Choosing Your Concrete Pump: How to Match Needs and Boost Efficiency?

Concrete pumps are vital on almost every big building project. They move concrete efficiently to where it is needed. This includes tall buildings, large structures, and even hard-to-reach areas. Knowing how these machines work changes how you manage your site. It helps avoid problems. It boosts your team’s efficiency and keeps everyone safe. I have designed many processing plants. I have also seen many construction sites. These machines offer huge benefits. Let us look at how a concrete pump works. We will see how it moves concrete from the truck to the exact pour spot.

Table of Contents

- Why Should You Understand the Concrete Pump Working Principle?

- How Do Concrete Pumps Move Concrete? What Is the Concrete Pumping Principle?

- How Can Knowing the Working Principle Help Find Pump Problems and Fix Them?

- What Are the Main Types of Concrete Pumps and How Do They Differ?

- Working Principle: How Does It Affect Pumping Efficiency and Equipment Life?

- What Are the New Trends and Innovations in Concrete Pumping Technology?

- Frequently Asked Questions

- Summary and Recommendations

- About Durable

Why Should You Understand the Concrete Pump Working Principle?

Understanding the concrete pump’s working principle is for everyone. This includes managers and operators. This knowledge helps you in many ways. This ensures smoother operations, reduces unexpected costs, and enhances workplace safety.If you know how the pump should work, you can spot issues fast. You can solve small problems quickly. This saves money and time on the job site. A good understanding improves concrete pumping efficiency.

Knowing the details helps you make better decisions. This enables more accurate pump selection for each job, improved operator guidance, and clearer communication with maintenance teams. This means less time for repairs. Your projects stay on track. This knowledge helps predict wear and tear. You can plan for parts replacement. This prevents sudden breakdowns. You save money by reducing emergency repairs. You also keep your team safer. A pump working correctly is a safe pump. Informed managers get the most from their equipment. They also keep budgets in check.

Your Benefit from This Knowledge

This prevents costly mistakes, accelerates project timelines, and enhances safety for everyone. Knowing the working principle is like having a secret tool. It helps you get the most out of your concrete pump. This is true when you use complex systems. It helps ensure your concrete is placed right every time. It is a vital part of effective construction. This knowledge makes you a more valuable asset on any construction team. It helps you lead with confidence. It lets you quickly solve pump problems.

How Do Concrete Pumps Move Concrete? What Is the Concrete Pumping Principle?

A concrete pump works like a giant syringe. It uses hydraulic power. This power makes a push and pull action. This moves concrete through a long pipe. It provides a steady flow. The concrete goes exactly where it needs to be. This basic idea is simple. Yet, its application is powerful. It makes moving concrete easy and fast. This is a core part of its operation. The concrete pump machine takes in concrete. Then it pushes it out. This happens over and over.

The system uses strong hydraulic force. This force moves large pistons. These pistons push the concrete. A special valve directs the flow. It sends concrete into the pipeline. This valve quickly switches positions. One side sucks in new concrete. The other side pushes out concrete already loaded. This quick switch makes the flow continuous. It means no stops in concrete delivery. This method prevents concrete from hardening inside the pump. It keeps the mix moving smoothly. This continuous movement is critical for big projects.This offers significant time savings, eliminates the need for manual concrete transport, and enhances worker safety. We rely on this principle for efficient construction.

What are the main systems and parts of a concrete pump machine?

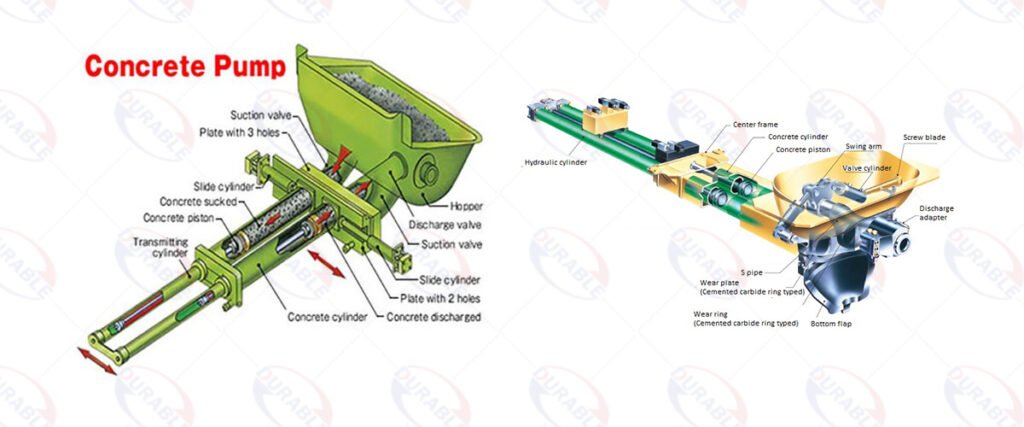

A concrete pump machine has several key parts. Each part works together. This ensures smooth operation. First, the hopper receives concrete from the truck. Inside, an agitator mixes the concrete. This keeps it from separating. Then, two big pumping cylinders push the concrete. The hydraulic system powers these cylinders with oil pressure. A valve system directs the concrete flow. It switches between cylinders. A delivery line carries concrete to the pour site. For some types, like boom pumps, a boom is an arm. It extends, folds, and places concrete. Outriggers stabilize the pump. A control system lets the operator manage everything. This full setup makes up the pump’s concrete pump machine structure.

