Decoding Charcoal Machine: Technology & Conversion Process

As an expert with 50 years in mining machinery and biomass energy, I know many charcoal machine descriptions miss key technical points. A modern charcoal making machine is more than a simple stove. It acts as a precise pyrolysis reactor system. It carefully controls and recycles heat, oxygen, and gases. This transforms waste into high-value products.

Table of Contents

- How Pyrolysis Makes Quality Charcoal from Biomass?

- What is the Charcoal Machine Process?

- Continuous vs. Batch Charcoal Machines: Which Fits You?

- How Machines Control Temp & Time for Dense Charcoal?

- How Charcoal Machines Handle Smoke & Recover Energy?

- What Affects Charcoal Yield and Quality?

- How should one evaluate a charcoal machine?

- 2025 Latest Biomass Carbonization Trends and Developments

- FAQs

- Summary & Recommendations

- About Durable

How Pyrolysis Makes Quality Charcoal from Biomass?

Many people mistakenly believe charcoal making means just burning wood. This idea is incorrect. Burning needs oxygen, which turns wood into ash and carbon dioxide. A charcoal making machine uses controlled pyrolysis. It heats wood with little or no oxygen. This process breaks down the wood. Volatile materials like water, wood tar, and gases then escape. What remains is solid carbon – charcoal.

This process demands precise control of temperature, heating speed, and residence time. Varying temperatures yield different products. For instance, lower temperatures produce more liquid byproducts. Higher temperatures increase solid carbon. Indirect heating is crucial here. An external chamber burns gases from carbonization. Heat then passes through furnace walls to the wood inside. This avoids direct flame contact. It keeps charcoal pure. It also ensures precise temperature control. This method is critical for quality charcoal and self-sustaining energy.

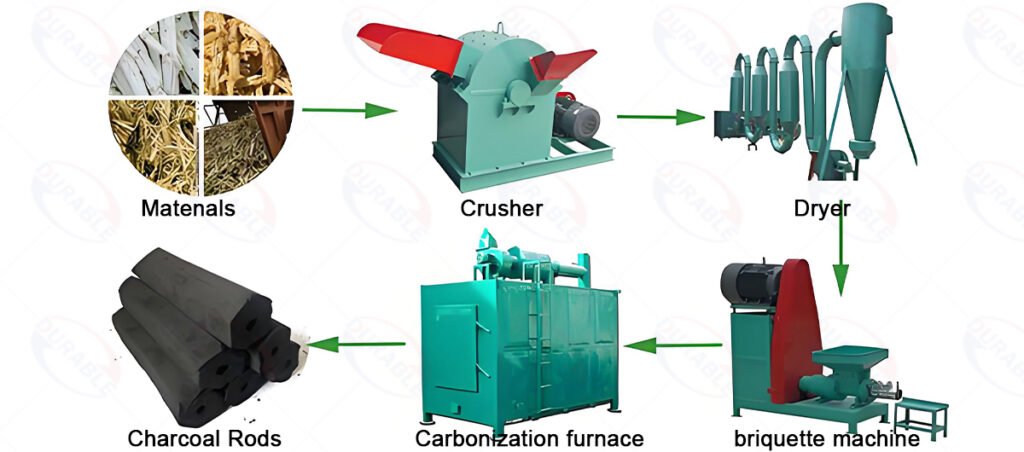

What is the Charcoal Machine Process?

A modern charcoal making machine transforms raw materials into charcoal through several controlled steps, emphasizing quality and eco-friendliness.

- Raw Material Pre-treatment: Crushing/chipping to uniform size and pre-drying to 10-20% moisture for optimal processing.

- Feeding System: A sealed system continuously feeds material, preventing oxygen ingress.

- Drying Zone (150-250°C): Uses waste heat to gently remove moisture.

- Pre-carbonization Zone (250-350°C): Wood begins decomposition, releasing initial gases and liquid byproducts.

- Carbonization Zone (350-650°C+): The core exothermic stage rapidly breaks down wood into solid charcoal, flammable gases, and wood tar. It’s self-sustaining via indirect heating fueled by its own generated gases, ensuring pure charcoal.

- Smoke Collection & Recycling:

- Dust removal cleans smoke.

- Cooling/condensation separates valuable byproducts (wood vinegar, wood tar) for revenue.

- Flammable non-condensable gases are recycled to fuel the carbonization chamber. This closed-loop ensures smokeless, energy-efficient production.

- Cooling Zone: Charcoal is slowly cooled in an oxygen-free environment to prevent self-ignition and maintain quality.

- Discharging System: A sealed, dust-proof system removes the finished charcoal.

This integrated process yields high-quality charcoal with minimal environmental impact.

Continuous vs. Batch Charcoal Machines: Which Fits You?

Choosing between continuous and intermittent (batch) charcoal making machines depends on your production needs. Each type features distinct operations and suitable uses.

