Concrete Batching Plant Cost: A Full 2025 Setup Budget Analysis

The total concrete batching plant cost is much more than the price of the machine. A complete setup budget involves many parts. This includes the main equipment, land preparation, support vehicles, and operational funds. As a manufacturer with decades of experience, we know that a successful batching plant investment analysis looks at the entire picture. Simply getting a quote for a plant is only the first step.

This guide provides a transparent breakdown of the full batching plant cost structure. We will cover every expense, from initial permits to long-term operational costs. This information helps you create a realistic budget for your new venture. You will understand the real price of a ready-mix concrete plant and avoid surprises.

Table of Contents

- What Parts Make Up the Total Batching Plant Investment?

- What Are the Costs for Land, Permits, and Design?

- What Factors Influence Core Equipment Costs?

- What Is the Budget for a HZS120 Batching Plant?

- How Much Do Environmental Systems Cost?

- What Is the Cost of Ancillary Equipment and Vehicles?

- What Are the Long-Term Batching Plant Operating Costs?

- How Do You Choose the Right Plant Size for Your Budget?

- Common Questions About Concrete Batching Plant Costs

- Summary: A Comprehensive Investment

- About Durable

- Get a Custom Quote for Your Project

What Parts Make Up the Total Batching Plant Investment?

A complete batching plant investment includes four main parts: the core plant machinery, site development and civil works, the ancillary equipment fleet, and soft costs like permits and design fees.

The total batching plant cost structure is a common point of confusion. Many investors focus only on the price of the physical plant. However, our experience shows that the main machinery often accounts for only 25% to 40% of the total setup budget. You must plan for all four areas to have a successful project.

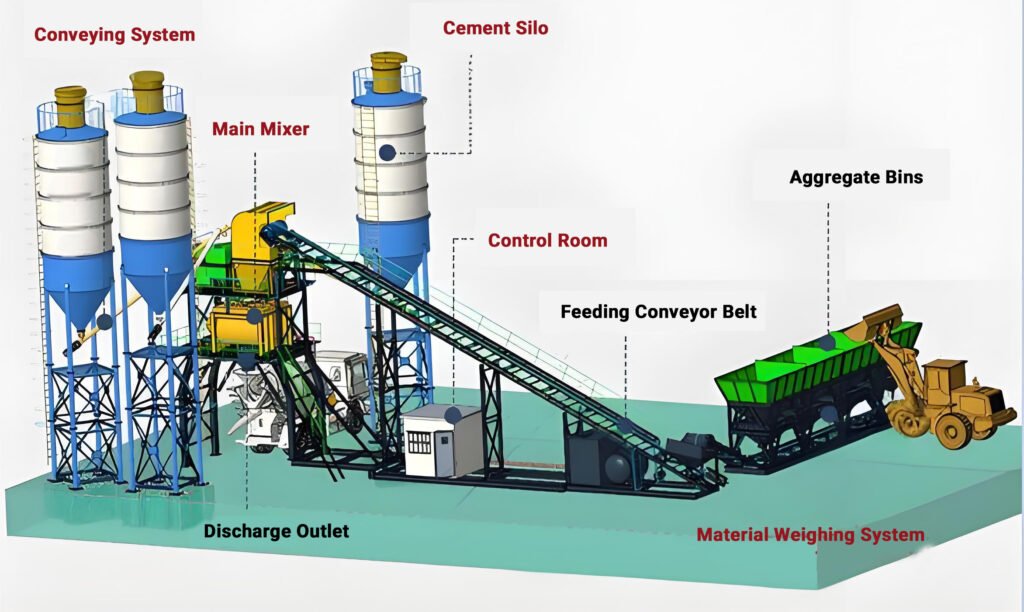

- Core Plant Equipment: This is the batching plant itself. It includes the mixer, aggregate bins, weighing systems, cement silos, and the control system.

- Site Development: This involves purchasing or leasing land. It also includes the significant cost of building concrete foundations, paving the yard, and installing utilities like power and water.

- Ancillary Equipment: A batching plant cannot operate in isolation. You need a wheel loader to feed aggregates. You also need a fleet of concrete mixer trucks for delivery.

- Soft Costs & Working Capital: This includes the money for permits, environmental studies, engineering design, and the initial funds to buy raw materials and pay staff before revenue starts.

What Are the Costs for Land, Permits, and Design?

The pre-construction phase costs are highly variable but substantial. They include land acquisition, geological surveys, foundation design, building permits, and environmental assessments.

