Drum Chipper

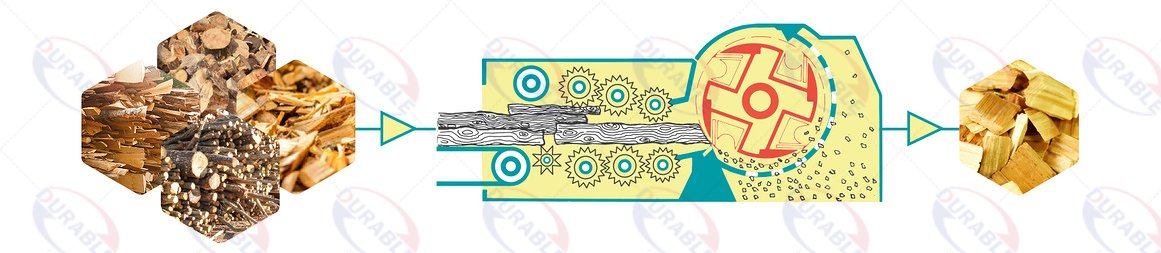

A Drum Chipper is a very common and efficient heavy-duty wood chipping machine in the industrial sector. Its core component is a large-diameter, heavy, rotating drum. You can think of it as a giant, rotating drum fitted with blades. When wood is fed in, it is rapidly cut into uniform wood chips by this high-speed rotating drum.

Application Fields of a Drum Chipper:

Given its high throughput and capacity to process large volumes of wood, the Drum Chipper is a cornerstone in several key industries. Its primary applications include:

Biomass Energy Sector,Engineered Wood Industry,Pulp and Paper Industry,Commercial Wood Chip Production.

At Durable, we have manufactured heavy-duty industrial machinery since 2001. We understand that when you are researching a Drum Chipper, you are past the basic questions. You are making a significant capital investment and need to know if this machine will deliver the performance, reliability, and return you expect. This guide is for you. We will go beyond the sales brochure and provide the critical technical details that determine a drum chipper’s true value. We will explain how it handles difficult materials and how to manage its operation to maximize profitability.

Table of Contents

- What are the primary applications for a Drum Chipper?

- What is the advantage of a Drum Chipper with large logs and irregular waste?

- How can I control the wood chip size and quality?

- What key technical parameters affect the output capacity (tons/hour)?

- Diesel vs. Electric Drum Chipper: Which has a lower running cost?

- What is the maintenance schedule for a Drum Chipper?

- How do I evaluate the ROI of a Heavy-Duty Drum Chipper?

- FAQs

What are the primary applications for a Drum Chipper?

A heavy-duty drum chipper is the preferred solution for high-volume wood processing across several key industries. Its robust design makes it ideal for applications where raw material is varied and throughput is the main priority. We see our machines used most often in these sectors.

- Biomass Fuel Production: This is the largest application. Biomass power plants and wood pellet factories need to process enormous quantities of low-grade wood, including whole trees, forestry residues, and urban wood waste. A drum chipper efficiently converts this inconsistent feedstock into uniformly sized chips suitable for boilers or Pellet Production Lines.

- Engineered Wood Panels: Factories that produce Medium-Density Fiberboard (MDF) and particleboard rely on high-quality wood chips as their primary raw material. A drum chipper can produce chips with the specific dimensions and low powder content required for these engineered products.

- Pulp and Paper Industry: While disc chippers are sometimes used for their highly uniform chips, many pulp mills use large drum chippers in their wood yards. They are used to process logs that are too large or irregular for other machines, ensuring all incoming wood fiber can be utilized.

- Large-Scale Land Clearing: Forestry contractors and land management companies use mobile, diesel-powered drum chippers to process felled trees and stumps directly on site. This turns a disposal problem into a marketable product and significantly reduces transportation costs.

What is the advantage of a Drum Chipper with large logs and irregular waste?

