Search the whole station liberty-fse

M7MI Mobile Pressed Earth Block Machine

Capacity:1-2 pieces per mould; 2500-5000 pieces per 8 hours

Power Type: Diesel Engine/Electric Motor

Workers Needed: 2-4 persons

Forming Cycle:15-20 seconds

Brick Size: Different sizes and shapes including interlocking bricks, lego bricks, etc..

Application: Rural housing projects; Construction in remote areas; Small-scale brick production businesses; Areas where clay is readily available

Introduction:

Designed to be easily moved between job sites, the M7MI compressed earth block machine eliminates logistical hurdles and brings production directly where it’s needed. With a remarkable molding cycle of just 15-20 seconds, this compressed earth machine offers outstanding productivity, making it a highly profitable asset for small to medium-sized construction businesses. It represents the perfect fusion of hydraulic strength, portability, and cost-effective operation.

DM2-40 Manual Small CEB Machine

Capacity:1-2 pieces per mould; 900-1400 pieces per 8 hours

Power Type: manual

Workers Needed: 1-2 persons

Forming Cycle:40-50 seconds

Brick Size: Different sizes and shapes including interlocking bricks, lego bricks, etc..

Application: Small-scale construction projects; Home building in rural areas; Self-building projects;

Introduction:

Upgrade your brick production with the DM2-40 Manual compressed block machine. Powered by manual, this brick machine for sale makes compression to create stronger, denser compressed earth bricks. As an efficient earth block machine, it yields 2 superior-quality bricks per cycle, making it the perfect soil block machine for projects that demand both speed and structural integrity.

ECOBRB Semi-automatic Hydraulic Brick Compressor

Capacity:1-2 pieces per mould; 1900-3900 pieces per 8 hours.

Power Type: Diesel Engine/Electric Motor

Workers Needed: 1-2 persons

Forming Cycle: 20-25 seconds

Brick Size: Different sizes and shapes including interlocking bricks, lego bricks, etc..

Application: Residential Construction; Housing Projects;Self-Build Projects;community buildings;Infrastructure Projects

Introduction:

The Eco BRB Earth Brick Machine sets a new standard for quality in compressed earth block production. Compressed soil block machine combines a powerful hydraulic system with superior manufacturing processes to deliver consistently flawless bricks. This block making equipment machine is the perfect investment for small to medium-sized businesses aiming to produce a premium product.

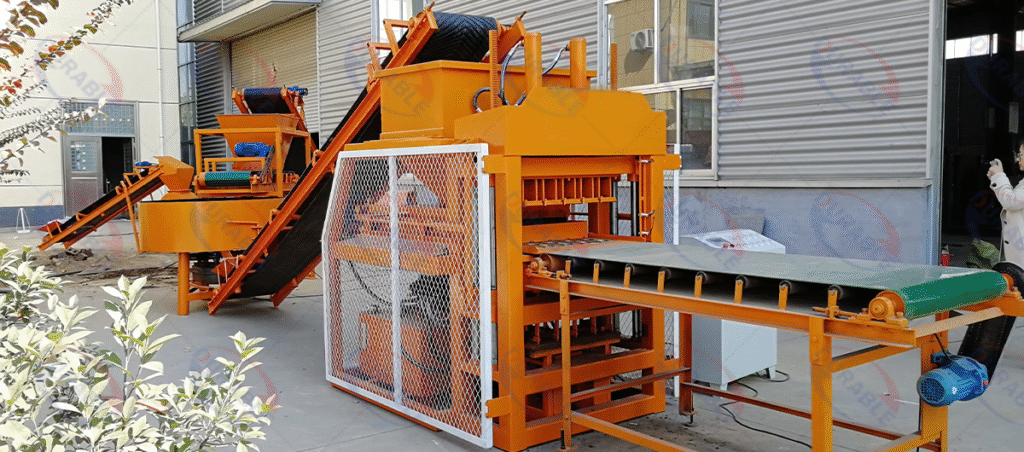

DM4-10 Fully Automatic Compressed Soil Blocks Machine Line

Capacity: 4 pieces per mould;11520 pieces per 8 hours

Power Type: electric power

Forming Cycle: 10-15 seconds

Introduction:

The DM4-10 block maker for sale represents the pinnacle of automated earth block manufacturing, engineered for medium to large-scale investors who demand maximum efficiency and output. This machine is a fully integrated production line, controlled by an advanced PLC system that automates the entire manufacturing process.

At its core, the DM4-10 blocks machine utilizes a powerful hydraulic press that simultaneously molds four high-density earth blocks per cycle, increasing productivity. This high-speed output is complemented by industrial-grade construction ensuring unparalleled durability and consistent performance under heavy-duty operation.