This initial phase of your setup budget is critical and can be very expensive. Land is often the single largest upfront cost, depending entirely on your location. You need a site with industrial zoning and good road access for heavy trucks. After securing the land, you must invest in site engineering. A geological survey is needed to determine the soil’s load-bearing capacity. This is essential for designing the massive reinforced concrete foundations that the plant and silos will sit on. This civil engineering work can cost from $50,000 to over $200,000. Additionally, you must budget for various permits. The environmental assessment cost for plant setup can be significant, as you will need plans for dust control and wastewater management. Building permits and utility connection fees also add to this initial expenditure.

| Pre-Construction Cost Item | Estimated Cost Range (USD) | What This Covers |

|---|---|---|

| Land Acquisition | $100,000 – $1,000,000+ | Purchase or long-term lease of industrial-zoned land. |

| Civil Works & Foundations | $50,000 – $200,000+ | Site grading, drainage, and concrete foundations. |

| Permits & Fees | $10,000 – $50,000 | Building permits, environmental permits, utility fees. |

| Design & Engineering | $5,000 – $25,000 | Geological survey, foundation design, and site layout plans. |

What Factors Influence Core Equipment Costs?

The core equipment cost is influenced by the plant’s production capacity (m³/hr), its type (stationary vs. mobile), the level of automation, and the quality of its components.

The ready-mix concrete plant price is not a single number. It depends heavily on your specific needs. The biggest factor is capacity. A small plant producing 25 m³/hr will cost much less than a large commercial plant producing 180 m³/hr. The type of plant also matters. A mobile concrete batching plant is designed for easy transport and setup, making it ideal for specific projects but often having a smaller output. A stationary batching plant is a permanent structure built for high-volume, long-term production. The configuration has a large impact on cost. For example, a plant that uses a conveyor belt to load aggregates into the mixer is faster and more expensive than one that uses a simpler skip hoist. Finally, the quality of the components, such as the twin-shaft concrete mixer, the electronic weighing sensors, and the PLC control system, will affect both the initial price and the plant’s long-term reliability.

What Is the Budget for a HZS120 Batching Plant?

The core equipment for a typical HZS120 plant has a budget of approximately $150,000 to $300,000. This includes the main mixer, batcher, control system, and two cement silos.

An HZS120 plant, with a theoretical output of 120 m³ per hour, is a very popular choice for a medium to large commercial ready-mix business. A detailed HZS120 plant investment analysis for the core equipment shows how the costs are distributed. The heart of the plant is the twin-shaft mixer, which is the most complex and expensive single component. The aggregate batching machine, with its storage bins and precision weighing hoppers, is the next major cost. The control system, housed in its own cabin with computers and PLC hardware, represents a significant investment in automation and quality control. Finally, you need at least one or two bolted silos to store cement and other powders like fly ash. The final price within this range depends on the specific brands of components used and the level of customization required for the plant.

| HZS120 Component | Estimated Budget (USD) | Key Function |

|---|---|---|

| Main Mixing Tower | $70,000 – $130,000 | Includes JS2000 mixer, weighing hoppers, and structure. |

| Aggregate Batcher | $30,000 – $60,000 | Four or more bins for sand and gravel storage/weighing. |

| Control System & Cabin | $15,000 – $30,000 | Computer, PLC, and software for automated production. |

| Cement Silos (2x 100T) | $30,000 – $60,000 | Storage for cement and other powdered materials. |

| Screw Conveyors | $5,000 – $15,000 | Transport cement from silos to the weighing hopper. |

How Much Do Environmental Systems Cost?

A budget for environmental systems typically ranges from $20,000 to $100,000+. This investment is mandatory in most regions and covers dust, noise, and wastewater control.

Modern concrete plants must meet strict environmental regulations. The environmental assessment cost for plant operation is a necessary part of your setup budget. The largest component is usually dust collection. Pulse-jet bag filters must be installed on top of each cement silo and at the main mixing point to capture airborne dust. These systems can cost from $15,000 to $50,000. Wastewater management is another critical area. You will need a system of settling ponds or a more advanced water recycling system to treat the water used for washing out mixers and the plant area. This can cost anywhere from $5,000 for simple ponds to over $50,000 for a mechanical reclaimer. Finally, you may need to invest in noise reduction measures, such as enclosing the main mixer or building sound-dampening walls, which adds to the total cost.

What Is the Cost of Ancillary Equipment and Vehicles?