What do pistons, S-valves, or gate valves do in concrete pumping?

Pistons within the pumping cylinders move back and forth, generating the push and pull to transport concrete. Simultaneously, one piston pulls concrete in while the other pushes it out. The valve system directs this flow. The common S-valve, a curved tube, swings to connect one cylinder to the hopper and the other to the delivery pipe. Its rapid switching action reverses these connections, ensuring continuous flow. A gate valve (or rock valve) alternatively uses a moving plate to open and close concrete paths. Both valve types switch quickly, maintaining smooth concrete flow and preventing blockages.

How does the hydraulic system power the concrete pump?

The hydraulic system is the pump’s muscle. It uses pressurized oil. This oil moves the pistons in the pumping cylinders. It also moves the valve system. For boom pumps, it powers the boom. The system includes a hydraulic pump. This pump creates high-pressure oil. There is an oil reservoir. It stores the oil. Valves control the oil flow. Hoses carry the oil. When an operator starts the pump, the hydraulic pump sends oil. This oil pushes the cylinder pistons. It makes them move. It also powers the valve’s switching action. A strong concrete pump hydraulic system ensures smooth power. It allows precise control. It is very reliable. A well-maintained hydraulic system is critical. It ensures consistent performance. It reduces breakdowns.

What are the steps in the concrete pumping cycle?

The concrete pumping process is a continuous loop. Concrete from the truck first enters the hopper, where an agitator stirs it. Using two pumping cylinders (A and B), the process alternates: Cylinder A fills with concrete via a suction stroke (piston moves away, pulling from hopper), while simultaneously Cylinder B empties via a discharge stroke (piston pushes into delivery line). The valve system directs this flow. When Cylinder A is full and Cylinder B is empty, the valve system quickly switches. Cylinder A then pushes concrete into the delivery line, and Cylinder B begins to fill from the hopper. This alternating cycle repeats many times per minute, ensuring a continuous, steady stream of concrete. This pumping principle is highly effective.

How Can Knowing the Working Principle Help Find Pump Problems and Fix Them?

If you know how a concrete pump works, you can find problems easily. You can fix issues fast. This saves you time and money. When the pump acts strangely, you know what to check. For example, if concrete flow is uneven, check the valve. It might not be switching right. If the pump struggles, the hydraulic system might be weak. Or, there might be a blockage. This understanding helps pinpoint the cause. You do not waste time checking every part. This knowledge turns guesswork into smart action. My experience shows this. Operators who know the principles solve problems faster. This means less downtime. This makes a big difference on busy construction sites. It is vital for quick concrete pump troubleshooting.

Strange pump noises are serious; banging might indicate piston problems, air in the concrete, or a dry mix. A slow boom suggests low hydraulic oil or a blocked filter. High pressure often signals a blockage, while low pressure points to hydraulic pump failure. Linking these symptoms to the pump’s working principle allows for targeted fixes and predictive maintenance. This proactive approach prevents costly repairs and dangerous situations by connecting observations to how the machine should function.

What Are the Main Types of Concrete Pumps and How Do They Differ?

All concrete pumps share the same basic pumping mechanism. They use pistons and a valve. But how they deliver concrete to the site differs. This is based on their design. There are two main types: Concrete Boom Pumps and Concrete Line Pumps. Their working mechanism is similar. Their deployment is different. This impacts how they are used.

Concrete Line Pumps (also known as concrete delivery pump or trailer-mounted pumps) are smaller, trailer- or skid-mounted units. Lacking an integrated boom, they use long, manually connected flexible hoses laid across the ground or up structures. Ideal for tight spaces (basements, indoor pours, shotcrete), their pumping mechanism is identical to boom pumps. While reach is limited by hose length and setup requires more labor/time, they are cost-effective for smaller jobs and offer flexible hose placement.

Concrete Boom Pumps are truck-mounted, featuring a long, articulated boom for precise concrete placement. These expedite large-area setups, reaching high and far for projects like high-rise buildings, large slabs, or bridges. Their pump mechanism is similar to a line pump, but the boom provides mechanical assistance, accelerating operations and reducing manual labor. Truck-mounted mobility makes them ideal for high-volume, precise placement needs.

Both types share the same core pumping action. The main difference lies in how concrete is transported from the pump to the pour location: line pumps use manual hoses, while boom pumps utilize a robotic arm. The choice depends on your project’s specific demands.

Working Principle: How Does It Affect Pumping Efficiency and Equipment Life?