This guide dives into the world of compressed earth block machines, explaining their advantages, types, applications, and how to choose the right one. Whether you’re interested in soil block machines, interlocking block machines, or understanding the used compressed earth block machine sale market, this comprehensive guide will provide valuable insights to help you make informed decisions. DURABLE MACHINE offers high-quality CEB machines designed for various production needs, from manual to fully automatic systems.

A Compressed Earth Block Machine is a machine that compacts a mixture of damp subsoil into uniform blocks used for construction. These machines are designed to create strong, durable blocks using locally available soil. This reduces the need for expensive and environmentally harmful materials like cement. CEB machines range from manual presses to fully automated systems. Each type offers different production capacities and levels of automation.

The CEB Machine compacts soil under high pressure. This creates blocks that are denser and more durable than traditional adobe bricks. The composition of the soil is crucial. The right balance of clay, sand, and silt results in blocks with optimal strength and water resistance. Some machines also allow for the addition of cement or lime as stabilizers, enhancing durability. DURABLE MACHINE offers CEB machines capable of producing various block sizes and shapes to meet diverse construction requirements. Our machines are designed for efficient soil block making.

CEB machines offer several advantages, including cost-effectiveness, sustainability, and ease of use.

The main difference lies in the materials used. CEB machines use soil, while traditional block machines use concrete.

CEB block machines:

Traditional block machines:

If you are looking for a used compressed earth block machine sale, consider the long-term benefits of reduced energy consumption.

CEB machines are available in manual, semi-automatic, and automatic versions. Each type caters to different production scales and budgets.

DURABLE MACHINE provides a range of CEB machines, ensuring we have the right machines that suit various production needs and budget considerations. DURABLE MACHINE prioritizes these features. Our machines use high-quality steel and user-friendly interfaces. DURABLE MACHINE uses high-strength steel as raw material, and parts from Siemens, Schneider, Emerson, and other famous brand. Machine quality is realiable.

DURABLE MACHINE’s CEB machines are known for their robust construction, ease of operation, and efficient production.

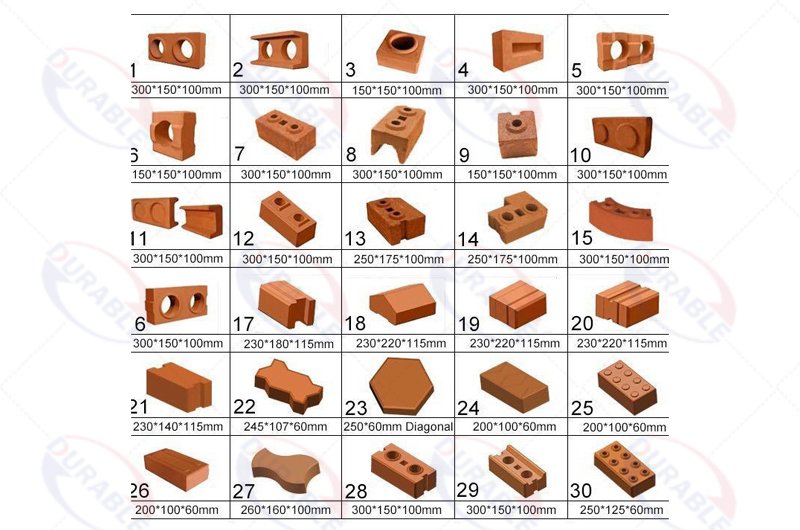

CEB machines can produce a variety of brick designs, including standard rectangular blocks, interlocking blocks, and decorative blocks.

The versatility of Interlocking Block Machine lies in their ability to create blocks suitable for load-bearing walls, partition walls, and even paving. The interlocking design enhances the structural integrity of the walls, making them more resistant to earthquakes and other natural disasters. Decorative blocks can be used for house building, creating visually appealing and sustainable buildings.

DURABLE MACHINE offers CEB machines with interchangeable molds, allowing customers to produce a variety of block designs with a single machine.

The best soil for making CEBs is a balanced mixture of clay, sand, and silt. Clay provides cohesion, allowing the blocks to hold their shape. Sand provides strength and stability, preventing excessive shrinkage and cracking. Silt fills the voids between the clay and sand particles, creating a dense and compact block. The ideal soil composition typically contains 15-30% clay, 50-70% sand, and 10-20% silt.

Too much clay can result in blocks that shrink and crack during drying. Too much sand can lead to weak and unstable blocks. It’s important to analyze the soil composition before making CEBs. Then, adjust the mixture accordingly. If the soil is too clayey, add sand to improve its stability. If the soil is too sandy, add clay to enhance its cohesion. DURABLE MACHINE recommends conducting soil tests, adjusting the mixture based on the specific soil properties, to achieve optimal block quality when using our soil block machine.

The main difference lies in the compaction method.

CEBs are compressed using a machine, while adobe bricks are sun-dried without mechanical compaction. CEBs are made by compressing a soil mixture under high pressure, creating denser and more durable blocks. Adobe bricks are made by molding a soil mixture and allowing it to dry naturally in the sun. This difference in production methods results in distinct properties and applications for the blocks.