The cost for essential ancillary equipment is significant, often matching or exceeding the cost of the plant itself. This includes at least one wheel loader and a fleet of mixer trucks.

A complete batching plant equipment list goes far beyond the plant. Without the right support machinery, your plant cannot function. The most critical item is a large wheel loader to keep the aggregate bins filled. A new, reliable wheel loader can cost over $150,000, while a good used one might be found for $50,000-$80,000. The largest single investment in this category will be your fleet of concrete mixer trucks. Each new truck can cost $150,000 or more. A startup business will need at least 3 to 5 trucks to provide reliable delivery service, representing a capital outlay of $450,000 to $750,000 for new vehicles. You will also need a quality control lab with equipment for slump tests and cylinder compression testing, which adds several thousand dollars to the budget. This part of the batching plant investment analysis is often underestimated by new investors.

What Are the Long-Term Batching Plant Operating Costs?

The main long-term operating costs are raw materials, labor, electricity, and maintenance. Raw materials alone typically account for 50-70% of the cost of producing concrete.

Your concrete plant business plan must include a detailed analysis of batching plant operating costs. These ongoing expenses determine your profitability.

- Raw Materials: This is your biggest variable cost. It includes cement, sand, gravel, water, and chemical admixtures. The price of these materials fluctuates with the market.

- Labor: You will need a plant operator, a wheel loader operator, a quality control technician, and a dispatcher or manager.

- Electricity: A concrete plant consumes a large amount of power to run the motors for the mixer, conveyors, and dust collectors.

- Maintenance: This includes regular servicing, spare parts like mixer liners and blades, and unexpected repairs. A good rule is to budget 1-3% of the initial equipment cost for annual maintenance.

- Fuel: This is for the wheel loader and the delivery trucks. It is a major operational expense.

Understanding these costs is vital for calculating your concrete production cost per cubic meter and setting a competitive selling price.

How Do You Choose the Right Plant Size for Your Budget?

The right plant size is a balance between your available investment capital and the real market demand for concrete in your area. Start with a market analysis, not an equipment list.

Choosing the right scale is the most important decision in your batching plant investment analysis. Buying a plant that is too large for your market will lead to high idle costs and a slow return on investment. Buying one that is too small will mean you cannot meet customer demand and will lose business. The process should start with a solid concrete plant business plan. Research your local market. How much concrete is being sold? Who are the competitors? What is a realistic sales volume you can achieve in the first one to three years? Once you have a target output in cubic meters per day, you can select a plant with the appropriate capacity. This market-driven approach ensures that your setup budget is aligned with your potential revenue, creating a sustainable and profitable business.

Common Questions About Concrete Batching Plant Costs

Question 1: How long does it take to set up a concrete batching plant?

From placing the order to full commissioning, a stationary plant setup typically takes 4 to 6 months. This includes 2-3 months for manufacturing and shipping, and another 2-3 months for foundation work, installation, and testing.

Question 2: Is buying a used batching plant a good way to save money?

It can be, but it carries risks. A used plant can reduce the initial capital cost. However, you must carefully inspect its condition, especially the mixer wear parts and the accuracy of the weighing system. You may also face challenges finding spare parts or technical support.

Question 3: What is the single biggest “hidden cost” in a plant setup?

The biggest surprise for most new owners is the cost of the civil works. The massive reinforced concrete foundations required for the plant and silos are a major construction project in themselves and are a very significant part of the total setup budget.

Summary: A Comprehensive Investment

The total concrete batching plant cost is a comprehensive investment that goes far beyond the machinery’s price tag. A successful batching plant investment analysis must account for the core equipment, extensive site development, a fleet of ancillary vehicles, and ongoing operational expenses. The machinery itself may only be a fraction of your total setup budget. By understanding the complete batching plant cost structure, you can create a realistic financial plan.

About Durable

Since 2001, Durable (Durablemac) has specialized in manufacturing high-quality and reliable concrete mixing equipment. We provide complete solutions, from single machines to full stationary batching plant installations. We have helped clients in over 120 countries build profitable ready-mix businesses by providing durable equipment and expert technical support from start to finish.

Get a Custom Quote for Your Project

Are you ready to create a detailed budget for your new concrete plant? Contact our engineering team today. We provide a free consultation to discuss your production goals and site conditions. We will give you a detailed, itemized quote that covers the entire batching plant equipment list and helps you build a solid concrete plant business plan.

Durable Machinery

Durable Machinery