Search the whole station liberty-fse

Energy-Saving Clay Brick Machine

Capacity: 8000-14000 pieces per hour

Power: 90-132KW

Introduction:

This industrial-grade vacuum extruder is engineered for large-scale brick manufacturing. With a powerful motor and a high capacity, it efficiently processes hard materials like clay, shale, and coal gangue.

Its core advantage is the advanced vacuum de-airing system, which effectively removes air from the raw material. This significantly increases the density and strength of the bricks, ensuring a superior, crack-free final product. It is the ideal choice for modern large-scale brick plants seeking efficient, stable, and high-quality production.

Semi-automatic Clay Brick Maker Machine

Capacity:2000-3000 pieces per hour

Power: 15HP/11KW

Introduction:

This is a low-cost and simple small brick extruder, designed for small-scale production. It uses a non-vacuum mechanical process to form solid clay bricks.

The core strength of this non-vacuum brick extruder lies in its straightforward design. The machine’s operation is semi-automatic: operators manually feed the prepared clay mixture into the hopper, and once the continuous clay column is extruded, it is cut into uniform bricks using a manual cutter. Its compact footprint and low energy consumption (typically powered by an 11-22KW motor) ensure it can operate efficiently even in workshops with limited space and power, keeping your running costs to a minimum.

Small Energy Saving Vacuum Extruder

Capacity: 4000-7000 pieces per hour

Power: 55KW/75KW

Introduction:

Elevate your brick manufacturing with our Small Energy-Saving Vacuum Extruder, the ideal solution for producing high-quality, high-density bricks. As a significant upgrade from non-vacuum models, this machine integrates a vacuum pump to de-air the clay, resulting in superior finished products. It is engineered for small to medium-sized brick plants that prioritize brick strength, durability, and a professional finish, all while keeping operational costs low.Small Energy-Saving Vacuum Extruder is the definitive choice for producers looking to upgrade their capabilities. It delivers the high-quality output of large-scale industrial machines but in a compact, affordable, and energy-efficient package, making it a smart and strategic investment for any growing brick business.

Two-Stage Vacuum Extruder

Capacity: 10000-16000 pieces per hour

Power: 155KW/177KW

Raw Material: Clay, soil, earth, water. etc.

Introduction:

The Two-Stage Vacuum Extruder, also known as a Double-Stage Vacuum Extruder, represents the highest standard in modern brick and tile manufacturing. Engineered for high-volume, continuous production, this industrial-grade machine is the ultimate solution for producing premium-quality bricks, especially from hard and low-plasticity raw materials like shale, coal gangue, and fly ash. Its advanced dual-stage design ensures unparalleled material processing, resulting in bricks of exceptional density, strength, and structural integrity. It is the definitive choice for any new or expanding brick plant focused on large-scale, high-quality, and profitable manufacturing.

Semi-automatic Hydraulic Clay Brick Making Machine

Capacity: 2 pieces per mould; 3840 pieces per 8 hours

Power: 5.5KW

Raw Material: Clay, soil, cement, sand ,water. etc.

Introduction:

The ECO BRB Manual Interlocking Brick Machine is a revolutionary solution for affordable and sustainable construction. Operating entirely without electricity, it uses a powerful manual press to transform local soil mixed with a small amount of cement into high-quality interlocking bricks. This innovative no-burn process eliminates fuel costs and harmful emissions, while the interlocking design drastically reduces the need for mortar, speeding up construction and lowering overall costs. It is the perfect low-investment tool for small-scale entrepreneurs, community housing projects, and anyone looking to build responsibly and economically.

Automatic Hydraulic Soil Brick Making Machine Line

Capacity: 4 pieces per mould; 6000-8000 pieces per 8 hours

Raw Material: Clay, soil, cement, sand ,water. etc.

Introduction:

The LT4-10 is a fully automatic hydraulic clay brick machine engineered for small to medium-scale commercial production. Integrating a PLC for automated operation, it significantly boosts output to thousands of bricks per day while minimizing labor requirements. Its powerful hydraulic system delivers high pressure, ensuring the production of high-density, uniform, and exceptionally strong bricks. With interchangeable molds, it offers the versatility to produce various types of interlocking blocks and pavers. By utilizing local soil and a no-burn curing process, the LT4-10 provides a highly efficient, cost-effective, and eco-friendly solution for businesses aiming to scale up their building material manufacturing.

Are you in the market for a clay brick making machine? Choosing the right machine is crucial for your business. This article explores the different types of machines, the brick manufacturing process, and the key factors to consider for your business. Understanding the nuances of sintered clay brick and hydraulic clay brick production will help you make the best decision. DURABLE MACHINE offers a range of reliable clay brick making machines to meet your specific needs.

Last Updated: June 2025 | Estimated Reading Time: 15 minutes

Clay bricks are a fundamental building material made from clay-rich soil that is molded, dried, and then hardened, usually by firing.

These bricks come in various types, each suited for different clay bricks applications:

A clay brick making machine is equipment designed to automate the production of clay bricks. These machines range from manual to fully automatic clay brick making machines, increasing production efficiency and consistency. These are used in the brick manufacturing process. They streamline the entire process, from mixing raw materials to shaping and ejecting the final product. A reliable brick manufacturing machine is essential for any brick-making business. DURABLE machines can be integrated into a clay brick production line.

The two primary types of clay brick making machines are:

These machines can be powered by diesel or electric engines, offering flexibility based on energy availability and cost. The choice depends on production volume, desired brick properties, and budget. DURABLE MACHINE offers both types to cater to diverse needs.

