Stone Crushing Products

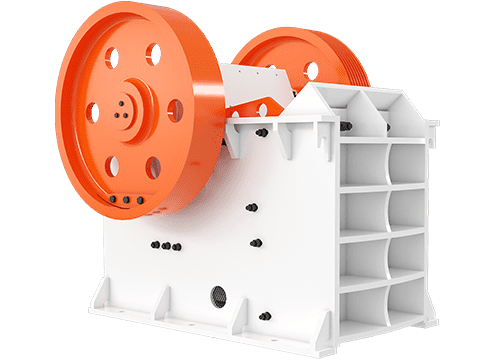

Jaw crusher

Jaw crusher is a new product absorbing world advanced technology, bases on our present traditional jaw crusher, and adopts three-dimensional design theory. Comparing with traditional jaw crusher, it has larger capacity and crushing ratio, b...

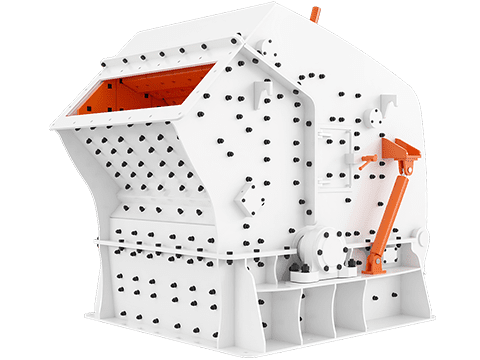

Impact Crusher

Impact crusher is widely used in the production of high grade stone materials used in highway, hydropower, artificial sand and stone, crushing, construction and other industries with its excellent performance. Feed particle size ≤1000...

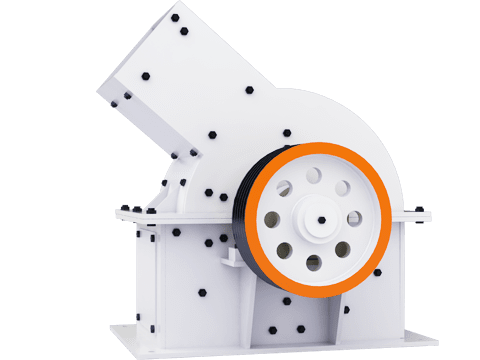

Hammer Crusher

Hammer Crusher, an efficient and powerful crushing equipment, is designed for crushing various medium-hard and brittle materials. It utilizes the high-speed rotating hammer head to rapidly crush the materials into the required size through viol...

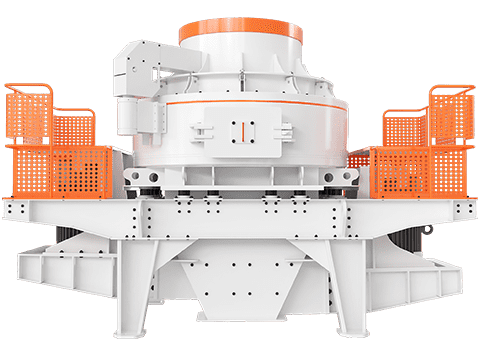

Sand Making Machine

Sand making machine is suitable for soft or medium hard and very hard ore materials with hardness not higher than 320 Pa. Also, we usually call it VSI sand making machine. It has the characteristics of stable and reliable work, easy mainten...

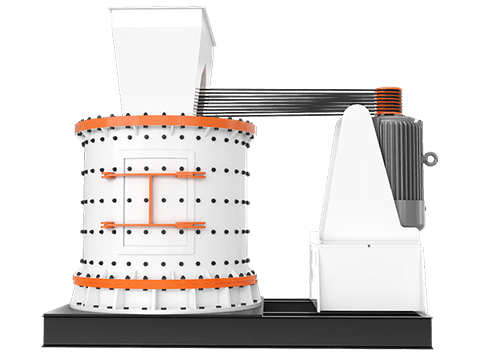

Fine Crusher

The fine crusher is mainly suitable for grinding and processing in metallurgy, building materials, chemical, mining, railway, water conservancy and other industries. It is used before the ball mill to increase the production efficiency of t...

Cone Crusher

Cone crusher is usually used as secondary or tertiary crushing stage. It is characterized by robust structure, excellent productivity and simple operation. It can process minerals with medium to high resistance, such as iron ore, river rock...

Compound Crusher

A compound crusher, also called vertical compound sand maker, is a double-rotor primary impact crusher. The compound crusher is an ideal machine for crushing high-moisture and viscous materials, commonly used in small-scale crushing an...

