Choosing Your Concrete Boom Pump: How to Match Needs and Boost Efficiency?

Choosing the right concrete boom pump for any project is a critical decision. This choice impacts project success directly. It can prevent costly delays. It can also boost overall construction efficiency. A wrong choice often leads to huge losses. It can slow work significantly. It can make concrete pouring difficult. Project needs must be understood well. This helps select the perfect machine. This article guides through the entire process. It helps make smart choices consistently. This ensures smooth operations and better results.

Table of Contents

- Why Does Choosing the Wrong Concrete Boom Pump Lead to Huge Project Losses?

- What Are the Main Types of Concrete Boom Pumps? Which Construction Scenarios Suit Them?

- How Do You Match a Concrete Boom Pump Model Precisely to Your Project’s Scale, Pouring Height, and Radius?

- Boom Length, Pumping Capacity, Hydraulic System: How Should These Technical Parameters Be Understood and Chosen?

- Facing complex terrain and narrow spaces, how should one choose between static and mobile concrete boom pumps?

- Besides Equipment Price, What Hidden Costs Must Be Considered When Buying or Renting a Concrete Boom Pump?

- How Do You Evaluate the Safety Performance, Operational Convenience, and Maintenance Costs of a Concrete Placing Boom?

- Brand, After-Sales Service, and Parts Supply: How Does One Pick a Trustworthy Concrete Boom Pump Supplier?

- What Common Mistakes Should Be Avoided When Buying or Renting a Concrete Boom Pump?

- Future Trends and Technical Innovations in Intelligent and Green Concrete Boom Pumps?

- Frequently Asked Questions

- Summary and Recommendations

- About Durable

Why Does Choosing the Wrong Concrete Boom Pump Lead to Huge Project Losses?

Wrong concrete boom pump selection harms projects. It affects money, time, and safety. A pump too small cannot reach areas easily. This needs more setups and more time. Labor costs increase. Low pumping efficiency slows concrete pouring. Project schedules suffer. Delays cost money and damage reputations.

The Ripple Effect of a Mismatched Boom Pump

A mismatched pump creates project problems. Money is lost. Powerful pumps waste fuel on small jobs. Weak pumps miss large job deadlines. This means client penalties and extra rental costs. Time is lost. Repositioning smaller booms wastes hours. Workers wait. Concrete trucks wait. Efficiency drops. Safety is a concern. Overloaded pumps are dangerous. They cause failures, costly accidents, and project stops. Poor performance hurts morale. It creates frustration. This lowers productivity and can cause staff turnover. The pump is key. Select it carefully. This protects profits, keeps teams safe, and productive. The decision impacts everything.

Hidden Costs of Poor Selection

Initial cost is clear. Many hidden costs add up fast. More labor is a hidden cost. If the boom cannot reach, manual labor increases. This is slow and expensive. Wasted concrete costs too. Blockages harden concrete inside. This material must be discarded. It is costly waste. Wear and tear is a problem. Overworked pumps wear out fast. This means frequent, expensive repairs. Downtime causes lost days. Renting a replacement adds cost. Poor concrete pumping efficiency delays other trades. Carpenters and electricians wait. This causes widespread delays. It increases cost control issues. Hidden costs exceed savings from cheap pumps. Do not only consider the sticker price.

What Are the Main Types of Concrete Boom Pumps? Which Construction Scenarios Suit Them?

Two main boom pump types exist: stationary and mobile. Each type has specific uses. They suit different project sizes and site conditions. Understanding these differences helps make the right choice. It ensures the best tool is available.

Stationary Concrete Boom Pumps

Stationary boom pumps are separate units. The pump feeds concrete through a pipeline to the boom. Mounted on a tower, column, or slab, these pumps offer high reach and cover large areas, making them ideal for skyscrapers and large industrial complexes.A central mast lets them “climb” with the building. This gives continuous coverage as the structure grows. Setup needs careful planning. Installation takes time and a large crane. Once set, they offer precise control. They deliver concrete exactly. They leave minimal ground footprint. This suits crowded sites. Moving them is hard. While less flexible for small pours, these pumps provide long-term solutions for large projects and are crucial for high-rise building pumping.

