 15%. Here’s why:

- Energy Waste: If the material is wet, the furnace has to expend a huge amount of energy just to boil off the water before pyrolysis can even begin. This dramatically increases your fuel consumption and lowers overall efficiency.

- Low-Quality Gas: The excess steam dilutes the combustible gas produced, lowering its heat value. This can make it impossible for the machine to be self-sustaining, forcing you to constantly burn external fuel.

- Incomplete Carbonization: High moisture can lead to uneven heating and incomplete carbonization, resulting in a low yield of poor-quality charcoal.

Therefore, a rotary dryer is an essential piece of pre-processing equipment for most charcoal production lines. You must factor the cost and energy use of a dryer into your business plan. Learn more about our specialized Rotary Dryers for this purpose.

How Many Workers Are Needed for the Entire Production Process?

For a typical semi-continuous charcoal production line, you will generally need 2 to 3 workers per shift.

The labor is divided among a few key tasks:

- Worker 1 (Feeding & Pre-processing): This person manages the feeding of raw materials into the crusher and dryer, ensuring a steady supply to the carbonization furnace.

- Worker 2 (Furnace Operation & Monitoring): This worker oversees the operation of the Carbonization Furnace itself, monitoring temperatures and pressures on the control panel. While the process is highly automated, it requires supervision.

- Worker 3 (Discharging & Post-processing): This person manages the discharge of the finished charcoal from the cooling system and oversees the briquetting and packaging line.

With a fully continuous and highly automated system, labor can sometimes be reduced to 1-2 operators, but 2-3 is a safe and realistic estimate for planning purposes.

Continuous vs. Hoisting Furnace: Which is Better for My Business?

Choosing between a continuous and a batch-type (like the hoisting furnace) depends entirely on your raw material, production scale, and budget.

| Feature | Continuous Carbonization Furnace | Hoisting Carbonization Furnace (Batch Type) | Your Best Choice? |

|---|---|---|---|

| Operation Mode | Non-stop feeding and discharging. Runs 24/7. | Works in batches. Load, run a cycle, cool, unload. | For large-scale, consistent production, Continuous is superior. For smaller operations or varied materials, Hoisting is more flexible. |

| Raw Material Size | Best for small, uniform materials (<20mm) like sawdust, rice husks. | Can handle larger, irregular materials like wood logs, coconut shells. | If you have small, granular waste, go Continuous. If you have large logs or chunks, you need a Hoisting furnace. |

| Automation Level | Very high. Fully automated PLC control. | Lower. Requires more manual labor for loading/unloading inner pots. | If you want to minimize labor costs, Continuous is the answer. |

| Initial Investment | Higher. More complex machinery. | Lower. Simpler design. | If your budget is tight to start, the Hoisting furnace is a more accessible entry point. |

For a deeper dive into your options, check out our comprehensive list of Biomass Briquette Machines and Production Lines.

Technical Parameters

Parameter of charcoal coal dust briquettes extruding machine

| Model | Power | Capacity | Weight | Diesel Engine |

| MBJ140 | 11kw | 500-800kg/h | 650kg | available |

| MBJ180 | 18.5kw | 1000-1200kg/h | 1100kg | available |

Parameter of honeycomb charcoal coal dust briquettes punching machine

| Type | MQJ140 | MQJ160 | MQJ220 |

| Power | 7.5kw | 11kw | 11kw |

| Capacity | 1000-1200kg/h | 1200-1300kg/h | 1300-1500kg/h |

| Conveyor Size | 2.1*1.3*0.6 | 2.1*1.5*0.8m | 2.1*1..6*1 |

| Weight | 900kg | 1100kg | 1300kg |

FAQs

Q1: Is the charcoal produced powder or lumps?

A: The charcoal that comes out of the furnace directly mirrors the size of the raw material you put in. If you feed in fine sawdust, you will get charcoal powder (biochar). If you feed in wood chunks or coconut shells, you will get charcoal lumps of a similar size.

Q2: What other budget considerations are there besides the machine itself?

A: The machine is only one part of the total project cost. You must also budget for:

- Site Preparation: A level concrete foundation.

- Workshop/Shed: To protect the equipment.

- Power Supply: Sufficient three-phase power for all motors (crusher, dryer, furnace, etc.).

- Pre-processing Equipment: A crusher and a dryer are almost always necessary.

- Post-processing Equipment: A charcoal briquette machine line (mixer, press, dryer) if you plan to sell briquettes.

- Labor and Installation Costs.

Q3: Is the charcoal making business profitable?

A: Yes, it can be highly profitable. You are taking a low-value (or even negative-value) waste product and converting it into a high-demand commodity. The profitability depends on the local cost of your raw material, labor, energy, and the selling price of charcoal in your market. A thorough business plan is essential.

Q4: Can I mix different types of raw materials, like wood chips and rice husks?

A: Yes, you can, but it is generally not recommended for optimal results. Different materials have different densities, moisture levels, and carbonization times. Mixing them can lead to uneven carbonization, where one material is perfectly cooked while the other is either under-processed or has turned to ash. For the most consistent quality and yield, it is best to process one type of material at a time.

Q5: How long does it take to install the equipment and train my staff?

A: The installation and commissioning time depends on the complexity of the production line. A simple hoisting furnace might be set up in a few days, while a full continuous line with a dryer and briquetting machines could take 1 to 2 weeks. As the manufacturer, we provide detailed layout drawings and can send engineers to your site to guide the installation and provide comprehensive operational training for your team.

Durable Machinery

Durable Machinery