The working principle of a concrete pump directly affects its efficiency and how long it lasts. When the pump works smoothly, it is efficient. It also lasts longer. If any part of the cycle is off, it causes problems. This reduces efficiency. It also wears out parts faster.

Inconsistent concrete mix hinders agitator performance, causing segregation. This can block pumping cylinders, increasing pressure, making the pump work harder, consuming more fuel, and accelerating wear on pistons and the valve.

A smooth valve switch is critical; delays allow concrete to harden at the switch point, leading to blockages, damaged valve parts, and reduced pumping efficiency and equipment life.

A well-tuned hydraulic system ensures consistent power for steady flow, preventing jolts that stress pipes and the boom.

Regular maintenance, rooted in understanding the working principle, is key. Knowing piston movement allows proper condition checks, and understanding hydraulic pressure ensures limits are maintained. This prevents overloading, which rapidly wears parts and can cause catastrophic failure. Familiarity with S-valve wear patterns enables preemptive replacement, avoiding costly emergency repairs and ensuring optimal machine performance. This proactive approach saves money, extends investment life, and is vital for concrete pump longevity.

What Are the New Trends and Innovations in Concrete Pumping Technology?

The world of concrete pumping is changing fast. New technologies are coming out. They make pumps smarter. They also make them greener. These changes boost concrete pumping efficiency. They help with sustainable building. Knowing these trends helps you prepare. It guides your choices for future pumps.

Smart Automation and Remote Control

Soon, concrete pumps will be highly automated. Sensors will watch everything. They will monitor position, flow, and pressure in real-time. Automation will make quick changes. This keeps the pump working at its best. It stops blockages. Remote control will get better too. Operators will use virtual reality (VR) or augmented reality (AR). This lets them control the pump from a safe distance. It gives a better view of the pour. Some pumps will move on their own, following set paths. This means fewer mistakes. It makes work faster. Operations will be safer and more exact.

Enhanced Safety Features with AI

Artificial intelligence (AI) will make pumps safer. AI systems will look at sensor data. They will predict stability problems. They will find unsafe conditions. AI can warn about strong winds. It can spot unstable ground. It will stop booms from hitting things. These systems prevent problems before they happen. This means fewer accidents. It makes pouring safer. AI will also help with maintenance. It will look at machine data. It will guess when a part might break. This helps plan repairs. It stops unexpected breakdowns. This means less wasted time. It cuts down on costs.

Greener and More Sustainable Solutions

As building becomes more sustainable, concrete pumps are following suit. Electric or hybrid pumps, now common, consume less fuel, emit less carbon, and operate more quietly – vital for city projects. Pump components are also evolving, with manufacturers using lighter, stronger materials that last longer and reduce waste. Hydraulic systems are likewise more energy-efficient, utilizing less power and creating less heat. Together, these innovations aid green production, meet environmental rules, make building better for the planet, and benefit all involved.

Data Analytics and Digital Twins

Future concrete pump machines will collect lots of data. This data tracks how they perform. It shows when they need maintenance. It helps make operations better. Digital twins will also appear. These are virtual copies of real machines. They show how the machine works in real-time. They let you test changes virtually. This helps you choose the best pump model. It makes existing equipment work better. This data-driven way of working makes things better all the time. It not only boosts efficiency and cuts waste but also embodies the future of smart construction equipment.This works well with other construction equipment, like a twin shaft concrete mixer or a concrete mixer pump.

Frequently Asked Questions

Question 1: Why is understanding the pumping cycle important for operators?

It helps operators quickly diagnose issues like uneven flow or strange noises. This prevents breakdowns, keeps projects on schedule, and boosts machine operation.

Question 2: What is the main role of the S-valve in a concrete pump?

The S-valve directs concrete flow. It rapidly switches paths, allowing continuous concrete flow by alternately filling and emptying the pumping cylinders.

Question 3: How does proper hydraulic system maintenance affect pump performance?

Proper hydraulic maintenance ensures smooth power. This means precise boom movements and consistent concrete pumping. Neglect leads to weak performance, slow operation, and costly breakdowns, directly impacting efficiency.

Summary and Recommendations

Understanding concrete pump principles is vital for project success, saving money and time, and boosting safety. Effective selection involves knowing pump types and technical aspects, matching them to project needs, and prioritizing long-term factors like safety, ease of use, maintenance, and reliable supplier support over just the initial price. New smart and green technologies are also enhancing industry efficiency and sustainability.

Ready for the perfect concrete pumping equipment? Durable’s experts provide high-quality, reliable solutions tailored to your site, ensuring improved construction efficiency and smooth concrete pouring every time. Contact us today.

About Durable

Durable engineers and manufactures mineral processing and drying equipment since 2001. We build complete solutions. We do not just sell machines. Our team of 15 engineers designs custom systems. Quality control is excellent at every production stage. We serve global B2B clients. We deliver advanced equipment from Zhengzhou. Products go to over 120 countries.

Durable Machinery

Durable Machinery