Mobile Concrete Boom Pumps

Mobile boom pumps are truck-mounted. Combining pump and boom, these mobile units drive directly to sites, setting up quickly. They prove versatile for diverse pours: homes, small commercial, bridges, and industrial slabs. Mobility is their key advantage, allowing easy movement between locations and saving hours with rapid deployment. However, reach is limited; it cannot match stationary pumps. Significant space for outriggers and stable ground for the unit and its supports are required, often challenging on some sites. The truck also contributes to site congestion. Despite these drawbacks, their flexibility and speed make them an invaluable workhorse.

How Each Type Fits Specific Scenarios

Each pump type suits specific scenarios. For skyscrapers, stationary pumps are key. They climb hundreds of meters. They deliver concrete consistently at all levels. For large bridge decks, stationary pumps cover wide areas. This reduces equipment moves. For homes, mobile pumps excel. They pour a foundation, then move. Quick setup saves time. For malls with low-rise slabs, mobile pumps offer flexibility. They cover wide areas efficiently. Some projects use both. Mobile pumps handle ground pours. Stationary pumps take over for high-rise sections. Matching the pump to demands is critical for efficiency. It prevents bottlenecks and maintains schedules. It optimizes pouring.

How Do You Match a Concrete Boom Pump Model Precisely to Your Project’s Scale, Pouring Height, and Radius?

Matching the boom pump model needs careful planning. Consider project size, pouring height, and pouring radius. Each factor influences selection. Getting this right saves money, improves safety, and boosts concrete pumping efficiency. Start with the biggest challenge: highest point, furthest corner. This sets minimum requirements.

Project Scale and Throughput Needs

Project scale dictates pump capacity. Large infrastructure projects (dams, highways) need massive concrete. They require high pumping rates. Large capacity pumps are needed, maybe several. Specialized equipment might also be needed. For multi-story buildings, total volume is high. But daily rates are less intense. Large pumps finish faster, cut hours, and save labor. For small commercial buildings, smaller pumps work well. They are efficient for moderate volumes. Calculate total concrete volume. Divide by project duration for average rate. Add a buffer for delays and maintenance. This ensures the pump meets demand. It prevents bottlenecks.

Pouring Height and Boom Length

Pouring height is key. Mobile pumps suffice for low-rise buildings (under 10 stories). Booms are 20-60 meters. High-rises (over 10 stories) need more reach. Stationary pumps excel here. They mount on climbing masts. These extend hundreds of meters. Specialized pipelines take concrete to great heights. Measure maximum height needed. Factor in boom clearance. Add extra length for flexibility. Check vertical reach specifications. This shows maximum accurate delivery height. Too short a boom means unfinished jobs. This causes costly re-planning. It means mid-project equipment changes and huge delays.

Pouring Radius and Boom Articulation

Pouring radius is the horizontal reach from the boom’s base. Wide structures (industrial floors) need long horizontal reach for full coverage. Boom length relates to this. More boom sections mean more articulation. This allows maneuvering in tight spots or around obstacles. Complex layouts need high articulation for precise placement. Simple pours need less. Map the pour area thoroughly. Identify furthest points from pump locations. This determines minimum boom length. Also, consider overhead obstructions like power lines. Enough reach ensures access to all pour parts. This enhances concrete pumping efficiency. It reduces manual handling.

Boom Length, Pumping Capacity, Hydraulic System: How Should These Technical Parameters Be Understood and Chosen?

Understanding boom pump technical parameters is vital. Make wise choices. Boom length, pumping capacity, and the hydraulic system are key elements. They define a pump’s capabilities. They affect its price and performance. Look beyond numbers. Consider how these parameters fit job site needs.

Boom Length: Reaching Every Corner

Boom length defines reach. It dictates how far and high concrete can be placed. Precisely map the site. Identify the furthest concrete placement point. This includes horizontal and vertical distances. Boom lengths vary. Mobile pumps have 20-60 meter booms. Stationary pumps reach much further. Always choose a boom with extra reach. This provides flexibility. It streamlines operations by tolerating less-than-ideal setups, accelerating tasks, and reducing the need for constant relocation. Longer booms mean heavier machines. They need more setup space. They cost more. Balance needs carefully. Find the optimal boom pump boom length.