An intermittent charcoal making machine processes biomass in batches. You load material, carbonize, then unload. This system is simpler and less expensive to buy. It suits smaller production volumes. It works well if your raw material supply is uneven. For example, it handles varied wood waste from small sources. This machine offers flexibility for different biomass types. However, it is less efficient. It loses heat during cycles. More manual labor is needed for loading and unloading.

A continuous charcoal making machine, like Durable’s models, operates without stopping. Raw material enters one end, moves through zones, and charcoal exits the other. The machine stays hot throughout. This offers much higher efficiency and better energy use. It is ideal for large-scale production. It requires a steady supply of uniform raw material. Examples include sawdust from large sawmills. Continuous machines use automated systems. These solutions reduce labor costs, integrate energy recovery, and are eco-friendly and cost-effective long-term.Durable provides various charcoal making machine options.

Your choice should align with your goals. For small operations or irregular biomass, an intermittent machine may suffice. For high volume, consistent quality, and lower operating costs, a continuous system is a better investment. It adheres to modern biomass carbonization equipment standards.

How Machines Control Temp & Time for Dense Charcoal?

Creating dense and hard charcoal demands precise control. A modern charcoal making machine achieves this by carefully managing temperature and time.

The carbonization zone is critical. Temperature directly impacts charcoal properties. Lower temperatures (400-500°C) yield more charcoal by weight. However, this charcoal often has less fixed carbon and can be softer. Higher temperatures (550-650°C+) create charcoal with high fixed carbon (over 85%). This charcoal boasts high heat value. It is denser and harder. Though the yield might be slightly lower, this is ideal for high-quality BBQ or industrial charcoal.

Modern machines employ indirect heating for this precision. An outer chamber burns produced wood gas. Heat transfers through furnace walls to the wood. This avoids direct flame contact. It allows very accurate temperature settings. Advanced controls monitor and adjust gas flow to maintain the desired temperature. This enables consistent, high-quality pyrolysis charcoal production.

Residence time also holds significance. This refers to how long material stays in the hot zone. Continuous machines use variable speed conveyors. These control material movement. Longer residence time, combined with correct temperature, ensures full carbonization. This increases density and hardness. By adjusting both temperature and time, charcoal production can be customized. This meets different market demands for fixed carbon and density. Such controls transform biomass into hard, dense charcoal.

How Charcoal Machines Handle Smoke & Recover Energy?

Modern charcoal making machines are environmentally responsible. They treat smoke harmlessly. They also efficiently recover heat and energy. This is vital for green production and economic value.

Smoke from carbonization is a resource, not waste. A well-designed charcoal making machine includes a strong smoke collection and recycling system. First, smoke leaves the carbonization zone. It passes through dust removal units. These use cyclone separators. They remove most particulate matter like tar droplets and charcoal dust. This cleans the gas.

Next, a cooling and condensation system cools the gas. This separates water vapor, wood tar, and wood vinegar. Wood vinegar is a valuable byproduct. It is acidic. It can serve as a bio-pesticide or soil improver. Wood tar can be fuel or a chemical raw material. Selling these byproducts brings extra income.

After cooling, non-condensable gases remain. These are flammable gases like methane, hydrogen, and carbon monoxide. They collect in a tank. Subsequently, they return to the charcoal making machine’s external combustion chamber. They fuel the carbonization process. This closed-loop system minimizes smoke emissions. It leads to clean production. It also improves overall energy efficiency. This forms a key part of eco-friendly carbonization equipment. It helps achieve smokeless charcoal production. It transforms pollutants into valuable energy and products.

What Affects Charcoal Yield and Quality?

Many factors influence charcoal output and quality. Understanding these helps you optimize your charcoal making machine. It also helps produce consistent, high-quality charcoal.

Raw material quality is crucial. The type of biomass matters. Hardwoods make denser charcoal with higher fixed carbon. Softwoods make lighter charcoal. Moisture content is critical. High moisture lowers yield and efficiency. Uniform particle size helps even heating and better quality. Impurities like soil or rocks can lower quality and damage the machine.

Carbonization temperature and time control greatly affect the charcoal. Higher temperatures (550-650°C) increase fixed carbon. This makes denser, harder charcoal. Lower temperatures (400-500°C) give more charcoal by weight. But this charcoal might be softer. The time material spends in the carbonization zone also matters. Enough time ensures full conversion. Too little time leaves uncarbonized wood. Precision in these settings is key.

The cooling process is vital for quality. Hot charcoal is very reactive. It will burn if exposed to air. Therefore, it must cool slowly in a sealed, oxygen-free space. Proper cooling prevents self-ignition and breakage. This preserves its density and hardness. Uncontrolled cooling can make brittle charcoal.

Finally, the charcoal making machine’s design plays a role. Indirect heating systems offer better temperature control. They lead to more consistent charcoal quality. Efficient gas recycling and energy recovery systems stabilize operation. They also help produce better charcoal. Good sealing of the furnace and feeding systems prevents oxygen entry. This ensures true pyrolysis. All these factors together decide the final charcoal yield rate and product quality.

