Concrete Batching Plant Price Guide: 6 Must-Know Parts

One of the first questions I always hear is, “What is the concrete batching plant price?” This is a critical question for any batching plant project investment. The answer, however, is not a simple number. A concrete plant is not a single machine you buy off a shelf; it’s a complete manufacturing facility. The final price is a direct result of key decisions you make about its capacity, components, and configuration.

As a manufacturer at Durable with over two decades of experience, I’ve seen many clients make the costly mistake of focusing only on the initial equipment quote. The true cost of a plant is not its sticker price, but the total cost of ownership over its lifetime. This guide will break down the batching plant cost composition to help you create an accurate batching plant budget for 2025 and understand what drives the final batching plant equipment quotation.

Table of Contents

How Do Plant Type and Capacity Affect the Price?

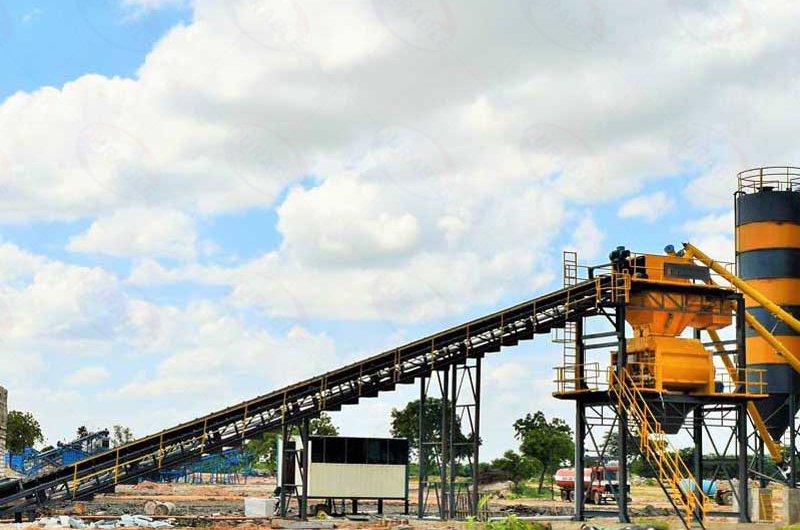

The most significant factors determining the base price of your plant are its type and production capacity. These two choices define the scale of your operation and directly impact the size, weight, and power of every component. You must first decide between a stationary or mobile setup. A stationary concrete batching plant is designed for long-term installation at a single site. It offers the highest productivity and storage options but requires significant foundation work, which adds to the total project cost. In contrast, the mobile batching plant price is higher for the equipment itself due to the integrated chassis and engineering for portability, but it saves you a great deal on civil works and offers flexibility.

Next, you must select the batching plant capacity, measured in cubic meters per hour (m³/hr). To give you a clear picture of how capacity translates into cost, here is a table of estimated price ranges for standard plant configurations.

| Plant Scale | Common Models | Typical Capacity (m³/hr) | Estimated Price Range (USD) | Best For |

|---|---|---|---|---|

| Small | HZS25, HZS35 | 25 – 35 m³/hr | $30,000 – $70,000 | Specific construction projects, small-scale precast work. |

| Medium | HZS60, HZS75 | 60 – 75 m³/hr | $80,000 – $150,000 | Commercial ready-mix suppliers, medium to large projects. |

| Large | HZS120, HZS180 | 120 – 180 m³/hr | $180,000 – $400,000+ | Major infrastructure projects, large-scale commercial supply. |