Pumping Capacity: Speed and Volume

Pumping capacity is m³/h. It shows how much concrete a pump delivers. Large volume projects (industrial slabs, high-rises) need high-capacity pumps. 100-150 m³/h is common for medium-large jobs. Some pumps exceed this. Match capacity to the pour schedule. If 500 cubic meters need pouring in 5 hours, a 100 m³/h pump is needed. Account for inefficiencies. Actual rates are often lower than maximums. Mix quality and pipeline resistance affect this. Right capacity prevents delays. It ensures fast pouring and keeps the project on schedule. Avoid waiting concrete trucks. This wastes money and time.

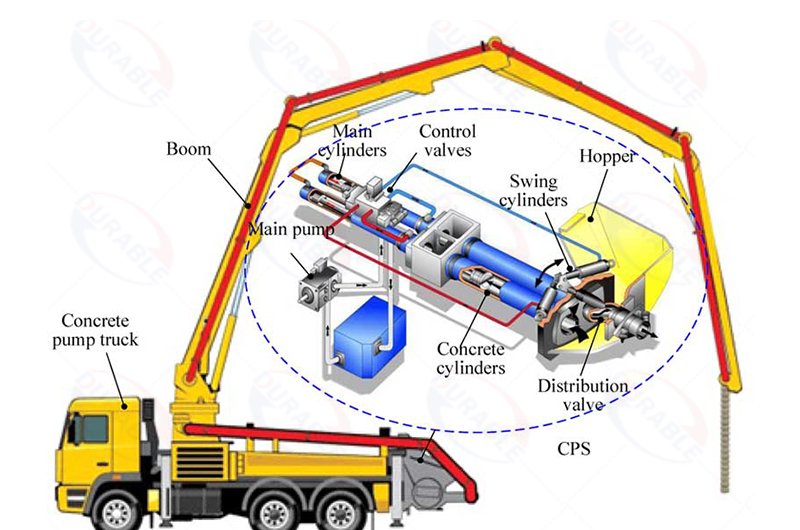

Hydraulic System: The Heart of the Pump

The hydraulic system powers the pump. It controls boom movements and pumping action. A good system ensures smooth, precise boom movements. It provides consistent power. Seek systems from reputable brands. This means better durability and easier parts availability. Pressure capability is important. Higher pressure pumps concrete longer and higher. This is crucial for high-rise building pumping. Consider the control system. Modern pumps use advanced electronic controls. These offer precise operation, safety features, and quick diagnostics. A robust system means less downtime.It reduces maintenance costs, boosts efficiency, and ensures reliable daily work. This makes a big difference in project success.

Facing complex terrain and narrow spaces, how should one choose between static and mobile concrete boom pumps?

Complex terrain and narrow spaces challenge boom pump selection. Choosing the right pump is key. This impacts setup, reach, and safety. Both stationary and mobile pumps have strengths. Match the pump to the site. This ensures smooth work and avoids problems.

Navigating Complex Terrain

Sites are often uneven, with slopes or soft soil. Mobile pumps need stable, level ground. Outriggers must extend fully for heavy loads. Uneven terrain makes mobile pump setup hard and dangerous. Temporary platforms add time and cost. Stationary pumps are better. They anchor to solid foundations for stability. They reach over difficult ground easily for precise pouring. Some mobile pumps level better. But fixed pumps are more stable on rough ground. Evaluate conditions thoroughly before choosing.

Working in Narrow Spaces

Urban construction means narrow spaces. Streets are tight. Building proximity is close. Equipment room is limited. Mobile pumps are hard here. They need space for outriggers. This blocks roads or sidewalks. It needs permits and causes public issues. Compact mobile pumps exist for urban areas. They have smaller footprints. Their boom length is shorter. For very tight spaces, stationary pumps work. They mount on building cores or courtyards. Their pumping unit stays distant. Concrete goes through a ground line. The boom unfolds above, limiting ground obstruction. This helps high-rise pumping in dense cities. Boom articulation is key. More sections mean easier unfolding in tight spots. This helps reach complex areas.

The Hybrid Solution

One pump type is sometimes not enough. Large projects have mixed conditions: tough terrain at the base, narrow spaces higher up. A hybrid approach works best. Mobile pumps handle initial ground pours. They are fast and flexible. Stationary pumps install as the building rises. These work on upper floors. They handle height and reach issues. This combines features. It maximizes efficiency and adapts to changes. It needs careful planning and coordination. This offers a strong cost control solution. Consult experts. They design the best pumping strategy for unique projects.

Besides Equipment Price, What Hidden Costs Must Be Considered When Buying or Renting a Concrete Boom Pump?