How should one evaluate a charcoal machine?

To make a profitable and sustainable investment in a charcoal making machine, thoroughly evaluate three key aspects:

- Technical Advancement: Look for precise temperature control, indirect heating, and energy self-sufficiency (using its own gas as fuel). Automation and durable furnace materials are also critical for efficiency and longevity.

- Production Efficiency: Focus on high carbonization efficiency and charcoal yield. Assess capacity, and ensure an efficient energy recovery system is in place. Flexibility to handle various raw materials is a bonus.

- Environmental Performance: This is crucial. Demand effective smoke collection and purification, aiming for smokeless production with a closed-loop gas recycling system. Verify compliance with local environmental standards to avoid fines and enhance your company’s image.

Finally, consider the Total Cost of Ownership (TCO), not just the purchase price. A machine with higher initial cost but superior efficiency and environmental benefits often delivers a better long-term ROI. We offer machines designed for these high standards, ensuring your biomass carbonization investment is both profitable and sustainable.

2025 Latest Biomass Carbonization Trends and Developments

Biomass carbonization is an evolving field. New technologies continually improve its efficiency and cleanliness. Key trends in 2025 are shaping the future of charcoal making machines.

Latest Progress Overview:

- Enhanced Automation: New machines feature advanced sensors and control systems. This allows precise temperature and material flow. It reduces manual work. It ensures consistent charcoal quality.

- Modular Design for Flexibility: Modern charcoal making machines are increasingly modular. This makes them easy to scale. It simplifies maintenance. It allows quick adaptation for various biomass types. This helps them adapt to changing raw material markets.

- Integrated Energy Recovery Systems: The focus is on maximizing energy use. This includes better systems to capture and reuse waste heat. It also uses all combustible gases from pyrolysis to power the process. This makes machines highly energy-efficient and self-sufficient. It supports green energy goals.

Market Insights:

The market for biomass carbonization equipment is expanding rapidly. Demand for sustainable energy and waste solutions is growing. Companies seek machines to transform agricultural and forestry waste into biochar and high-quality charcoal. Stricter environmental rules and circular economy models drive this demand. The focus remains on systems with high efficiency, low emissions, and reliable operation. This leads to more investment in advanced charcoal making machines.

FAQs

Question 1: What raw materials can I use in a charcoal making machine?

Many biomass types are suitable. This includes wood chips, sawdust, rice husks, coconut shells, bamboo, and agricultural waste. The machine often requires specific raw material sizes and moisture levels.

Question 2: How long does the charcoal making process take?

Process time varies. It depends on the machine type (continuous or intermittent), raw material, and desired charcoal quality. Continuous systems operate non-stop, producing charcoal faster overall. Intermittent systems take several hours per batch.

Question 3: Is a charcoal making machine easy to operate?

Modern machines are increasingly automated, making operation simpler. Still, trained operators are necessary for monitoring, maintenance, and handling raw materials and finished products.

Question 4: What are the main benefits of using a continuous charcoal making machine?

Continuous machines offer higher efficiency, lower operating costs per ton, consistent product quality, and better energy recovery. They are ideal for large-scale production with a steady supply of raw materials.

Question 5: Can I produce biochar with a charcoal making machine?

Yes, charcoal making machines can produce biochar. Biochar is a form of charcoal used for soil improvement. The process involves specific temperature and residence time controls to create biochar with desired properties.

Question 6: How do I calculate the potential profit from wood waste recycling?

Calculate profit by subtracting all costs (raw material, energy, labor, maintenance, disposal) from the revenue generated by selling processed products. Consider both direct sales and saved disposal fees.

Summary & Recommendations

Mastering charcoal making machine technology is key. It transforms biomass waste into high-value products. Focus on raw material preparation, precise temperature and time control, and efficient smoke/heat recovery. These elements ensure high charcoal yield and product quality. Evaluate a machine’s technical advancement, efficiency, and environmental performance before investing. With the right charcoal making machine, you achieve profitable and green production.

If you are looking to start or improve your charcoal production, choosing the right charcoal making machine is the first step. Consider your raw materials, desired output, and environmental goals. Then, find a supplier who offers advanced, efficient, and environmentally friendly solutions.

About Durable

Durable, established in 2001, is a leading Chinese manufacturer. We specialize in mineral processing equipment and construction machinery, and also apply our industrial process knowledge to biomass carbonization equipment, designing and building complete, integrated charcoal making lines. Our solutions prioritize efficiency, reliability, and environmental responsibility. We understand every project is unique. Our team works closely with clients. We design systems to match your specific biomass, production needs, and business goals. From initial consultations and plant design to custom equipment manufacturing, installation support, operator training, and comprehensive after-sales service, Durable ensures your investment leads to success.

For expert advice and a custom plan for your charcoal making machine project, contact Durable’s engineering team today.

Durable Machinery

Durable Machinery