The core advantage of a drum chipper is its sheer power and aggressive processing design. This makes it uniquely capable of handling difficult materials that would stall or damage other types of chippers. The advantage comes from its fundamental mechanical structure. The machine uses a very large, heavy, rotating steel drum. This drum acts as a massive flywheel, storing a huge amount of kinetic energy in its rotation. When a large log or a tough bundle of branches enters the chipper, the drum’s inertia provides the force needed to power through the material without a significant drop in speed. The horizontal infeed system also allows for the safe and easy loading of large, heavy logs using equipment like a grapple loader. In contrast, other chippers often have angled infeeds that are less suitable for bulky material. This combination of stored energy and a direct, open infeed path is why the drum chipper excels at converting challenging, low-value wood waste into a consistent, valuable product with high efficiency.

How can I control the wood chip size and quality?

Controlling the final chip size is critical, especially for applications like panel production or pulp. While many believe this is only about motor power, the actual control comes from two specific mechanical adjustments within the machine. Getting these right is the key to producing high-quality, on-spec chips.

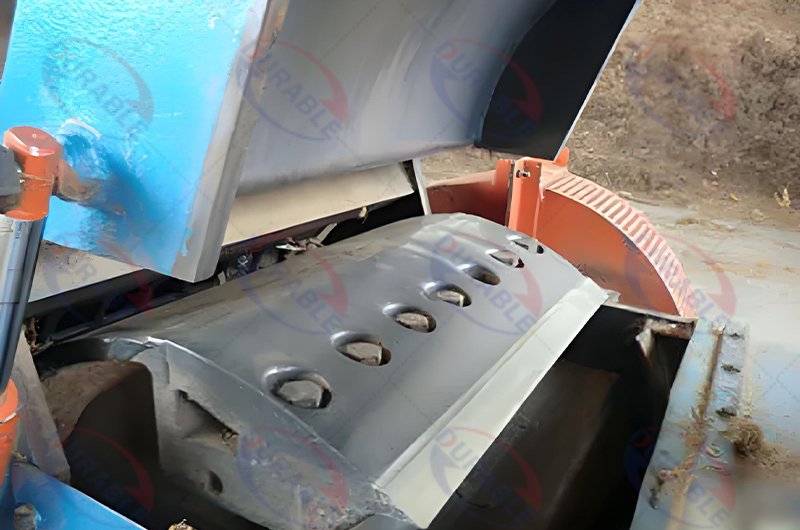

The first and most direct method of control is the screen. A heavy-duty perforated screen is installed directly below the cutting drum. As chips are cut, they are thrown against this screen. Only chips that are small enough to pass through the screen holes are discharged from the machine. Oversized chips remain in the cutting chamber until they are broken down further. By changing the screen with one that has different hole sizes, you can precisely control the maximum dimension of your final product. For biomass fuel, you might use a large-hole screen or no screen at all for maximum throughput. For high-grade panel production, you must use a screen with a specific aperture to guarantee chip uniformity.

The second, more technical factor is the cutting geometry. This is the precise relationship between the rotating chipper knives and the stationary bed knife (also called the anvil). The gap between these two knives should be set between 0.5 mm and 1.5 mm. If this gap is too large, the machine will not make a clean cut. Instead, it will tear the last part of the wood fiber, resulting in long “tails” or “slivers” on the chips. This dramatically reduces the quality and value of the output. If the gap is too small, the knives can strike each other, causing catastrophic damage. Correctly setting this gap ensures a clean shearing action, producing uniform chips with low powder content (typically under 5%) and reducing stress on the machine’s bearings.

What key technical parameters affect the output capacity (tons/hour)?

The advertised capacity of a drum chipper is a theoretical maximum. The actual, achievable throughput in your operation depends on the integration of several key technical systems. Understanding these parameters is essential for realistic production planning.

