Search the whole station liberty-fse

QMJ2-40 Manual Mobile Egg Laying Block Maker

Capacity:1500-3000 per 8 hours according to your brick size

Power: 1.5kw

Weight: 215KGS

Workers Needed: 1-2 persons

Pallet Size: No need Pallet

Block size: 4inch 6inch 8inch Hollow blocks, Solid bricks

Raw Material: Concrete/ Cement/Fly ash+ water

Introduction:

The QMJ2-40 egg laying block making machine is the perfect low-cost concrete block maker machine for startups. It’s incredibly easy to operate with just 1-2 workers and requires no pallets, saving you significant money. Built with a durable steel frame and capable of producing 1280 blocks in 8 hours, this efficient, mobile machine is your ideal choice for a profitable start.This mobile block machine is characterized by its exceptional affordability and high efficiency, offering an outstanding return on investment.

QMJ4-45 Simple Mobile Cement Block Making Machine

Capacity: 2500-4000 pieces per day( depends on your block size)

Power Type: Electric Motor

Pallet size: No need pallet

Moulding Method: Vibration moulding

Weight: 1200KGS

Introduction:

Boost your output with the QMJ4-45 brick making machine, the perfect upgrade for your block business. This reliable egg-laying block maker uses high-quality parts to produce precise, high-density blocks, pavers, and curbs. With a high capacity of 2560 blocks/8 hours and no need for pallets, it’s the most efficient and cost-effective choice for serious production.Its versatility is a major asset; by simply changing the mold, you can easily expand your product line to include paver blocks, curb stones, and more, unlocking new market opportunities.

DM4-40 Simple Concrete Bricks Making Machine

Capacity: 2000-7000 pieces per 8 hours (capacity is still depends on your brick size)

Power: 9.5KW

Forming Cycle:40-50 Seconds

Pallet Size:850*450*22mm

Weight: 2T

Introduction:

The DM4-40 Manual Concrete Block Machine is the perfect entry-level solution for startups and small businesses. This Simple block machine offers an unbeatable combination of low investment and high performance, producing strong, high-density hollow and solid bricks. With easily interchangeable molds, it provides the versatility to meet diverse market demands. Its efficient production cycle makes it a reliable and profitable choice for launching your brick-making business with a minimal budget.

DM4-35 Fly Ash Bricks Making Equipment

Capacity: 3000-9000 pieces per 8 hours depends on your brick size

Power: 9.7KW

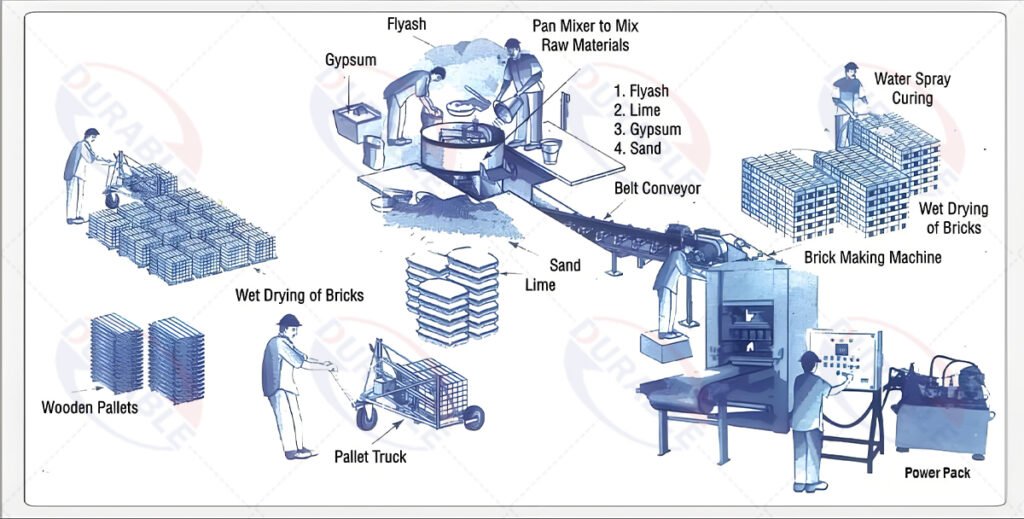

Components: JQ350 Mixer+ 6M Beltconveyor+ DM4-35 block machine

Forming Cycle: 35-40 Seconds

Pallet Size: 850*450*22mm

Introduction:

The DM4-35 Manual Concrete Block Maker represents the next step in efficiency and productivity, engineered as an ideal upgrade for small to medium-sized operations. Its standout feature is the integrated materials hopper, which allows for a seamless connection to a mixer via a conveyor belt. This crucial enhancement automates the material feeding process, significantly reducing labor intensity and boosting overall workflow efficiency. Built on a reinforced, robust frame for superior durability, the DM4-35 is designed for long-term, reliable service. For those seeking an affordable machine that bridges the gap between basic manual and semi-automatic production, the DM4-35 is your perfect choice.

QT4-25 Automatic Block Making Machine Line

Capacity:6000-12000 pieces per 8 hours depends on your brick size

Power: 20.75KW

Forming Cycle: 25-30 Seconds

Pallet Size:850*550*22mm

Introduction:

The QT4-25 cement block making machine is a semi-automatic block machine ideal for SMEs, balancing affordability with efficient production. It offers versatile mold options for producing various blocks and pavers. A 45KN vibration system and Siemens PLC ensure high-density, strong blocks. With a 20-25 second cycle, it achieves high daily output (e.g., 5,760 hollow blocks). Built with durable steel and heat-treated components, the QT4-25 brick making machine line integrates into a complete production line for streamlined operation, making it a cost-effective solution for establishing a profitable block manufacturing business.

QT4-15 Fully Automatic Concrete Block Making Machine Line

Capacity:8000-60000 pieces per day depends on your block size

Forming Cycle: 15 Seconds

Brick Size: 400*200*200mm 400*150*200mm 240*115*53mm

Land Require: 1000m²

Introduction:

This is a fully automatic, hydraulic block machine controlled by a Siemens PLC system. It features a rapid 15-second cycle time with a high output of up to 86,400 pieces in 8 hours. Highly versatile, it produces various blocks (hollow, solid, pavers) by simply changing the mold. Its unique recycle feeding system eliminates raw material waste, making it an ideal choice for efficient, versatile, and cost-effective production.Engineered for large-scale, high-demand production, the QT4-15 is a flagship fully automatic block making machine that sets the standard for performance.Choosing the QT4-15 means investing in superior automation, unparalleled output, and limitless potential.

Are you ready to start producing concrete blocks? A concrete block maker is your first step towards a profitable venture. This guide will take you through everything you need to know about starting your own concrete block production, including market demand, machine types, material requirements, and how to choose the right block making machine for your needs. Let’s explore the world of concrete block manufacturing with DURABLE MACHINE!

Last Updated: June 2025 | Estimated Reading Time:18 minutes

A concrete block maker, also known as a block making machine, is a machine used to manufacture concrete blocks. These blocks are essential in construction. The primary purpose is to produce uniform, durable blocks efficiently. DURABLE MACHINE offers a range of these machines.A concrete block maker automates mixing, molding, and compacting concrete. Different machines exist, from manual to automated. Selecting the right concrete block machine optimizes production and ROI. Factors to consider when choosing include production capacity, automation level, and budget.

Moreover, the use of a concrete brick making machine is vital to the construction industry because it allows mass production. These blocks simplify construction, reduce waste, and ensure integrity. DURABLE MACHINE provides user-friendly and efficient machines.

Starting a concrete block making business can be profitable due to consistent demand. Construction is growing. This makes concrete blocks essential. DURABLE MACHINE provides the tools for success.