Purchase or rental price is just one part. Many hidden costs exist. They affect construction cost control. Ignoring them leads to budget overruns. Consider all expenses. This helps make an informed decision. It affects the boom pump rental or buying choice.

Operating Costs Beyond Fuel

Fuel is clear. Other operating costs are less visible. Wear parts are a major expense. Abrasive concrete wears pipelines, elbows, and cylinders fast. These need regular replacement. Quality parts last longer but cost more. Frequency depends on concrete volume and mix. Lubricants and hydraulic fluids need checks and changes. Proper lubrication extends life. Neglecting it causes costly repairs. Maintenance labor costs money. Skilled technicians are needed for checks and minor repairs. Specialized tools may also be needed. These are all part of running the machine. They impact construction cost control.

Transportation and Setup Costs

Transporting the boom pump costs money. Mobile pumps drive themselves. This is less costly, but fuel is still a factor. Stationary pumps need complex transport. Special trucks and oversized load permits are required. Setup needs a crane. This means crane rental fees and specialized rigging crews. These costs are substantial. Dismantling incurs similar costs. Ground preparation is needed. A concrete foundation for fixed pumps must be poured upfront. Setup costs are often overlooked. They are crucial to the budget. They impact the true cost of concrete boom pump selection.

Training, Insurance, and Downtime

Operator training is essential. Boom pumps are complex. They need skilled operators. Training costs money. Untrained operators damage equipment, cause accidents, and injure people. This leads to massive legal and financial problems. Invest in certified operator training. Proper training ensures safe operation. It maximizes concrete pumping efficiency. It extends machine life. Skilled operators identify problems early. They prevent major breakdowns. This is a crucial investment in safety and productivity. Also consider training on related equipment like a twin shaft concrete mixer or a concrete mixer pump for versatility.

How Do You Evaluate the Safety Performance, Operational Convenience, and Maintenance Costs of a Concrete Placing Boom?

When choosing a boom pump, look beyond reach and capacity. Evaluate safety features. Consider ease of use and long-term maintenance costs. These factors affect daily operations. They impact worker well-being. They also influence total ownership cost.

Assessing Safety Performance

Safety is paramount. Boom pumps are powerful. They are dangerous if not designed or operated safely. Seek pumps with advanced safety features. This includes automatic stability control. It prevents boom overextension. It monitors outrigger pressure. Emergency stop buttons must be accessible on pump and remote. Overload protection prevents lifting too much weight. Robust hydraulic lock valves prevent sudden boom collapse. The pump must comply with safety standards. Request certified tests. Check the manufacturer’s safety record. Proper lighting and alarms make night operations safer. A safe machine protects workers and investment. This prevents costly accidents and legal issues.

Evaluating Operational Convenience

An easy-to-operate pump boosts efficiency. It reduces operator fatigue. Seek intuitive control systems. Remote controls should be lightweight, user-friendly, with clear displays. Ergonomic design is important for comfort. Boom articulation speed and smoothness matter. Fast, smooth movements improve concrete pumping efficiency. Quick setup/breakdown for mobile pumps is a plus. For stationary, ease of assembly and climbing is important. The machine needs clear diagnostic displays. These help operators troubleshoot minor issues. Good visibility from the control point is key. It helps place concrete precisely. It prevents accidents. A convenient machine is productive. It saves time and effort daily.

Analyzing Maintenance Costs

Maintenance costs are long-term. They affect construction cost control. Inquire about wear part lifespan: pipelines, elbows, seals. Are parts available? Are they expensive? Long-life wear parts cost more upfront but save money over time. Evaluate ease of maintenance. Are service points accessible? Can in-house staff handle it, or is specialized service needed? Consider service intervals. Longer intervals mean less downtime. Robust hydraulic systems need less maintenance. Seek pumps with high-quality components. They break down less. Downtime is expensive. A reliable machine saves money. Inquire about the manufacturer’s warranty. A good warranty shows product confidence. It protects against early failures.

Brand, After-Sales Service, and Parts Supply: How Does One Pick a Trustworthy Concrete Boom Pump Supplier?

Choosing the right supplier is as important as choosing the boom pump. A good supplier offers more than equipment. They provide essential support. They ensure smooth operations. Seek trust and reliability. This affects long-term success.