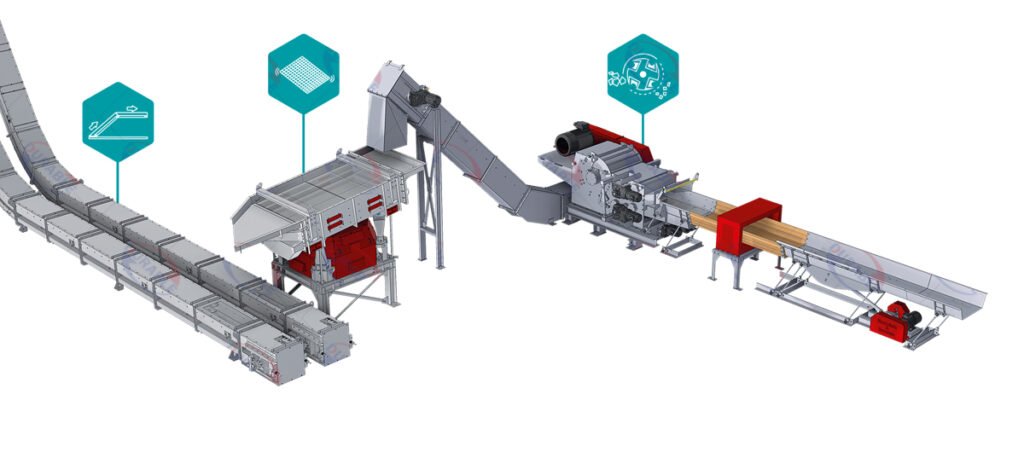

The most critical factor beyond the motor size is the intelligent feed system. A drum chipper’s capacity is maximized when the cutting drum maintains a consistent, high rotational speed. If you feed material too quickly, it will bog down the drum, causing the motor’s amperage to spike and tripping the overload protection, which stops production. If you feed material too slowly, the machine is underutilized and inefficient. A modern industrial drum chipper solves this with an automated feed system. Sensors constantly monitor the electrical load on the main motor. If the load exceeds a preset level (indicating the drum is working too hard), the controller automatically slows down or temporarily stops the hydraulic feed rollers. Once the motor load returns to normal, the feed rollers automatically resume their optimal speed. This self-regulating process ensures the machine is always operating at its peak possible rate without overloading, delivering the highest, most consistent real-world tonnage per hour.

Other important factors include:

- Drum Inertia: A heavier, larger diameter drum stores more kinetic energy and can process difficult material with less speed loss.

- Infeed Opening Size: A larger throat allows for bulkier, less prepared material to be fed, reducing pre-processing labor.

- Knife Sharpness: Dull knives tear wood instead of cutting it, which requires significantly more power and drastically reduces capacity.

Diesel vs. Electric Drum Chipper: Which has a lower running cost?

The choice between a diesel engine and an electric motor is a strategic decision based on your work environment and business model. Each has a very different cost profile.

| Feature | Diesel Drum Chipper | Electric Drum Chipper | Your Practical Takeaway |

|---|---|---|---|

| Capital Cost | Higher (Engine is expensive) | Lower (Motor is cheaper) | If you need mobility, the higher initial cost is unavoidable. |

| Mobility | Fully mobile, can work anywhere | Stationary, tied to the grid | Diesel is for forestry and remote sites. Electric is for fixed plants. |

| Energy Cost | High (Diesel fuel prices fluctuate) | Lower (Industrial electricity rates are more stable) | In a plant setting, electric power is significantly cheaper per ton produced. |

| Maintenance | High (Engine oil, filters, coolant, repairs) | Very Low (Motor has few moving parts) | Diesel engine maintenance is a major and continuous operational expense. |

| Emissions/Noise | High | Very Low / None | Electric is required for indoor operation or in areas with strict regulations. |

Conclusion: For a fixed processing plant like a pellet mill or sawmill, an electric drum chipper has a significantly lower running cost due to cheaper energy and minimal maintenance. For any application that requires moving the machine to the wood, such as forestry or land clearing, a diesel drum chipper is the only practical option, and its higher operational costs must be factored into the job pricing.

What is the maintenance schedule for a Drum Chipper?

A rigorous maintenance schedule is not optional; it is essential for protecting your investment and ensuring safe, efficient operation. The focus is on the components that do the cutting and absorb the most stress.