Demand is driven by urbanization and development. This ensures customers. Profitability depends on capacity, costs, and price. Choosing the right concrete block machinery improves efficiency and quality. Consider these factors for success:

Maximize profits by diversifying your product line, or focusing on specialized blocks. Reducing costs and improving efficiency is important. A reliable concrete brick making machine helps with that.

A concrete block maker can produce various types of concrete blocks. This includes hollow, solid, and pavers. Each has specific uses. Understanding block types helps cater to customer needs. DURABLE MACHINE provides machines for various block types.

Hollow blocks are lightweight and good for walls. They offer insulation. Solid blocks are stronger. This makes them suitable for load-bearing walls. Pavers are used for walkways and patios. Paver block machine can allow you to manufacture blocks that offer a variety of design options.

Here is a breakdown of common block types:

| Block Type | Common Use | Advantages |

|---|---|---|

| Hollow | Walls, partitions | Lightweight, good insulation |

| Solid | Load-bearing walls, foundations | Strong, durable |

| Pavers | Walkways, driveways | Decorative, durable |

Production depends on your machine blocks. A versatile block mould machine allows adapting to markets and maximizing profit.

Concrete block making machines come in different types: manual, semi-automatic, and automatic. The best choice depends on production volume, budget, and labor. DURABLE MACHINE offers a range to suit your needs.

Manual block making machines are basic and affordable. They require manual labor. Semi-automatic machines automate some processes. This reduces labor and increases speed. Automatic concrete block machines fully automate the process. This results in high volume with minimal labor.

When considering a used block machine for sale, check the condition. The concrete block machinery from DURABLE MACHINE combines technology with durability. Features like automatic feeding systems, PLC controls, and hydraulic pressing can enhance efficiency.

An automatic concrete block machine operates through automated steps. This includes mixing, molding, and curing. These steps ensure efficient block production. DURABLE MACHINE’s automatic machines are designed for optimal performance.

First, raw materials are automatically mixed. The mixture is fed into the molding block machine, where the machine compacts and shapes it. Vibration ensures the concrete fills the mold completely. Finally, the molded blocks are automatically ejected and moved to curing.

Curing involves maintaining blocks in a controlled environment. Regular maintenance of the blocking machine allows continuous production. Selecting the right machine block streamlines operations and increases efficiency. DURABLE MACHINE offers training and support. Automation ensures consistency and reduces errors.

The production capacity of concrete block making machines varies widely. It depends on the type and size of the machine. Manual machines have lower capacity; automatic machines have higher capacity. DURABLE MACHINE offers machines with various production capacities.

Manual machines might produce 100 to 200 blocks daily. Semi-automatic block machine may produce 500 to 1000 blocks daily. Fully automatic concrete block machine can produce thousands daily.

Here’s an example of capacity ranges:

| Machine Type | Production per hour |

|---|---|

| Manual | 100-200 blocks |

| Semi-Automatic | 500-1000 blocks |

| Automatic | 2000+ blocks |

Specific capacity depends on machine design, mold size, and cycle time. When selecting, consider production goals and market demand. Investing in a machine for concrete blocks can enhance production.

The primary materials are cement, sand, and aggregate. The quality and proportion impact the strength and durability of blocks. DURABLE MACHINE can advise on the best material mixes.

Cement acts as the binding agent. Sand fills voids between aggregate particles. Aggregate provides bulk and strength. The ideal mix depends on the desired block strength and application. Common mix ratios are available for different block types.

Using quality materials in the right proportions is crucial for strong blocks. The cement block maker combines materials to create durable components. A balanced mix results in strong and resistant blocks.

The cost of a concrete block maker machine varies. It depends on the type, production capacity, brand, and features. Understanding these factors helps make an informed decision. DURABLE MACHINE offers competitive pricing.