The Importance of Brand Reputation

Strong brand reputation means quality. Established brands have a history of reliability. They invest in R&D. This improves boom pump technical parameters. They follow strict standards. Globally recognized brands like Putzmeister, Schwing, Zoomlion, and Sany have proven performance. Reputable brands reduce risk and build confidence. They have global service networks. Help is always nearby. Avoid unknown brands. Their low price means inconsistent quality. Parts are hard to find. This leads to costly downtime. A good brand choice is a smart investment. It ensures high concrete pumping efficiency.

Exceptional After-Sales Service

After-sales service is critical. Quick help is needed when problems occur. A good supplier offers prompt technical support. Skilled technicians diagnose and repair fast. Inquire about response times. How fast can a technician be dispatched? Is 24/7 support offered? Training is part of service. A good supplier trains operators and maintenance staff. This ensures proper operation. It extends machine life. Poor service causes long downtimes. This hurts schedules. It increases construction cost control challenges. A partner, not just a seller, is needed. A supplier who supports their product. They offer ongoing assistance. This is crucial for long-term success.

Reliable Parts Supply

Spare parts availability is often overlooked. It is very important. Wear parts need regular replacement. Breakdowns need specific components. A reliable supplier maintains large parts inventory. They ship quickly. They have a robust supply chain. Inquire about their parts availability guarantee. How long to get common parts? What about specialized ones? Delayed parts mean extended downtime. This costs money and delays projects. Some suppliers offer cheaper generic parts. Their quality can be poor. Prioritize genuine parts. They ensure compatibility, maintain performance, and uphold safety. A supplier with a strong parts network ensures the machine runs. This keeps efficiency steady. It is vital for continuous project operation.

What Common Mistakes Should Be Avoided When Buying or Renting a Concrete Boom Pump?

Mistakes in boom pump selection are costly. They delay projects and increase expenses. Know what to avoid. Learning from errors saves time and money. It helps make smart decisions.

Overlooking Project Specifics

A common mistake is choosing a pump based on general needs. Examine project specifics. Do not assume one-size-fits-all. Consider boom length for furthest reach. Think about high-rise pumping requirements. Is the site congested? Is terrain uneven? Many buyers focus on price. They overlook site conditions. This leads to ineffective pumps. It results in costly rentals. It means manual labor. This reduces efficiency. Always conduct detailed site analysis. Map all pour areas. Identify all obstacles. Precise planning prevents costly oversights.

Neglecting After-Sales Support and Parts

Many buyers focus only on initial price. They ignore after-sales service and parts. This is a big error. A cheaper, unknown pump might save upfront. But what about breakdowns? Can parts be obtained fast? Is technical support available? Long waits for repairs or parts cost more than initial savings. Downtime means lost money and project delays. Always evaluate the supplier’s service network. Check their parts inventory. A reliable support system keeps the pump running. This maintains concrete pumping efficiency. It protects construction cost control.

Underestimating Operating and Hidden Costs

The sticker price is just the start. Many hidden costs exist: wear parts, fuel, maintenance labor, and insurance. Many buyers fail to budget for these. Wear parts (pipes, elbows) need frequent replacement. This is true for abrasive concrete mixes. Fuel consumption varies by model. Higher capacity pumps use more fuel. Maintenance is complex. It needs skilled technicians. These costs add up quickly. They can surprise later. Always request a detailed cost of ownership breakdown. Include projected wear part costs and service schedules. This helps understand true long-term expense. This view aids better boom pump model selection. It prevents budget surprises.

Skipping Operator Training

Operating a boom pump needs skill. It is not just driving. Many companies use untrained operators to save money. This is a dangerous mistake. Untrained operators damage equipment, cause accidents, and injure people. This leads to massive legal and financial problems. Invest in certified operator training. Proper training ensures safe operation. It maximizes concrete pumping efficiency. It extends machine life. Skilled operators identify problems early. They prevent major breakdowns. This is a crucial investment in safety and productivity. Also consider training on related equipment like a twin shaft concrete mixer or a concrete mixer pump for versatility.

Future Trends and Technical Innovations in Intelligent and Green Concrete Boom Pumps?

The concrete pumping industry evolves fast. New technologies emerge. They focus on smart control and green solutions. This leads to better concrete pumping efficiency. It promotes sustainable construction. Knowing these trends helps prepare well. It guides future boom pump selection.