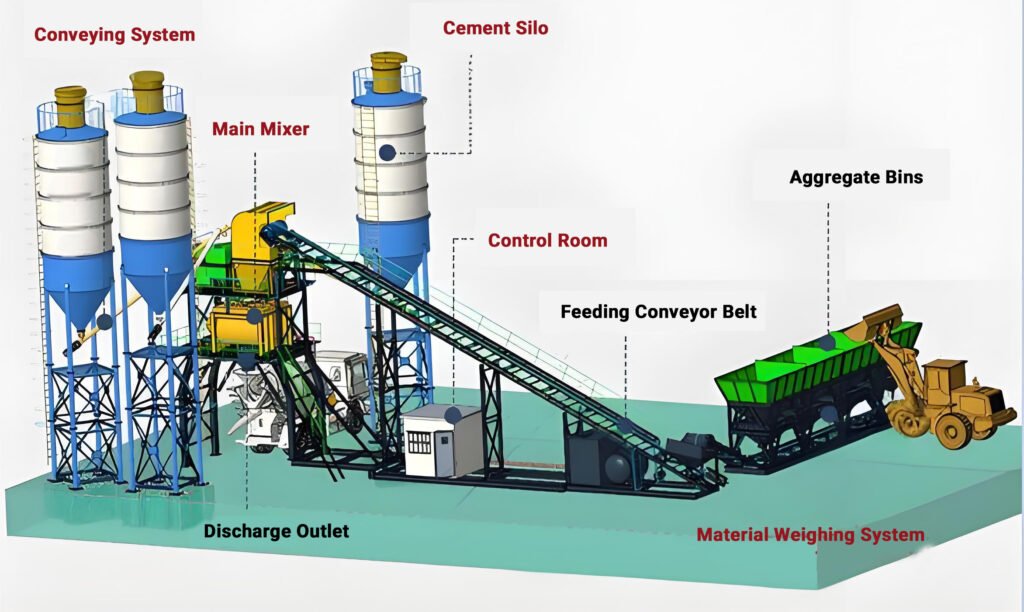

How Do Core Components Impact Your Quotation?

The quality and brand of the core components are the “hidden” factors that create large variations in plant prices. Two plants might look identical and have the same advertised capacity, but one could cost 30% more. This difference almost always comes down to the quality of the parts you cannot easily see. This is where professional-grade plants separate themselves from equipment that will cause you constant problems. The final batching plant equipment quotation heavily depends on these systems.

The most critical components are the mixer, the weighing system, and the batching plant control system. For instance, a plant equipped with a powerful and durable twin-shaft concrete mixer from a reputable brand will cost more than one with a generic mixer, but it will deliver better concrete quality and have a much longer service life. The same applies to the load cells used for weighing; premium brands ensure accuracy, saving you from wasting expensive cement. A fully automatic PLC control system with components from a global brand like Siemens will be more expensive than a manual system, but it eliminates human error, ensures consistency, and reduces labor costs, paying for itself quickly. Skimping on these core parts is a false economy that leads to higher long-term operating cost.

What About Optional Configurations and Your Budget?

Beyond the standard equipment, your specific operational needs will require optional configurations that add to the total investment. A basic plant quote usually includes the essential machinery, but no two job sites are the same. Your final batching plant budget must account for these necessary additions. The number and size of cement silos are a primary example. You might need one large silo for standard cement, but if your mix designs require fly ash or slag, you will need additional, separate silos, each adding to the cost.

Environmental equipment is another major consideration. Local regulations may require you to install a central dust collection system that covers all material transfer points, which can be a significant expense compared to just a small dust collector on the mixer. Furthermore, your climate plays a huge role. If you operate in a cold region, you will need to invest in a boiler system for hot water and aggregate heating to produce concrete year-round. In a very hot climate, you might need an expensive water chiller system. These are not minor add-ons; they are essential for operation in certain environments and must be factored into your batching plant cost composition from the very beginning.

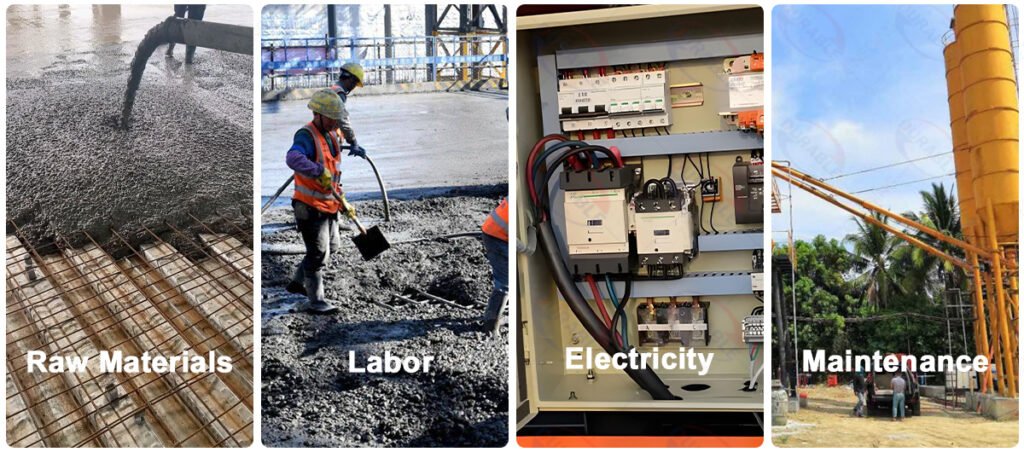

What Are the Hidden Costs Beyond the Equipment Price?