CEBs are generally stronger and more water-resistant than adobe bricks due to the compaction process. The compaction process also reduces shrinkage and cracking during drying. Adobe bricks are more susceptible to erosion and require regular maintenance. CEBs offer greater durability and longevity. Both CEBs and adobe bricks are sustainable building materials. However, CEBs offer improved performance and reduced maintenance requirements, making them a reliable choice for construction when produced with a quality CEB Machine.

CEBs are versatile building materials, suitable for a wide range of applications, including housing, walls, and foundations. They can be used to construct load-bearing walls and partition walls. They can also be used for foundations in certain soil conditions. CEBs are ideal for building low-cost housing, schools, and other community structures.

The excellent thermal mass of Earthen Blocks House helps regulate indoor temperatures, reducing the need for heating and cooling. CEB buildings are also resistant to fire, termites, and other pests. CEBs can be used in both urban and rural settings, offering a sustainable and affordable building solution for diverse communities. With proper design and construction techniques, CEB buildings can provide comfortable, durable, and environmentally friendly living spaces. Using a reliable CEB machine ensures consistent quality for these applications.

CEB machines work by compacting a soil mixture into a mold under high pressure. In manual machines, the pressure is applied manually, using levers or cranks. In hydraulic machines, the pressure is applied using a hydraulic system. The compaction process forces the soil particles together, creating a dense and stable block.

Hydraulic adobe brick machine offer greater compaction force. They also offer more consistent block density compared to manual machines. The hydraulic system allows for precise control over the compaction pressure, ensuring uniform block quality. Manual machines are simpler and more affordable, but require more physical effort and may result in less consistent block density. The choice between hydraulic and manual machines depends on the desired production capacity, budget, and available resources.

CEB blocks are made through a series of steps:

The curing process is crucial for the long-term durability of CEB blocks. The blocks are typically cured by keeping them moist for several days. This allows the clay particles to bind together and the stabilizer to react. The curing process also reduces shrinkage and cracking. Proper curing techniques can significantly improve the strength and water resistance of CEB blocks made with a CEB Machine.

The cost of a CEB machine varies based on several factors:

The manual block making machine price also depends on the manufacturer. The quality of materials also matters. The level of automation also affects price. Factors such as the machine’s production capacity also play a role. The size and shape of the blocks it can produce are also factors. Any additional features, such as automatic soil mixing or block ejection, can also affect the price. It’s important to consider your budget and production needs. Consider your long-term goals when choosing a CEB machine. Look for a used compressed earth block machine sale if you have a limited budget.

When choosing a CEB machine, consider the following factors:

Also, consider the types of blocks you need to produce. Consider the soil properties in your area. Choose a machine that is capable of producing the desired block designs. It should also be compatible with the local soil. Research different manufacturers. Compare their machine features, prices, and customer support. It’s also helpful to visit existing CEB construction sites. Talk to experienced builders to learn about their experiences with different machines and techniques. Using an Interlocking Block Machine can simplify construction.

Proper curing involves several key steps:

Covering the blocks with plastic sheeting can help maintain moisture levels. This can prevent cracking. Regularly misting the blocks with water can also help keep them moist. Avoid stacking the blocks too tightly during curing. This allows for proper air circulation. Monitor the blocks for signs of cracking or excessive shrinkage. Adjust the curing process as needed. Proper curing techniques can significantly improve the strength and water resistance of CEB blocks made with your CEB Machine.

DURABLE MACHINE offers several compelling reasons to choose our brick machines:

DURABLE MACHINE has a proven track record. We provide high-quality brick machines to customers around the world. Our machines are made with durable materials. We use advanced manufacturing techniques. This ensures long-term reliability. We also offer customizable options. This meets specific customer requirements. Our commitment to customer satisfaction is strong. Our expertise in brick-making technology makes us a trusted partner for your brick production needs. Investing in a soil block machine from DURABLE is a decision to make things easier for you.

Q1: How to feed hydraulic oil to compressed earth block machine for sale used correctly?

Feed hydraulic oil according to the machine’s manual. Ensure the oil is clean and the correct viscosity. Regularly check oil levels to prevent damage to your CEB Machine.

Q2: How to correctly change the brick mold for compressed earth block machine for sale used?

Turn off the machine. Release any pressure. Follow the manual to safely remove the old mold. Install the new one, ensuring it’s securely fastened to your adobe brick machine.

Q3: Will earth block making machine be damaged during long-term transportation?

Proper packaging can prevent damage. Secure the machine and protect sensitive parts. Consider insurance for long-term transport of your earth block machine.

Q4: How to build house using compressed earth blocks?

Design a structurally sound plan. Lay a proper foundation. Stack the CEBs, using mortar if necessary. Reinforce as needed. Protect the finished structure with sealant. Ensure the blocks are high-quality from a reliable CEB machine.