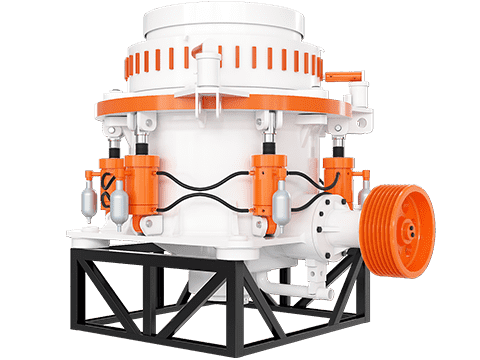

Hydraulic Cone Crusher

Hydraulic Cone Crusher, a cutting-edge product in the crushing industry, integrates modern mechanical technology, hydraulic technology and electronic technology, and is designed for crushing ores and rocks of various hardness. With compact ...

Symons Cone Crusher

Symons cone crusher developed by our company is the crushing equipment is produced on the basis of spring cone crusher and hydraulic cone crusher. Capacity 48-500 TPH Inlet Size 280mm Min. Output Size 6-70mm ...

Spring Cone Crusher

Spring cone crusher is is the earliest cone crushing equipment which adopts the laminating crushing principle. It is suitable for the medium, fine and super fine crushing of moderate hardness rocks and ores. Feed particle size ≤300mm ...

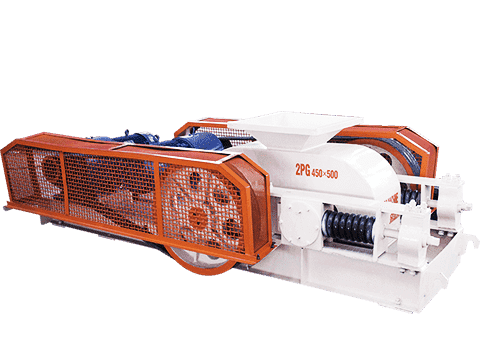

Roller Crusher

Roller crusher is also known as roll crusher, which relies on the high-speed rotation of roll wheel to crush materials. The commonly used roll crusher types include double roller crusher, toothed roller crusher, four roller crusher, etc. ...

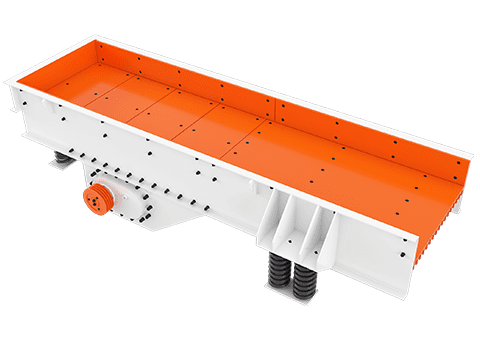

Vibrating Feeder

The vibrating feeder can evenly feed materials for the crushing equipment in the sand production line, and screen materials roughly. It can also serve materials for belt conveyors, bucket elevator, screening equipment, crushing equipment an...

Toothed Roller Crusher

Toothed roller crusher is a new type of high efficiency crusher. With its recognized operation degree,the applications of toothed roller crusher in coal, cement, building industry, metal mines and non metal mine industry will increase. ...

Sand Washer

The sand washer produced by our company is the bucket type sand washing machine. It is the high efficiency washing equipment which uses advanced technology and combines the actual situations of the domestic sand industry. Bucket Diameter ...

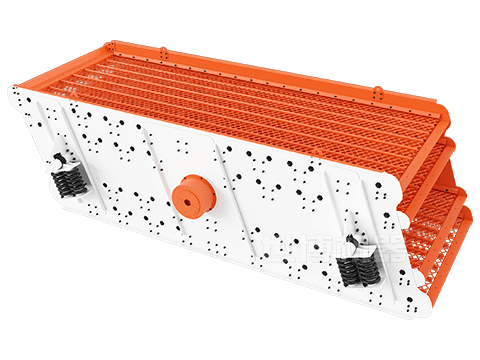

Vibrating Screen

Vibrating Screen characterizes simple structure, high efficiency, reliable use and convenient installation, and can perform multi-special segmentation screening of loose materials. which is main equipment to separate soild materials, ...

Conveyor Belt

Conveyor belt is also called rubber conveyor belt, which relies on the friction between the roller and the conveyor belt to continuously transport materials. Length 0–40m Capacity Raw materials Granite, limestone, concrete, lime...

loading...

已经是到最后一篇内容了!