A common mistake when budgeting for a batching plant project investment is overlooking the costs that exist outside the manufacturer’s quotation. The price you are quoted for the machinery is almost never the final price you will pay to get your plant operational. These “soft costs” can easily add 15-25% or more to your total project budget, so it is crucial to plan for them.

The first major hidden cost is the batching plant transport cost. This is large, heavy equipment that must be shipped from the factory to your site, which can be very expensive, especially for international shipping. Next is the cost of civil works; a stationary plant requires extensive concrete foundations, which you will have to prepare. The batching plant installation cost is another key factor. You must clarify if the supplier’s price includes sending engineers to your site to supervise the assembly, commissioning, and training of your staff. These services are vital for ensuring the plant runs correctly from day one. Failing to account for shipping, foundation work, and installation can turn a seemingly good deal into a financial problem.

How Does the Manufacturer Affect Long-Term Costs?

Your choice of concrete batching plant manufacturer has a profound impact on your long-term operating cost and the overall success of your investment. While it might be tempting to choose the supplier with the lowest initial price, a reliable partner offers value that extends far beyond the equipment itself. A reputable manufacturer provides a solid warranty and, more importantly, responsive after-sales support. When a critical part fails, you need a supplier who can get you a replacement quickly to minimize downtime.

A good manufacturer acts as a long-term partner. They will help you configure the plant correctly for your market, provide comprehensive training for your operators and maintenance staff, and maintain a stock of critical spare parts. This level of support prevents costly delays and ensures your plant operates at peak efficiency for its entire lifespan. When evaluating suppliers, ask detailed questions about their warranty, spare part availability, and technical support process. This support system is a crucial part of your batching plant project investment and is often more valuable than a small discount on the initial purchase price.

FAQs

1. What is the typical price range for a concrete batching plant?

The concrete batching plant price can range from as low as $30,000 for a small, simple mobile unit to over $500,000 for a large, high-capacity stationary plant with extensive customization. The final price depends entirely on the factors discussed in this guide.

2. What does the “HZS” in a model name like HZS120 mean?

“HZS” is a standard model designation in China. “H” stands for concrete (Hùnníngtǔ), “Z” stands for station (Zhàn), and “S” means the aggregate is lifted by a belt conveyor (Shusongdai). The number, like 120, indicates the theoretical production capacity in cubic meters per hour.

3. How much more does a wet mix plant cost than a dry mix plant?

A wet mix (central mix) plant is significantly more expensive than a dry mix (transit mix) plant of the same capacity. The inclusion of the large, heavy-duty central mixer and its powerful drivetrain can add 30-50% to the initial equipment cost.

4. How long does the installation of a concrete plant take?

Installation time varies greatly. A small mobile plant can be set up in a few days. A large stationary batching plant cost includes a longer installation period, typically taking 3 to 6 weeks, depending on the complexity and the preparedness of the site foundation.

5. How can I get an accurate batching plant equipment quotation?

To get an accurate quote, you must provide the supplier with detailed information. This includes your required capacity (m³/hr), desired plant type (stationary or mobile), number of aggregate bins and cement silos, and any special requirements like environmental controls or climate packages.

Summary and Final Advice

Understanding the concrete batching plant price requires looking beyond the initial quote. The total batching plant project investment is a combination of equipment costs and additional expenses for transport, installation, and site preparation. The final price is determined by your choices regarding plant capacity, type, component quality, and optional configurations.

To create a realistic batching plant budget, carefully consider each of these factors. The wisest approach is to view this purchase not as buying a machine, but as investing in a facility that will reliably produce quality concrete for the next two decades. Focusing on quality and long-term support will always provide a better return than simply choosing the lowest upfront price.

About Durable

Since our founding in 2001, Durable Machine has been a trusted global concrete batching plant manufacturer. We specialize in providing complete, customized solutions for our B2B clients, from small project-based mobile plants to large-scale stationary facilities. With factory-direct sales and exports to over 120 countries, we deliver high-quality, cost-effective equipment backed by comprehensive engineering support, installation guidance, and reliable after-sales service.

Contact our team with your project requirements today, and we will help you build a detailed and accurate quotation tailored to your business needs.

Durable Machinery

Durable Machinery