Smart Automation and Remote Control

Boom pumps will be highly automated. Sensors will monitor position, flow, and pressure in real-time. Automation controls make real-time adjustments. This ensures optimal performance. It prevents blockages. Remote control will be sophisticated. Operators use VR/AR interfaces. This allows safe distance control. It gives a better pour view. Some pumps will have semi-autonomous features. They follow pre-programmed paths. This reduces human error. It boosts efficiency. Operations become safer and more precise.

Enhanced Safety Features with AI

AI will revolutionize safety. AI systems analyze sensor data. They predict stability issues. They detect unsafe conditions. AI can warn of wind loads. It identifies ground instability. It prevents boom collisions. These systems exceed current safety interlocks. They offer proactive protection. This reduces accidents. It makes pouring safer. AI will assist predictive maintenance. It analyzes machine data. It forecasts part failure. This allows planned maintenance. It prevents breakdowns. This means less downtime. It reduces construction cost control.

Greener and More Sustainable Solutions

Construction moves to sustainability. Boom pumps follow this trend. Electric or hybrid pumps are common. They reduce fuel use, carbon emissions, and noise pollution. This is key for urban projects. Pump component materials change. Manufacturers develop lighter, stronger materials. These extend wear part life. They reduce waste. Energy-efficient hydraulic systems are key. They use less power. They generate less heat. These innovations aid green production. They meet environmental regulations. They make construction eco-friendly. This benefits everyone.

Data Analytics and Digital Twins

Future boom pumps generate vast data. This data tracks performance. It monitors maintenance needs. It optimizes operational strategies. Digital twins will emerge. These are virtual models of physical machines. They simulate real-time performance. They allow virtual testing of operational changes. This improves boom pump model selection. It optimizes existing equipment. This data-driven approach leads to continuous improvement. It maximizes efficiency. It minimizes waste. It represents the future of smart construction equipment, complementing other construction equipment like hollow block machines and paver block machines.

Frequently Asked Questions

Question 1: Why is selecting the correct boom length so critical?

Selecting the correct boom pump boom length is critical. It ensures all concrete placement points can be reached. An insufficient length requires multiple setups. This wastes time. It increases labor costs. It reduces construction efficiency improvement. Always choose a boom with some extra reach for flexibility.

Question 2: What are the main differences between static and mobile boom pumps?

Mobile boom pumps are truck-mounted for easy transport. They offer quick setup. They are good for varied, smaller pours. Stationary boom pumps are separate units. They mount on towers or slabs. They offer exceptional height and reach. They are ideal for large, high-rise projects. They are less flexible for moving.

Question 3: How does high pumping capacity improve project efficiency?

High pumping capacity improves efficiency. It delivers concrete faster. This means quicker concrete pouring. It reduces concrete truck waiting times. It allows meeting tight project schedules. This avoids costly delays. It directly boosts overall construction efficiency improvement.

Question 4: What is the most common hidden cost when operating a concrete boom pump?

The most common hidden cost is wear parts replacement. Concrete is abrasive. It causes pipes, elbows, and pumping cylinders to wear out. These parts are expensive. They need frequent replacement. This cost often surprises buyers. It significantly impacts construction cost control.

Question 5: Why is strong after-sales service important for boom pumps?

Strong after-sales service is vital. Boom pumps are complex machines. They need expert support. Good service ensures quick repairs. It provides timely parts. This minimizes downtime. It keeps the project on schedule. This is key for maintaining concrete pumping efficiency.

Summary and Recommendations

Choosing the right boom pump is strategic. It affects project success, costs, timelines, and safety. Understand pump types and technical parameters. Match the pump to specific project needs. Consider initial and hidden costs. Prioritize safety, convenience, and maintenance. Select a reliable supplier with strong after-sales support. Avoid common mistakes for the best choice. Intelligent and green technologies promise greater efficiency. They make construction more sustainable.

Ready for the perfect concrete placing boom? Durable helps. Our experts understand site requirements. We offer high-quality construction equipment, including reliable concrete pumping equipment. Contact Durable today. We boost construction efficiency. We ensure smooth and effective concrete pouring.

About Durable

Durable engineers and manufactures mineral processing and drying equipment since 2001. We build complete solutions, not just sell machines. Our team of 15 engineers designs custom systems. Quality control is excellent at every production stage. We serve global B2B clients. We deliver advanced equipment from Zhengzhou. Products go to over 120 countries.

Durable Machinery

Durable Machinery