A sintered brick machine extrudes clay through a die and then cuts it into individual bricks. The bricks are then dried and fired in a kiln at high temperatures. This process fuses the clay particles together, creating a strong and durable sintered clay brick.

What are the Advantages of Sintered Clay Bricks?

What are the Types of clay extrusion machine?

A hydraulic clay brick machine uses a brick compressor to press clay into molds under high pressure. The bricks are then ejected and dried. This method creates bricks with precise dimensions and uniform density. A reliable brick compressor ensures consistent brick quality.

What are the Advantages of Hydraulic Clay Bricks?

What are the Types of clay brick makers?

The key differences lie in the manufacturing process and brick characteristics:

| Feature | Sintered Clay Brick Machine | Hydraulic Clay Brick Machine |

|---|---|---|

| Manufacturing | Extrusion and firing at high temperatures | Compression under high pressure |

| Brick Properties | High strength, good thermal insulation | Precise dimensions, high density |

| Energy Consumption | High (due to firing) | Lower (no firing required) |

| Production Volume | Suitable for large-scale production | Suitable for various production scales |

DURABLE MACHINE offers both options to suit different production needs.

DURABLE MACHINE is engineered for excellence. We utilize Manganese 16 (Mn16) super wear-resistant steel in our construction, ensuring a structurally stable and exceptionally durable machine.Our precision molds undergo meticulous heat treatment and wire-cutting, guaranteeing accurate brick dimensions every time. This superior craftsmanship ensures 24-hour stable operation with an extremely low fault rate, providing a reliable foundation for your high-volume brick production project. Trust DURABLE MACHINE for consistent, dependable performance.

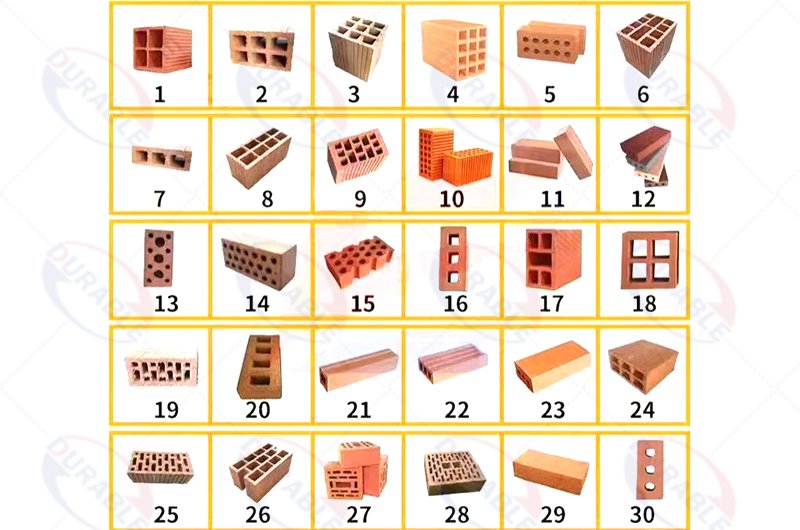

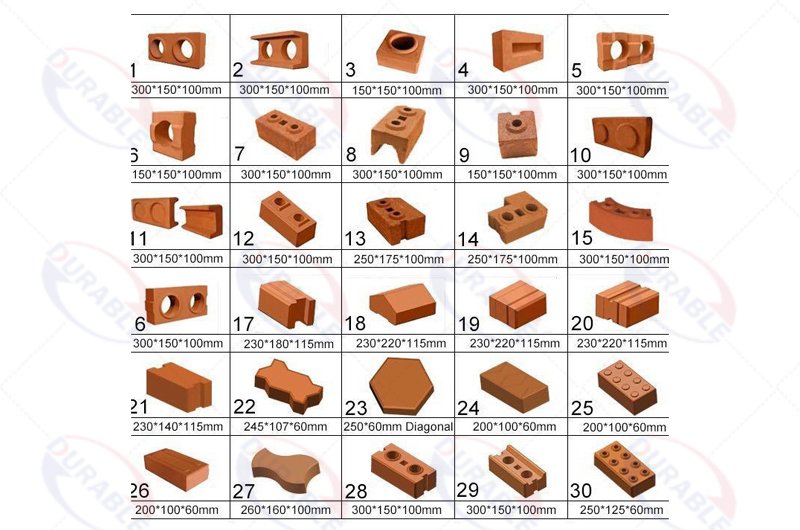

Clay brick making machines can produce a variety of brick types:

DURABLE MACHINE machines can be configured to produce many different types of bricks.

The primary raw materials include:

Selecting the right clay brick making machine depends on several factors:

DURABLE MACHINE team can help you to understand how to set up a production line for concrete blocks

DURABLE MACHINE’s clay brick machines stand out with:

DURABLE MACHINE focuses on providing automated solutions for your brick production machine needs.

The brick manufacturing process typically involves:

Several factors influence the clay brick machine price of clay brick production:

Contact DURABLE to know the latest price of clay bricks making machine!

Regular maintenance is crucial for ensuring the longevity and efficiency of clay brick making machines:

Common issues include:

These problems can be mitigated by regular inspections

The clay brick machine price is influenced by:

DURABLE MACHINE offers competitive pricing for high-quality machines.

Clay brick production can have environmental impacts:

Sustainable practices, such as using recycled materials and energy-efficient kilns, can help mitigate these impacts.

Recent innovations include:

Safety is paramount when operating a clay brick making machine:

Reliable suppliers can be found through:

DURABLE MACHINE welcomes you to visit our facilities.

Choose DURABLE MACHINE for:

DURABLE MACHINE stands out as your partner for Clay Brick Making Solutions. Contact DURABLE MACHINE today to discuss your clay brick making machine needs and find the perfect solution for your business.