1. Chipper Knives: These are your primary consumable.

- Sharpening Cycle: For clean wood, knives may last 8-10 hours before needing to be sharpened. When processing dirty wood or waste with soil and grit, this can fall to just 2-3 hours. Dull knives must be changed immediately.

- Material: Most knives are made of a tough tool steel like D2, which resists chipping. For clean wood applications, tungsten carbide inlaid knives offer much longer wear life but are more brittle and can shatter if they hit metal.

- Sharpening Process: Knives must be sharpened on a professional grinding machine with liquid coolant. This maintains the precise cutting angle and prevents the heat from softening (annealing) the blade’s edge.

2. Bed Knife (Anvil): This is the most commonly neglected part.

- Function: This stationary knife provides the solid edge for the rotating knives to cut against.

- Maintenance: The bed knife also wears down. If its edge becomes rounded, chip quality will decrease, and power consumption will increase, even with sharp new knives. It should be inspected every time the chipper knives are changed. Most bed knives have two or four cutting edges and can be turned before needing replacement. A good rule is to turn the bed knife after every 3-5 sets of knife sharpenings.

3. Bearings and Foundation:

- Greasing: The massive bearings that support the cutter drum require regular greasing according to the manufacturer’s schedule. Bearing failure is a catastrophic and expensive event.

- Foundation: A stationary chipper produces significant vibration. It must be installed on a steel-reinforced concrete foundation built exactly to the manufacturer’s specifications. An improper foundation will lead to chronic vibration, causing premature bearing failure and fatigue cracks in the machine’s frame.

How do I evaluate the ROI of a Heavy-Duty Drum Chipper?

Evaluating the Return on Investment (ROI) for a drum chipper requires looking at more than just its purchase price. You must analyze its total impact on your business’s revenue and costs. A proper evaluation considers the following core metrics.

1. Capital Expense (CAPEX): This is the total upfront cost, including the machine price, shipping, installation, and the cost of building a proper foundation or purchasing a diesel power unit.

2. Operational Expense (OPEX): This is the ongoing cost to run the machine.

Energy: The daily cost of diesel fuel or electricity.

- Wear Parts: The budget for replacement knives, bed knives, and screens.

- Maintenance: The cost of labor, lubricants, and other service parts.

- Labor: The wages for the operator(s).

3. Revenue Generation and Cost Savings:

- Value of Output: The market price per ton for the wood chips you produce. This is your primary revenue stream.

- Throughput and Uptime: The machine’s actual production rate (tons per hour) multiplied by its operational availability (uptime). High reliability is critical.

- Cost Avoidance: The money saved by not having to pay for wood waste disposal. This can be a very significant number.

FAQs

Q1: What happens if metal enters the drum chipper?

A: Metal is the number one enemy of a chipper. It will cause instant, catastrophic damage, shattering the knives and potentially cracking the knife holders on the drum itself. For this reason, feed conveyors for systems using recycled wood must be equipped with powerful magnets and a metal detector that automatically stops the belt.

Q2: Why is a drum chipper better than a disc chipper for biomass?

A: A drum chipper is more aggressive and has a higher tolerance for dirty, irregular material like branches, bark, and roots. It prioritizes high volume over the perfect chip uniformity that a disc chipper provides, which makes it ideal for producing fuel.

Q3: Can a drum chipper process wood with dirt and rocks?

A: Yes, it can handle it without immediate mechanical failure, which is one of its strengths. However, any dirt, sand, or rocks are highly abrasive and will dramatically accelerate the wear on the knives, increasing your maintenance costs.

Q4: How important is the concrete foundation for a stationary chipper?

A: It is absolutely critical. The foundation is part of the machine system. An undersized or poorly constructed foundation will not absorb the machine’s vibration, leading to premature failure of the main bearings and structural cracks in the chipper frame.

Q5: What is the typical percentage of powder (fines) in the output chips?

A:With sharp knives and a correctly set cutting geometry, a well-maintained drum chipper should produce chips with less than 5% fines content. High fines content is a clear sign that maintenance is required.

Durable Machinery

Durable Machinery