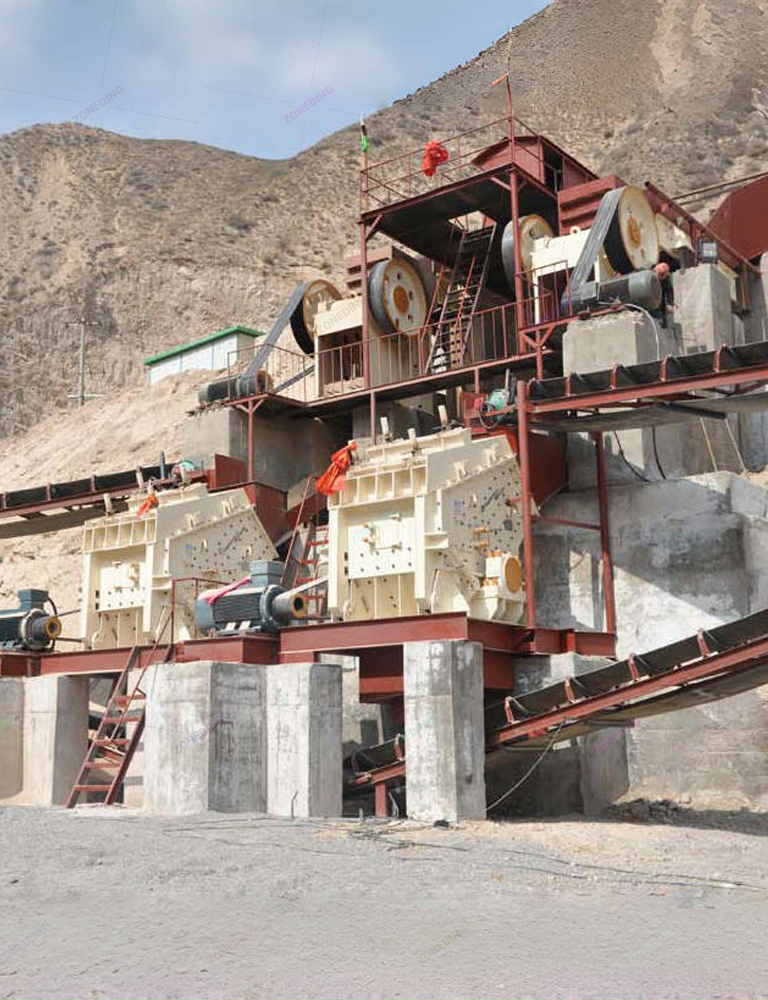

Stone Crushing Process

We offer a variety of stone crushing solutions, tailor-made for each customer.The process flow of the stone crushing and screening plant includes feeding, crushing, screening, transportation and other links. If the requirements for the particle size of the finished product are high, sand making and other steps will be added after screening.

It contains feeding, coarse crushing, medium crushing, screening, optional fine crushing, conveying, and storage and transportation of finished products. Feeding through the vibrating feeder uniform continuous feeding, coarse crushing by the jaw crusher will be crushed into small pieces of stone, crushing in the impact crusher, and then by the vibrating screen screening, does not meet the requirements of the particle size of the stone returned to the re-crushing, for the higher requirements of the particle size of the optional fine crushing links, between the links by the belt conveyor transportation stone, finished products are stored in the yard and transported as needed.

It needs to be emphasized that different engineering projects and raw material types will lead to differences in the crushing plant process flow. Therefore, in practical applications, engineers need to develop suitable process flows and configurations based on specific conditions.

Customer Cases

Construction Industry

The stone crushing plants provide aggregates including gravel, crushed stone, and sand for concrete mixture production, which are key components of construction projects.

- Processing capacity: 150tph

- Configurations: Vibrating Feeder, PEV Jaw Crusher, Cone Crusher, VibratingScreen, etc.

- Finished Product: 0-5,10-20mm

Road Construction

In the road construction industry, the stone crusher plant is essential for producing the crushed stone materials used as base layers, sub-base layers, and aggregate for asphalt and concrete paving.

- Processing capacity: 150tph

- Configurations: Vibrating Feeder, PEV Jaw Crusher, Cone Crusher, VibratingScreen, etc.

- Finished Product: 0-5,10-20mm

Mining Industry

The stone crushing plants for sale are instrumental in processing raw materials extracted from mines. They mainly crush large rocks and ores into smaller pieces, facilitating the extraction of valuable minerals such as gold, copper, and iron.

- Processing capacity: 150tph

- Configurations: Vibrating Feeder, PEV Jaw Crusher, Cone Crusher, VibratingScreen, etc.

- Finished Product: 0-5,10-20mm

Durable Machinery

Durable Machinery