Manual machines are the most affordable. Semi-automatic machines balance automation and cost. Automatic machines are the most expensive. Consider these cost factors:

Higher capacity, advanced features, and reputable brands command higher prices. When looking at the concrete block machine price, compare your budget to goals.

Regular maintenance is essential for the longevity and performance of your concrete block maker. Proper maintenance minimizes downtime and ensures consistent quality. DURABLE MACHINE provides maintenance guidelines.

Maintenance includes cleaning, lubrication, and inspection. Hydraulic system maintenance is also essential. Follow the manufacturer’s schedule. These steps are key:

Train operators on procedures. A consistent program will benefit the blocks machine. DURABLE MACHINE offers maintenance support and spare parts.

The labor requirements depend on the machine you are using. Manual machines require more labor than automatic machines. DURABLE MACHINE can help determine the optimal labor force.

Manual machines require 3-5 workers. Semi-automatic machines require 2-3 workers. Automatic machines require 1-2 workers.

Here’s a breakdown:

| Machine Type | Labor Required |

|---|---|

| Manual | 3-5 workers |

| Semi-Automatic | 2-3 workers |

| Automatic | 1-2 workers |

Reducing labor costs is a factor of using automated block machines. The more advanced your concrete block making equipment, the lower your costs.

The space requirements depend on the machine size and production scale. You’ll need space for the machine, material storage, mixing, curing, and block storage. DURABLE MACHINE can help plan your plant layout.

A manual operation might require 500 square feet. A fully automated plant can require thousands of square feet. Consider the flow of materials. Allocate space for:

Ensure adequate space for equipment and storage. The physical size of your block making equipment is key.

Effective marketing and sales strategies are crucial. Identifying target customers and setting competitive prices are essential. DURABLE MACHINE can provide marketing guidance.Target customers include construction companies, builders, and homeowners. Develop a pricing strategy considering costs and competitor prices. Consider these marketing channels:

Utilize marketing channels. Provide excellent customer service. Reaching out to local businesses is critical for success with a block manufacturing machine.

DURABLE MACHINE offers reliable and efficient concrete block makers. Our machines are built with quality materials and advanced technology. This ensures consistent quality and productivity. With us you get great block making equipment.

We have experience in the industry. We are committed to providing solutions that meet customer needs. Our equipment is engineered for durability. DURABLE MACHINE uses high-strength steel and reliable components. We focus on delivering machines that stand the test of time.

Our machines are easy to operate. Choosing DURABLE MACHINE means investing in a reliable partner.

Our concrete block machines are made to be reliable. We incorporate technologies in our cement block manufacturing machine.Choosing DURABLE MACHINE ensures access to high-quality concrete block maker. DURABLE MACHINE has over 30 years of experience. We excel in providing solutions. Our machines are built with quality components. We offer training and support. By choosing DURABLE MACHINE, you are investing in a long-term partnership.

The return on investment depends on several factors. These factors include production volume, selling price, material costs, and operating expenses. DURABLE MACHINE can help estimate your potential ROI.

To calculate your ROI, estimate annual revenue. Then subtract expenses. Divide profit by the initial investment. ROI = (Annual Revenue – Annual Expenses) / Initial Investment. Factors affecting ROI include:

Careful planning and operations are essential for ROI. Don’t neglect your block machinery.

Q1: What type of foundation is needed for a block making machine?

A concrete foundation is generally recommended. It should be strong enough to support the weight and vibration of the machine.

Q2: Can I use recycled materials in my concrete block mix?

Yes, you can use recycled materials such as crushed concrete or fly ash. Make sure the materials meet quality standards.

Q3: How can I ensure consistent block quality?

Use high-quality materials, maintain accurate mix proportions, and ensure proper machine operation and maintenance.

Q4: What is the best way to cure concrete blocks?

The best way to cure concrete blocks is to maintain them in a controlled environment with high humidity and moderate temperature.

Contact us today for a free consultation. Discover how our concrete block makers can help you. Let DURABLE MACHINE be your trusted partner.